Visual positioning method based on side-axis visual structural galvanometer puzzle processing

A visual positioning and visual technology, applied in metal processing equipment, manufacturing tools, instruments, etc., can solve problems such as inability to calculate, dislocation, and calculation errors, and achieve the effects of less error-prone, less calculation, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

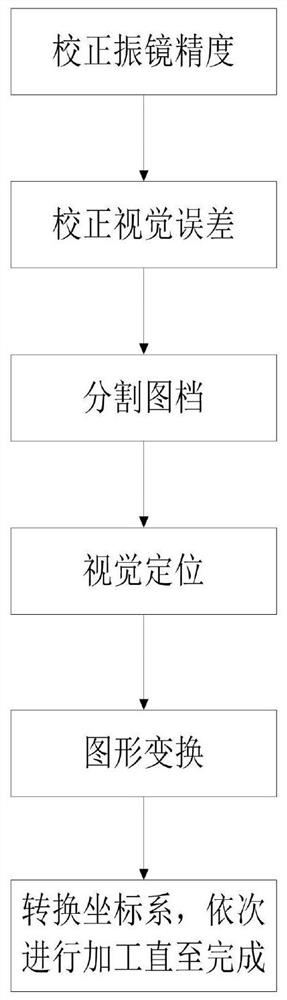

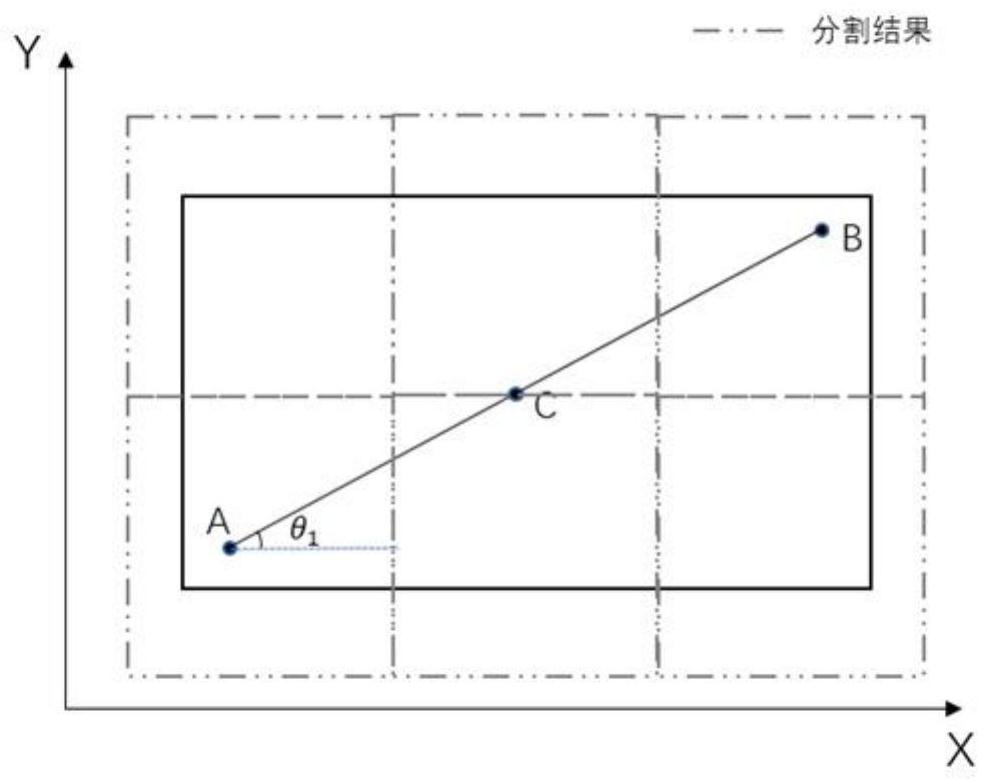

[0064] Such as figure 2 As shown, this embodiment provides a visual positioning method based on paraxial visual structure galvanometer jigsaw puzzle processing. figure 2 for theoretical graphics. The method comprises the steps of:

[0065] Step 1: On the basis of the positioning accuracy of the motion control platform < 1um, repeatability < 0.5um, repeatability of the galvanometer < 2urad, and a focal length of about 160mm, correct with a format of 50mm*50mm, and the positioning accuracy of the galvanometer after correction is <±5um .

[0066] Step 2: Correct the visual error, and the compensation values in the XY direction are dboffsetX and dboffsetY respectively.

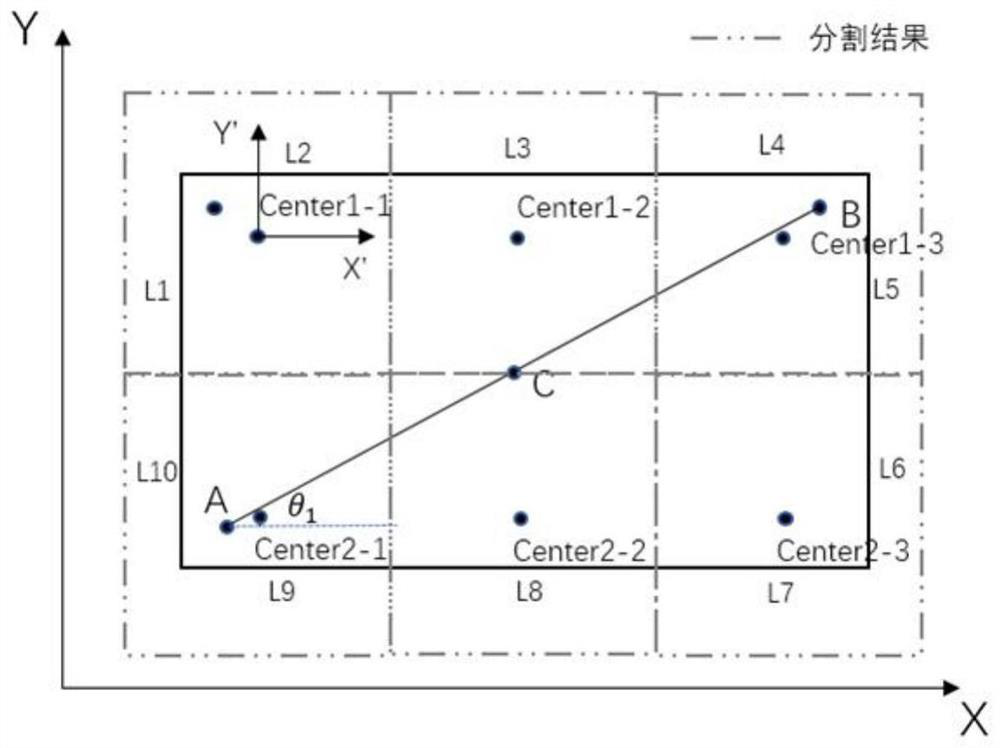

[0067] Step 3: If image 3 As shown, the result after segmentation is obtained.

[0068] Such as image 3 As shown, Center1-1, Center1-2, Center1-3, Center2-1, Center2-2, Center2-3 are the center points to be marked each time, and L1~L10 are the paths to be processed.

[0069] Save the following data: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com