Splicing detection device based on minor caliber circular Shack-Hartmann wavefront sensor

A detection device and sensor technology, applied in the field of optical detection, can solve the problems of harsh experimental conditions, lack of universality, and slow detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

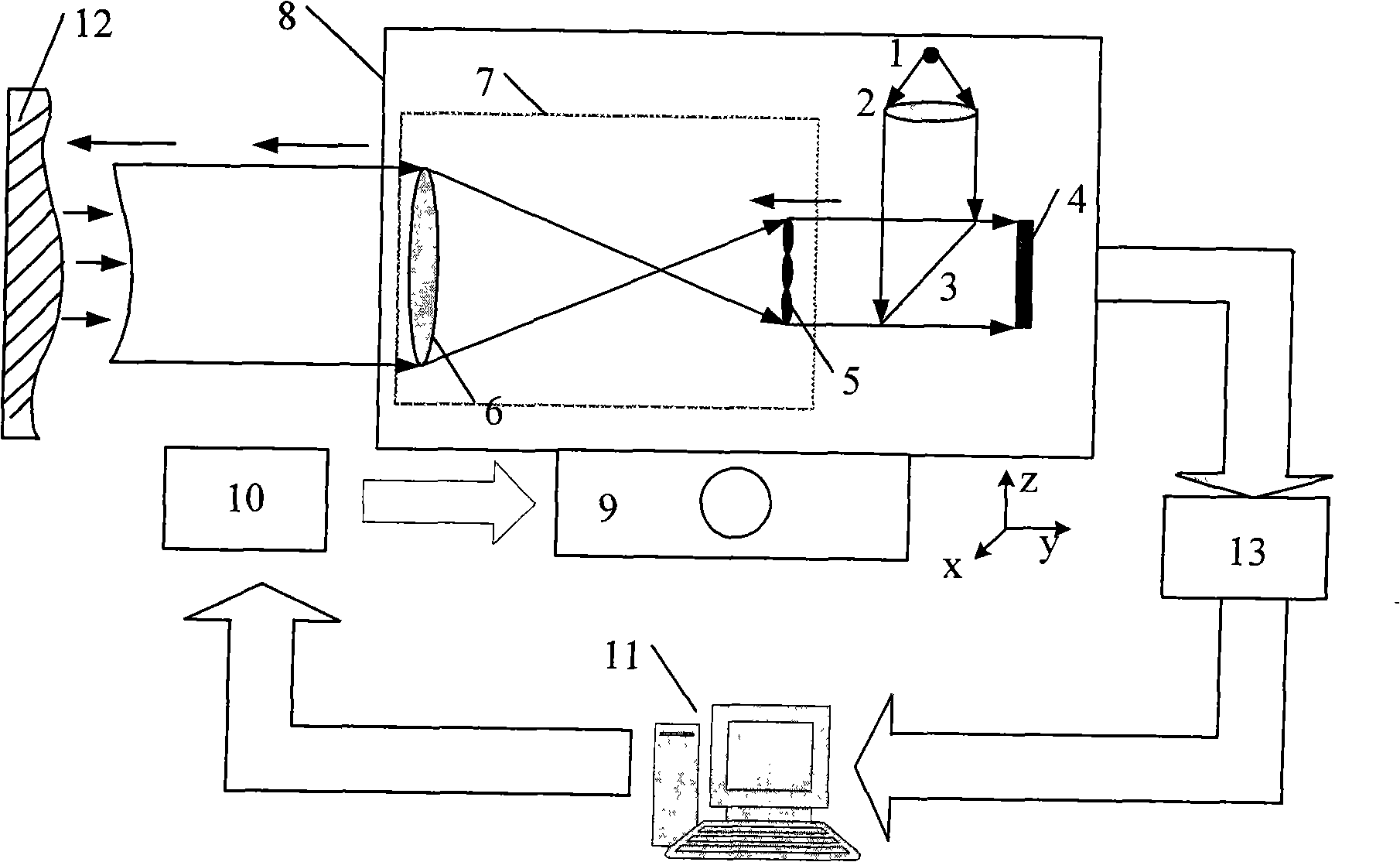

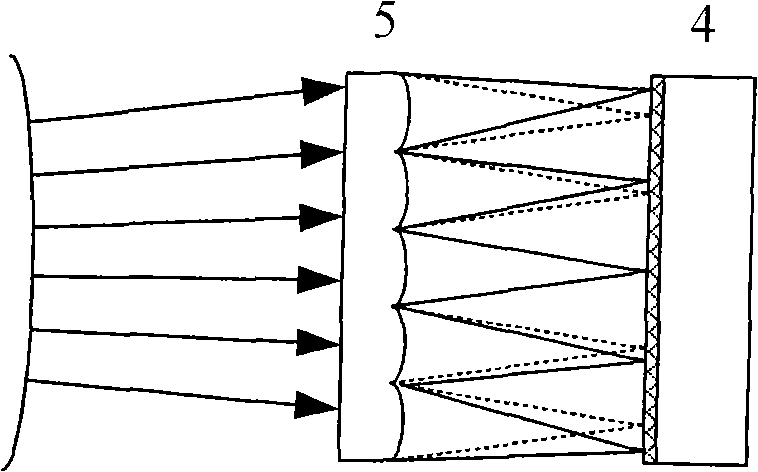

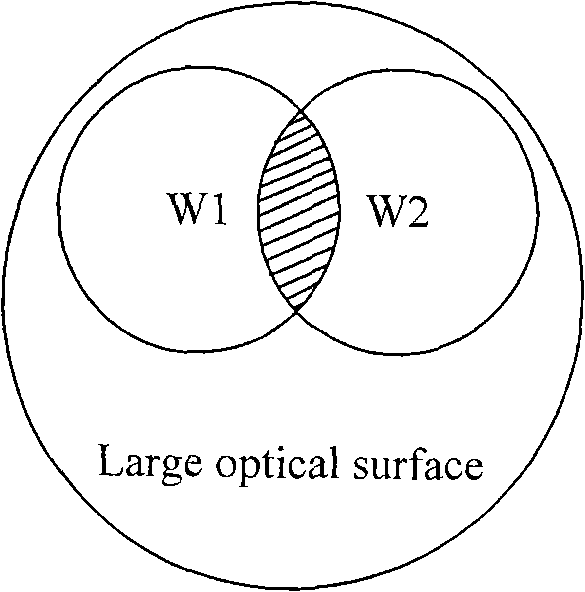

[0046] Such as figure 1 As shown, the splicing detection device based on the small-diameter circular Hartmann-Shack wavefront sensor of the present invention includes a Hartmann-Shack wavefront sensor 8, an x-z two-dimensional electronically controlled translation stage 9, a stepper motor controller 10, and a computer 11, the mirror surface to be measured 12 and the data acquisition card 13; Hartmann-Shack wavefront sensor (8) detects a certain area of the mirror surface to be measured (12) and forms light spot lattice at Hartmann-Shack wavefront sensor 8, by The data acquisition card 13 collects the above-mentioned spot data and transmits them to the computer 11 for storage; the computer 11 sends instructions to the stepper motor controller 10 to control the two-dimensional electronically controlled translation stage 9 to move along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com