Multi-type workpieces batch visual measuring system and method

A visual measurement, multi-type technology, used in measurement devices, instruments, and optical devices, etc., can solve the problems of workpieces that cannot be automatically identified, single, and cannot be detected in batches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

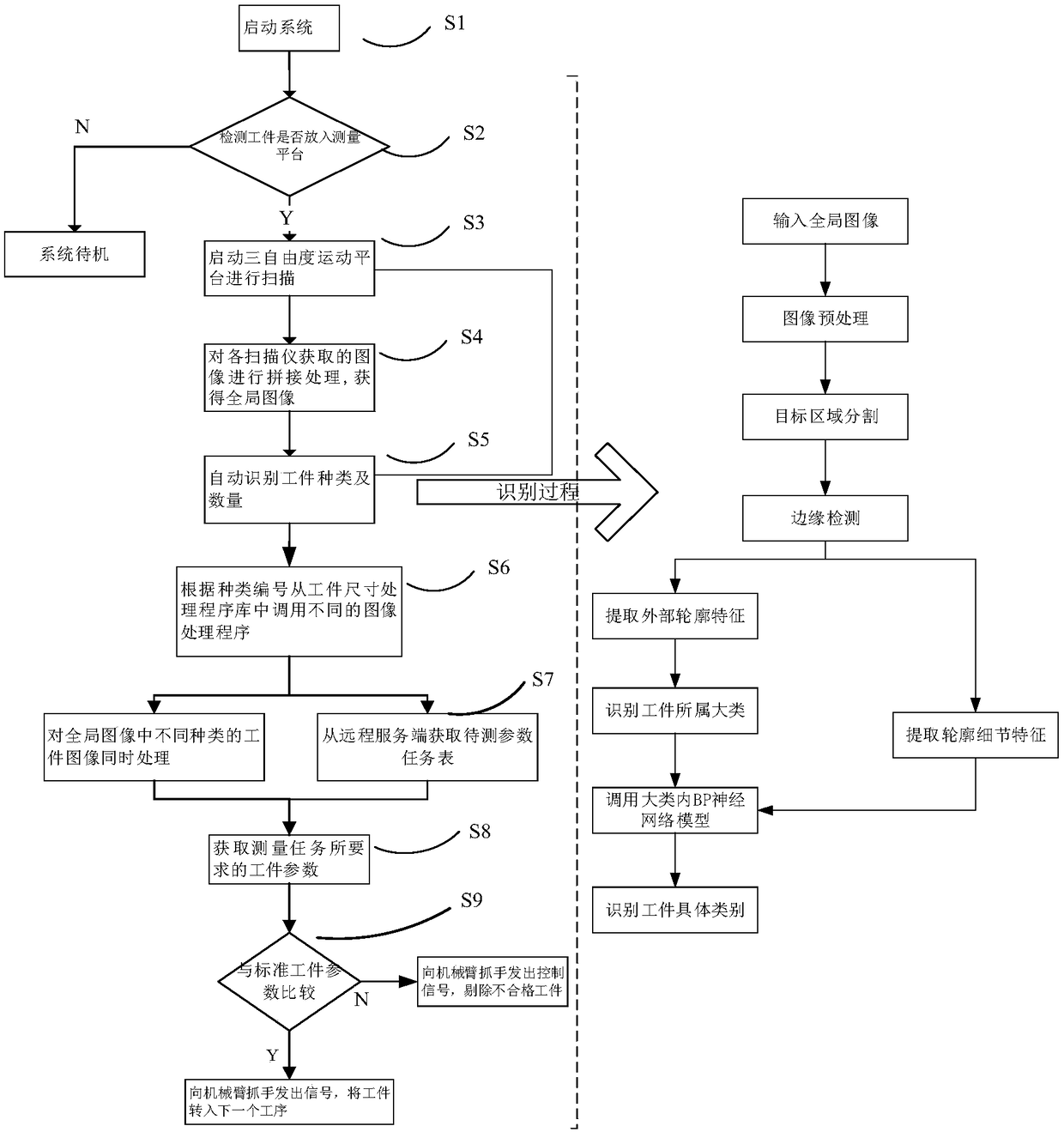

Embodiment 1

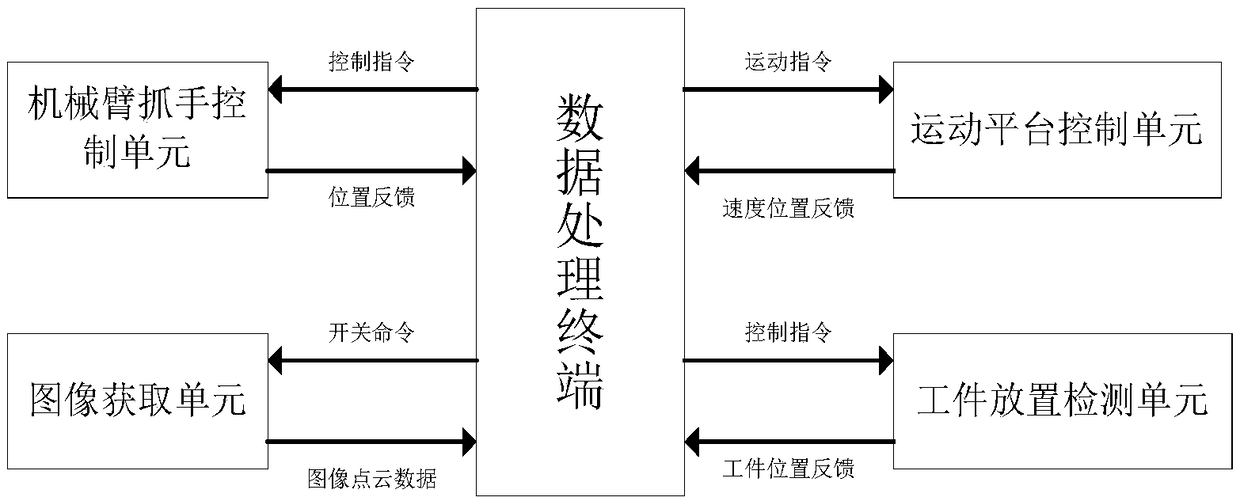

[0086] Such as Figure 4 and 5 As shown, a multi-type workpiece batch visual measurement system includes a data processing terminal, a workpiece detection unit, an image acquisition unit, and a control unit;

[0087] The data processing terminal is used to store and process data information;

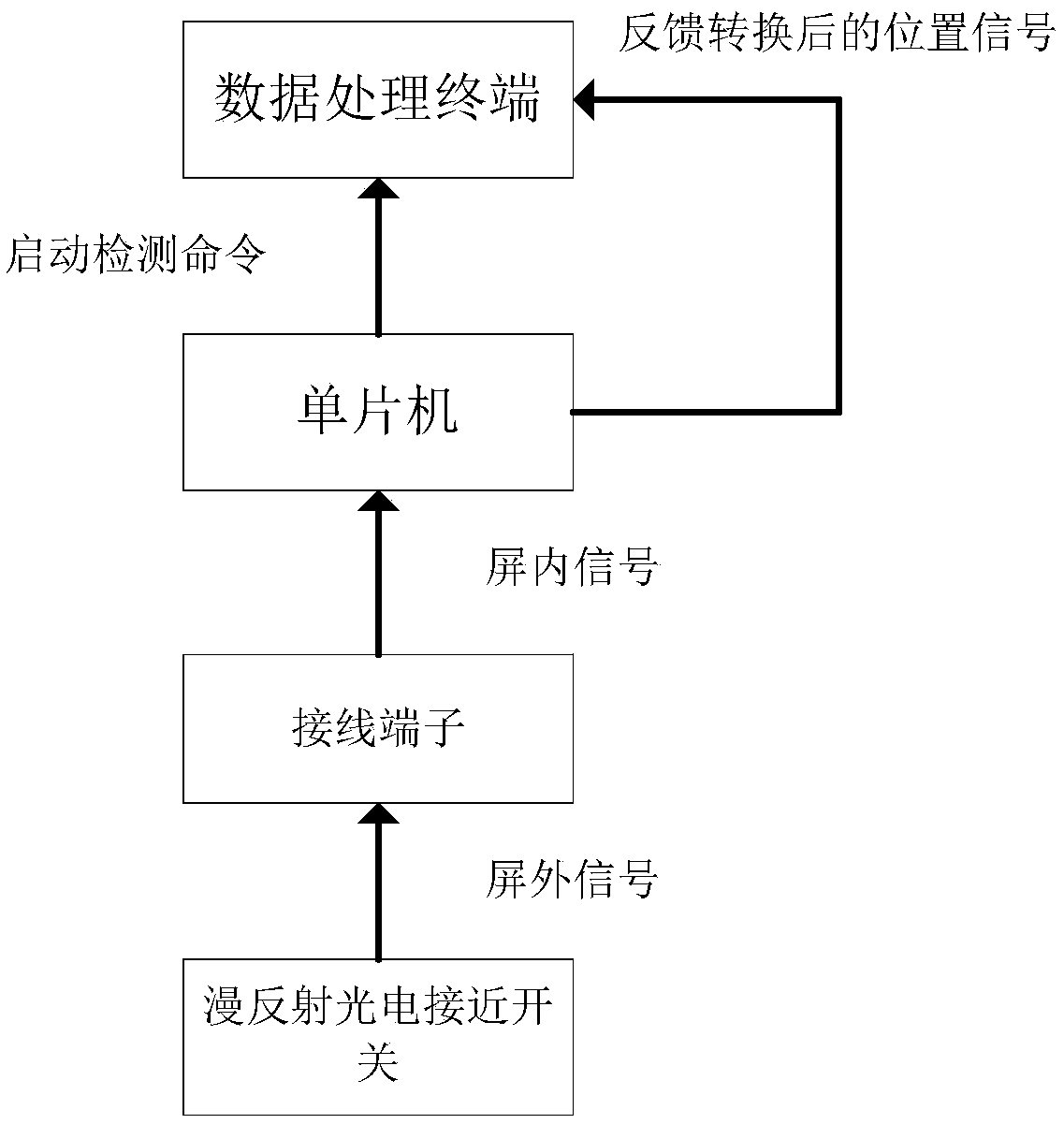

[0088] The workpiece detection unit is used to place the workpiece to be tested and start the detection system;

[0089] The image acquisition unit is used to acquire a local depth image;

[0090] The control unit includes a motion platform control unit and a gripper control unit;

[0091] The motion platform control unit includes a motion control card and a motor driver. The motion control card is built into the PCI card slot of the main board of the industrial computer for sending pulses of different frequencies and numbers to the driver. The motor driver communicates with the motion control card through a signal line for receiving Pulse to control the speed, direction and position...

Embodiment 2

[0153]The scheme of embodiment 2 is basically the same as that of embodiment 1, the only difference being that image stitching adopts the following steps: the image acquisition unit is a scanner, several scanners scan line by line, and each line of data collected by each scanner is respectively Continuously stored in the memory address block, the memory address corresponds to the data source one by one, knowing the first address of each row of data collected by each scanner, and obtaining the offset of the data storage according to the width of the overlapped field of view, from the specified row of data Start to read the image data continuously at the first address of the image data, find the data storage location of the repeated pixel and not read it, so that image stitching is performed in the image data reading link to obtain a global scanning image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com