Internal thread detection device and method

A detection device and detection method technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of inability to perform detection, single detection parameters, slow detection speed, etc., and achieve easy program implementation, simplified measurement operations, and simplified design. the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing:

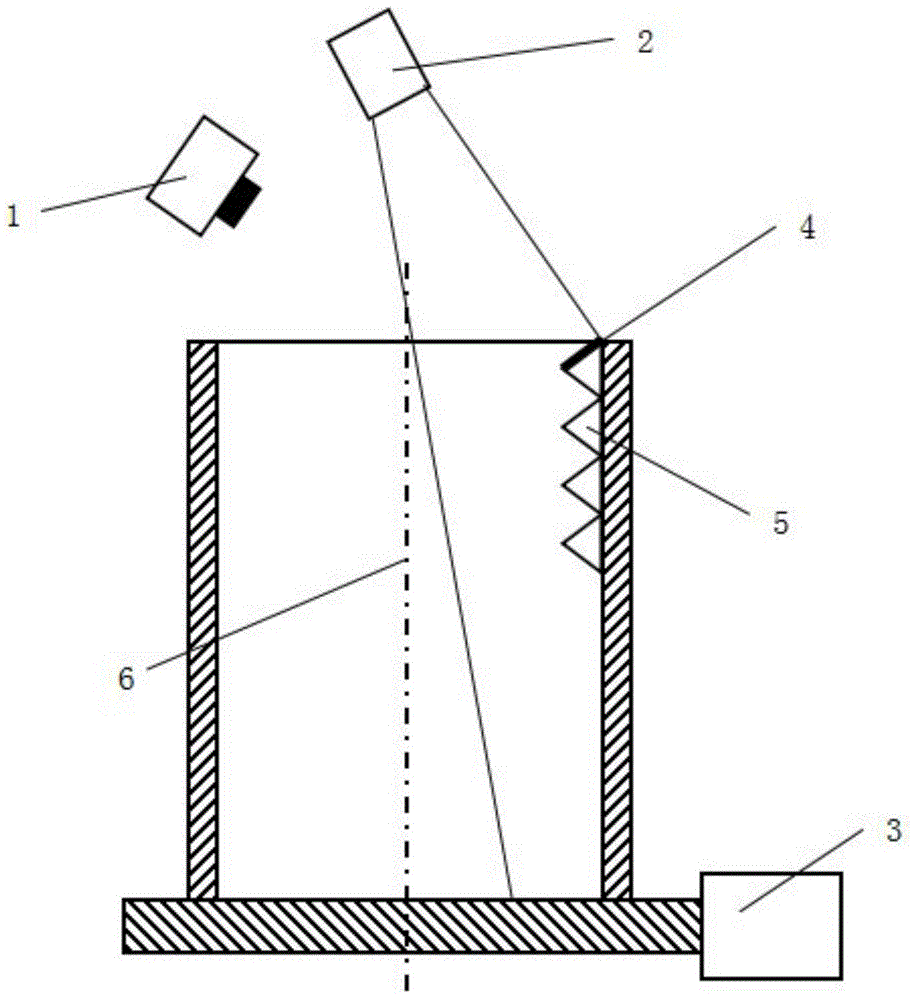

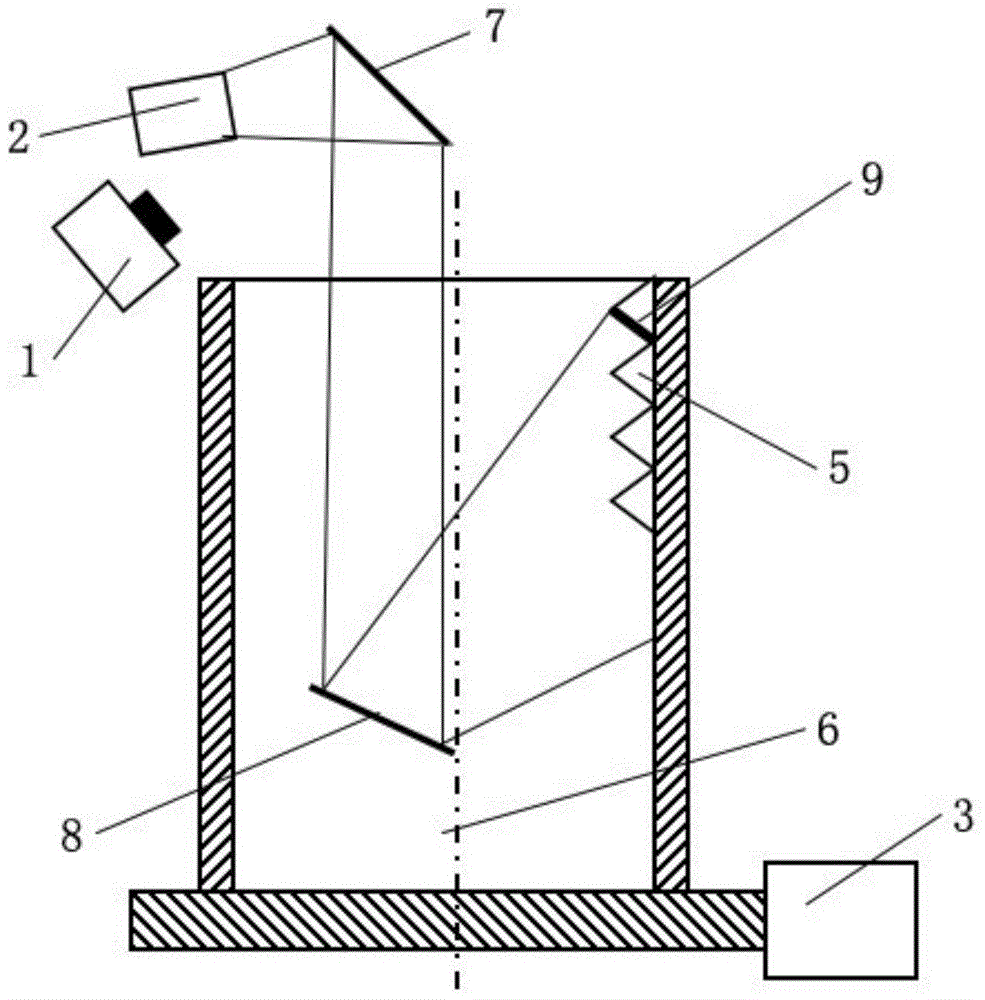

[0056] The complete detection process is: detection of upper thread surface (see figure 1 ) and lower thread face detection (see figure 2) 2 parts. For workpieces with larger inner diameters, the two inspections can be performed simultaneously; for workpieces with smaller inner diameters, they can be performed separately.

[0057] The complete detection process is:

[0058] 1. Carry out upper thread surface detection;

[0059] 2. Carry out the inspection of the lower thread surface;

[0060] 3. Splicing of measurement data of upper and lower thread surfaces;

[0061] 4. Calculate the parameters of thread profile, pitch and depth.

[0062] The detection principle of the upper thread surface in step 1 is as follows: figure 1 Said:

[0063] The detection process is:

[0064] (1) Carry out the calibration of camera internal parameter K;

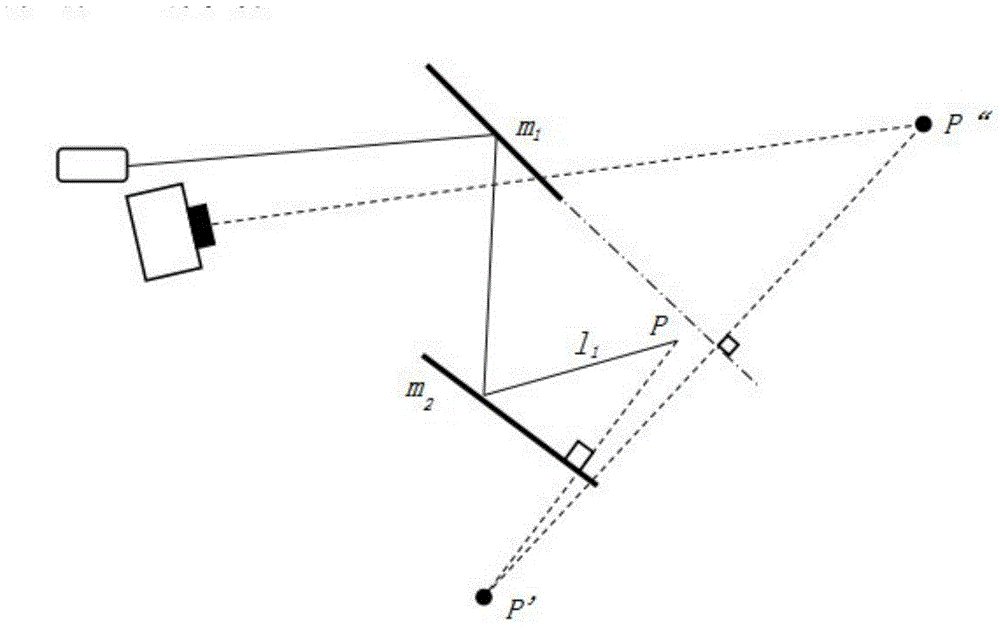

[0065] (2) Calibrate the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com