Reactor for continuously leaching valuable metal of electroplating sludge and leaching method thereof

A technology for electroplating sludge and valuable metals, applied in the direction of improving process efficiency, etc., can solve problems such as complex connection of reactors, achieve high extraction efficiency, high infection efficiency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

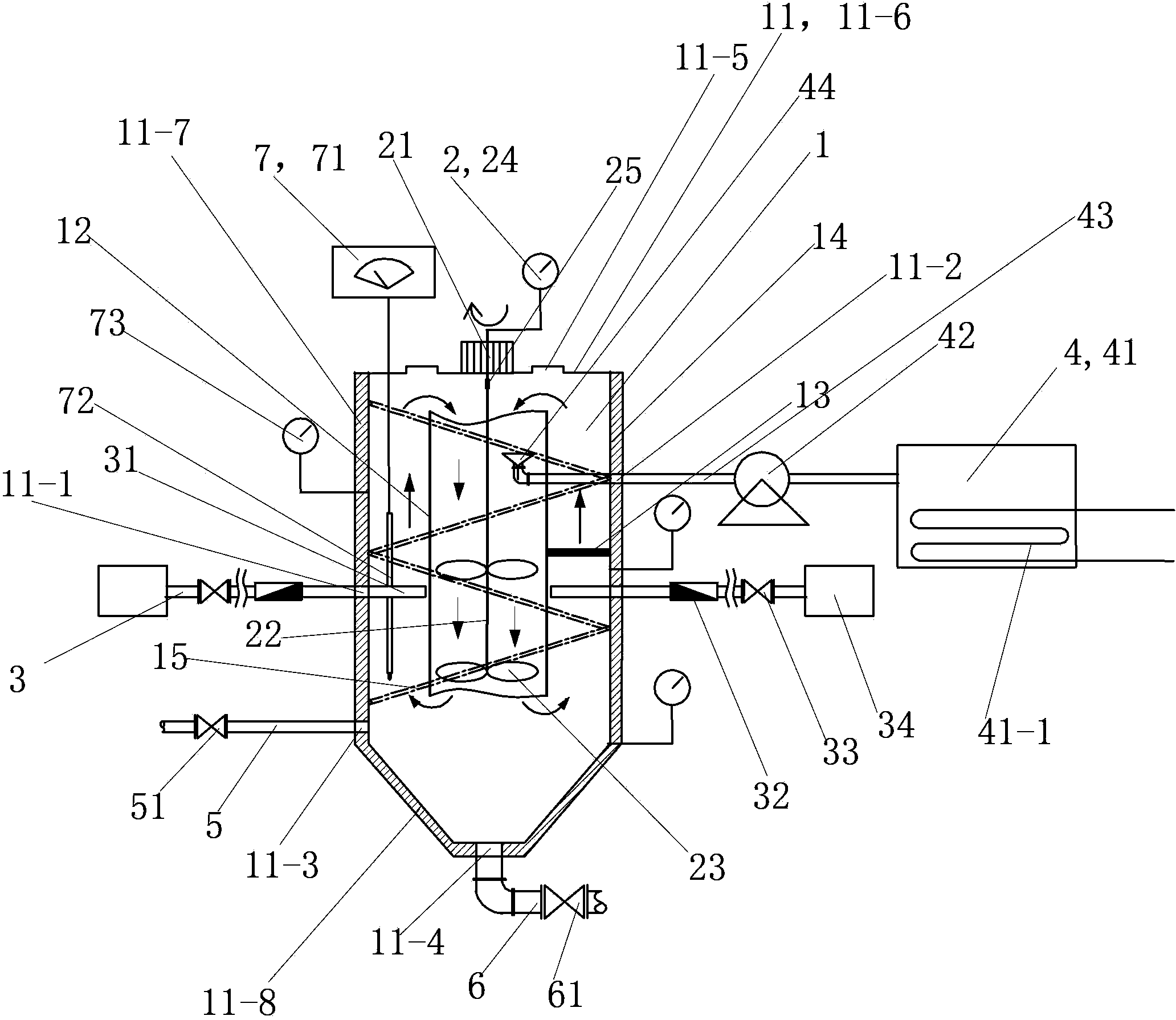

[0048] (Example 1, a reactor for continuously extracting valuable metals from electroplating sludge)

[0049] See figure 1 The reactor for continuously extracting valuable metals from electroplating sludge in this embodiment includes a reaction tank 1, a stirring assembly 2, an air supply assembly 3, a bacterial liquid supply assembly 4, a leachate outlet pipe 5, a waste residue discharge pipe 6 and a temperature control System 7.

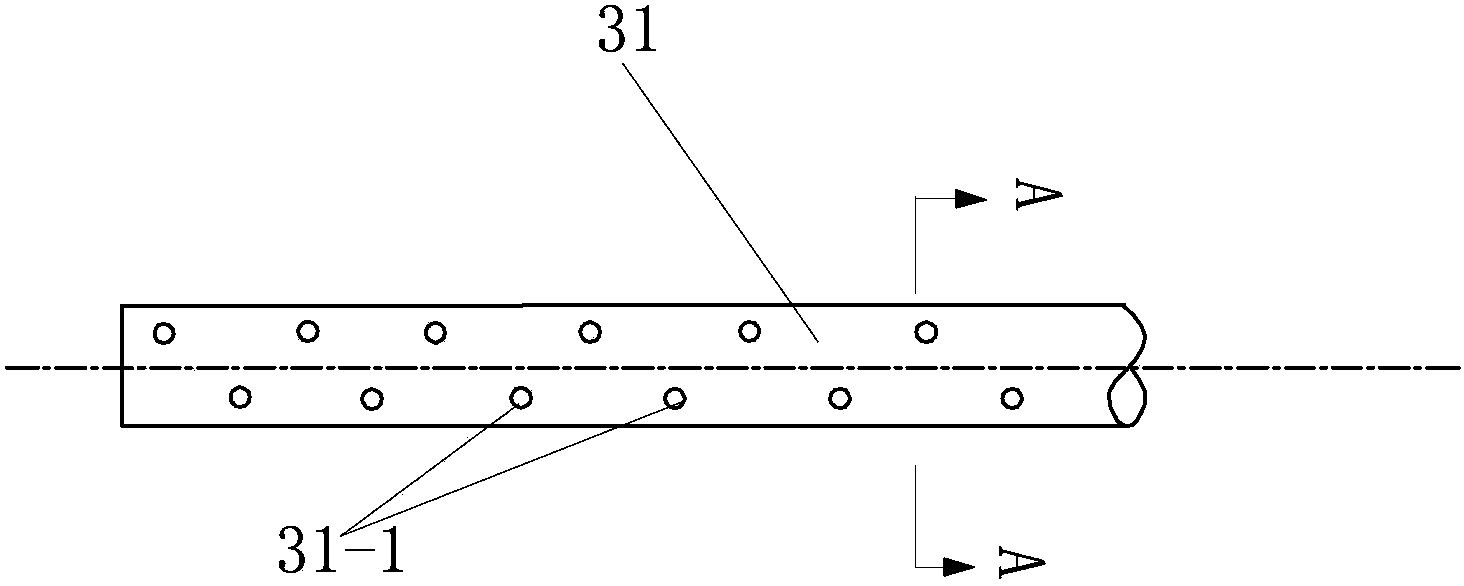

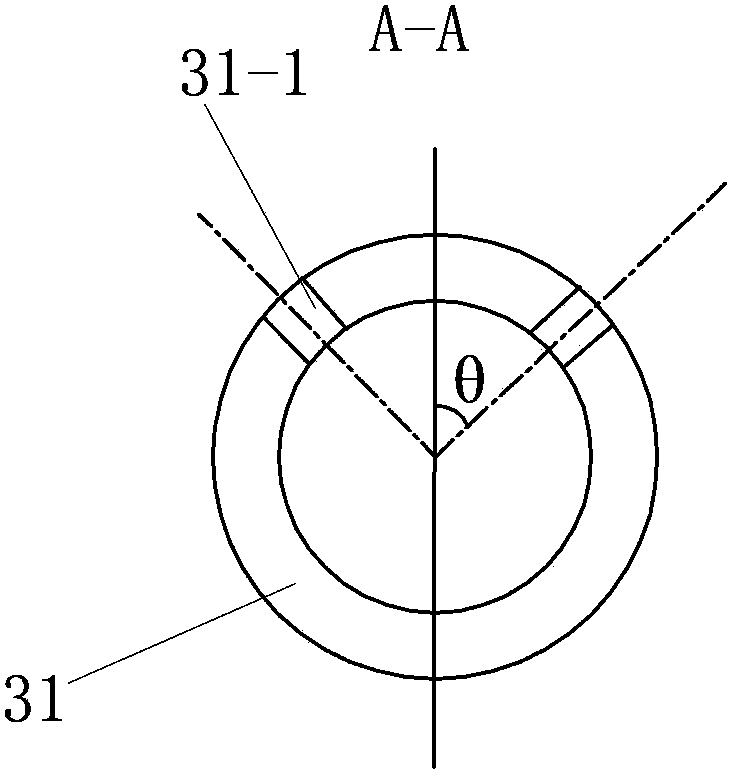

[0050] The reaction tank 1 includes a tank main body 11 , a draft tube 12 , a support frame 13 , an insulation layer 14 and an electric heating coil 15 . The tank main body 11 is mainly formed by connecting a cylindrical upper body 11-7 at the top and an inverted truncated circular lower body 11-8 at the bottom. The volume of the tank body 11 is 0.2 to 1 cubic meter (this embodiment 0.5 cubic meters), the height of the tank main body 11 is 1 to 1.5 meters (1.2 meters in this embodiment), wherein the volume of the lower cylinder 11-8 accounts for ...

Embodiment 2

[0068] (Example 2, bioleaching method of valuable metals from electroplating sludge)

[0069] The bioleaching reaction of electroplating sludge involves the interfacial reaction and mass transfer among three phases (ie gas phase, liquid phase and solid phase). The liquid phase is not only the carrier of solid electroplating sludge particles, but also the medium of the unit reaction process, such as the growth and reproduction of leaching bacteria, the contact between solid particles and leaching bacteria, the chemical action of solid particles, the release of metal ions, the oxygen and Uniform distribution and mass transfer of carbon dioxide, etc. The mixing and interaction of these three phases are the basic factors affecting the bioleaching reaction of electroplating sludge. See Figure 4 , use the reactor leaching metal of embodiment 1 to comprise the following steps:

[0070] ① Feeding: add the pretreated electroplating sludge powder into the reaction tank 1, and then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com