Patents

Literature

235results about How to "Improve stitching accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

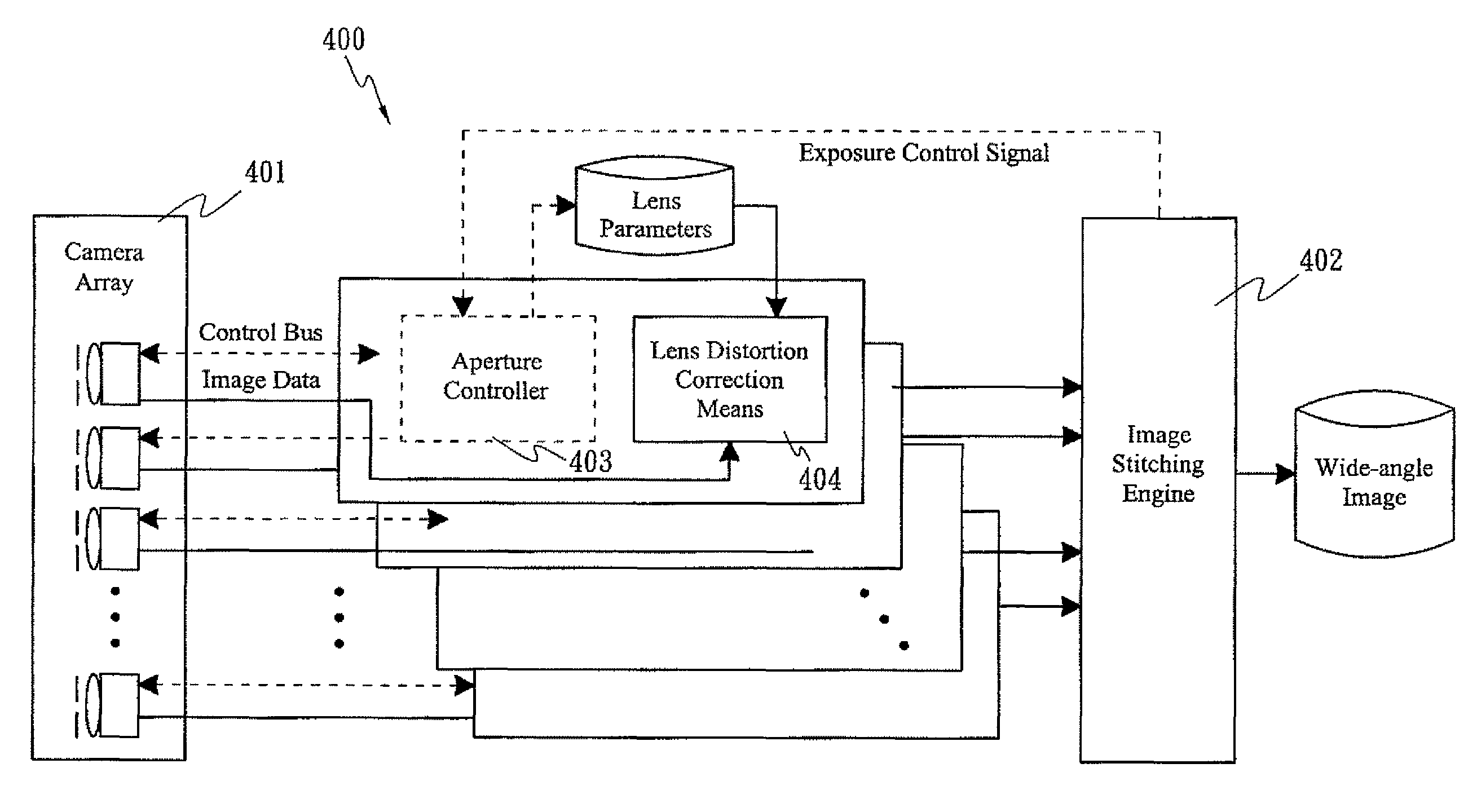

Method for Improving Image Stitching Accuracy with Lens Distortion Correction and Device for Implementing the Same

InactiveUS20070236595A1Improving image stitching accuracyImprove stitching accuracyTelevision system detailsGeometric image transformationCamera lensMulti camera

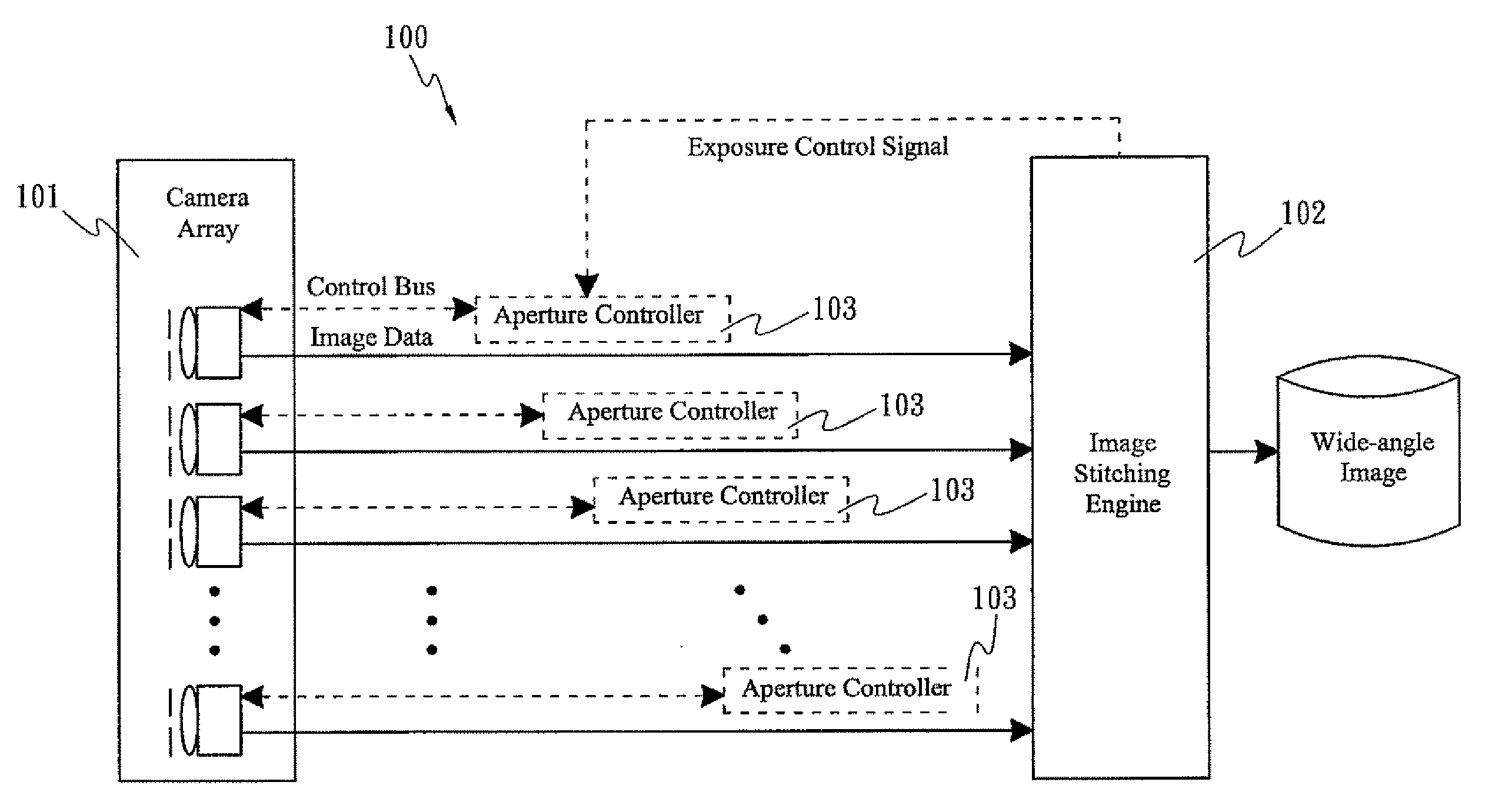

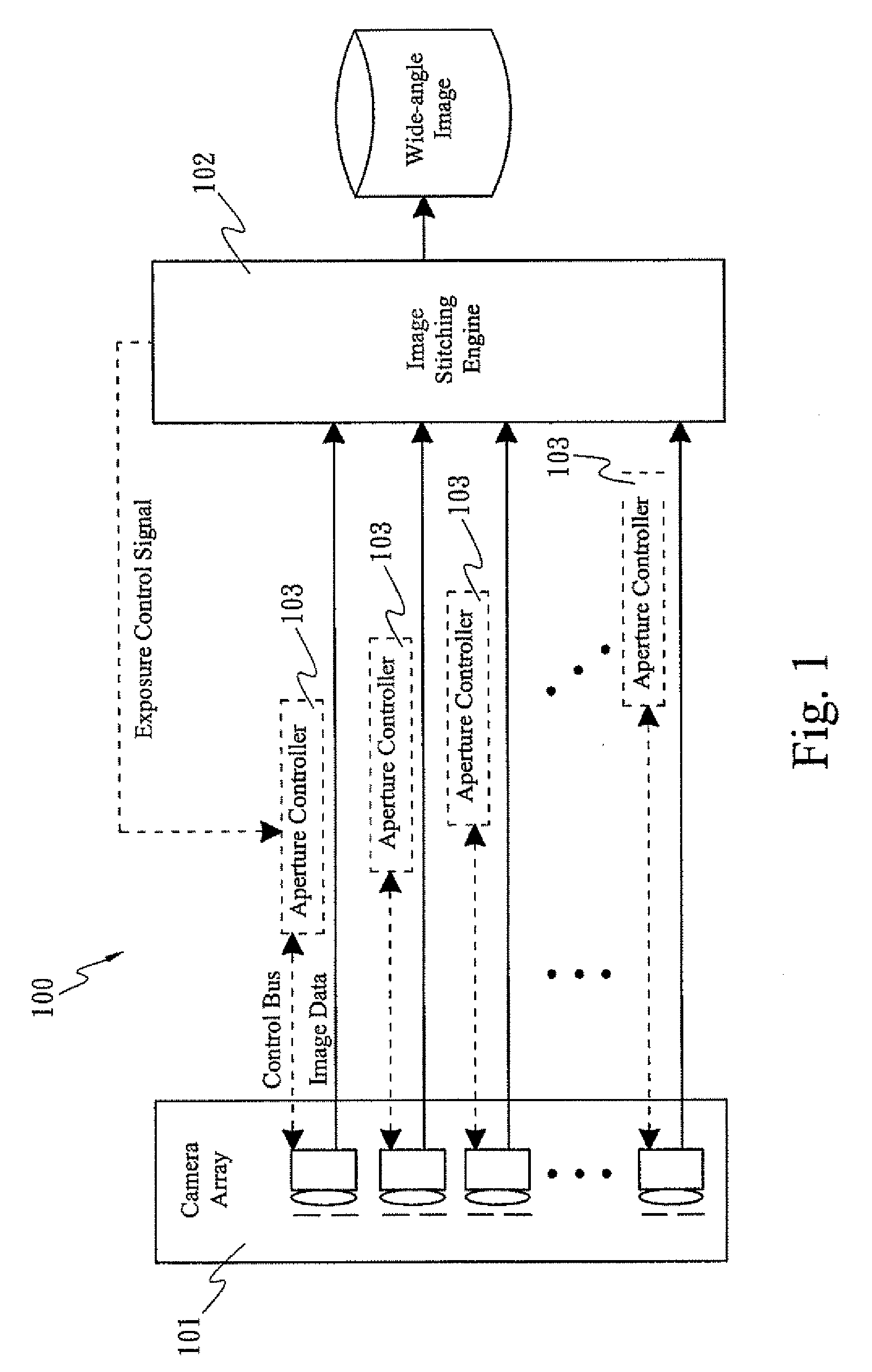

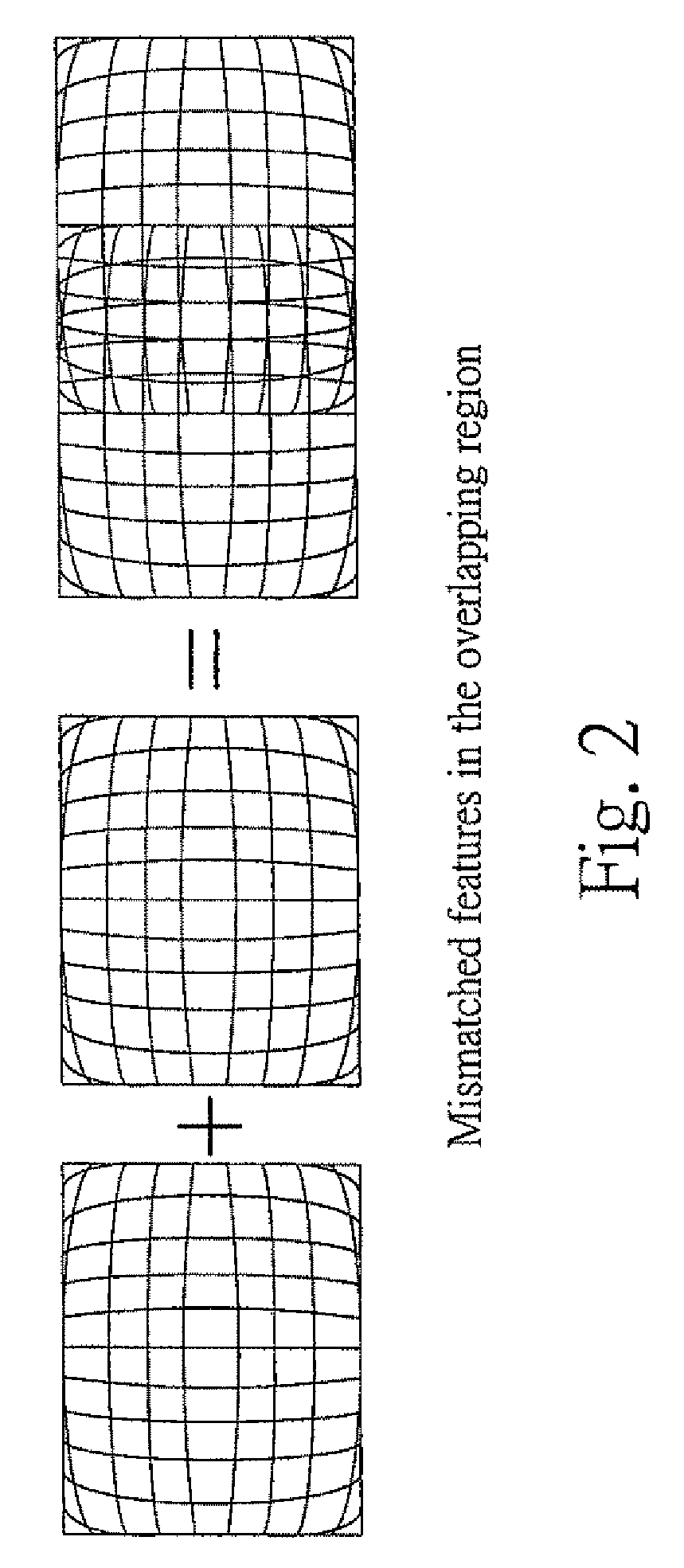

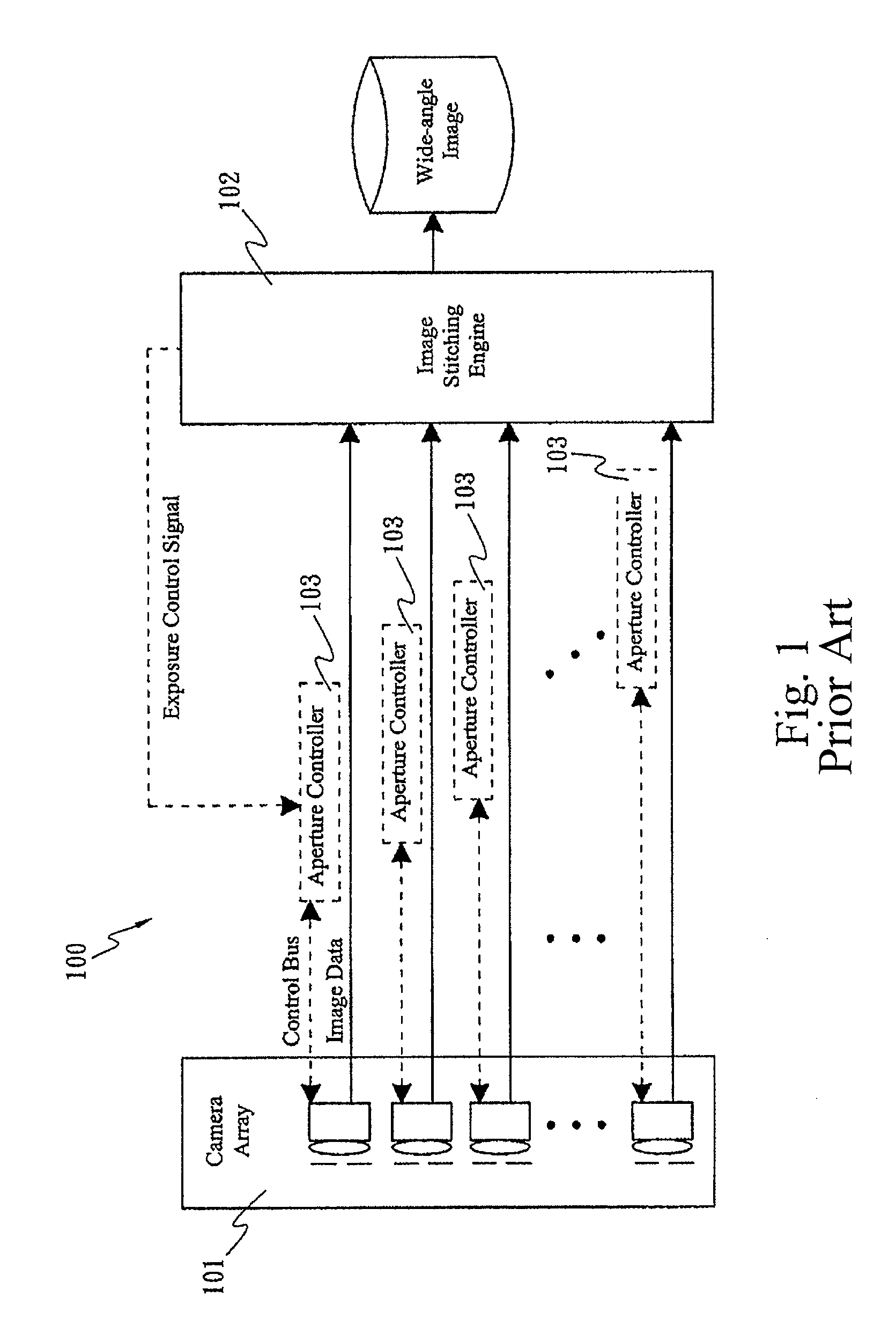

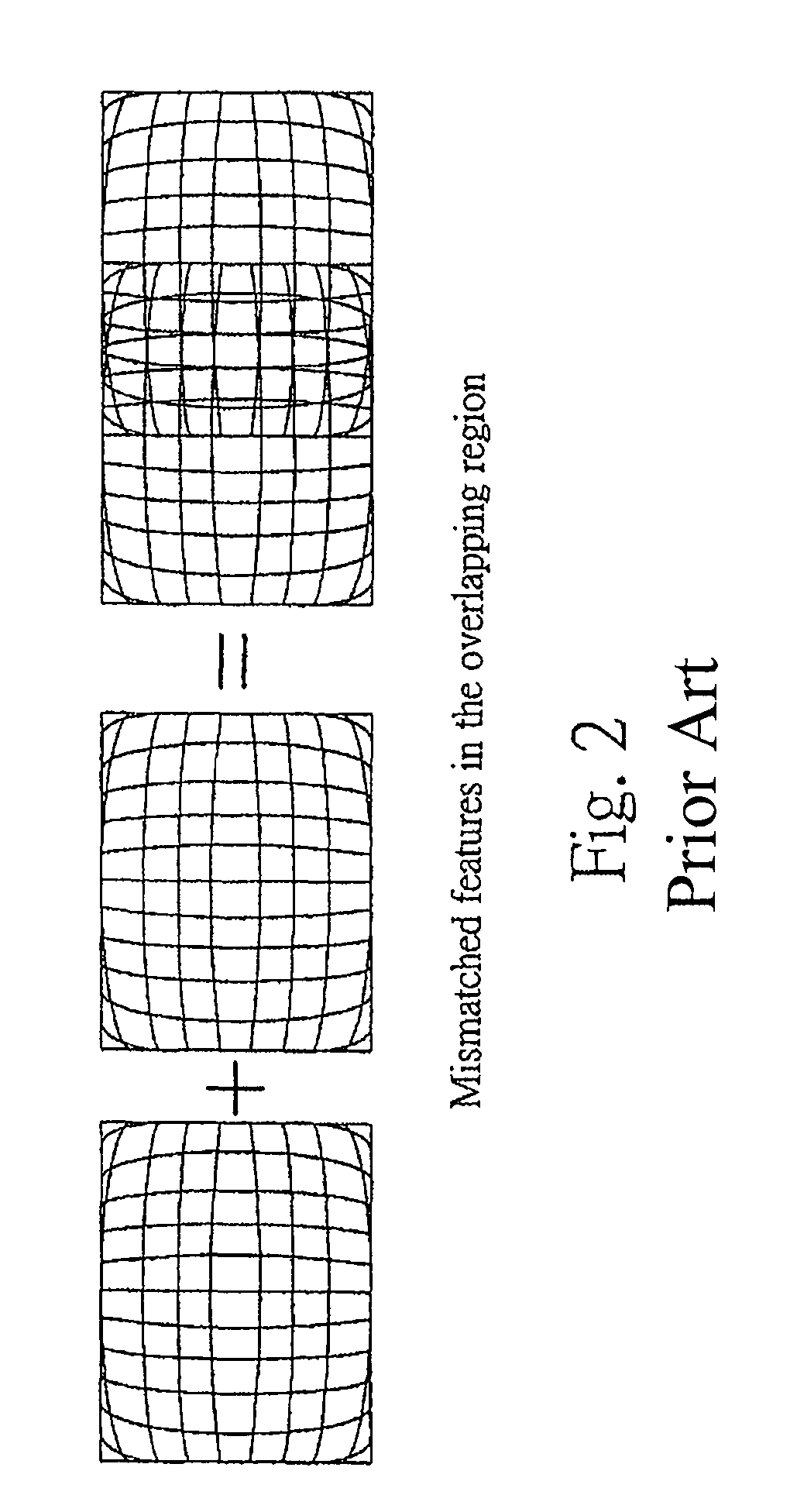

The invention provides a method for improving image stitching accuracy and a device for implementing the same, which apply to the multi-camera system for wide-angle image generation. Lens distortion causes mismatches of the features in the overlapping region of the images captured by the multi-camera system. As a result, the mismatches on the stitched wide-angle image are visible. The method and device for improving image stitching accuracy correct the lens distortion before stitching the images captured by the multi-camera system, so that the features in the overlapping region are matched and a seamless wide-angle image is generated by the stitching engine.

Owner:SONY TAIWAN

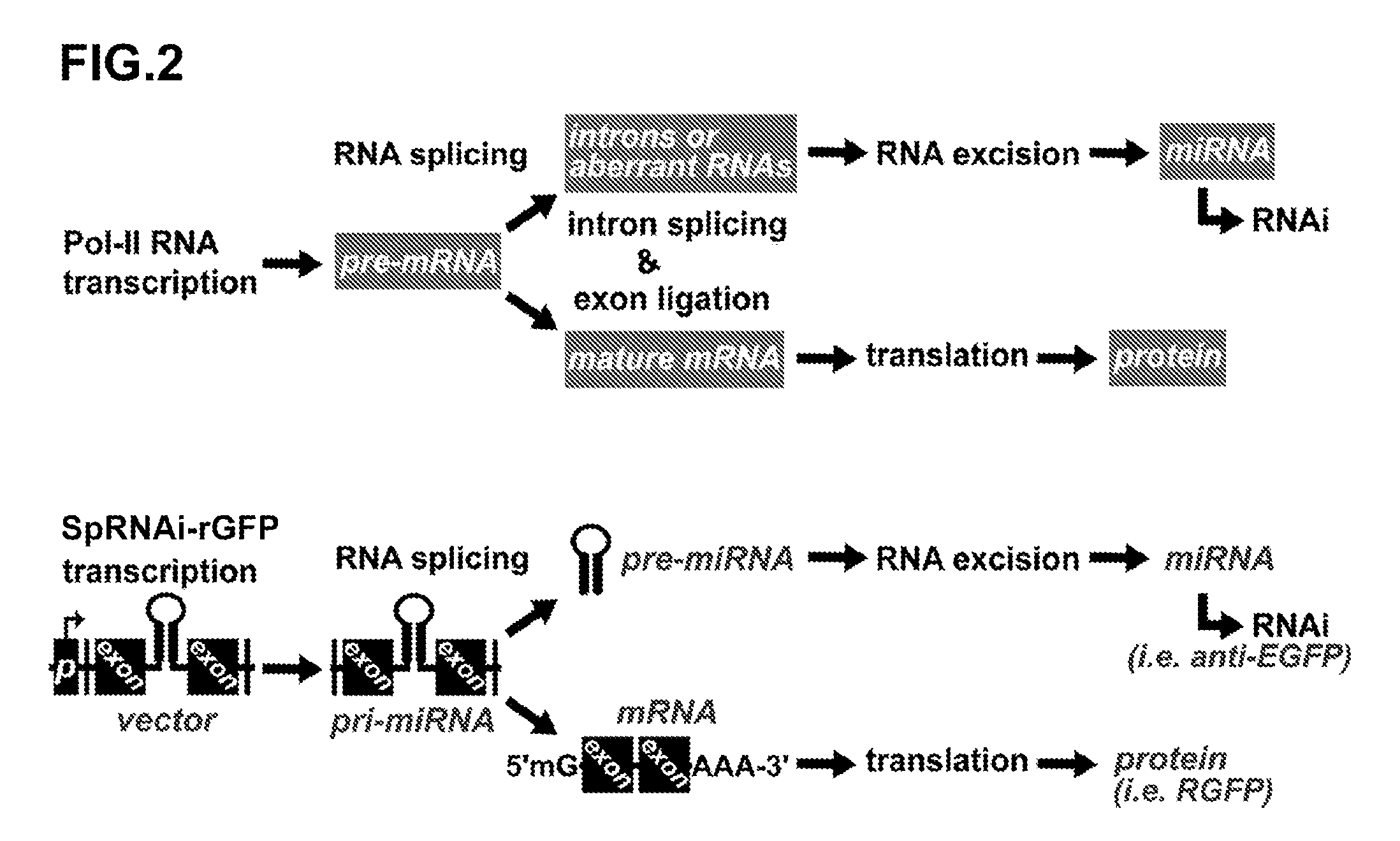

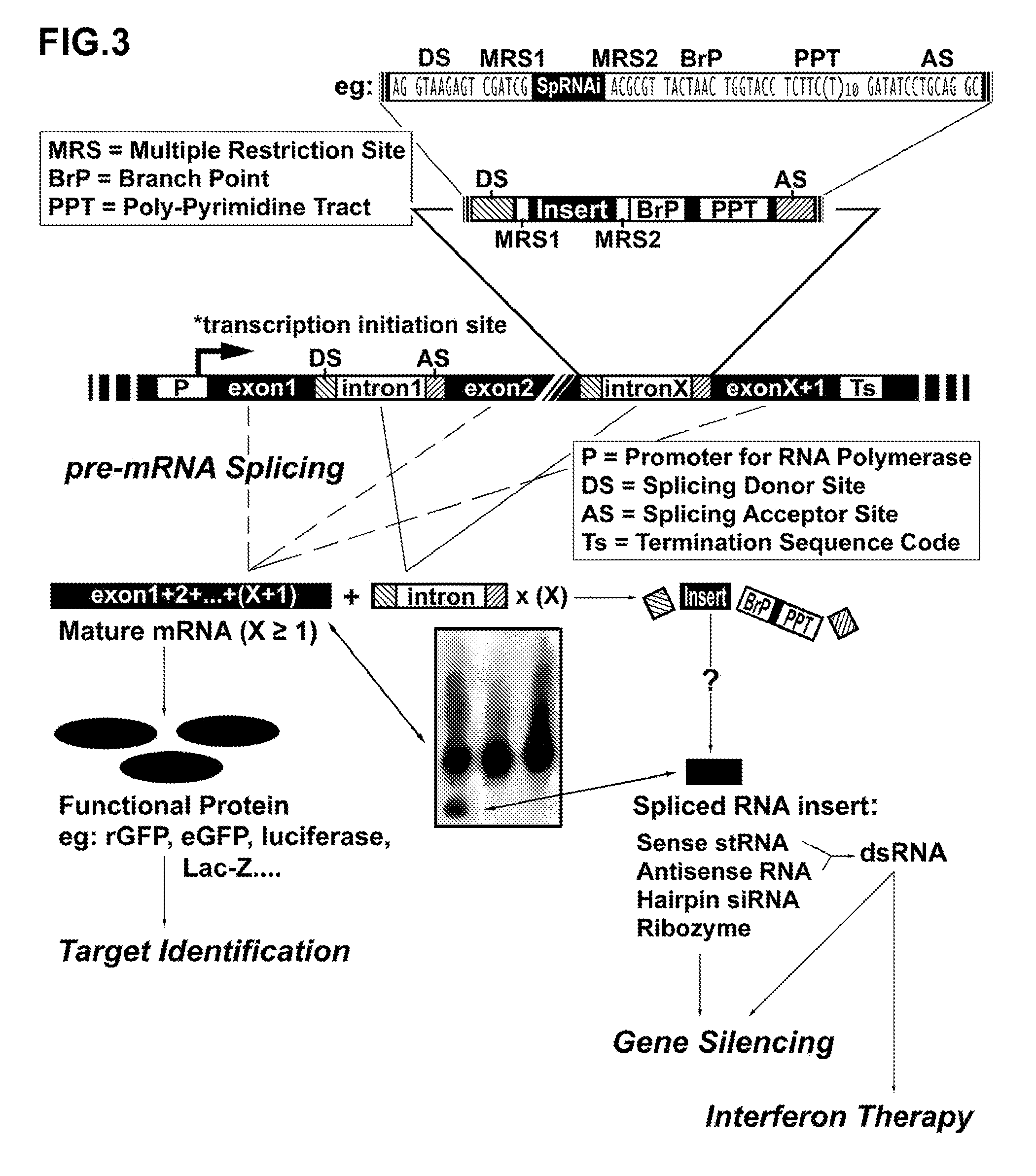

Novel Transgenic Methods Using intronic RNA

InactiveUS20060228800A1Reduce concernInhibitionMicroencapsulation basedFermentationBiotechnologyIntron

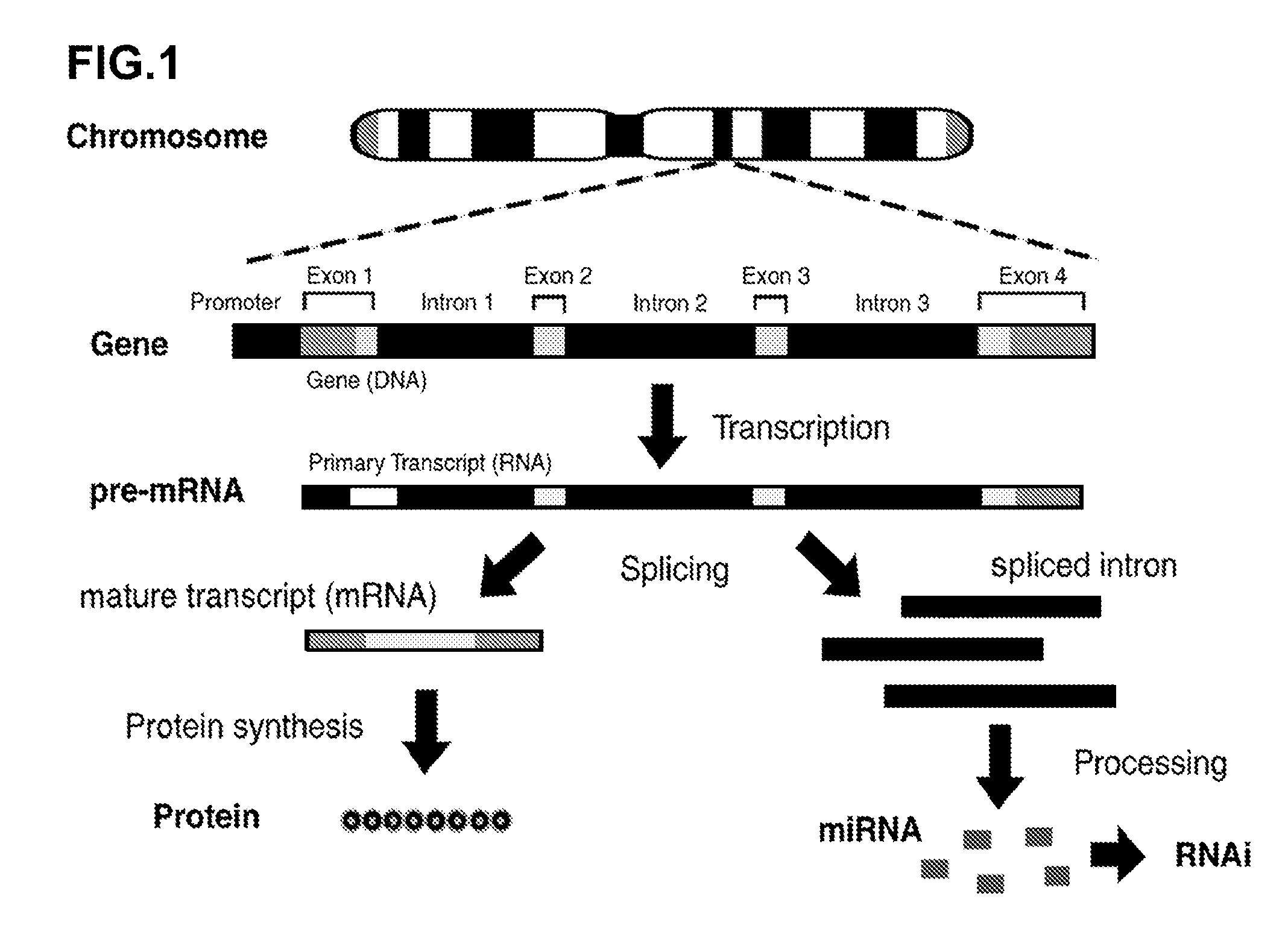

The present invention relates to a method and composition for generating an artificial intron and its components capable of producing microRNA (miRNA) molecules and thus inducing specific gene silencing effects through intracellular RNA interference (RNAi) mechanisms, and the relative utilization thereof. The miRNA-producing intron so generated is not only useful for delivering desired miRNA function into the intron-mediated transgenic organisms or cells but also useful for suppressing unwanted gene function in the transgenic organisms or cells thereof. Furthermore, the derivative products of this novel man-made miRNA-producing intron have utilities in probing gene functions, validating drug targets, generating transgenic animals and gene-modified plants, developing anti-viral vaccines and treating as well preventing gene-related diseases (gene therapy).

Owner:UNIV OF SOUTHERN CALIFORNIA

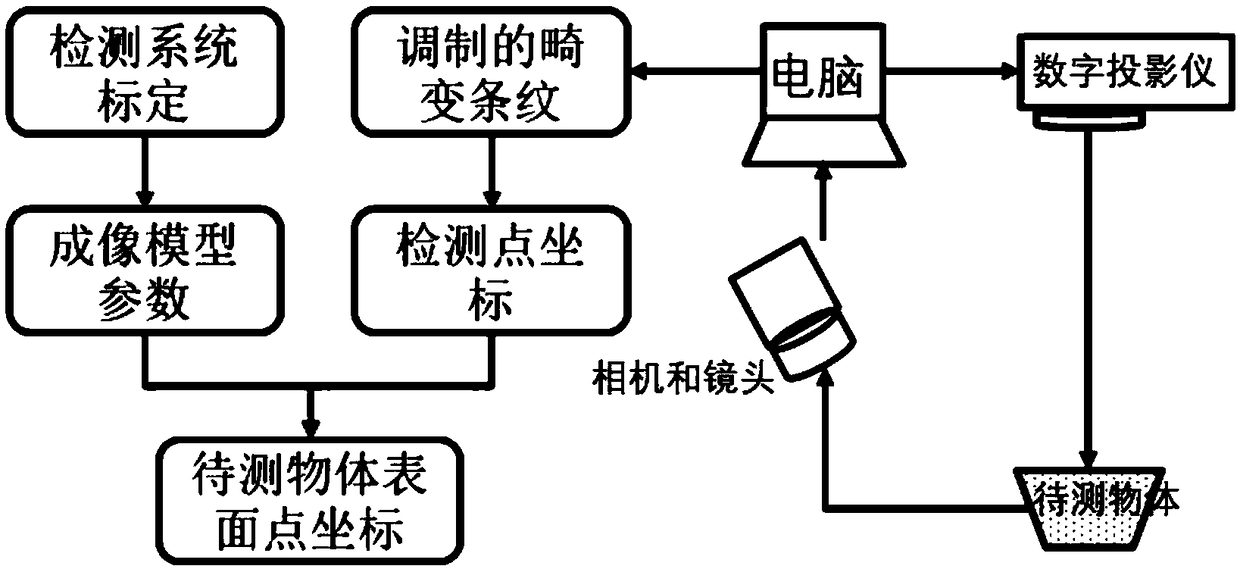

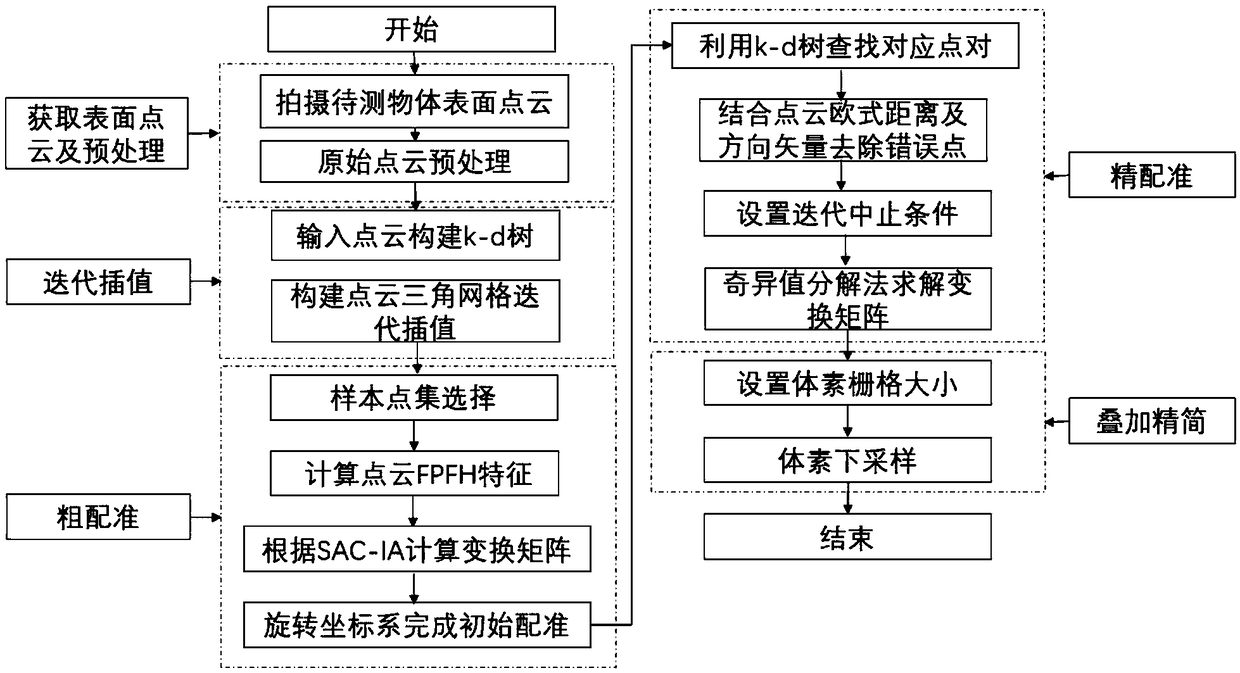

An improved ICP object point cloud splicing method for fusing fast point characteristic histogram

ActiveCN109345620AImprove processing efficiencyImprove processing precisionImage enhancementImage analysisLocal optimumGrating

The invention discloses an improved ICP object point cloud splicing method for fusing fast point characteristic histogram. The method comprises the steps of projecting a standard sinusoidal digital grating onto the surface of the object to be measured, photographing stripe images of the surface of the object projected with the standard sinusoidal digital grating from different angles of view by aCCD camera, and obtaining photographing point clouds from multiple angles of view; for two image point clouds that need to be stitched together, building a k-D tree and interpolate to obtain that interpolated point cloud; for the two interpolated point clouds to be spliced, computing the fast point feature histogram, and obtaining the point cloud by random sampling consistent transformation; usingthe improved iterative nearest point method to obtain the first interpolated point cloud which is precisely registered; overlaying point cloud and mesh to realize the mosaic of two different angles of view of the shooting point cloud. The invention has low requirement for the initial position of the splice point cloud, the robustness is remarkably improved, the local optimization is not easy to fall into, the splice accuracy is improved, and the precise splicing of the point cloud under multi-view angles is realized, so that the practical industrial application requirements can be met.

Owner:ZHEJIANG UNIV

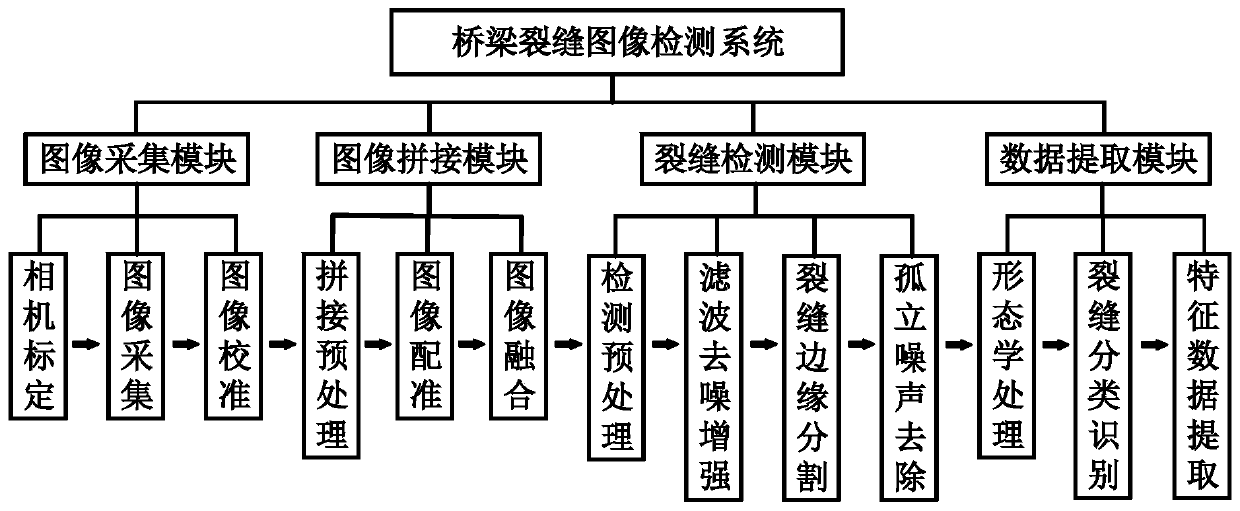

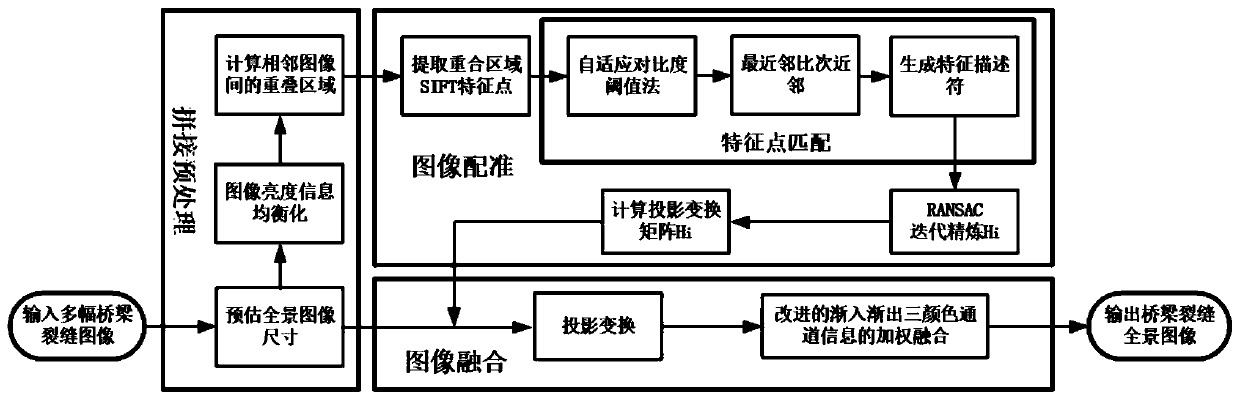

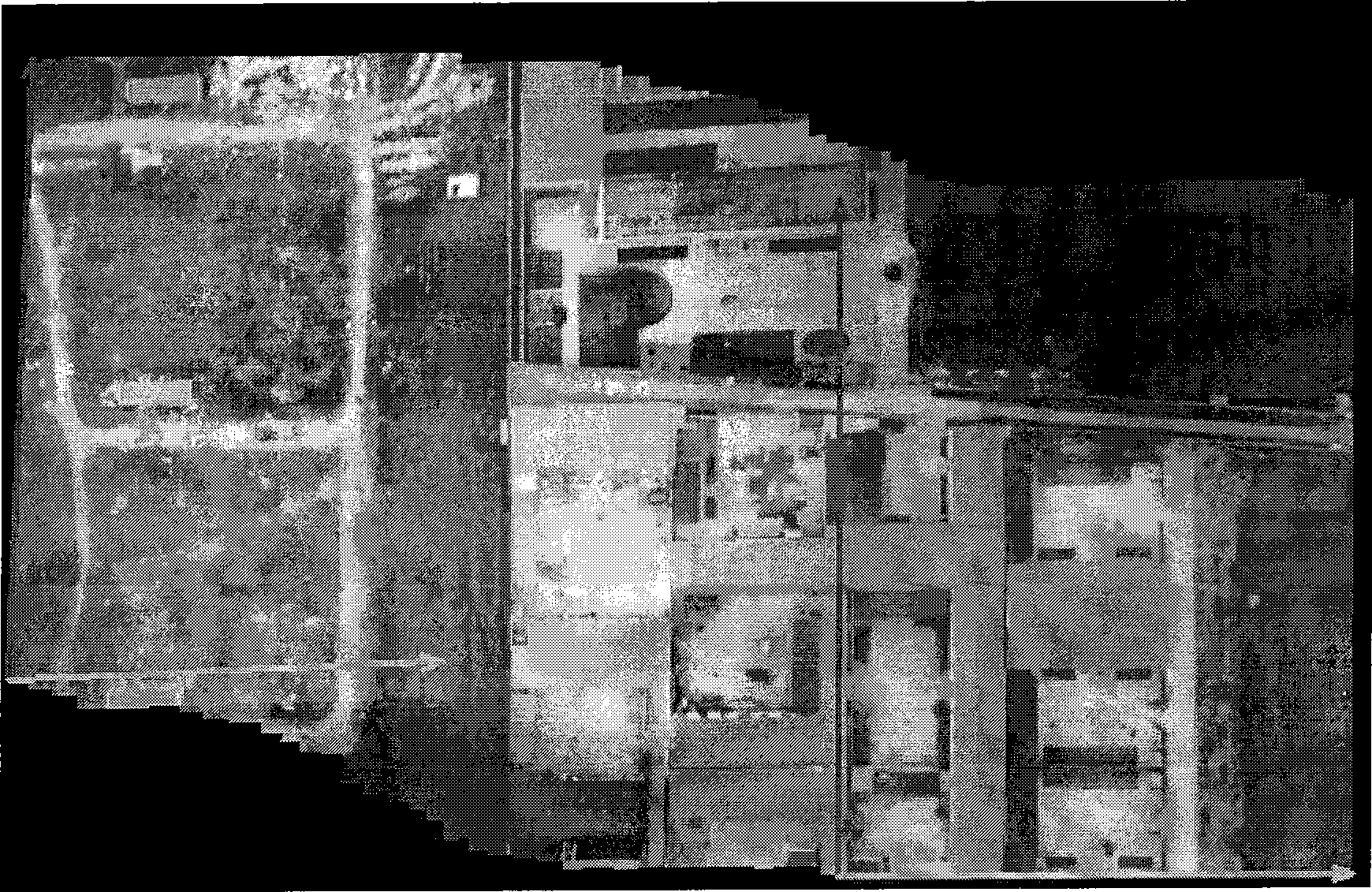

Bridge crack detection method

ActiveCN110378879AImprove mobilityIncrease flexibilityImage enhancementImage analysisTerrainBridge deck

The invention discloses a bridge crack detection method. Due to the fact that manual marking has certain subjectivity, the pavement crack detection precision depends on experience knowledge of experts, and experience lacks objectivity in quantitative analysis. The method comprises the following steps: 1, collecting images of a detected bridge floor one by one to obtain a bridge floor image set; 2,splicing images; 3, detecting crack; 4, extracting crack parameter. According to the invention, the image acquisition and processing technology replaces human eyes to complete automatic nondestructive detection of the bridge crack, and has very important practical significance for research of the bridge crack detection technology in a complex terrain environment. On one hand, the construction safety is enhanced, and on the other hand, the operation maneuverability and flexibility are improved. According to the invention, fidelity splicing of multiple groups of bridge deck images is realized,the image splicing precision and efficiency are improved, a working foundation is laid for subsequent bridge crack image detection, and a technical reference is provided for image splicing detection in other fields.

Owner:HANGZHOU DIANZI UNIV

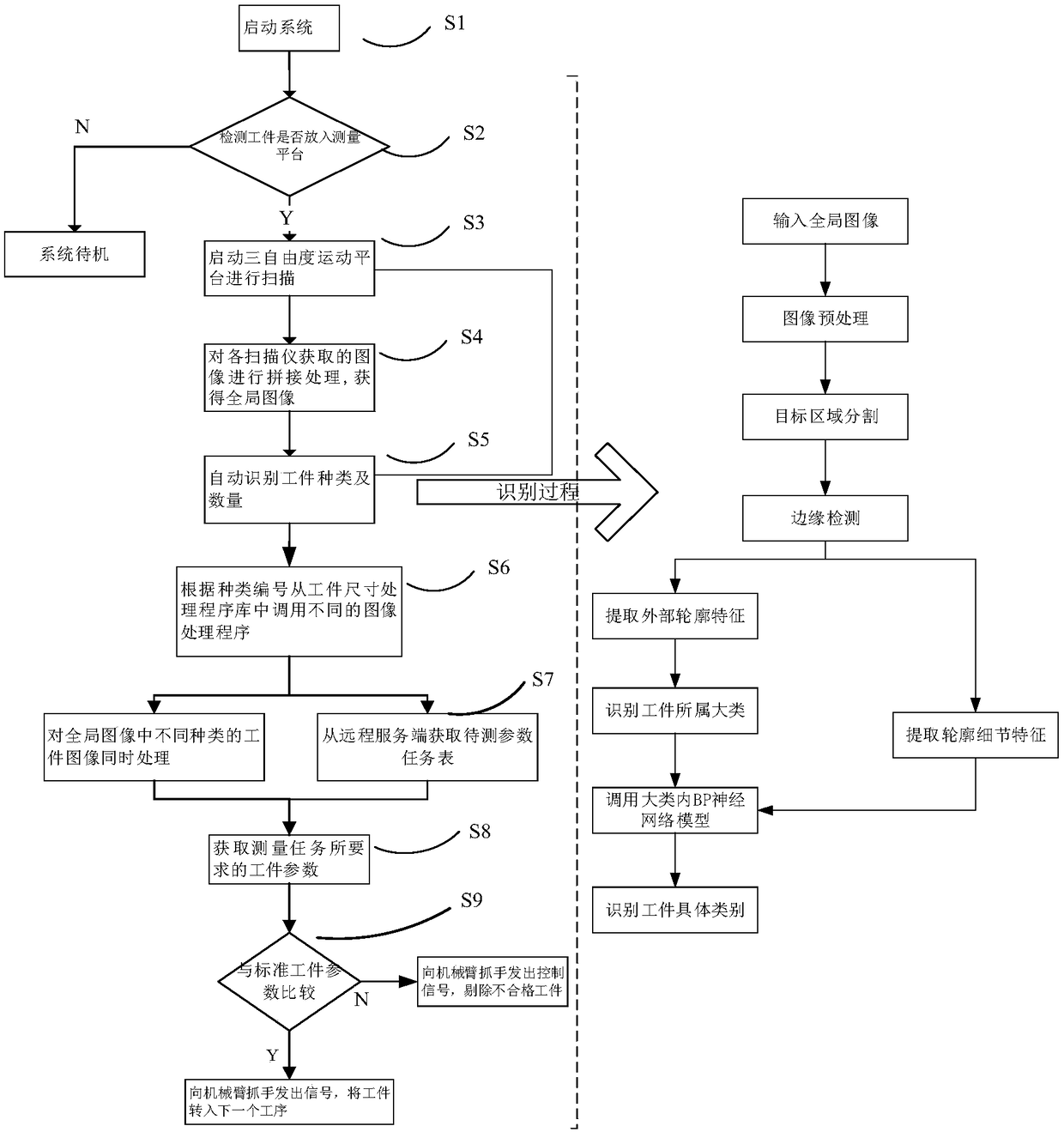

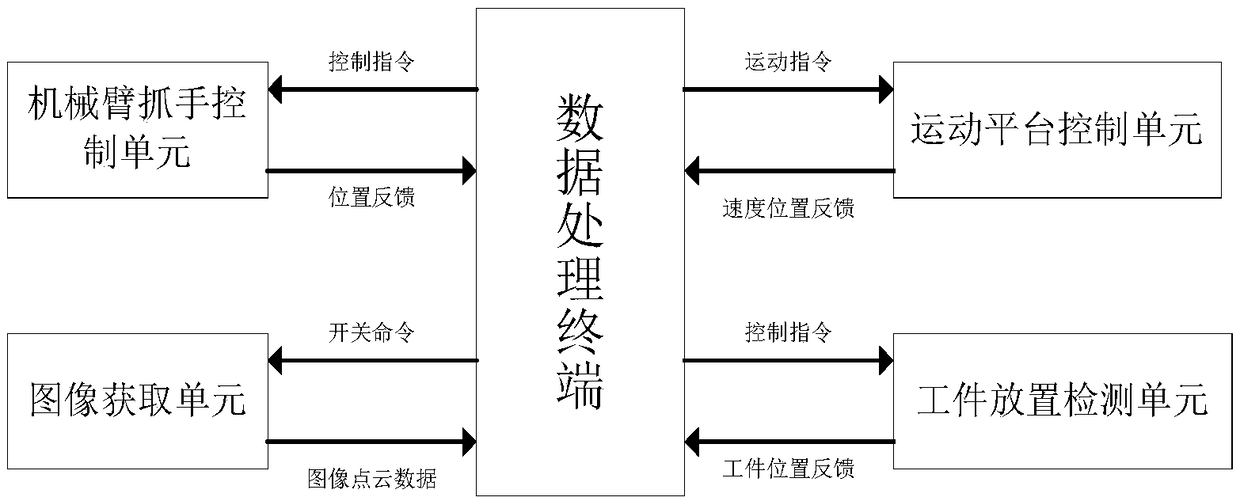

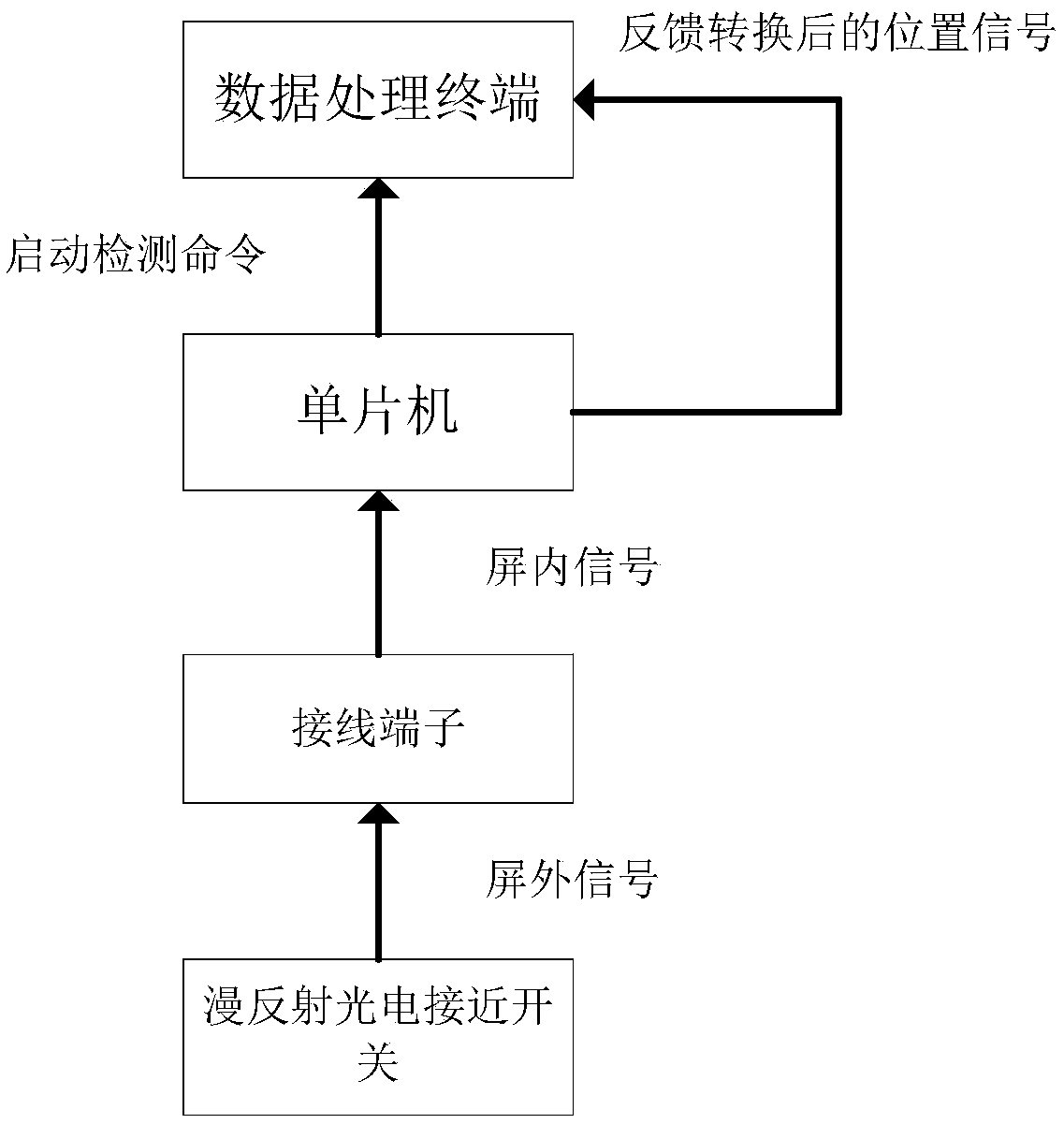

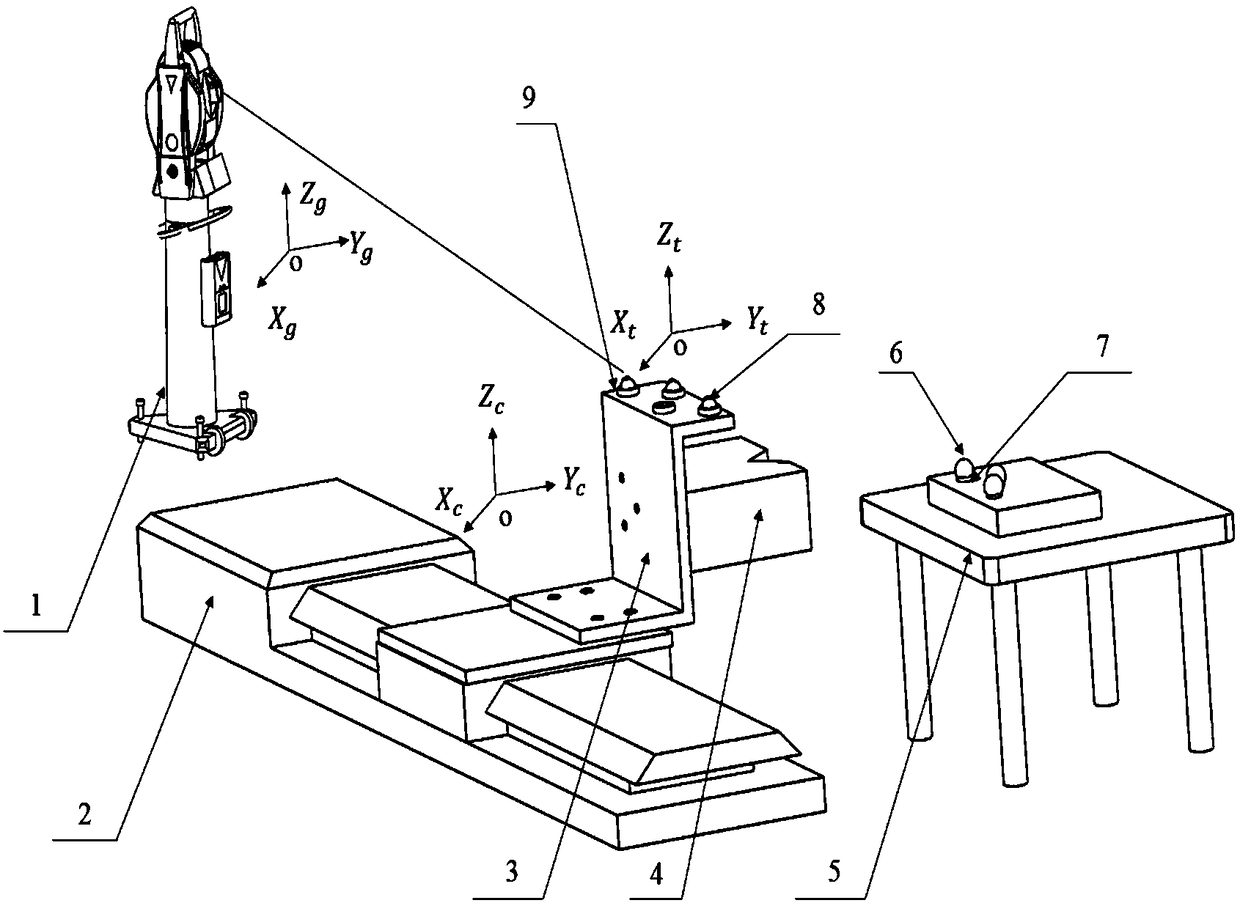

Multi-type workpieces batch visual measuring system and method

ActiveCN109357630AReduce manual intervention in the measurement processReduce labor costsUsing optical meansComputer scienceSize parameter

The invention provides a multi-type workpieces batch visual measuring system and a method, and belongs to the field of industrial detection automation. The measuring system comprises a data processingterminal, a workpieces detecting unit, an image acquiring unit, a control unit and the like. The measuring method comprises the following steps of: judging whether the to-be-detected workpieces are put into a detecting platform or not; obtaining a local depth image; obtaining a global image; identifying the type and number of the workpieces; and completing the size parameter measurement requiredby the measurement task. According to the multi-type workpieces batch visual measuring system and method, multiple kinds and multiple workpieces can be simultaneously detected at the same time; compared with traditional measurement means, the type and quantity of the workpieces, speed and accuracy and the like in measuring are significantly improved.

Owner:NANJING UNIV OF TECH

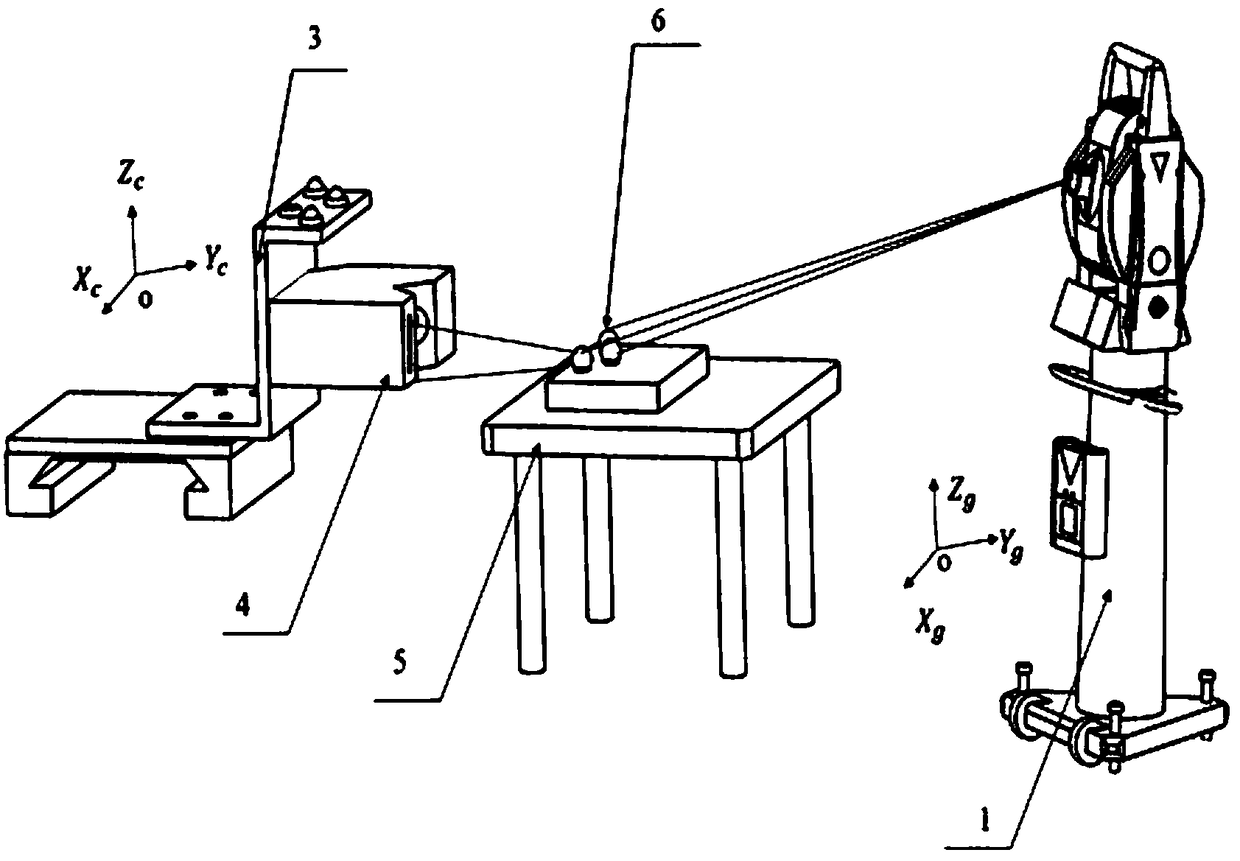

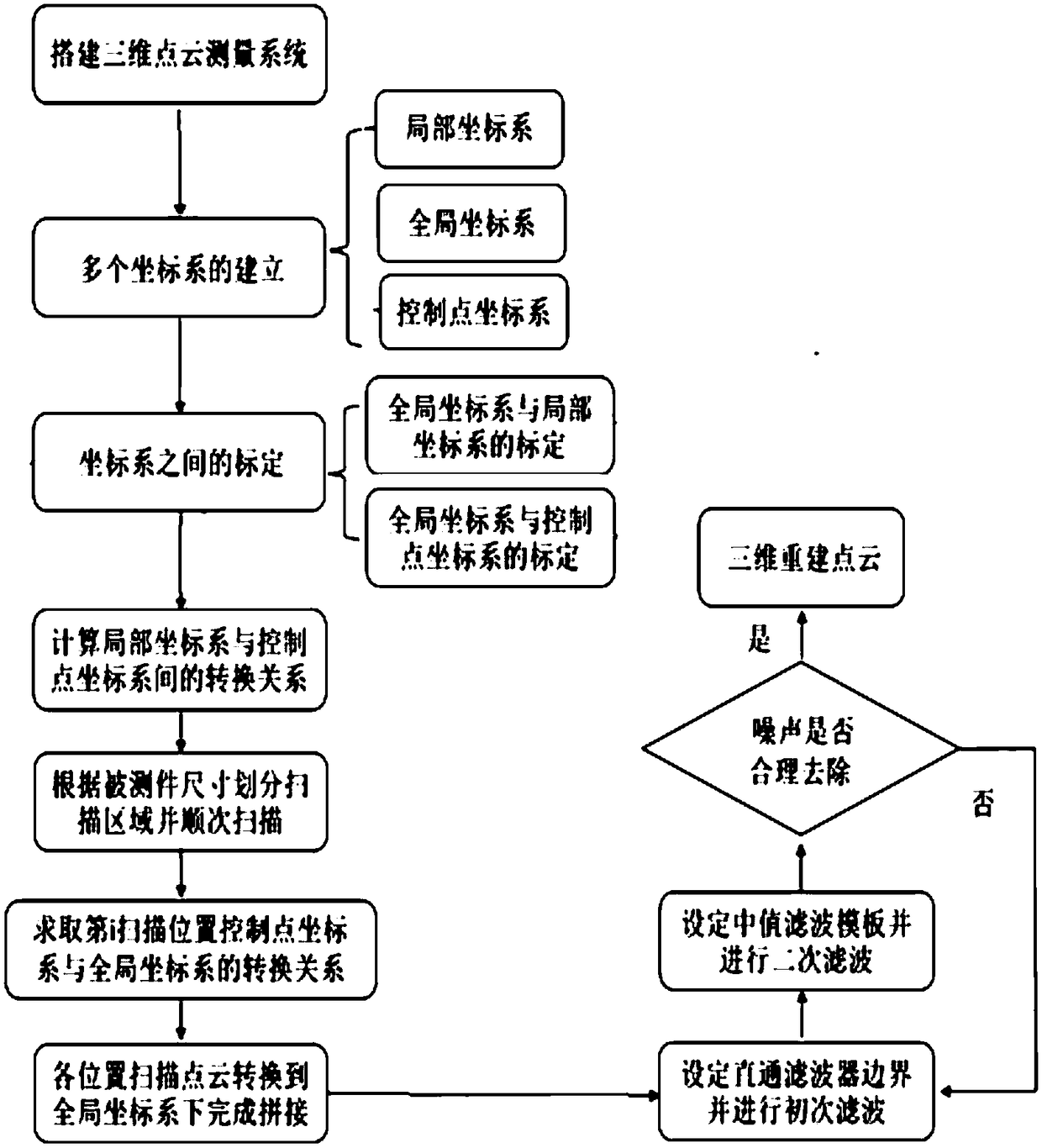

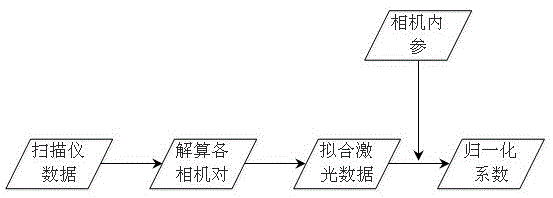

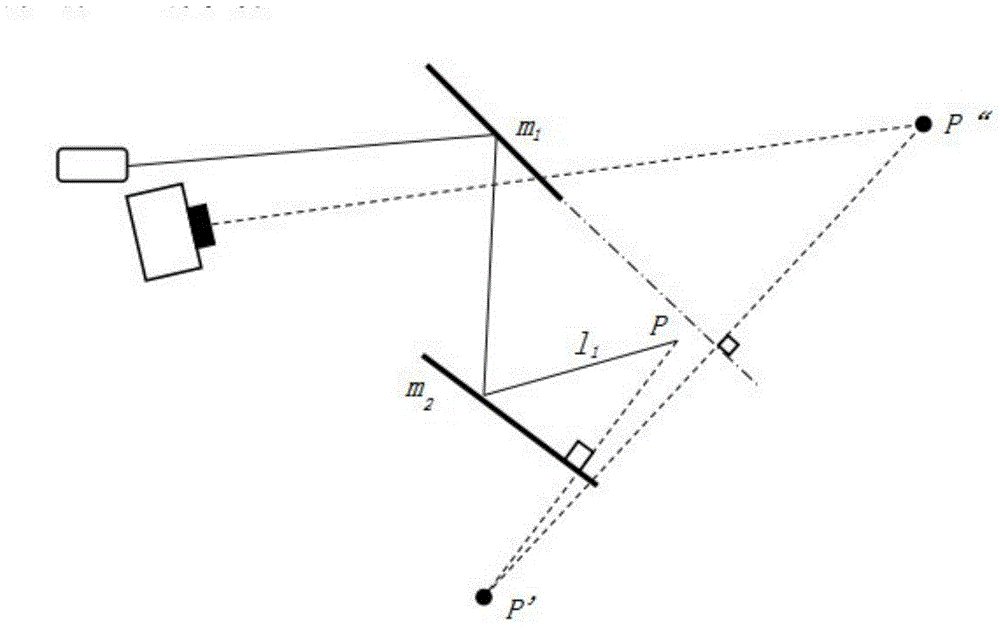

High-precision measuring method for three-dimensional shape of surface of large-sized measured part

The invention discloses a high-precision measuring method for the three-dimensional shape of the surface of a large-sized measured part, belongs to the field of visual measurement and reverse engineering, and relates to a line laser scanner-based high-precision measuring method for the three-dimensional shape of the surface of the large-sized measured part. According to the method, a high-precision three-dimensional point cloud acquisition system is built by utilizing a line laser scanner and a PI electric control platform, and multi-station high-precision splicing is realized by the aid of alaser tracker. A control point coordinate system is adopted as a transition coordinate system for local and global coordinate system conversion, and the laser tracker is used for recording each position of the three-dimensional point cloud acquisition system. All data point clouds are transformed to a global coordinate system through a quaternion coordinate transformation method to complete the splicing, noises are removed by a filter, and the three-dimensional geometric shape of the surface of the measured part is reconstructed based on a least square method. According to the method, the splicing process is simplified, the splicing precision is improved, and the problem that a traditional non-contact type measuring method is unlikely to meet the high-precision, high-efficiency and high-robustness measurement requirements of the large-sized measured part at the same time is improved.

Owner:DALIAN UNIV OF TECH

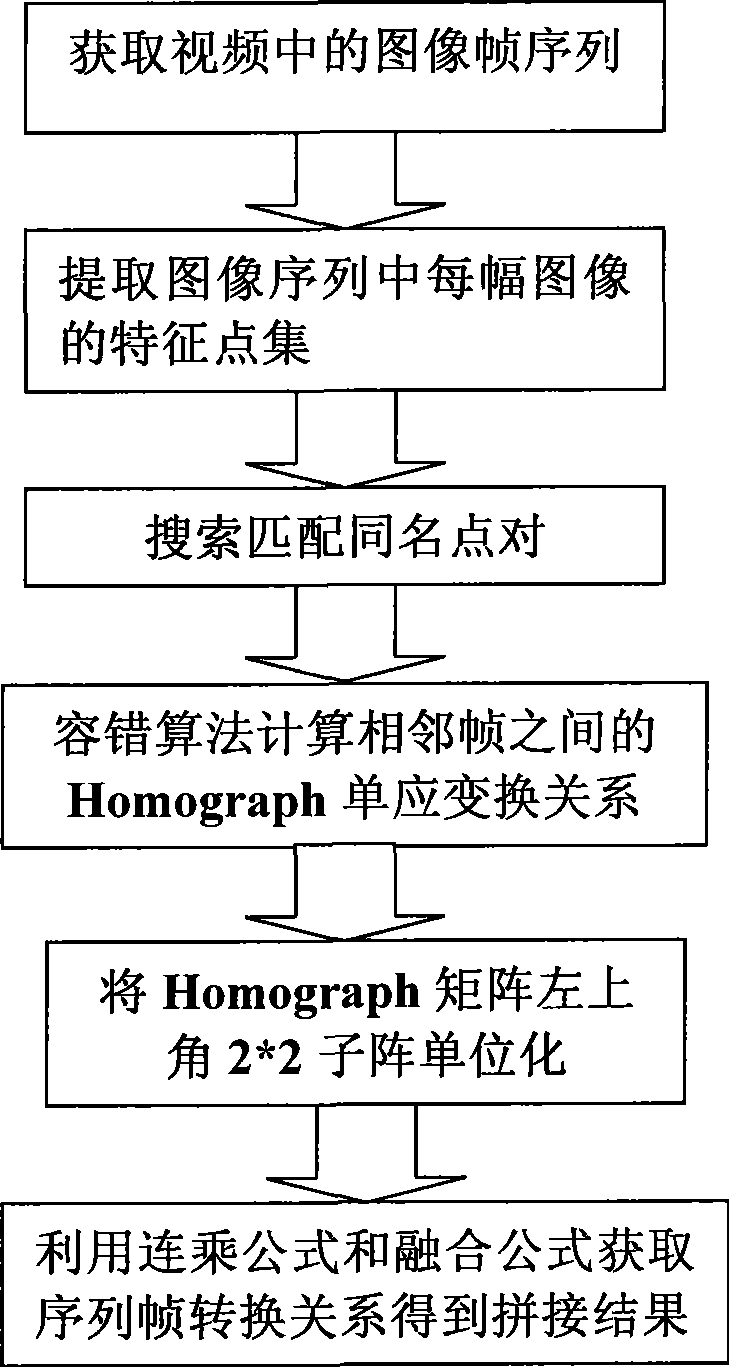

Method for splicing non-control point image

ActiveCN101442619AHigh precisionImprove efficiencyTelevision system detailsColor television detailsErrors and residualsPoint pair

The invention relates to a method for image mosaic without control points, which comprises the following steps: (1) acquiring an image sequence; (2) extracting a characteristic point set of each image in the image sequence; (3) searching homonymy point pairs of characteristic points between two adjacent images; (4) calculating a Homograph transformation relation between the adjacent images by using an RANSAC error-tolerant algorithm; and (5) using a continual multiplication formula and fusion technology to obtain mosaic results. Aiming at each characteristic point, the method can automatically collect a color channel with highest characteristic significance degree, so as to not only improve amount of the characteristic points greatly, but also improve significance and accuracy of the characteristic points. The method can be used as a correction method for human-computer interactive air photos to correct micro errors accumulated during mosaic. The method needs no control points, and has the advantages of high accuracy, low application cost and high efficiency.

Owner:SHENZHEN D & W SPATIAL INFORMATION TECH

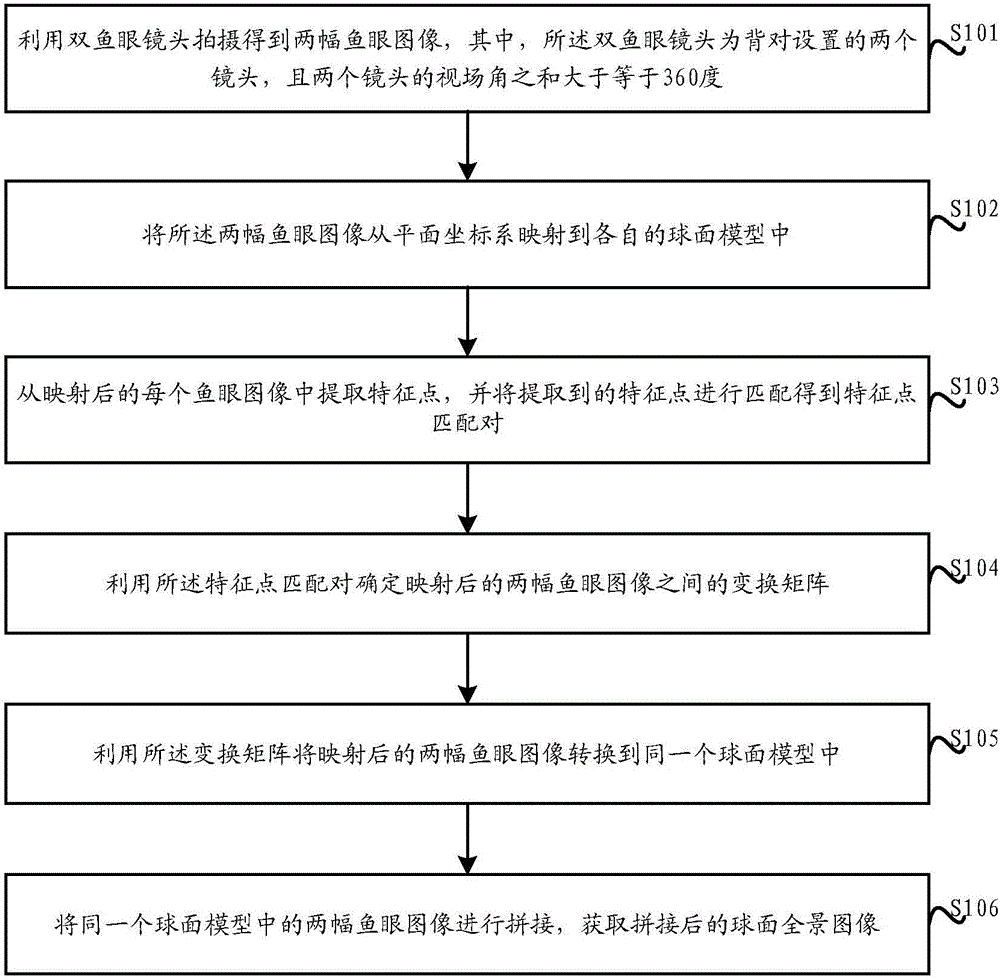

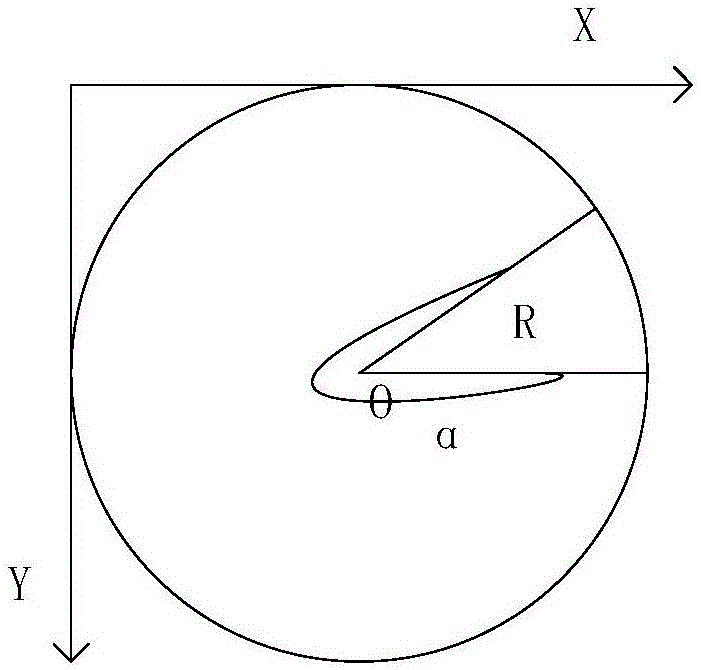

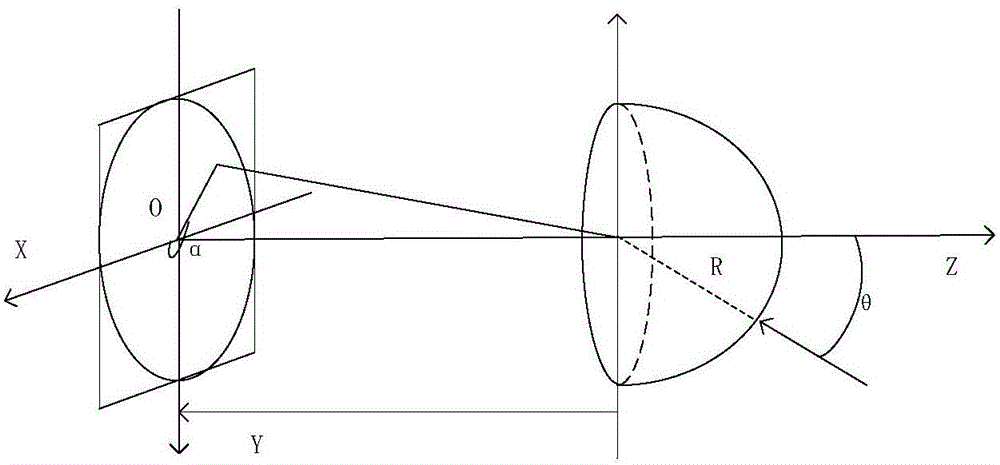

Panoramic image obtaining method and apparatus

InactiveCN106651767AReduce Stitching ErrorsSmall image errorImage analysisGeometric image transformationFeature point matchingPoint match

The invention discloses a panoramic image obtaining method and apparatus. The method comprises the steps of performing shooting by utilizing double fisheye lenses to obtain two fisheye images, wherein the double fisheyes lenses are two lenses arranged oppositely, and a sum of view field angles of the two lenses is greater than or equal to 360 degrees; mapping the two fisheye images to respective spherical models from a planar coordinate system; extracting feature points from the fisheye images subjected to the mapping, and performing matching on the extracted feature points to obtain feature point matching pairs; determining a transformation matrix between the two fisheye images subjected to the mapping by utilizing the feature point matching pairs; transforming the two fisheye images subjected to the mapping to be in the same spherical model by utilizing the transformation matrix; and splicing the two fisheye images in the same spherical model to obtain a spliced spherical panoramic image. The method and the apparatus are used for improving the splicing precision of the fisheye panoramic image.

Owner:北京超维智铁科技有限公司

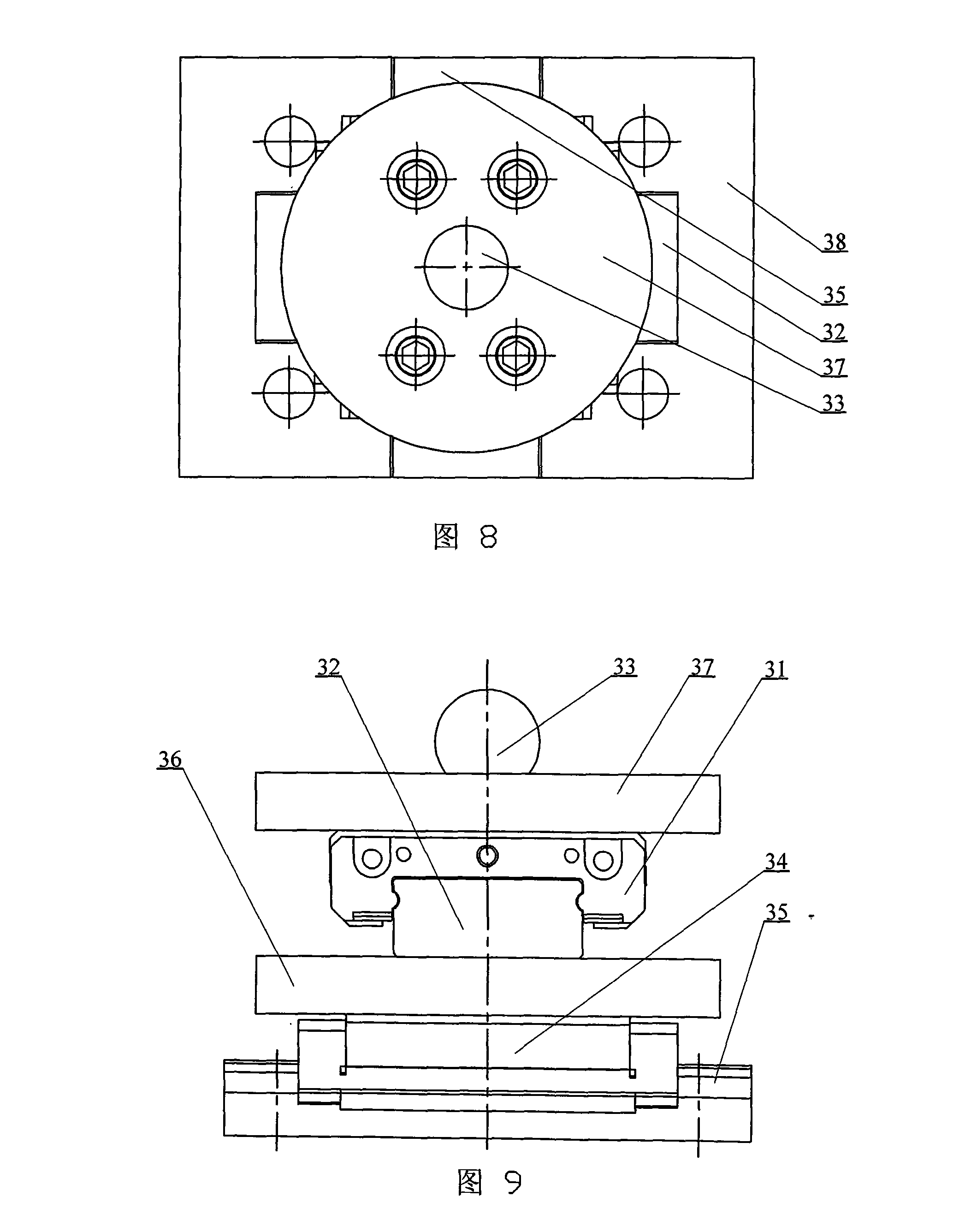

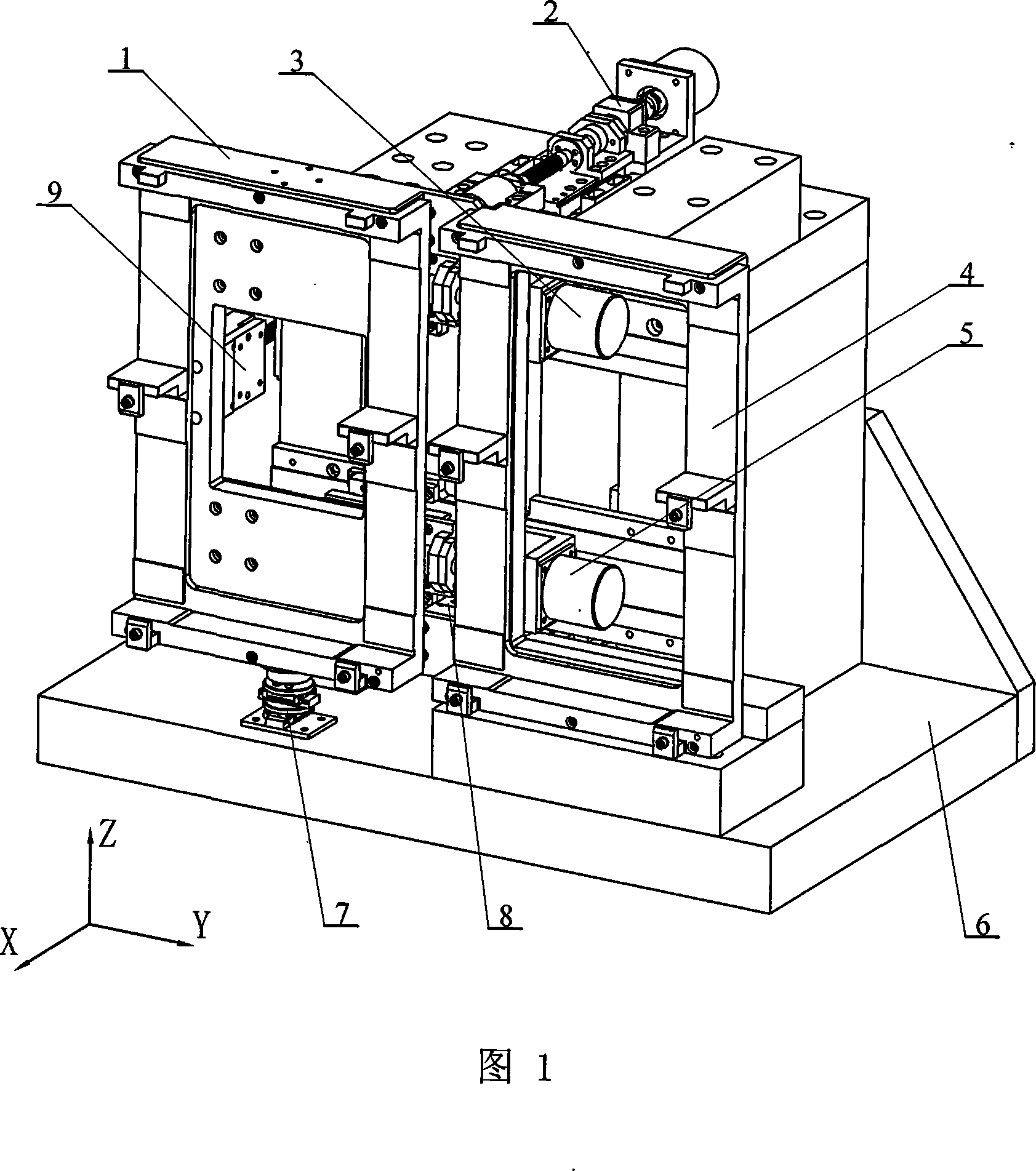

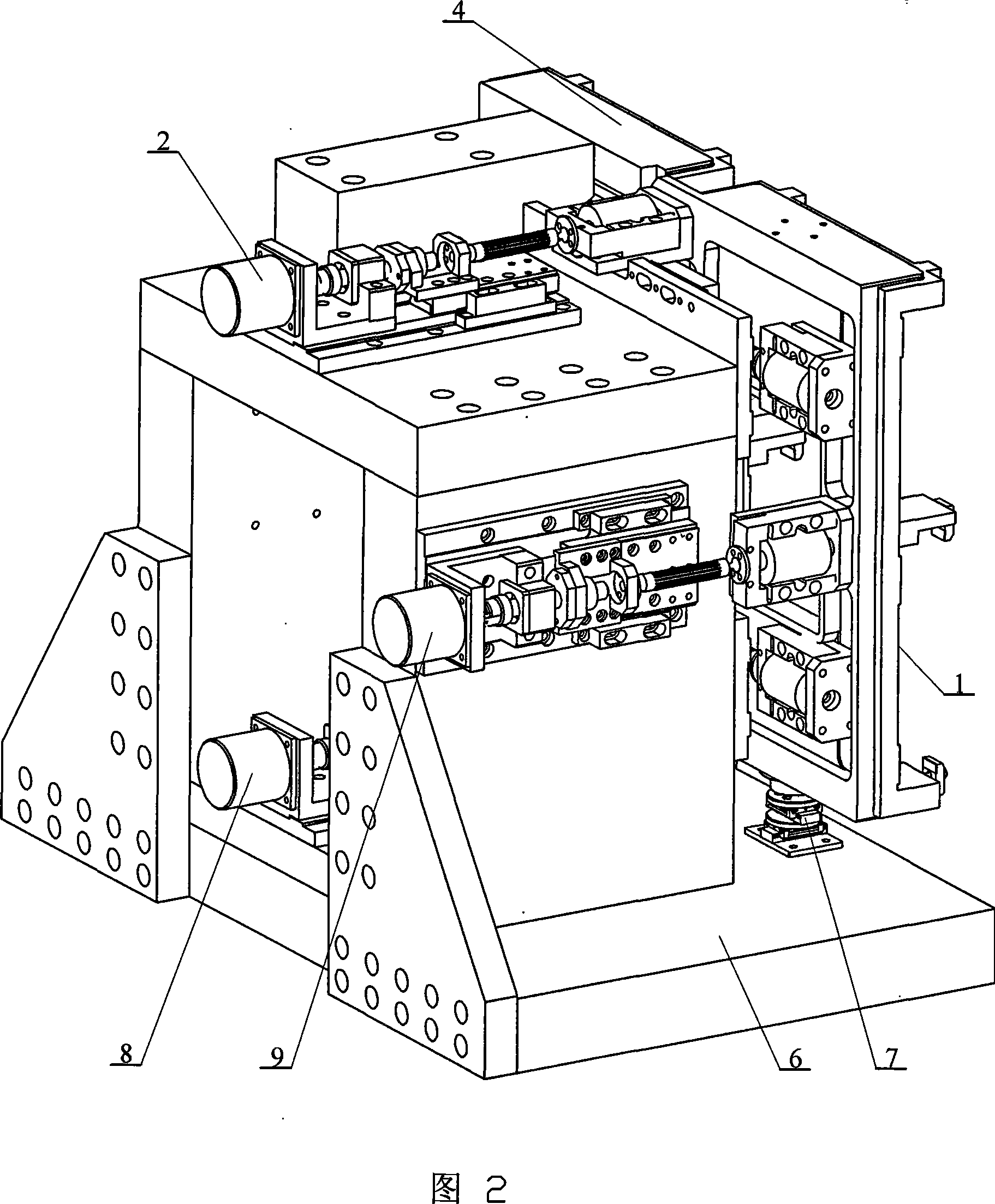

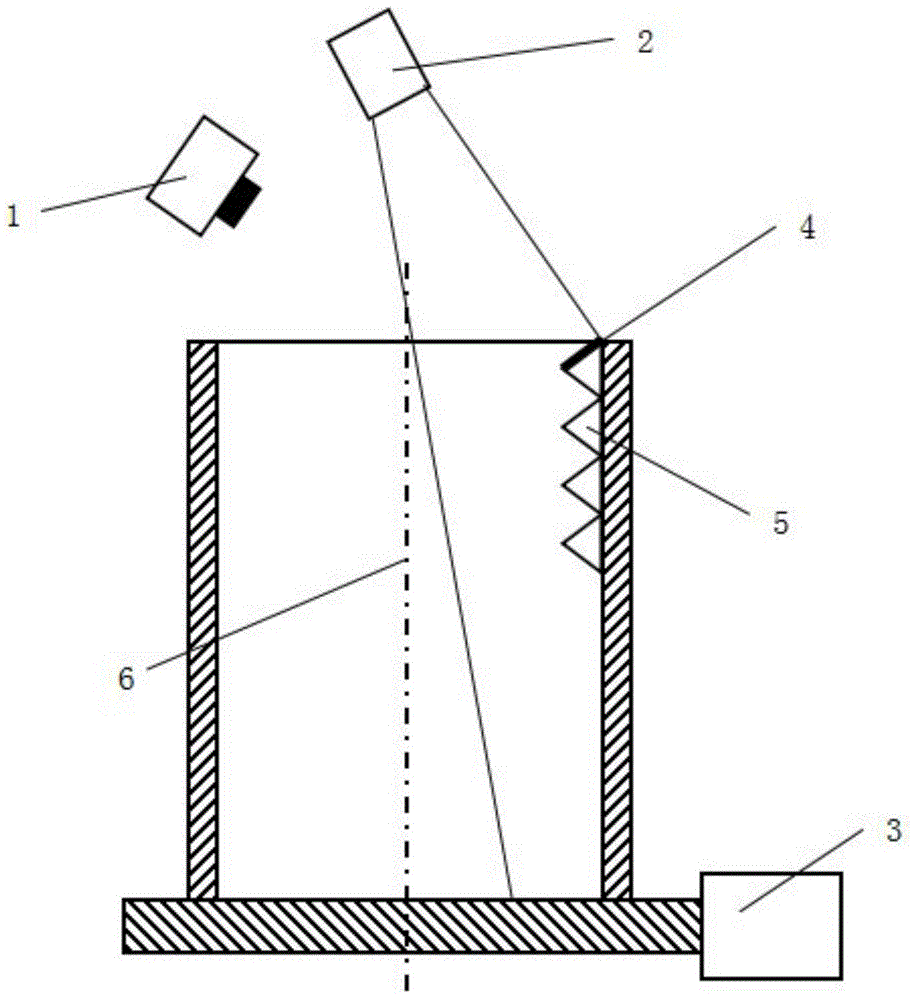

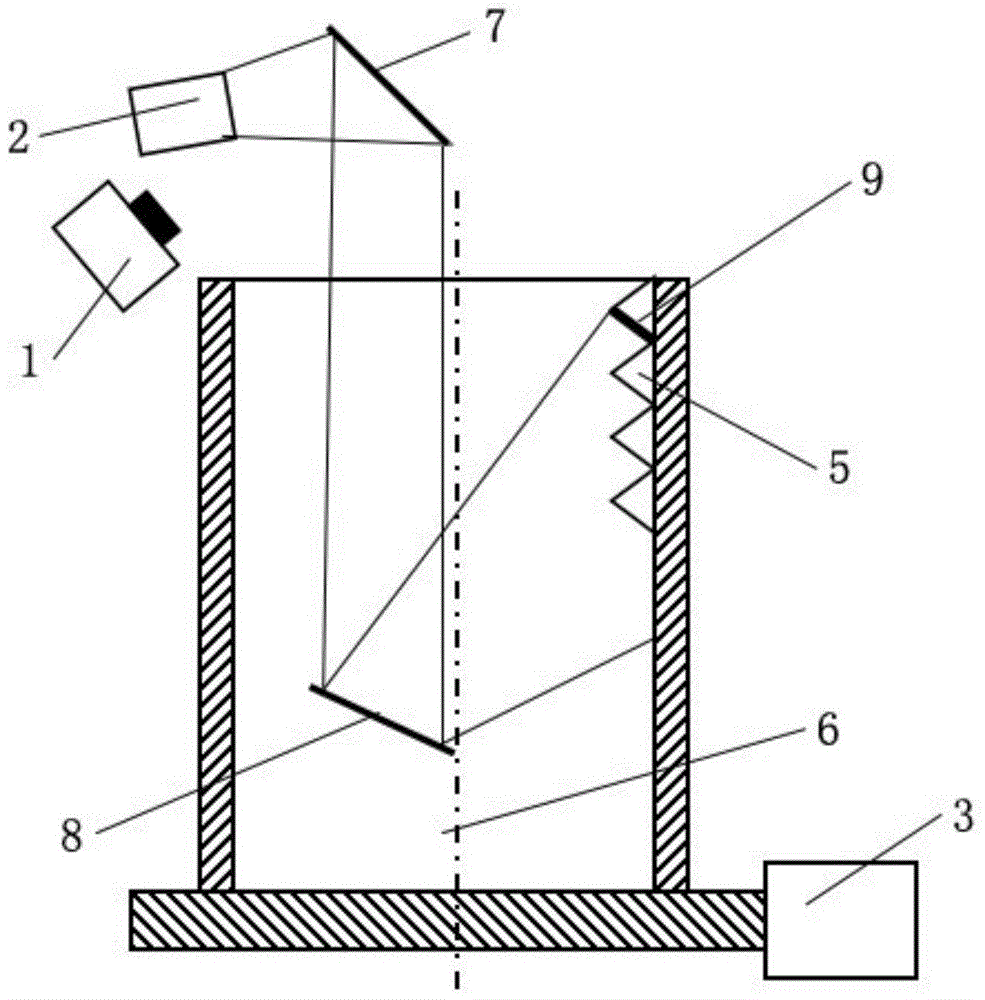

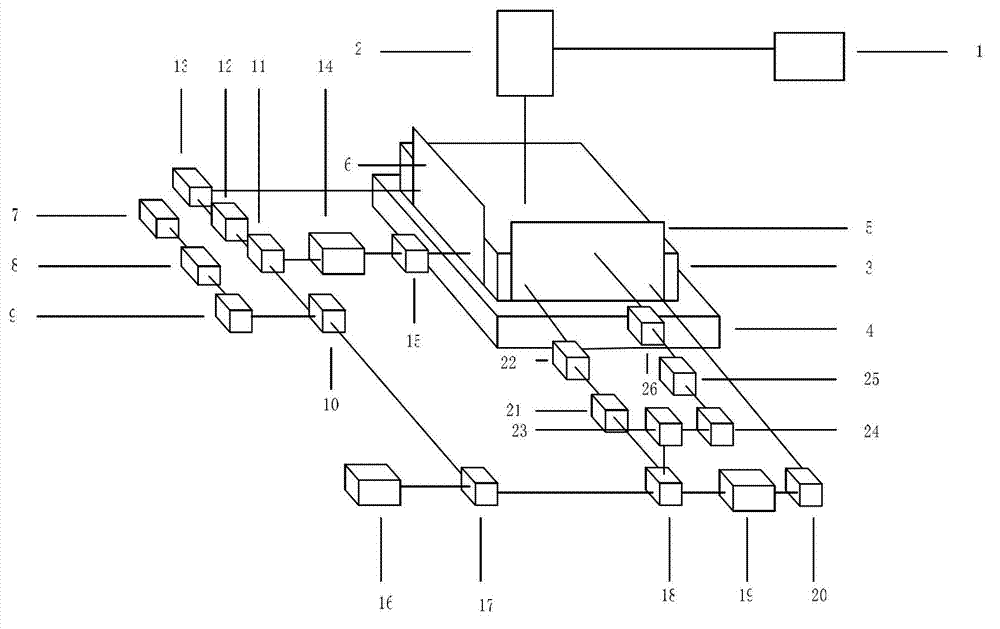

Parallel type macro-micro-driven high-precision heavy-caliber optical grating split joint device

A parallel type macro-micro driven raster splicing device with high precision and big caliber relates to a raster splicing device with high precision and big caliber. The invention can solve the problem that China has no raster splicing devices with high precision and big caliber. A two-dimensional moving platform part (7) is fixed on a base (6); the lower end of a movable raster part (1) is hinged with the upper end of the two-dimensional moving platform part (7); a fixed raster part (4) is fixedly arranged on the base (6); a first X-axle linear driver (2), a third X-axle linear driver (9) and a second X-axle linear driver (8) are arranged on the base (6) from top to bottom along the direction of an X-axle in turn; each linear driver is respectively fixedly connected with the base (6) and the raster part (1). The invention has the advantages of compact structure, convenient adjusting, flexible operation and high splicing precision, etc., and can realize the splicing with high precision in five space free directions of the movable raster and a static raster in a large area.

Owner:HARBIN INST OF TECH

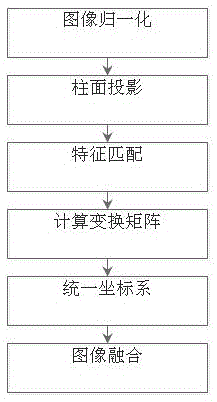

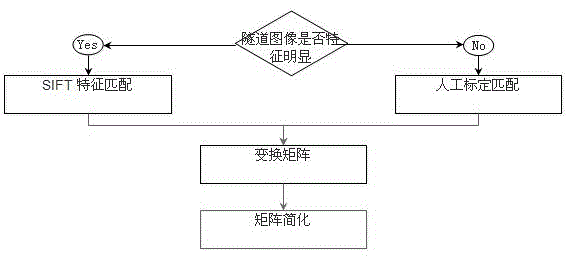

Tunnel image splicing method and system

ActiveCN105550995ASplicing speed is fastImprove stitching accuracyImage enhancementImage analysisScale-invariant feature transformCollection system

The invention provides a tunnel image splicing method and a tunnel image splicing system; the method and the system are used for carrying out splicing on an image collected by each camera in a tunnel image collection system; the tunnel image collection system comprises multiple cameras and a laser scanner; when carrying out the splicing on the tunnel images obtained by all cameras via single exposure on a certain section, the method comprises the following steps: working out an object distance corresponding to each of the cameras based on data of the laser scanner, carrying out normalization processing on the image collected by each camera, projecting all to-be-spliced images to a cylindrical surface, adopting SIFT (Scale Invariant Feature Transform) characteristic matching and obtaining matching points, calculating an initial transformation matrix, simplifying and extracting translation parameters to obtain a final transformation matrix among images, unifying a coordinate system, and fusing the images to obtain the splicing reconstructed smooth seamless tunnel image. The technical scheme disclosed by the invention has the advantages of fast splicing speed, relatively high splicing precision, high robustness, strong practicability and the like, and is convenient for subsequent tunnel disease detection.

Owner:WUHAN WUDA ZOYON SCI & TECH

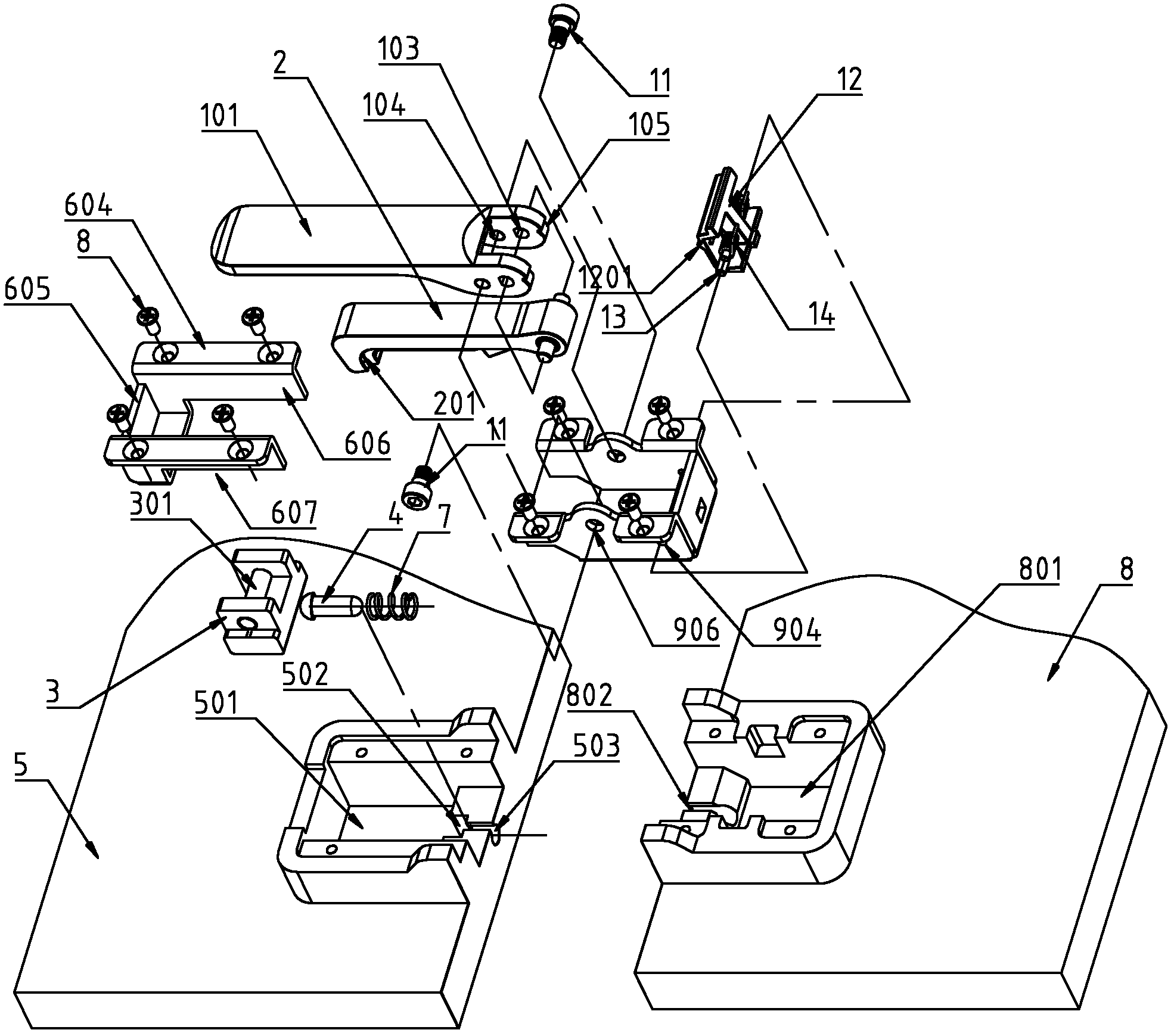

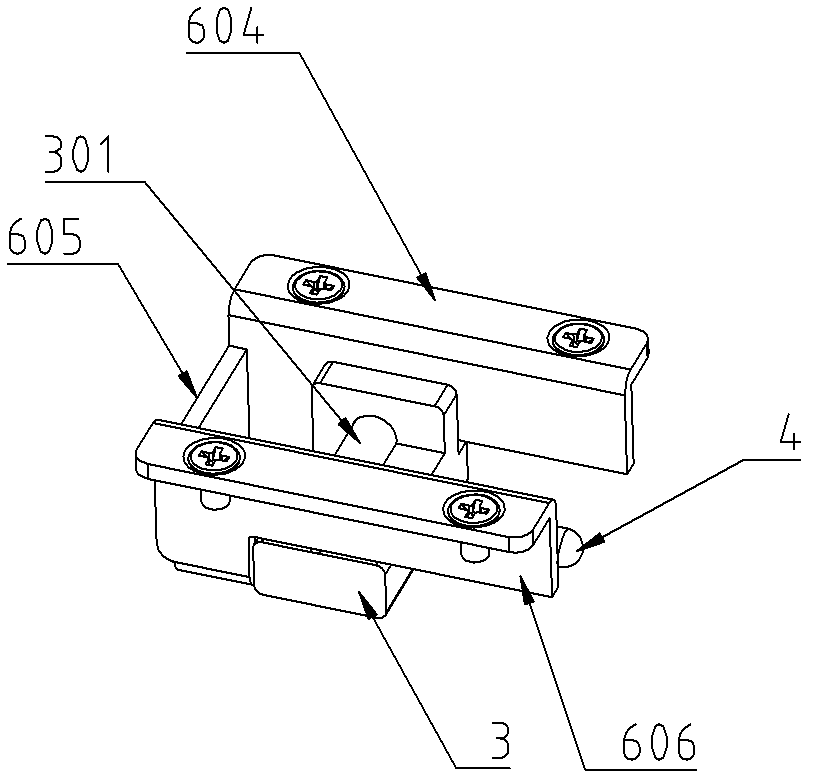

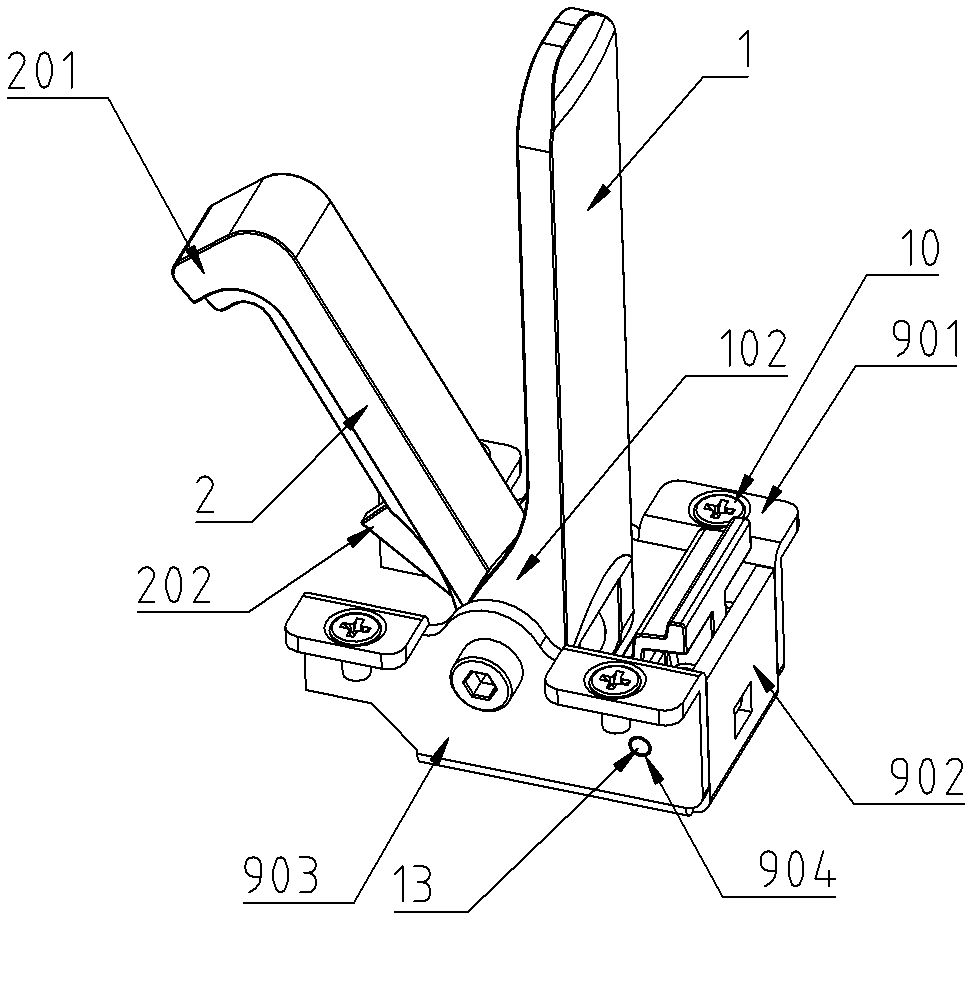

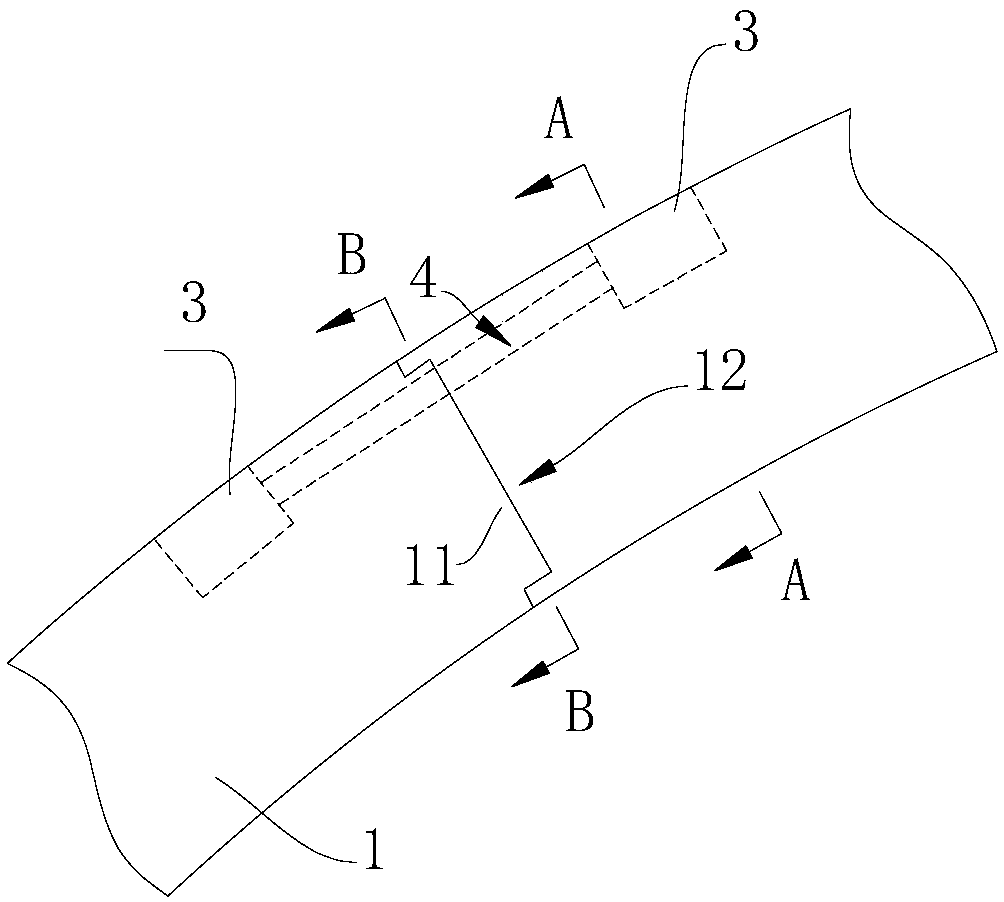

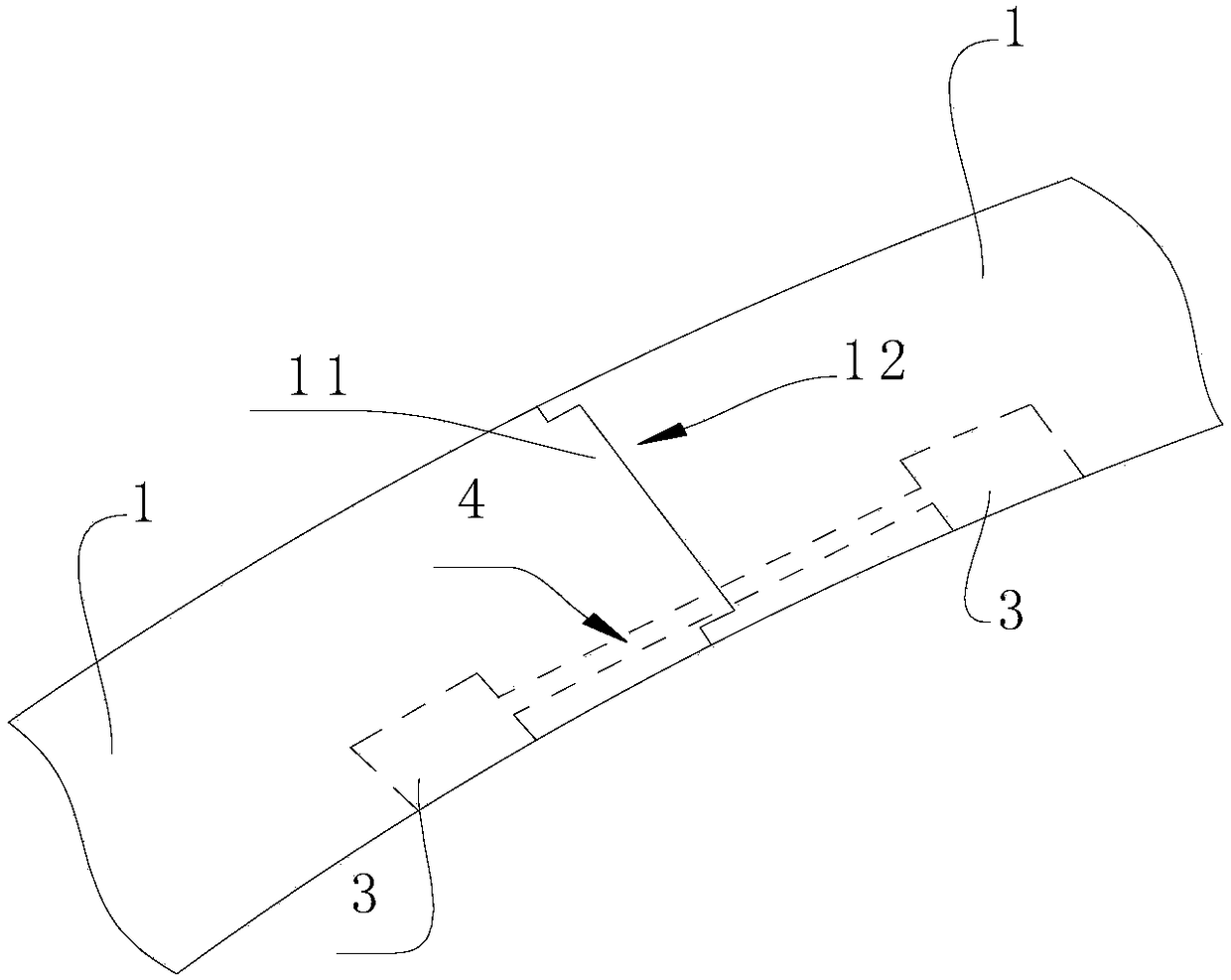

LED (Light Emitting Diode) combined screen latching mechanism, LED unit screen and LED combined screen

InactiveCN102637389ATime-saving and labor-saving assembly processImprove stitching accuracyCasings/cabinets/drawers detailsIdentification meansWrenchEngineering

The invention discloses an LED (Light Emitting Diode) combined screen latching mechanism, an LED unit screen and an LED combined screen. The LED combined screen latching mechanism comprises a first connecting part and a second connecting part, wherein the first connecting part comprises a slide block, a locating pin, a first screen board and a locating pin offsetting spring; the first screen board comprises a shaft hole of the locating pin and a longitudinal slideway of the slide block, and the locating pin is inserted to the shaft hole of the locating pin from the front to the back; the second connecting part comprises a latch hook, a wrench and a second screen board, the wrench is hinged with the second screen board, and the rear end of the latch hook is hinged with the wrench; and when the latching mechanism is latched, a hook head at the front end of the latch hook is lapped and hung on the slide block, the slide block slides along the slideway, and the rear end of the locating pin is inserted to a locating pin hole of the second screen board, so that the first screen board and the second screen board are connected together. When being used for splicing the unit screen, the LED combined screen latching mechanism is free of using an auxiliary mounting tool or high professional staff, time-saving and labor-saving purposes are achieved in the assembling process, the splicing precision is high, and the LED combined screen latching mechanism is suitable for splicing a display screen with high resolution.

Owner:GTEK GRP LTD

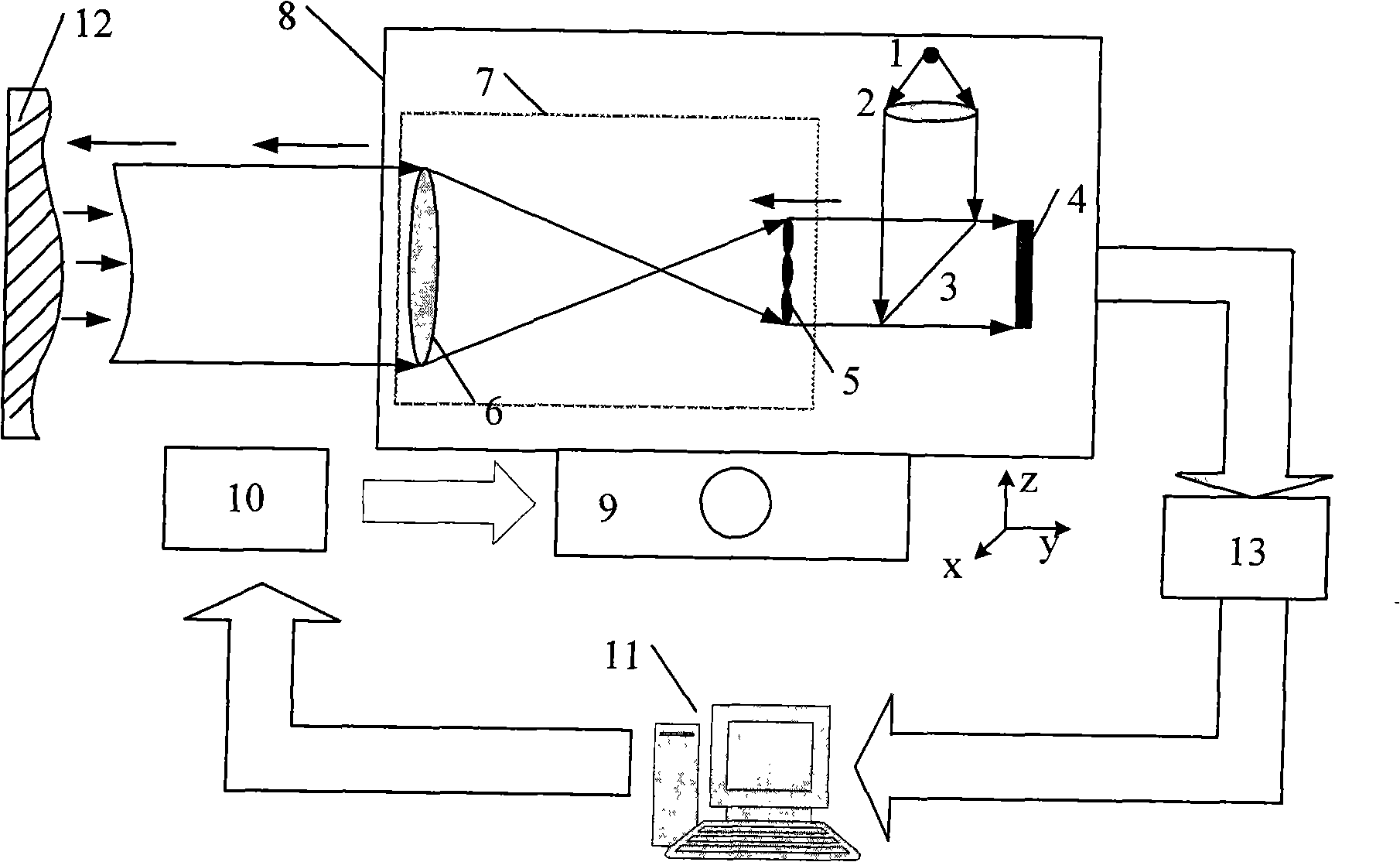

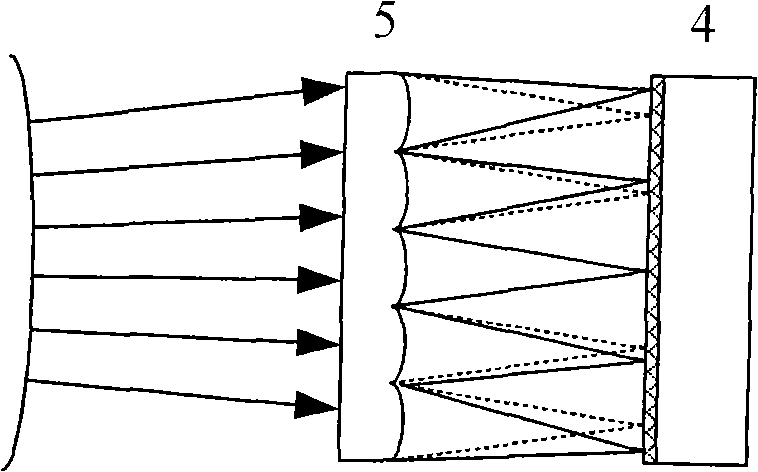

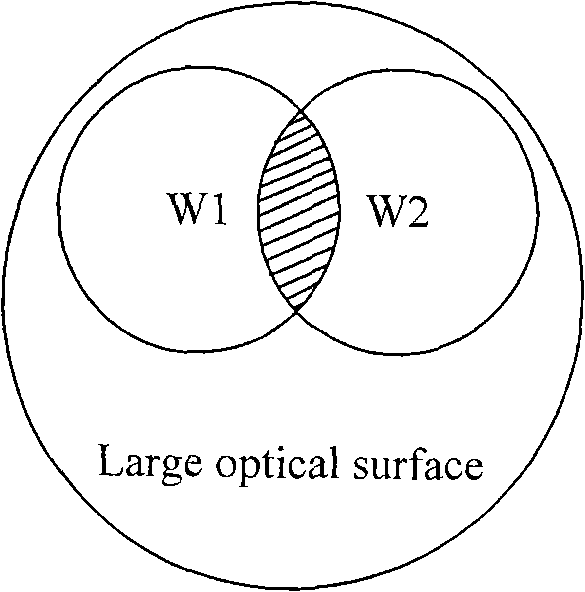

Splicing detection device based on minor caliber circular Shack-Hartmann wavefront sensor

ActiveCN101493375AReduce computational complexityEliminate translation errorsOptical apparatus testingComputation complexityData acquisition

The invention discloses a splicing detection device of a circular Hartmann-Shack wave-front sensor based on a minor caliber. The device is characterized by comprising the Hartmann-Shack wave-front sensor, an x-z 2D electric control translation stage, a step motor controller, a computer, a mirror surface to be detected and a data acquisition card; the Hartmann-Shack wave-front sensor is positioned behind the mirror surface to be detected to detect the mirror surface to be detected, and a facula lattice is formed on the Hartmann-Shack wave-front sensor, and the data acquisition card acquires the facula data and transmits the data to the computer for storing; the computer sends an instruction to the step motor controller, and controls the 2D electric control translation stage to move along an x axis and a z axis to scan and detect the mirror surface to be detected; the data acquisition card sequentially acquires the facula data of a wavelet surface of each frame, and then a wave surface to be detected is obtained by a centroid algorithm, a splicing method and a restoration algorithm. The device and the method help improve a formula by ignoring a defocus error in theoretical analysis, eliminate a principle error of a translation error, improve splicing precision and lower computation complexity of solving splicing parameters.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

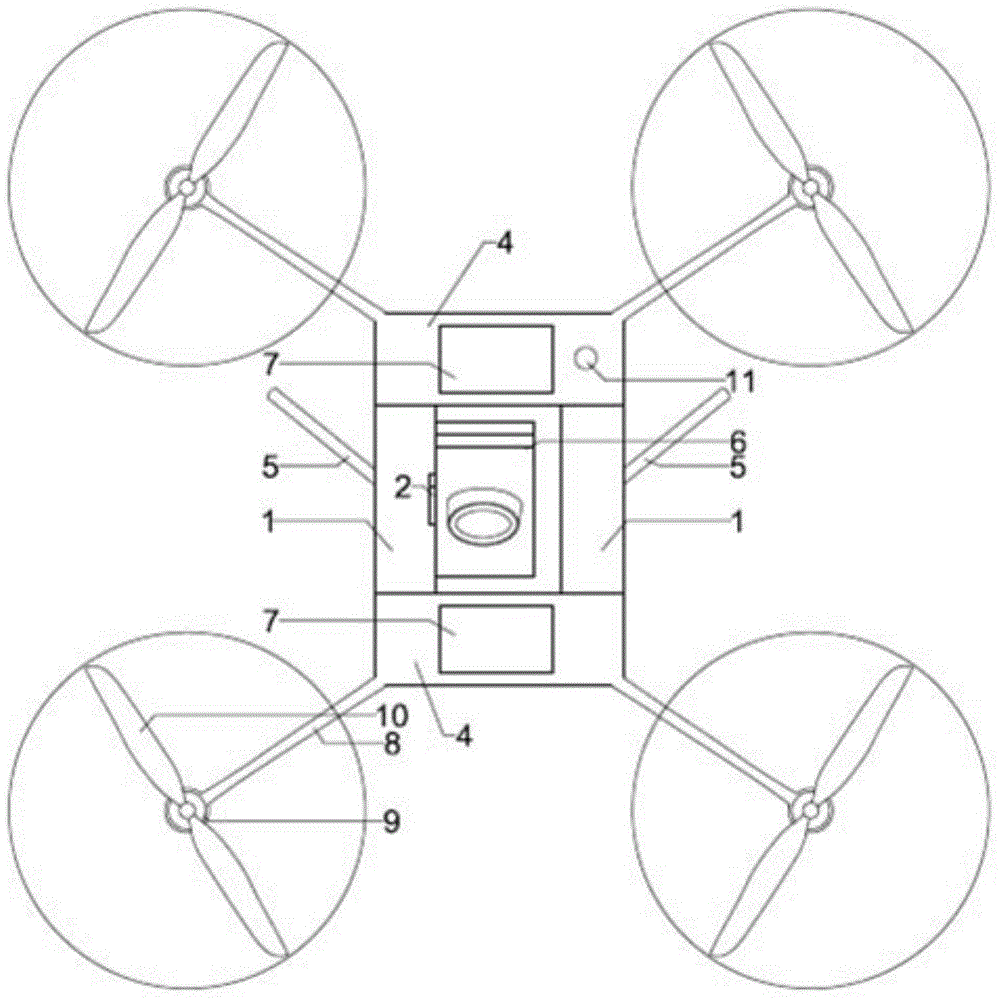

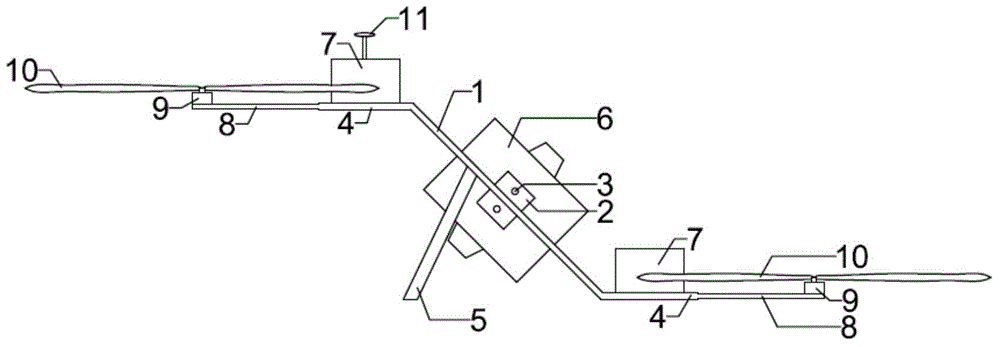

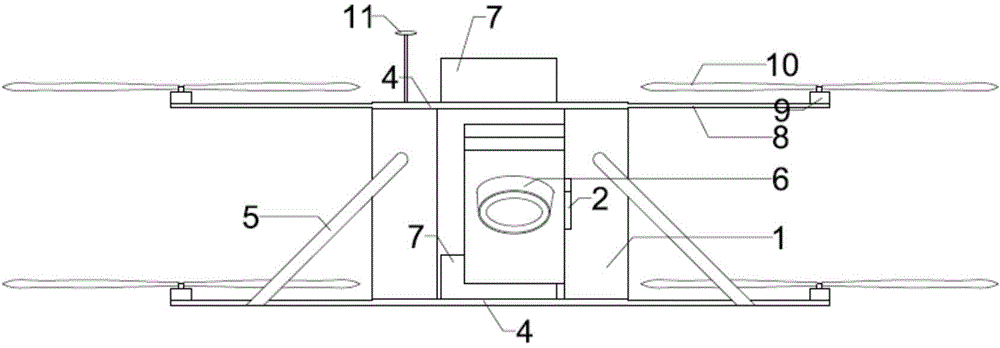

Multi-rotor-wing unmanned aerial vehicle for panoramic shooting

InactiveCN104890875AMeet the following requirements for panoramic roaming shootingMeet the requirements of panoramic shootingAircraft componentsRotocraftShortest distanceUncrewed vehicle

The invention relates to a multi-rotor-wing unmanned aerial vehicle for panoramic shooting. The multi-rotor unmanned aerial vehicle comprises unmanned aerial vehicle body plates, wherein equipment compartments and four motor cantilevers are arranged on the unmanned aerial vehicle body plates, a motor and a rotor wing are arranged on each motor cantilever, the unmanned aerial vehicle body plates comprise two horizontal unmanned aerial vehicle body plates and a middle inclined unmanned aerial vehicle body plate for connecting the two horizontal unmanned aerial vehicle body plates, cameras are arranged on the upper side surface and the lower side surface of the inclined unmanned aerial vehicle body plate, and an undercarriage is arranged at one side, facing the ground, of the inclined unmanned aerial vehicle body plate. The multi-rotor unmanned aerial vehicle for panoramic shooting can realize shooting without blind area, and can meet the requirement on panoramic shooting in short distance and confined space of heritage, the location difference of the cameras is minimized, the image splicing accuracy is high, the shooting speed is high, the drifting interference is low, and an unmanned aerial vehicle body is light and small, and can realize flight in confined space easily.

Owner:TIANJIN UNIV

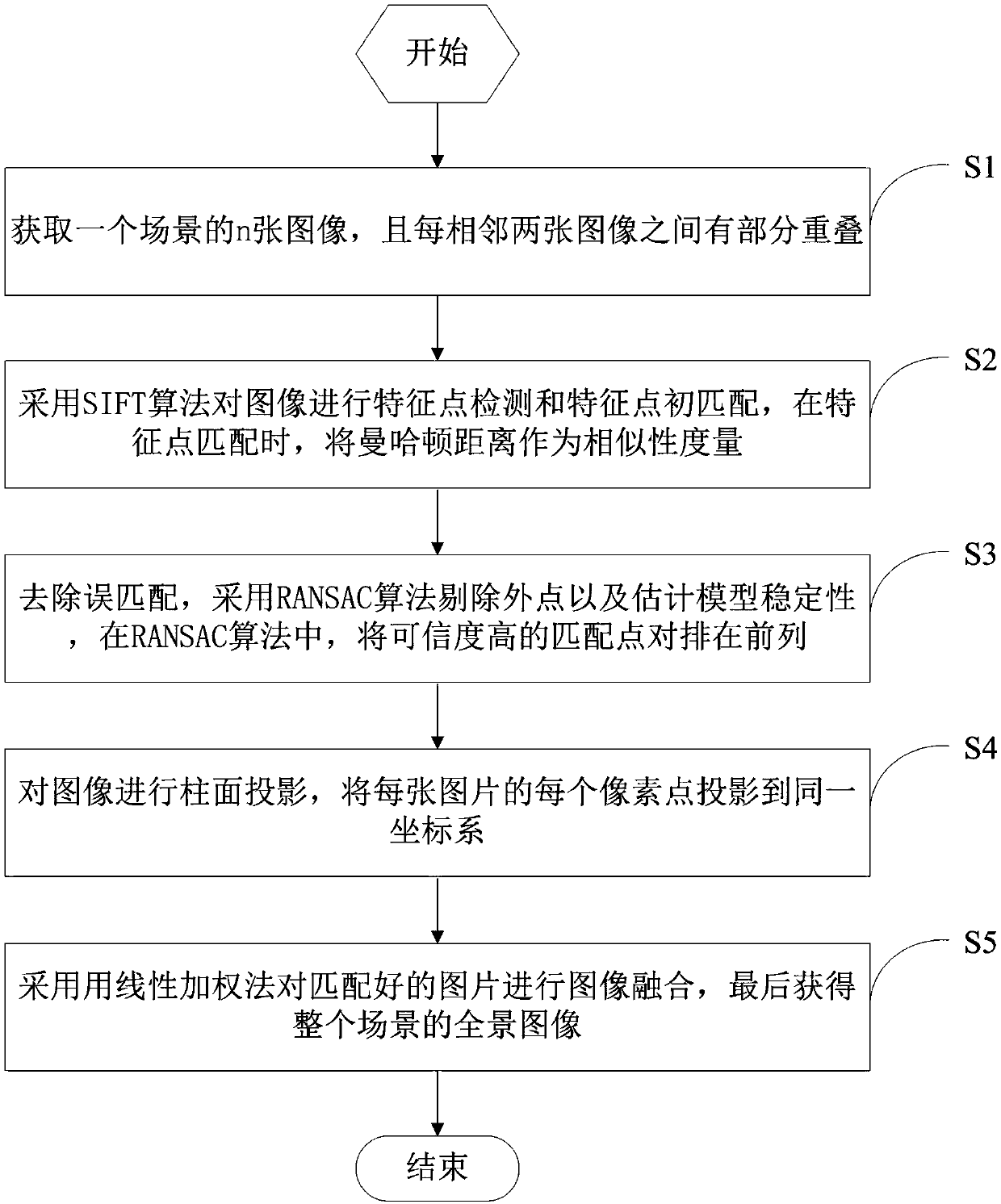

Quick splicing method and system of infrared images

InactiveCN107833179AAvoid Full Data InspectionDoes not affect the splicing effectImage enhancementImage analysisImage fusionFeature point matching

The invention discloses a quick splicing method and system of infrared images. The method comprises steps of acquiring n images of a scene, wherein every adjacent two images are partially overlapped;using the SIFT algorithm to carry out characteristic point detection and characteristic point pre-matching on the images, and using a Manhattan distance as the similarity measurement during characteristic point matching; removing error matching, using the RANSAC algorithm to remove outer points, estimating model stability, and arranging the matching point pairs with the high reliability to be thefront line in the RANSAC algorithm; carrying out cylindrical projection on the images, projecting each pixel point of each picture to the same coordinate system, and using the linear weighting methodto carry out image fusion on the matched pictures so as to acquire a panoramic image of the whole scene. The system corresponds to the method. According to the invention, by improving the classic SIFTalgorithm and the RANSAC algorithm, under the condition that the splicing effects are not influenced, the splicing speed is increased and the splicing precision is quite high.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

Internal thread detection device and method

ActiveCN104567722AEasy accessSimple design and manufactureUsing optical meansLaser projectorSpecular reflection

The invention discloses an internal thread detection device and method and discloses a method for performing measurement and reconstruction on the upper surface and the lower surface of a thread respectively, and then thread parameter measurement can be achieved. Due to the fact that only the upper surface or the lower surface of the thread is measured each time, it is not necessary for a camera to capture a complete tooth form image at a time, the camera and a laser projector can be arranged outside a detection hole, and the limitation on the size of equipment is avoided. Through the method, complete shape information of the internal thread is obtained finally, and foreign substance examination and measurement of the depth, the pitch and the tooth form parameter of the thread can be carried out simultaneously. Because the majority of threads are made of metal, projection light performs specular reflection on a processing surface of the thread, the camera and the laser projector are arranged on the same side of the detection face, and therefore the camera can obtain clear projection light images beneficially; in addition, an automated surface splicing technology based on the optimization theory is put forward, the splicing accuracy of the upper surface and the lower surface of the thread is improved, a program can be implemented easily, automation of subsequent data processing is improved, and measurement operations are simplified.

Owner:成都实唯物联网科技有限公司

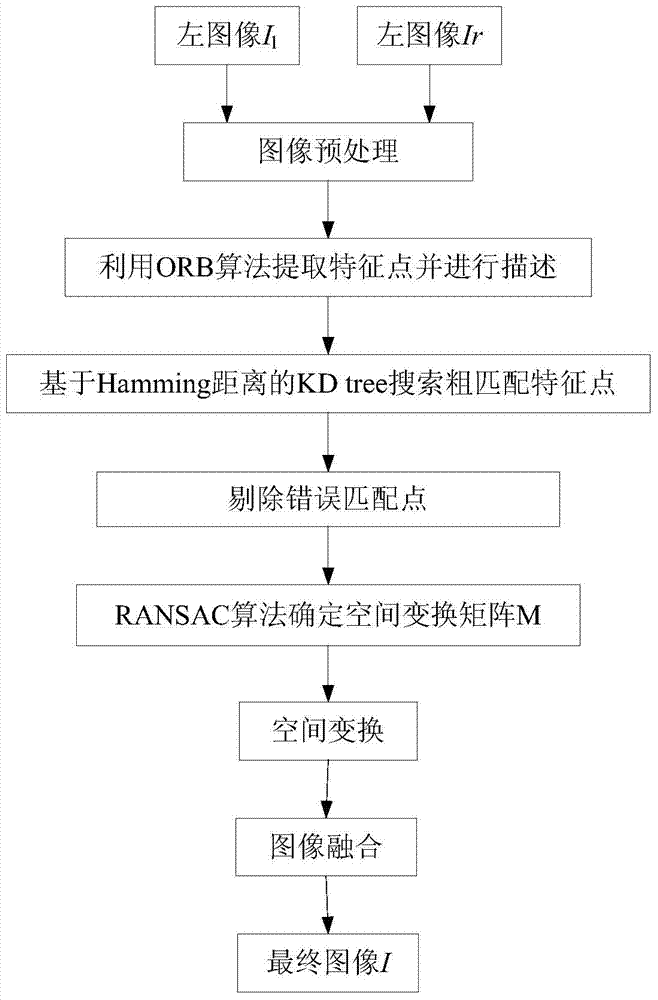

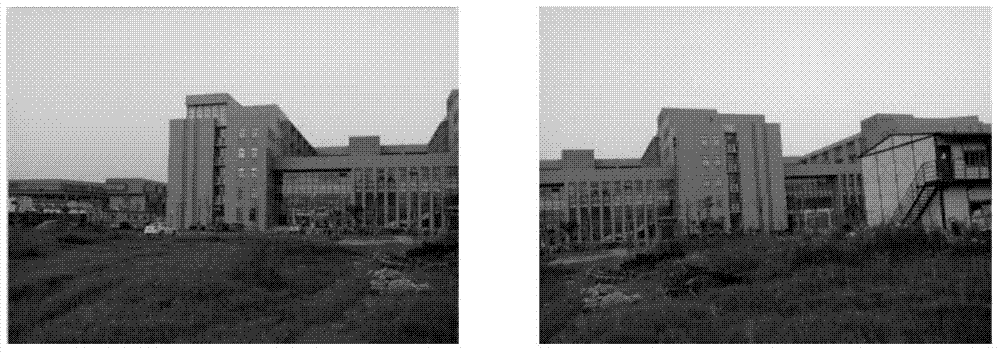

Stereoscopic vision fast image stitching method suitable for space tether-robot

ActiveCN103761721AImprove stitching accuracyImprove robustnessImage enhancementGeometric image transformationSpace tetherVisual perception

The invention relates to a stereoscopic vision fast image stitching method suitable for a space tether-robot. Based on ORB feature detection and an image stitching algorithm of a description algorithm, by comparing the method with a traditional stitching algorithm, it can be seen that the method is high in stitching precision and robustness and good in final image stitching effect, has the highest speed when compared with the traditional stitching algorithm, and has a wide application range and good application prospects. Compared with the prior art, the method has the advantages that time consumption of the method is small, the stitching speed is significantly improved, the infusion effect of stitching portions of an image is good, and noise immunity is strong.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Production method for seamless nickel sheet with microprism array

InactiveCN103009016AAvoid pollutionImprove stitching accuracyElectroforming processesElectroformingNickel plate

The invention relates to a production method for a seamless nickel sheet with a microprism array. The production method includes the steps of manufacturing unit nickel sheets of required amount; performing finish machining to and removing burrs of the unit nickel sheets, and cutting two sides of a front surface of each unit nickel sheets to form a cut surface with certain angle; arranging the machined nickel plates as required, and welding the unit sheets from reverse surfaces to be sequentially connected to form a required large nickel sheet matrix; bending the welded large nickel sheet matrix, selecting a plastic cylinder with smooth inner wall, and fixing the bent large nickel sheet matrix on the smooth inner wall of the plastic cylinder; and placing the plastic cylinder with the large nickel sheet matrix adhered into an electroforming groove for electroforming, and forming the required seamless nickel sheet on the front surface of the large nickel sheet matrix. Cutting precision and splicing precision of the unit nickel sheets are controlled strictly, the surface of a die for producing the large nickel sheet matrix of the nickel sheet is seamless by the aid of the cylinder, and accordingly production of the seamless nickel sheet is truly achieved.

Owner:CHANGZHOU HUA R SHENG REFLECTIVE MATERIAL

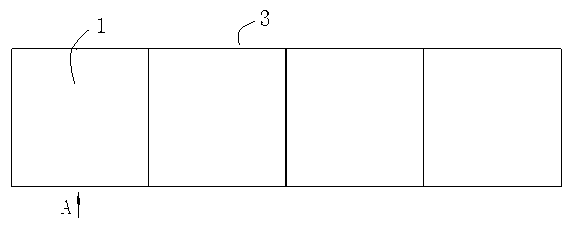

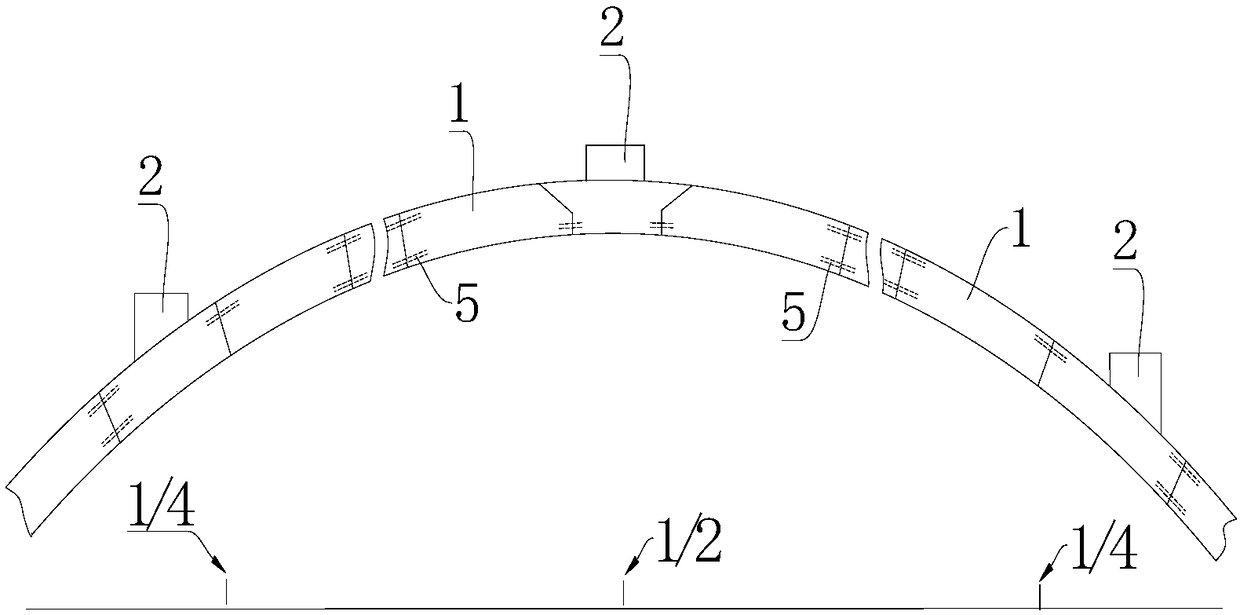

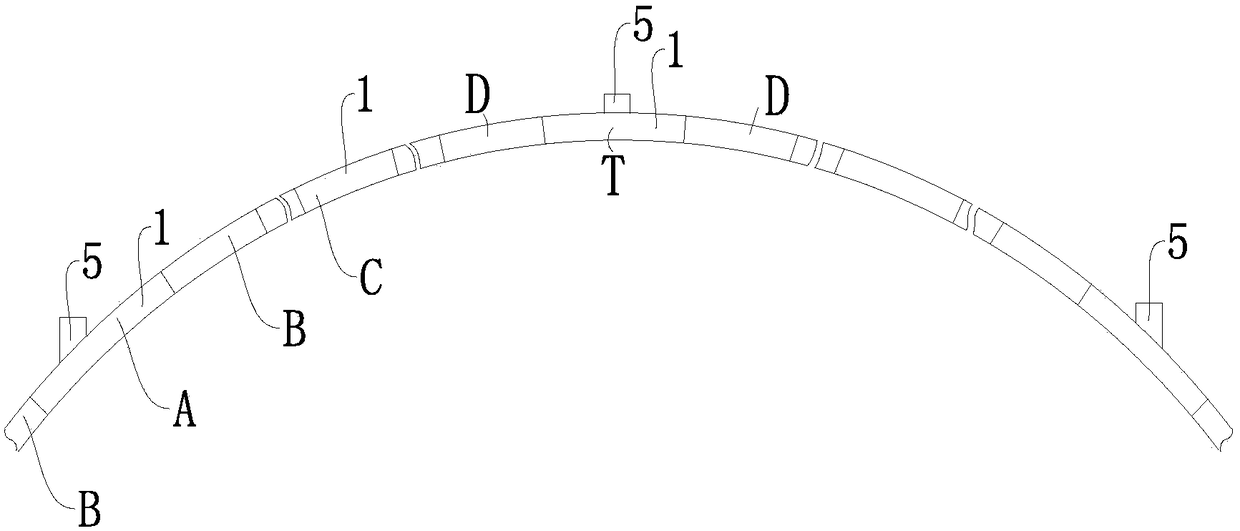

Pre-casting and mounting method for super-high performance concrete deck type slab arch bridge segments

ActiveCN108179700ALight structureStructural thinningBridge erection/assemblyBridge materialsCopperSpandrel

The invention provides a pre-casting and mounting method for super-high performance concrete deck type slab arch bridge segments, and belongs to the technical field of bridge construction methods. According to the pre-casting and mounting method for the super-high performance concrete deck type slab arch bridge segments, each of the slab arch segments of the deck type slab arch bridge is pre-casted by using the super-high performance concrete. Plush coppers are arranged on a joint between the two ends of the slab arch segments in a matched and abut-joint mode, and grooves are formed in the joint between the two ends of the slab arch segments in a matched and abut-joint mode. Tensioning cable channels and grooves are formed in the inner portions of the two ends of the slab arch segments. The slab arch segments are hoisted by a hoisting device to the own positions, the abut-joint plush coppers and grooves of the two adjacent slab arch segments are abut-joint with each other, and tensioning cables are installed in channels in a penetrating mode and are fixed in the grooves in a tensioning mode. Tensioning pintle cables and guy-cables are arranged on the slab arch segments to adjust elevation and arch axes of the slab arch segments, and an arch ring is formed by the splicing of the slab arch segments in sequence. Spandrel columns and bent caps are arranged, so that the ancillary works of the slab arch bridge are completed, and the construction is completed. According to the pre-casting and mounting method for the super-high performance concrete deck type slab arch bridge segments, the speed and quality of the construction can be improved, the cost of the super-high performance concrete arch bridge is reduced, and a thinner and more attractive bridge shape is generated.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD +1

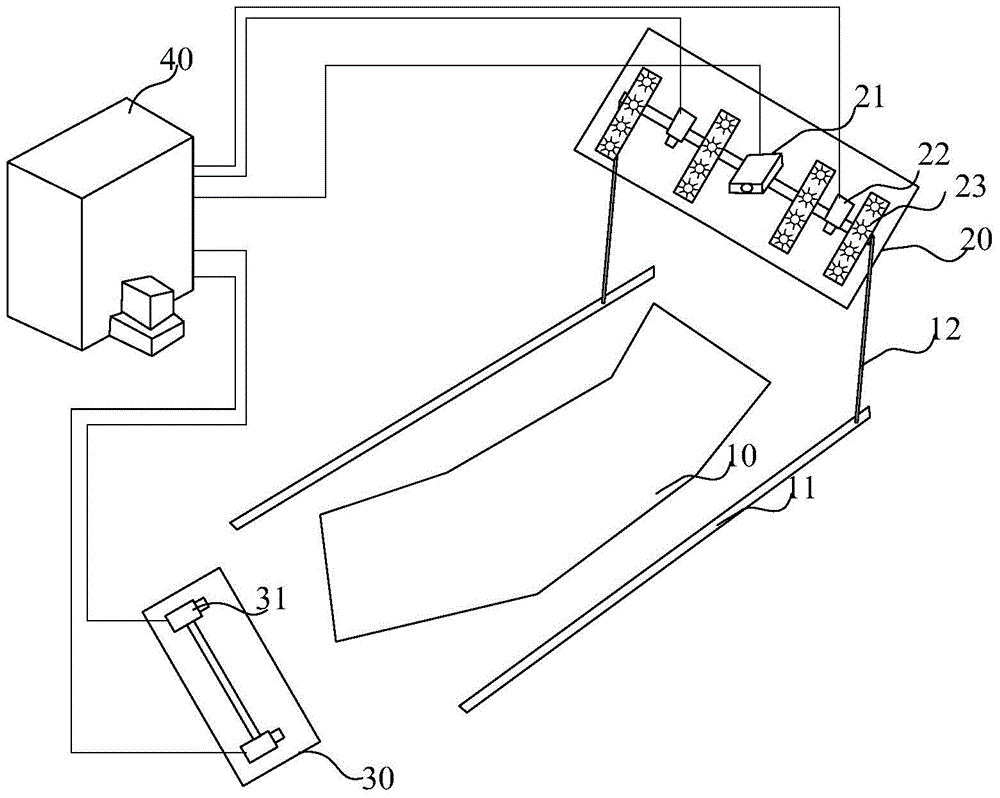

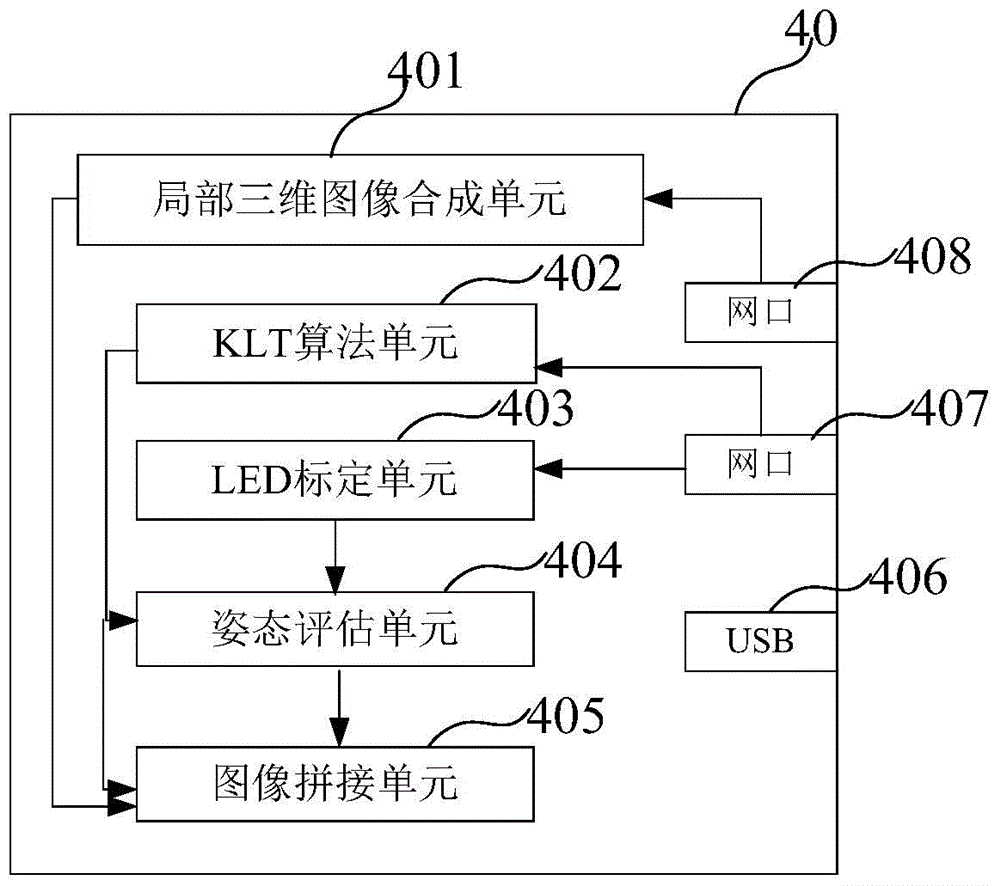

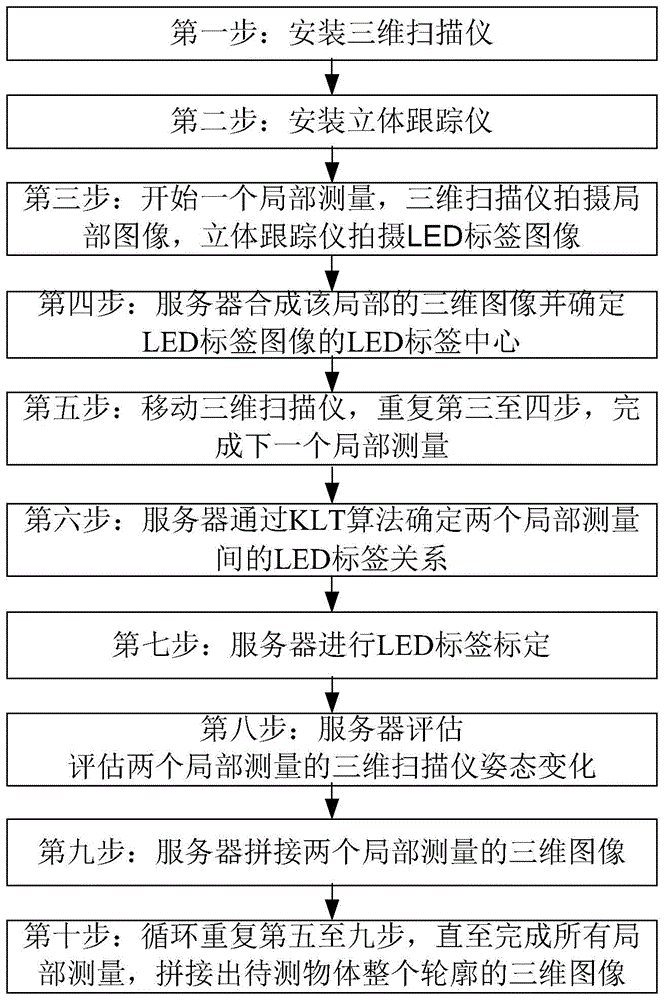

Three-dimensional geometrical measurement method and three-dimensional geometrical measurement system based on LED tag tracking

InactiveCN104976968AFlexible block measurementConvenient block measurementUsing optical meansThree dimensional measurement3d scanning

The invention provides a three-dimensional geometrical measurement method and a three-dimensional geometrical measurement system based on LED tag tracking. A three-dimensional scanner is arranged such that the three-dimensional scanner can move along a track and is close to an object to be measured, and blocked local measurement is flexibly and conveniently carried out on a large-scale object by a structured light method to obtain a high-resolution local image. Meanwhile, as the light of an LED tag is bright enough, even when the distance between a stereoscopic tracker and the LED tag increases, the stereoscopic tracker can quickly and accurately track the LED tag to ensure that a server can precisely locate the center position of the LED tag and the position of the LED tag in the coordinate system of the three-dimensional scanner, precisely obtain the LED tag relationship between two local measurements, accurately evaluate the attitude change of the three-dimensional scanner and realize precise stitching of local measurement results. Moreover, three-dimensional measurement of the whole contour of a large-scale object can be completed conveniently, stably and accurately without the need for tedious switching between multiple projectors.

Owner:JIANGSU UNIV OF SCI & TECH

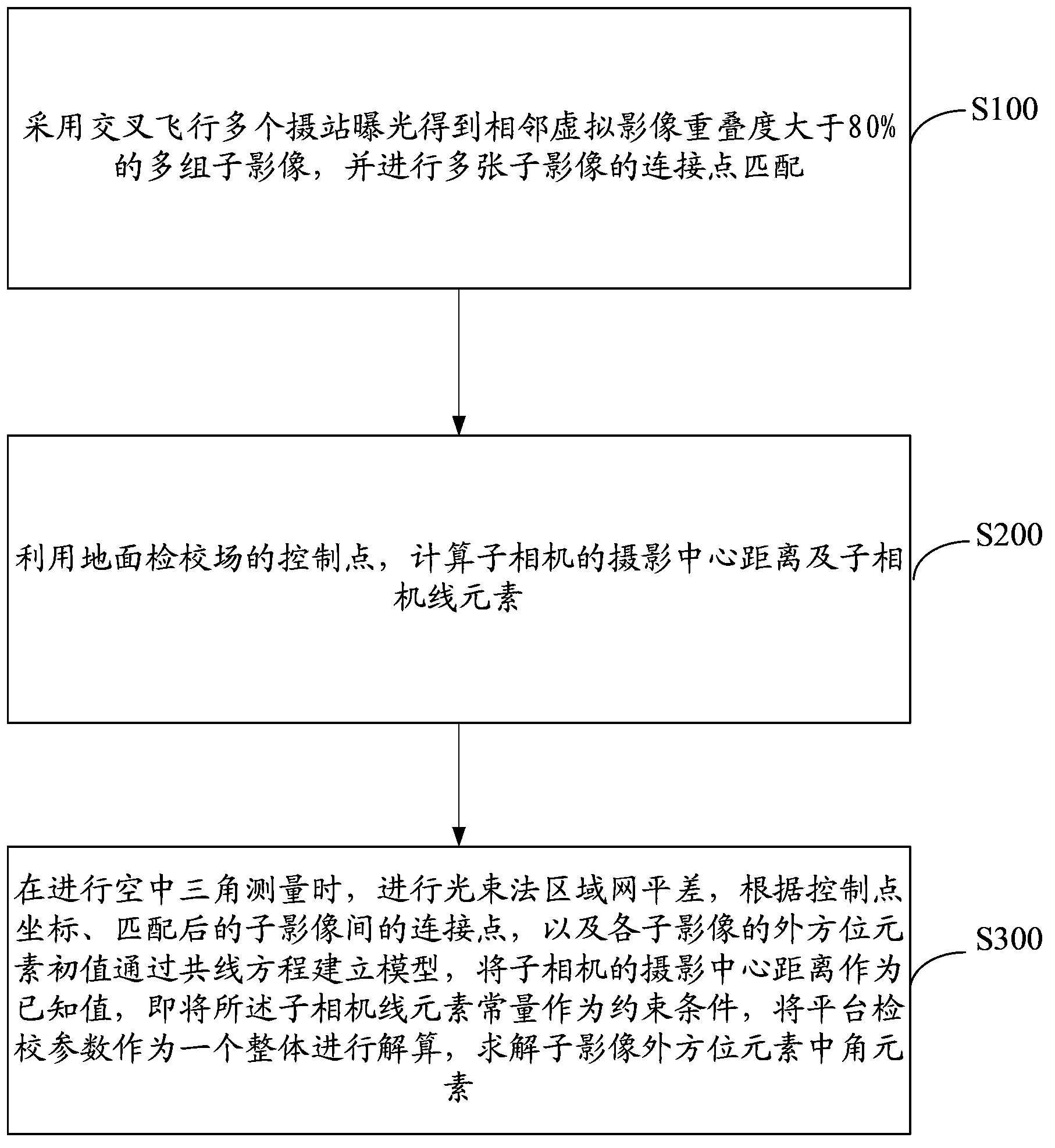

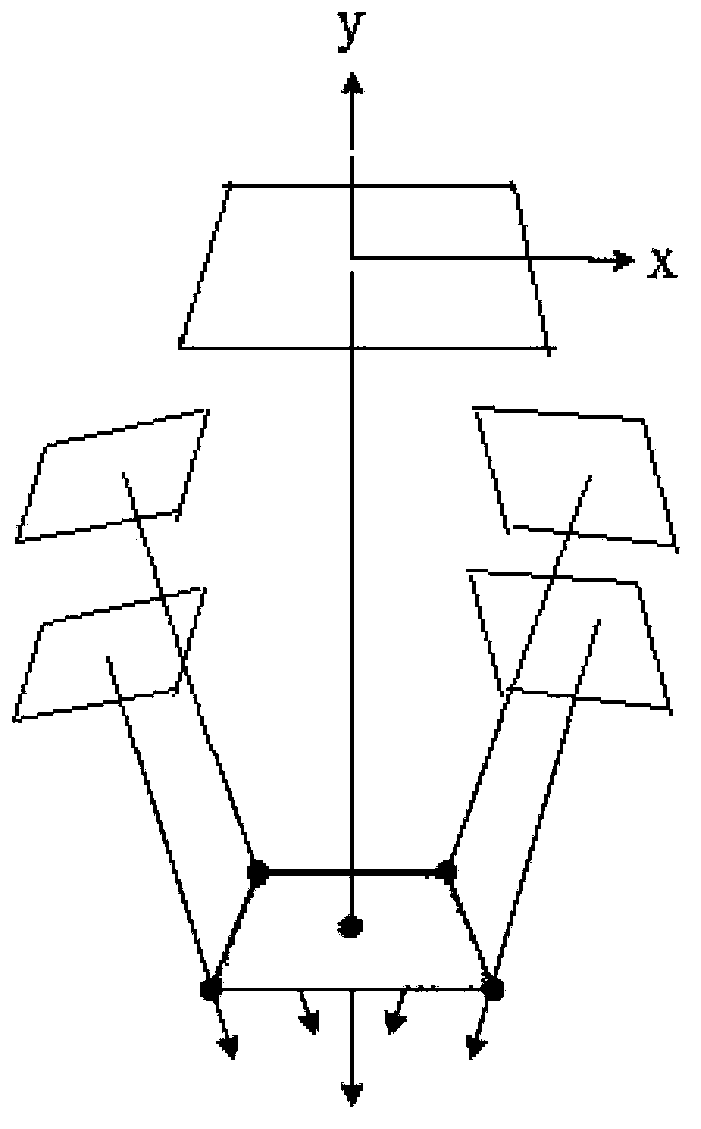

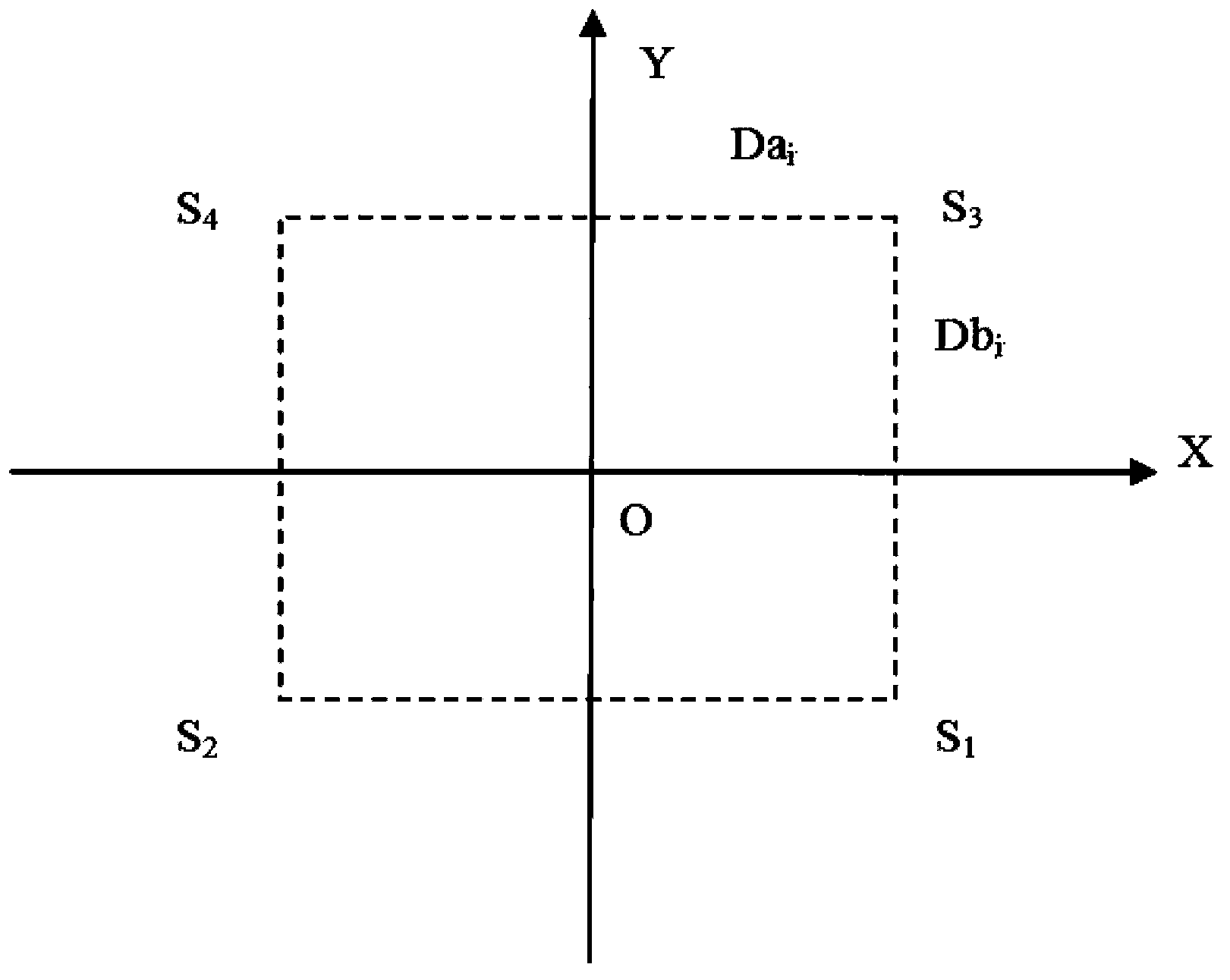

Multi-area array aerial camera platform calibration method with constraint condition

The invention discloses a multi-area array aerial camera platform calibration method with a constraint condition. The method includes: employing a data acquisition strategy of multiple cross flying camera station exposure to acquire multiple groups of sub-images with an adjacent virtual image overlap degree of more than 80%; making use of the control point of a ground calibration field to calculate a photographing centre distance of sub-cameras and a sub-camera line element; during aerotriangulation, conducting bundle block adjustment, according to the control point coordinate, the connection points among matched sub-images, and the external orientation element initial value, establishing a model through a collinearity equation, adopting the photographing centre distance of the sub-cameras as a given value, i.e. taking the sub-camera line element constant as the constraint condition, and taking platform calibration parameters as a whole to perform calculation to solve the angle elements in the external orientation elements of the sub-images. According to the calibration method, a lot of uniformly distributed connection points are matched, precision of the platform calibration parameters is improved through the constraint condition, higher stitching precision of the generated virtual images can be guaranteed, and the mapping precision can be higher.

Owner:CHINA TOPRS TECH

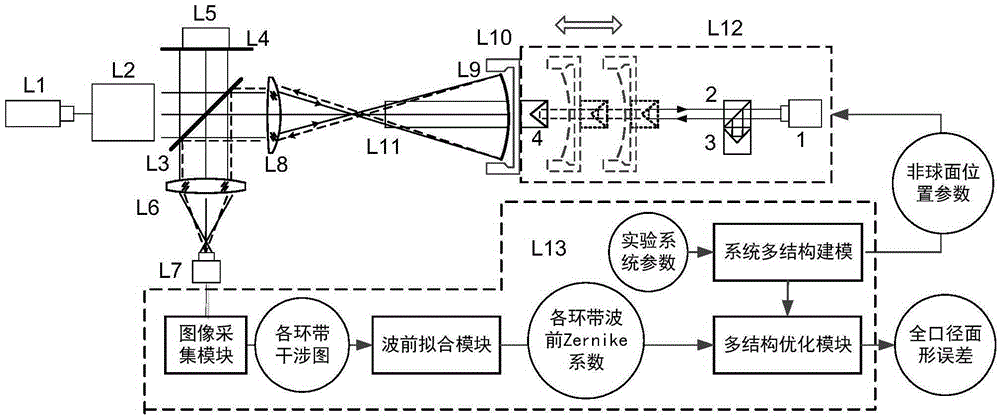

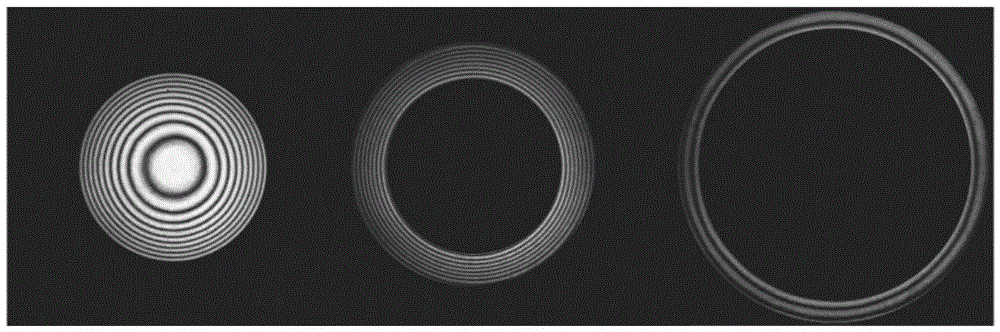

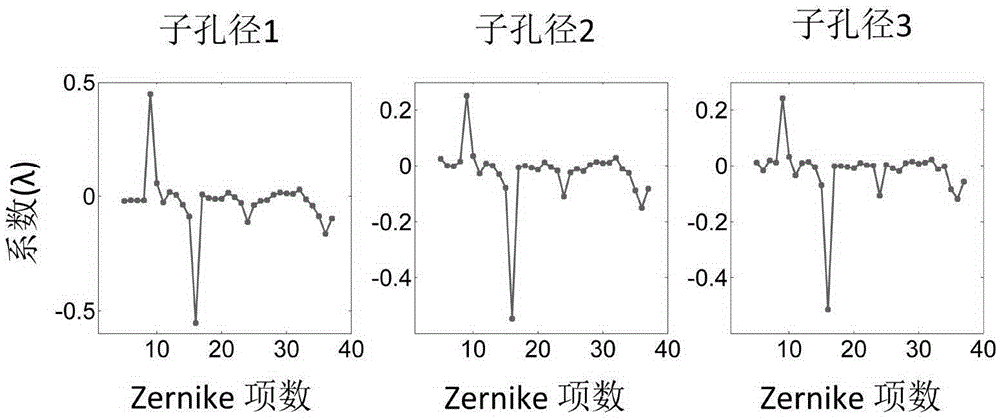

Aspheric non-zero digit circular subaperture stitching method based on system modeling

InactiveCN105318847AReduce the number of subaperturesImprove stitching accuracyUsing optical meansWavefrontAlgorithm

The invention discloses an aspheric non-zero digit circular subaperture stitching method based on system modeling, comprising modeling an experiment interference system, establishing a multiple structure model corresponding to aspheric positions of different belts, and establishing an optimization function based on the multiple structure model, wherein the actually measured wavefront Zernike coefficients of all the belts are meanwhile used as optimization objects, the wavefront Zernike coefficients of the belts in the model are used as dependent variables, and aspheric full aperture surface-shape errors are used as independent variables. The measured surface positions corresponding to each aspheric belt are as used as constraint conditions to execute the optimization function, making the wavefront Zernike coefficient of each belt approach an actual measured value, and thereby the measured surface full aperture surface-shape errors in the model are regarded to approach actual measured values so as to obtain the measured surface full aperture surface-shape errors. The method does not need special form stitching operation or overlapped areas, reduces subapertures possibly required, and improves stitching precision.

Owner:ZHEJIANG UNIV

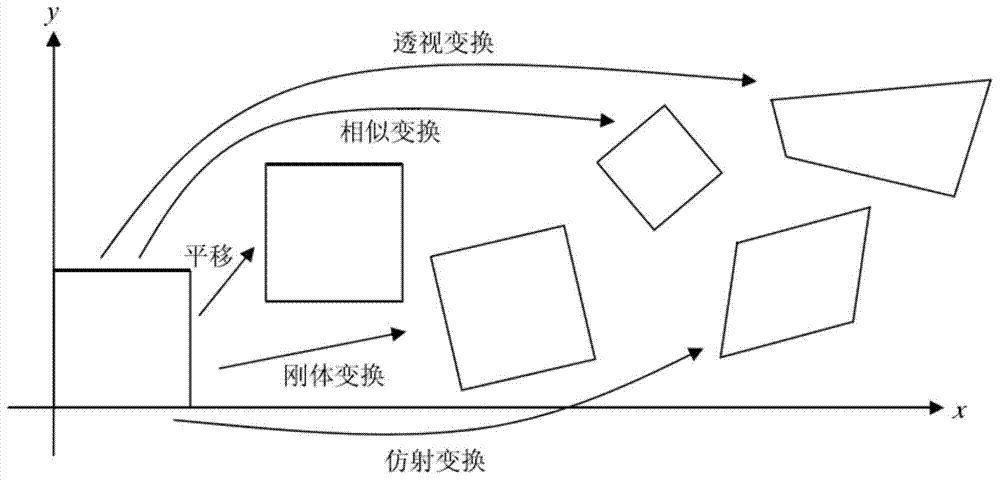

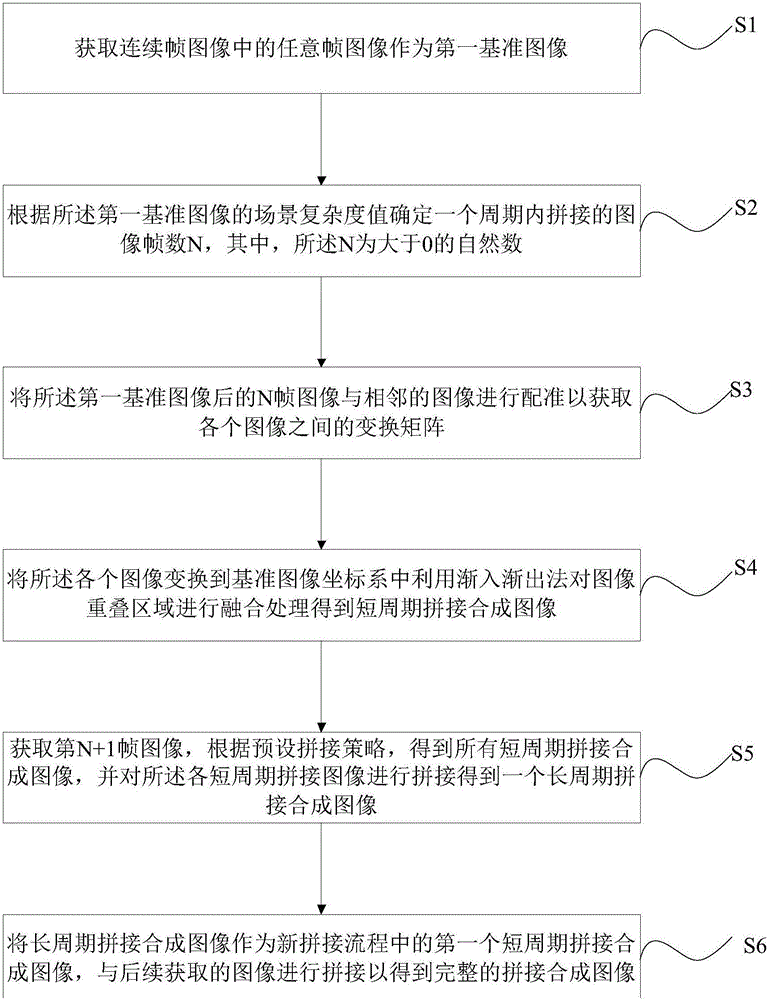

Image stitching method and apparatus

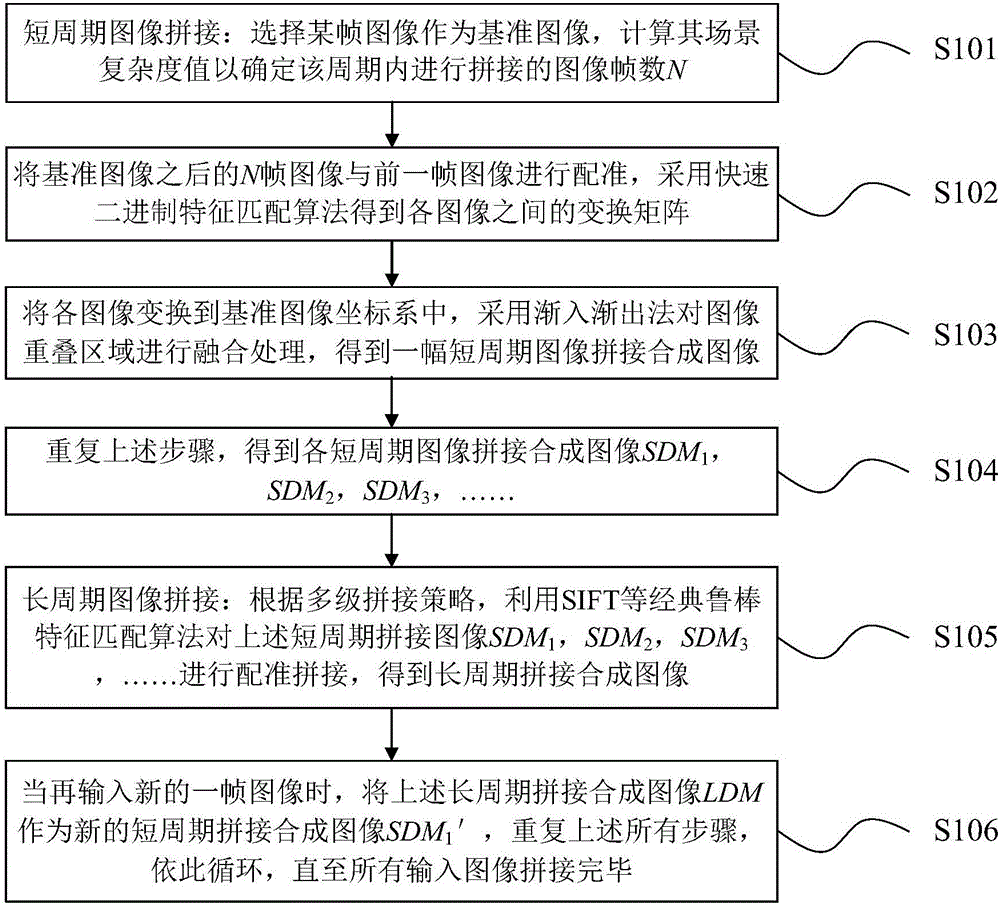

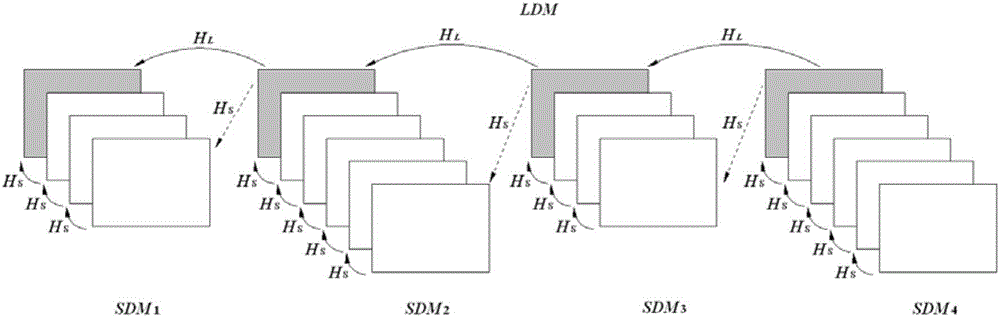

ActiveCN106447607ASplicing speed is fastSolve the problem of spreadingImage enhancementImage analysisAviationVideo image

The invention provides an image stitching method and apparatus which can be intended for reducing errors accumulated by stitching in adaptive multiple hierarchical stitching of aviation video images, can adaptively select proper processing level and registration algorithm on the basis of object scenario characteristics, which effectively addresses the dissipation and spreading caused by the increasing of image stitching errors alongside the image frames; also, a registrated image is subject to fusion processing by phasing in and phasing out, which better eliminates the stitching gaps caused by image transformation matrix accumulated errors and image brightness difference, a synthesized image of wide field of view and high resolution is obtained, and the precision and robustness of image stitching are noticeably improved; "characteristic stack" is used to store the characteristics of each frame image for performing registration and stitching with follow-up images, which can effectively reduce the amount of computing, saves the time for repetitively extracting image features, and further increases the speed of image stitching.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

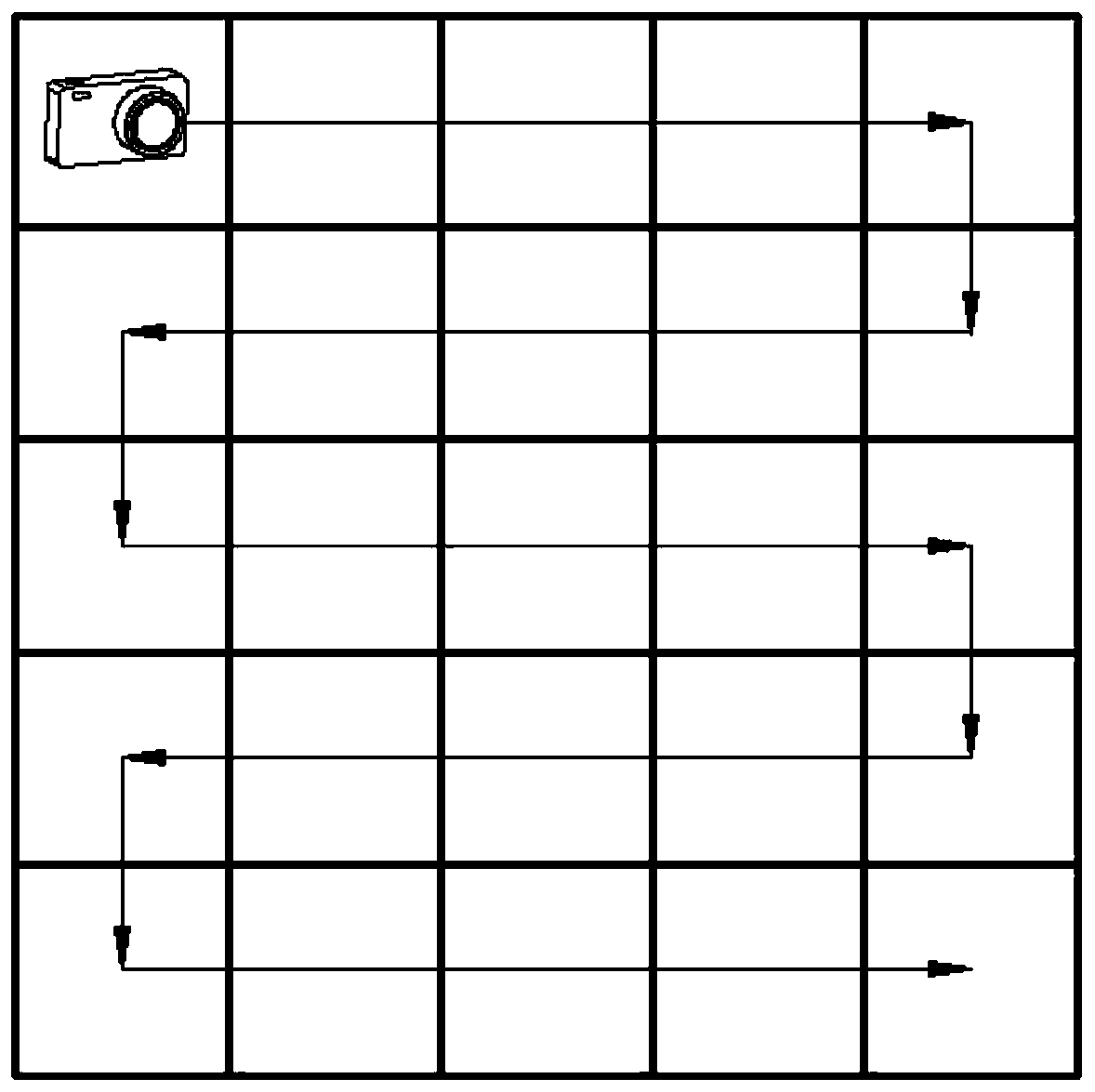

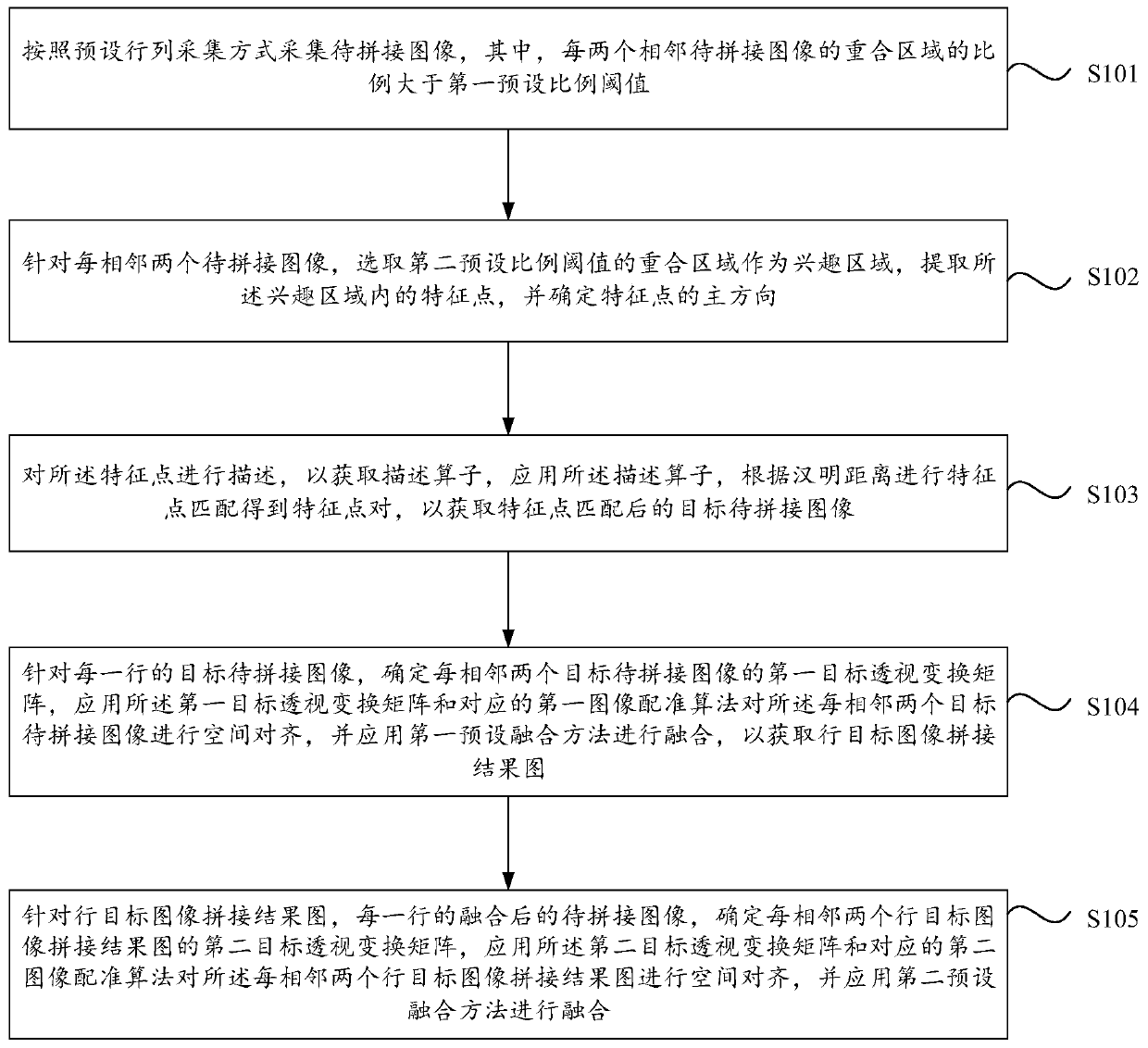

Two-dimensional panoramic image acquisition method and device, equipment and storage medium

ActiveCN110197455AImprove stitching accuracyRealize splicingImage enhancementImage analysisHamming distanceFeature point matching

The invention relates to a two-dimensional panoramic image acquisition method and device, equipment and a storage medium, and the method comprises the steps: collecting to-be-spliced images accordingto a preset row and column collection mode, and enabling the proportion of the overlapped area of every two adjacent to-be-spliced images to be greater than a first preset proportion threshold value;for every two adjacent to-be-spliced images, selecting an overlapped area with a second preset proportion threshold value as an interest area, extracting feature points in the interest area, and determining the main direction of the feature points; describing the feature points to obtain a description operator, and performing feature point matching according to the Hamming distance by applying thedescription operator to obtain a feature point pair so as to obtain a target to-be-spliced image after feature point matching; aiming at the target to-be-spliced image of each row, carrying out registration and fusion to obtain a row target image splicing result image; and aiming at each line of target image splicing result image, carrying out registration and fusion to obtain a two-dimensional panoramic image. The precision of the panoramic image in the industrial application is improved, and the flexibility of obtaining the panoramic image is improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

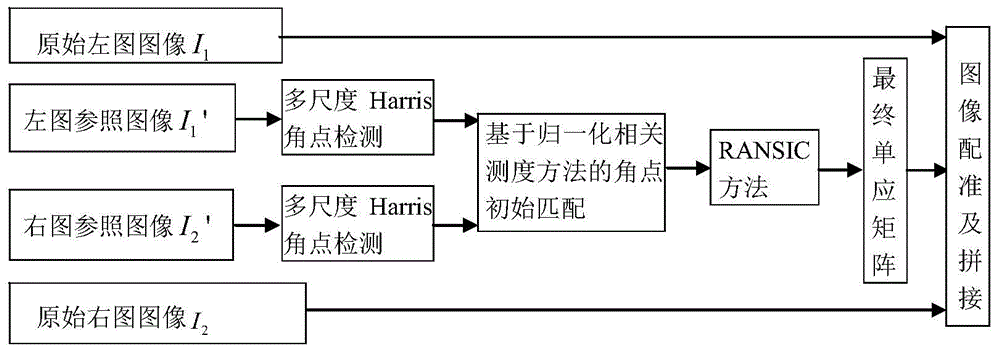

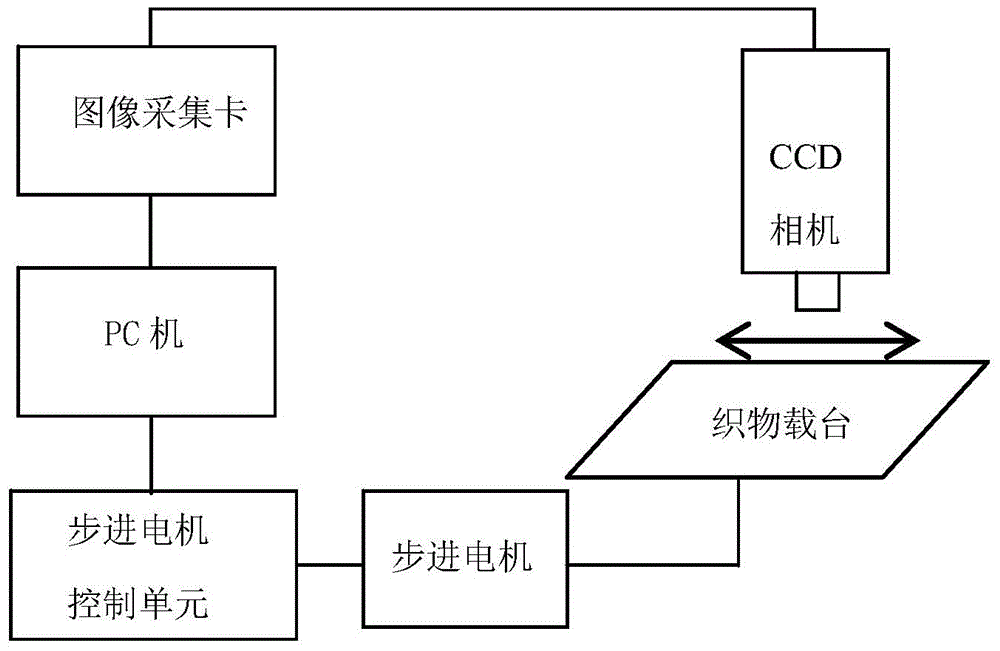

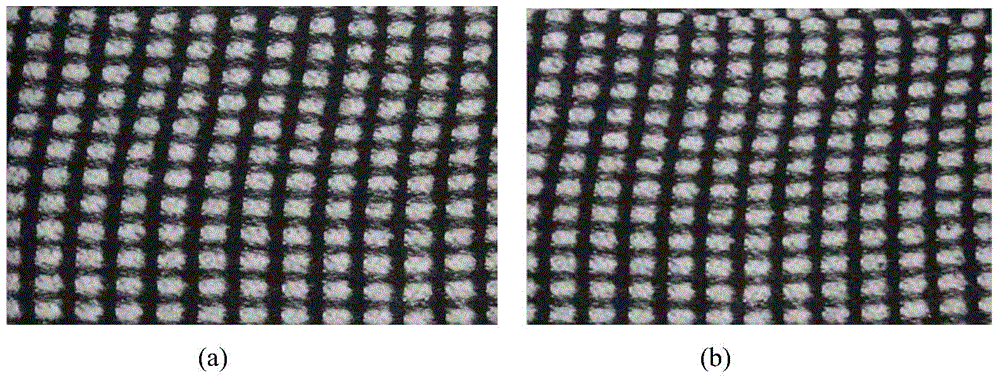

Wide fabric image acquiring and splicing method based on reference characteristics

ActiveCN104637041ARealize seamless splicingTest accurateImage enhancementImage analysisInterference resistanceAngular point

The invention discloses a wide fabric image acquiring and splicing method based on reference characteristics. The method comprises the steps: horizontally arranging the fabric on a fabric carrier table, horizontally arranging a reference fabric in the middle of the fabric carrier table, then moving the reference fabric, and respectively acquiring a left reference image, a right reference image, an original left image and an original right image in the process; obtaining a respective Harris angular point set by adopting a multi-scale Harris angular point detection method for the left reference image and the right reference image; carrying out the initial matching by adopting a normalization relevant measurement method to obtain an initial matching point set; carrying out the initial matching characteristic point refinement and homography solution by adopting an RANSAC method to obtain a final homography; carrying out the projection conversion registration on the original left image and the original right image, then splicing and fusing, and acquiring and splicing the fabric image. By adopting the method, the seamless splicing of the fabric image with high circulating period or no obvious characteristic is realized, the splicing precision is high, the relative geometric position relation of the original fabric image can be precisely calculated, and the interference resistance is high.

Owner:杭州光羽新材料科技有限公司

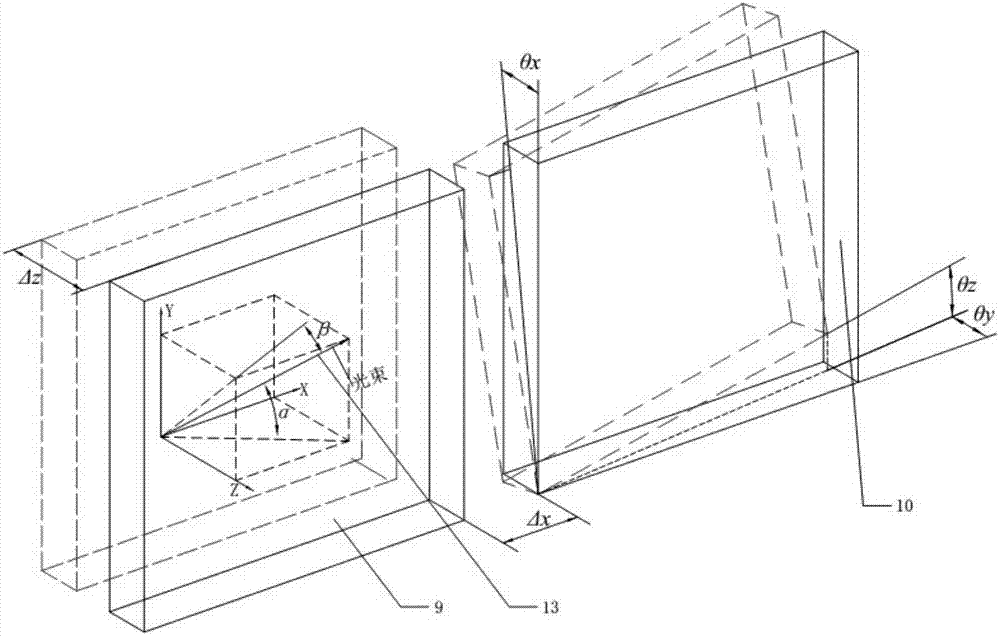

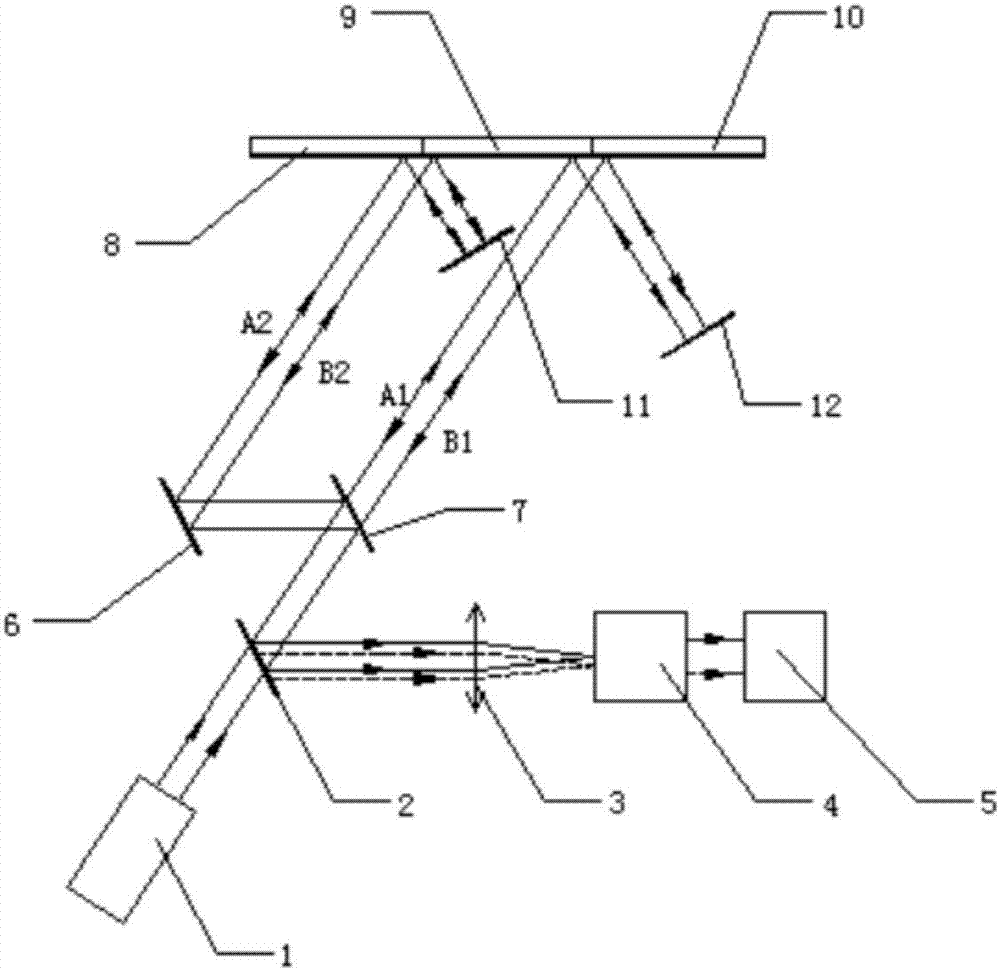

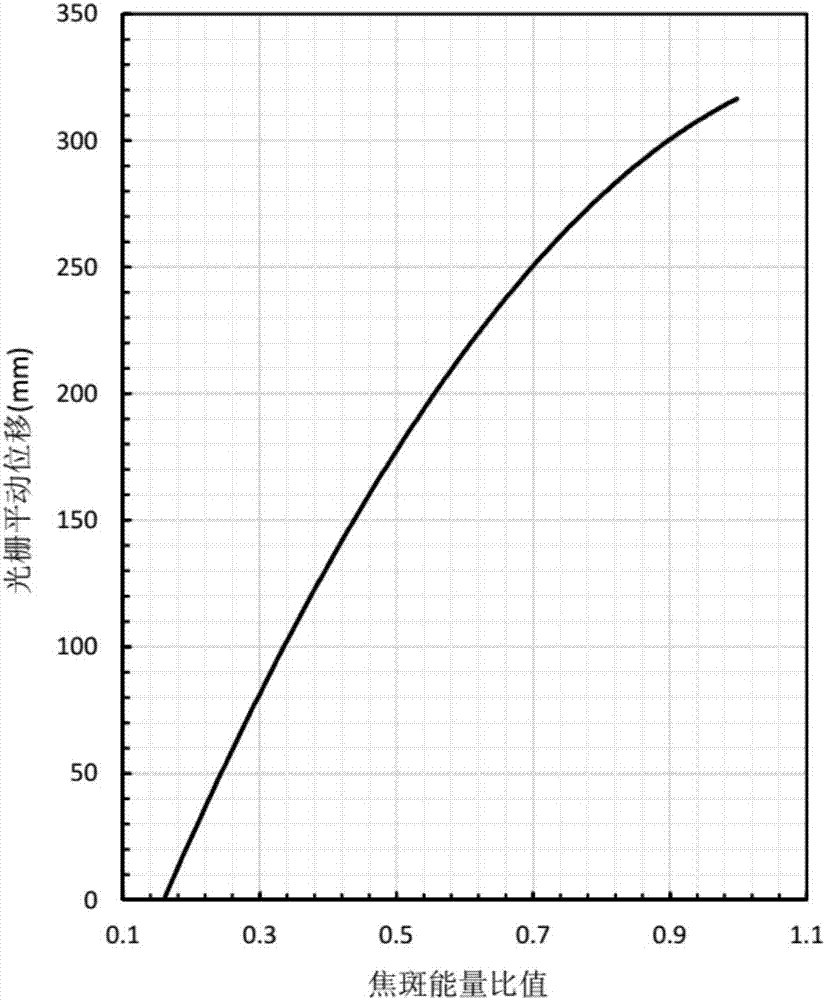

High-precision large-aperture grating five-degree-of-freedom splicing precision measurement method

ActiveCN106932173ALow measurement couplingImprove splicing efficiencyOptical apparatus testingGratingCoupling

The invention discloses a high-precision large-aperture grating five-degree-of-freedom splicing precision measurement method. The method comprises the following steps that step one, grating three-dimensional rotation precision measurement: a test light beam is incident to the splicing slit of gratings to be spliced, and the three-dimensional rotation splicing precision, the pitch angle theta<x>, the deflection angle theta<y> and the rotation angle theta<z>, of the gratings to be spliced is acquired according to zero-order reflected light and first-order diffracted light generated by the splicing gratings; and step two, grating two-dimensional translational precision measurement: the pitch angle theta<x>, the deflection angle theta<y> and the rotation angle theta<z> are adjusted to the qualified range, the test light beam is incident to the splicing slit of the gratings to be spliced, and the two-dimensional translational precision of the gratings is measured according to the far-field focal spot energy ratio of the zero-order reflected light generated by the splicing gratings. The method has the advantages of being high in measurement precision, weak in the coupling degree between all the degrees of freedom and easy and convenient to operate so that the splicing efficiency and the splicing precision of the gratings can be effectively enhanced, and the method can be used for space five-degree-of-freedom splicing precision measurement of the splicing gratings.

Owner:HARBIN INST OF TECH

Method for improving image stitching accuracy with lens distortion correction and device for implementing the same

InactiveUS8049786B2Improving image stitching accuracyImprove stitching accuracyTelevision system detailsGeometric image transformationMulti cameraImage capture

The invention provides a method for improving image stitching accuracy and a device for implementing the same, which apply to the multi-camera system for wide-angle image generation. Lens distortion causes mismatches of the features in the overlapping region of the images captured by the multi-camera system. As a result, the mismatches on the stitched wide-angle image are visible. The method and device for improving image stitching accuracy correct the lens distortion before stitching the images captured by the multi-camera system, so that the features in the overlapping region are matched and a seamless wide-angle image is generated by the stitching engine.

Owner:SONY TAIWAN

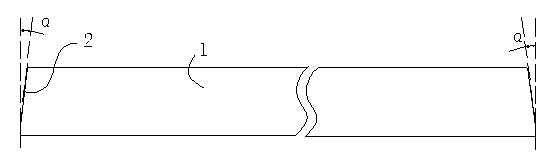

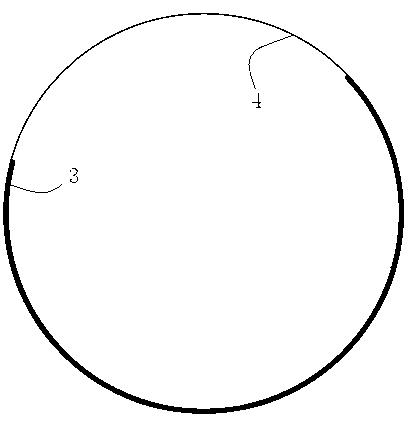

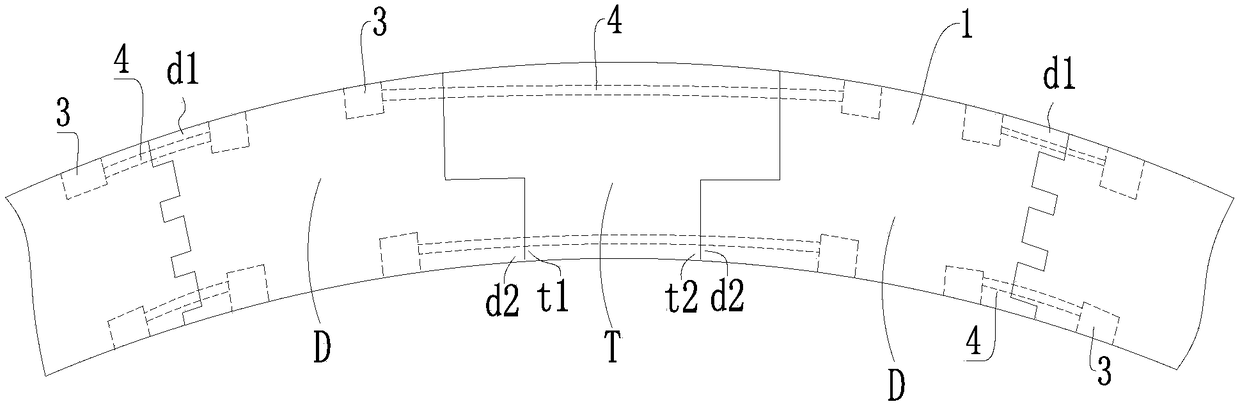

Prefabrication installation method for ultra-high performance concrete deck type box arch bridge segments

ActiveCN108239915ALight structureStructural thinningBridge erection/assemblyArch-type bridgeButt jointBridge deck

The invention provides a prefabrication installation method for ultra-high performance concrete deck type box arch bridge segments, and belongs to the technical field of bridge construction methods. According to the prefabrication installation method for the ultra-high performance concrete deck type box arch bridge segments, box arch segments of the ultra-high performance concrete prefabricated deck type box arch bridge are adopted; and joints at both ends of the box arch segments are provided with raised heads and grooves which are in matching butt joint, and pore passages and grooves of stretching cables are formed in the box arch segments. The box arch segments are lifted in position, the butting raised heads and the grooves of every two adjacent box arch segments are in butt joint witheach other, and the stretching cables penetrate through the pore passages and are fixed to the grooves in a stretching mode; buckle cables and wind absorbing cables are installed and stretched on thebox arch segments, the elevation and arch axes of the box arch segments are adjusted, the box arch segments are sequentially spliced, and joints of closure segments are connected by smearing epoxy resin glue or pumping into a grouting agent and stretched steadily for arching. Spandrel columns and cover beams are installed to complete auxiliary works and bridge deck pavement. The prefabrication installation method for the ultra-high performance concrete deck type box arch bridge segments improves the construction speed and precision, reduces the construction cost of the ultra-high performanceconcrete arch bridge, and promotes a more attractive, slim and concise bridge shape.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD +1

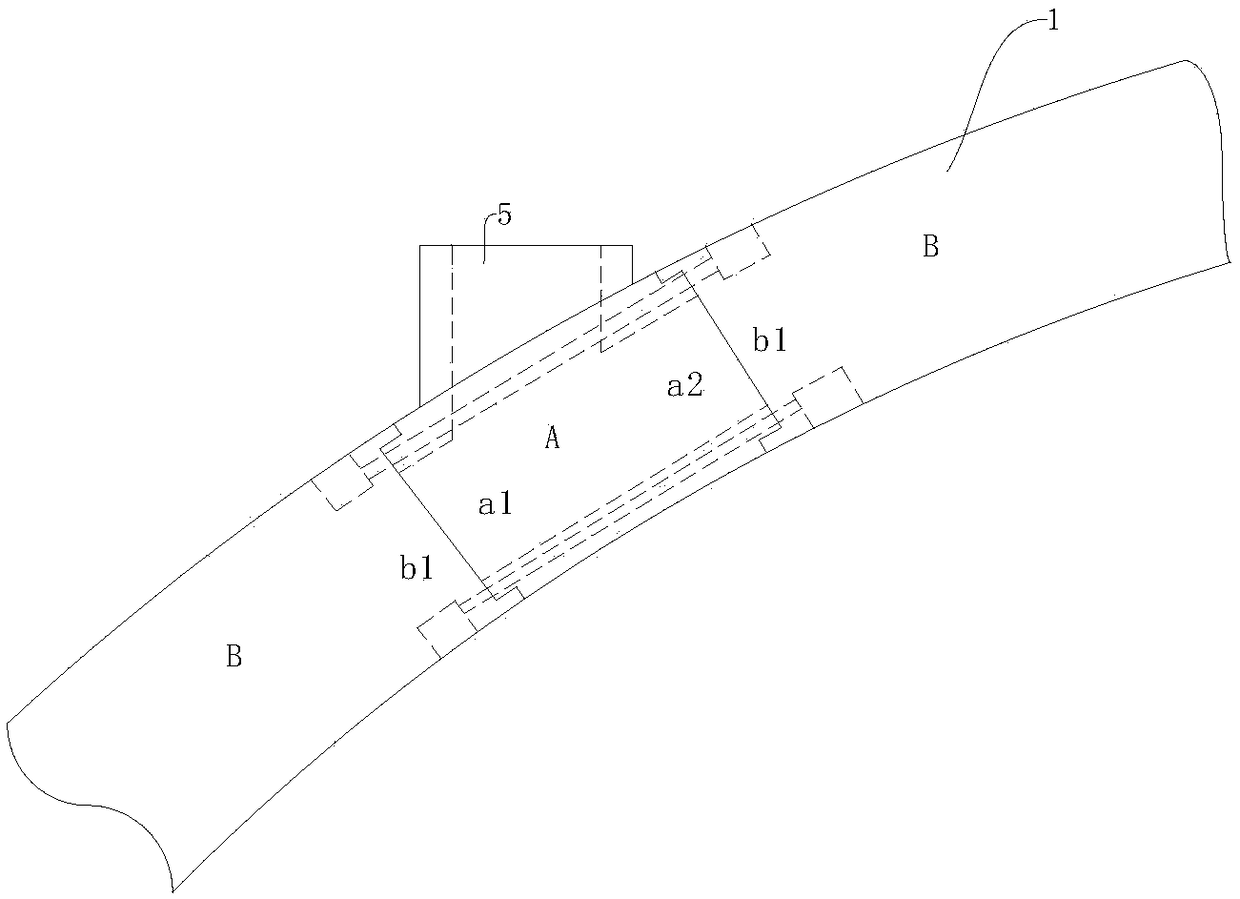

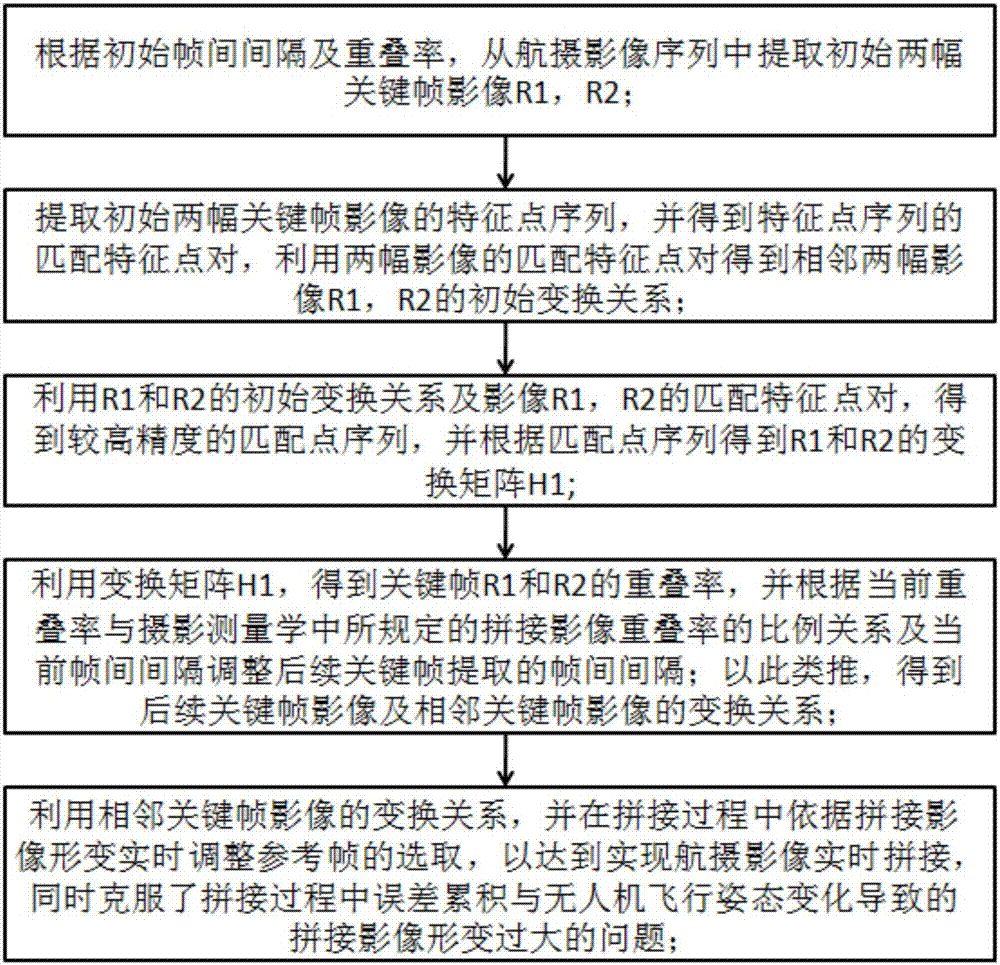

Real-time splicing method for unmanned aerial vehicle aerial stereo images

ActiveCN107507132AIncrease overlapImprove efficiencyImage enhancementImage analysisImaging processingReference image

The invention relates to the field of image processing, in particular to a real-time splicing method for unmanned aerial vehicle aerial stereo images. According to the splicing method for the unmanned aerial vehicle aerial stereo images, an inter-frame interval of key aerial stereo images is adjusted and extracted in real time according to the overlapping ratio of adjacent to-be-spliced aerial stereo images; a transformation matrix of every two adjacent frames is obtained according to a matching relation between homonymy points of every two adjacent frames, and the serial aerial stereo images are transformed to a coordinate system of reference images; and reference frames are adjusted in real time according to set reference frame adjustment judgment conditions, so that accumulative errors generated in the process that the aerial stereo images are transformed to a coordinate system of the reference frames are dispersed to all frames of images, and the situation that serious distortion of subsequent images is caused by error accumulation is avoided.

Owner:CHENGDU JOUAV AUTOMATION TECH

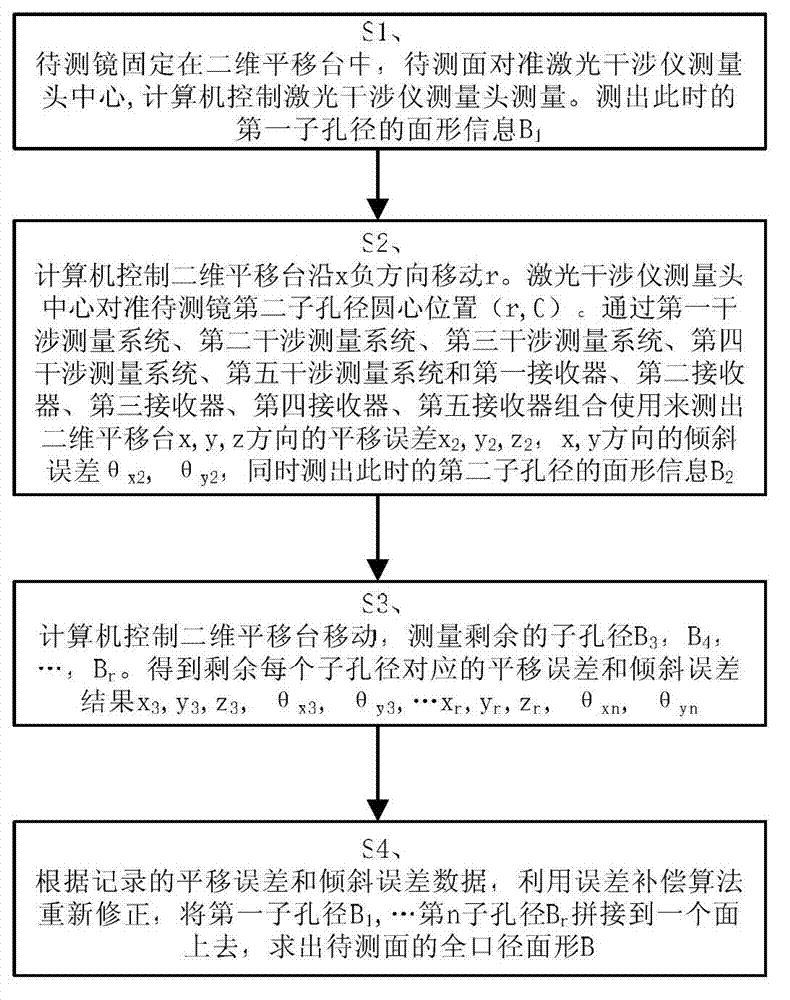

Device for detecting sub-aperture splicing surface shape with movement coordinate feedback

The invention discloses a device for detecting a sub-aperture splicing surface shape with movement coordinate feedback. The device is characterized in that a mirror to be measured is disposed on a two-dimensional translation stage; the two-dimensional translation stage is controlled by a computer to move two-dimensionally on a plane of the mirror to be measured; reflecting mirrors are placed on two side surfaces of the mirror to be measured; meanwhile, a length measurement interferometer system is placed opposite to the reflecting mirrors; location error in an x direction and a y direction as well as inclination in the x direction and the y direction of the mirror to be measured are measured after two-dimensional movement through five paths of lasers, measurement data is fed back to a computer by the length measurement interferometer system, and the location error in the x direction and the y direction as well as the inclination in the x direction and the y direction into an algorithm through a sub-aperture position compensating algorithm so as to carry out splicing calculation. On a basis of the original sub-aperture splicing algorithm, with the adoption of the device disclosed by the invention, measurement precision is increased by measuring location and inclination errors during a sub-aperture splicing progress and by bringing the errors into algorithm.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

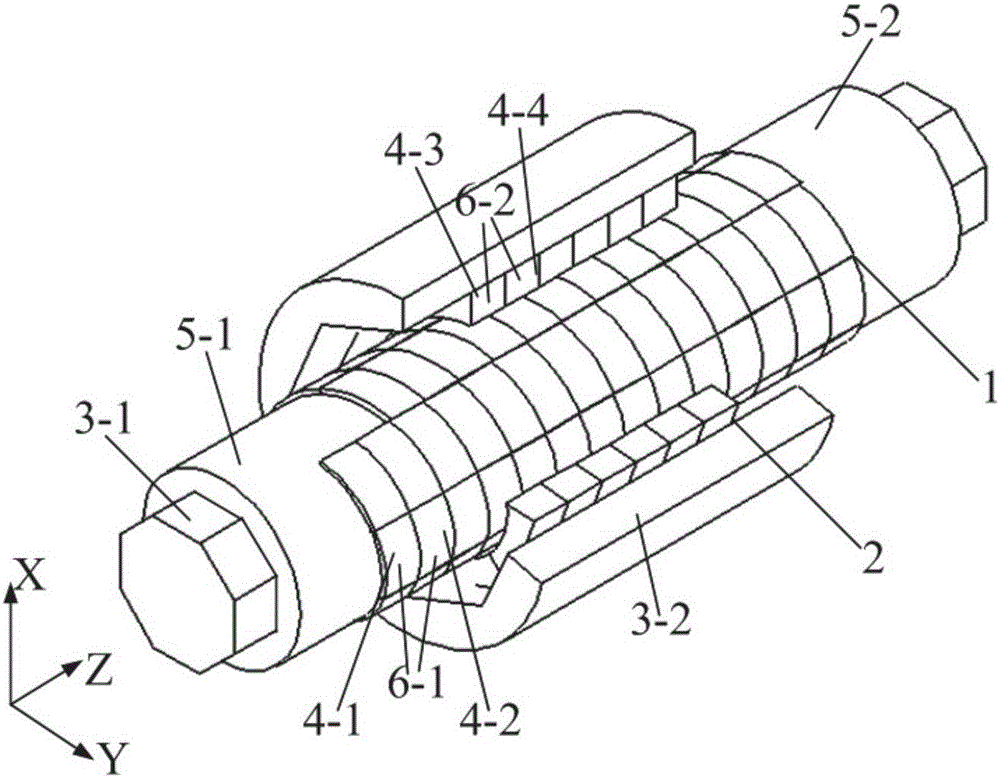

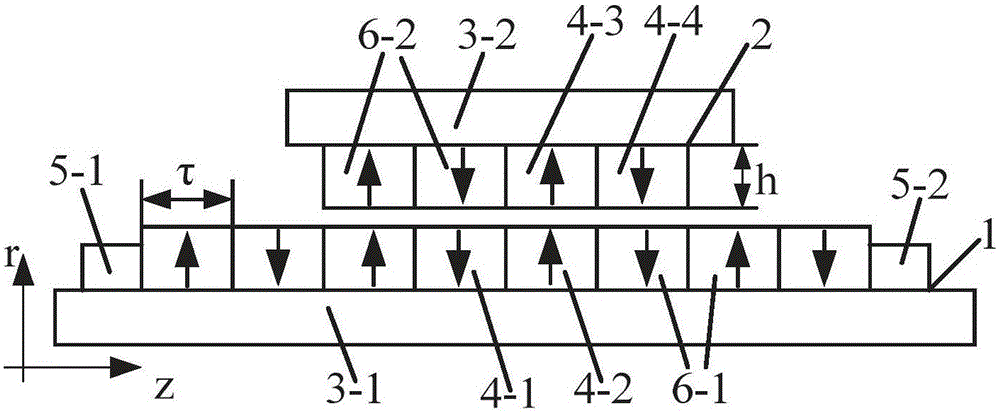

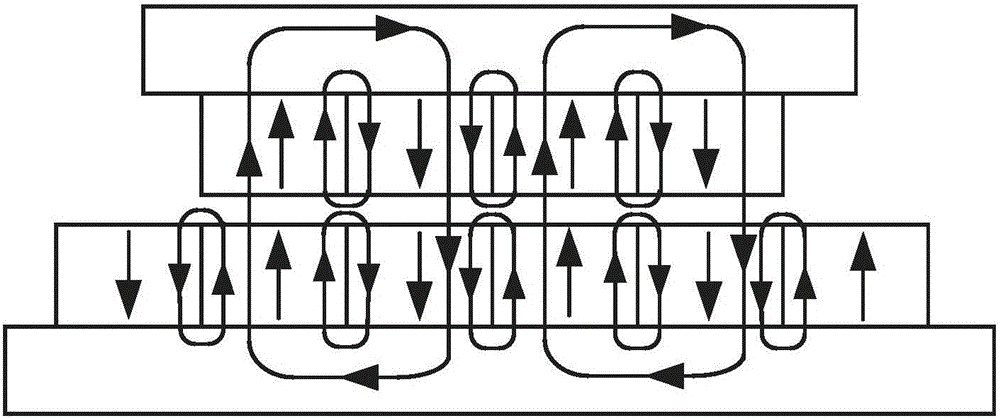

Surface-mounted magnetic lead screw and processing method thereof

ActiveCN105743322AHigh mechanical strengthReduce process complexityManufacturing dynamo-electric machinesPermanent-magnet clutches/brakesMagnetic tension forceSurface mounting

The invention discloses a surface-mounted magnetic lead screw and a processing method thereof, and belongs to the field of magnetic lead screws. The magnetic lead screw comprises segmented permanent magnets, an electric iron rod and limiters. A magnetic nut comprises segmented permanent magnets and an electric iron ring. In the magnetic lead screw, the segmented permanent magnets are mounted on the outer surface of the electric iron rod; and in the magnetic nut, the segmented permanent magnets are mounted on the inner surface of the electric iron ring. The method comprises the following steps of leveling the inner diameters of the segmented permanent magnets of the magnetic lead screw; turning the outer surface of the electric iron rod to form the electric iron rod of which the axial section is a regular polygon according to the size of the segmented permanent magnets and simultaneously installing the limiters at the end parts of the electric iron rod; and leveling the outer diameters of the segmented permanent magnets of the magnetic nut, and drilling the electric iron ring to form a through hole of which the axial section is a regular polygon according to the size of the segmented permanent magnets. Through cooperation of the permanent magnets and a ferromagnetic material, the processing difficulty of a spiral permanent magnet and the assembly difficulty of the magnetic lead screw can be effectively reduced; and the thrust density and the mechanical strength are improved.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com