Water purification system

A water purification and water body technology, applied in the field of water treatment, can solve problems such as lack of consideration of environmental friendliness, residual biofilm filler, ecological environment impact, etc., and achieve the effects of improving oxygen mass transfer efficiency, uniform bubbles, and high oxygen utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

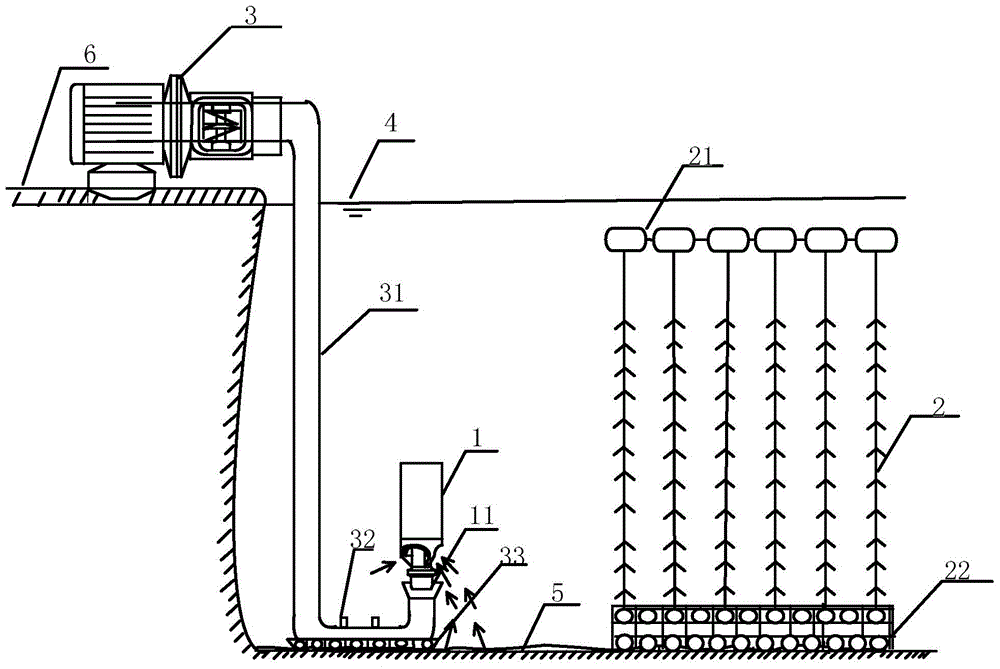

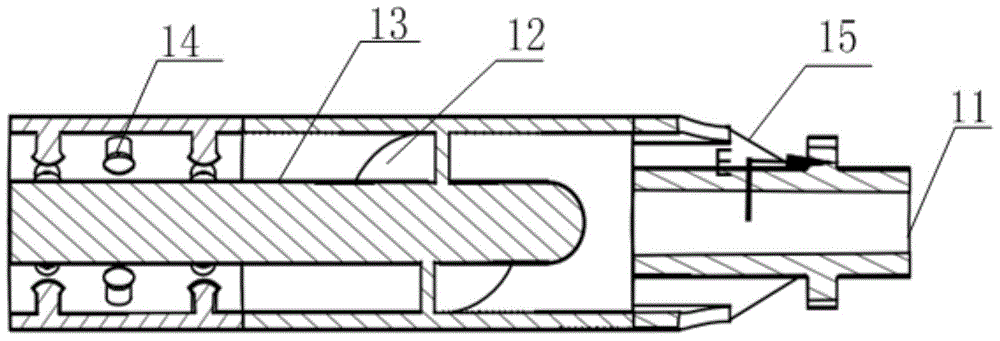

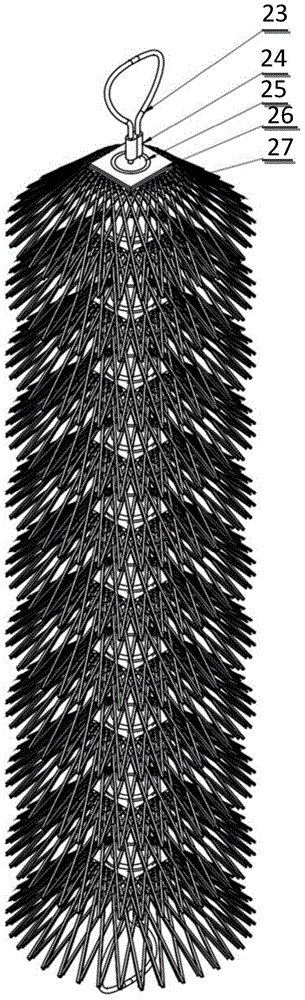

[0031] according to figure 1 , when dealing with a closed water body with a water depth of 2m, the air compressor 3 is arranged on the closed water bank 6, and is connected with the air inlet 11 of the magnetic-assisted swirl diffuser pipe 1 placed at the bottom of the water 5 through the air intake pipe 31, Air intake pipe 31 is divided into horizontal section and vertical section, makes support 33 with concrete prefabricated block, and size is 15 * 50cm, and the horizontal section of air intake pipe 31 is fixed on the concrete prefabricated block support 33 with buckle 32, then air intake pipe uses internal The wire elbow is connected to the magnetic-assisted swirling air diffuser 1, so that the magnetic-assisted swirl air diffuser 1 is in the vertical direction; the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com