LED (Light Emitting Diode) combined screen latching mechanism, LED unit screen and LED combined screen

A locking mechanism and combined screen technology, which is applied in the direction of cabinet/cabinet/drawer components, instruments, identification devices, etc., can solve the problems of inapplicable stitching accuracy, time-consuming, inconvenient disassembly of the display screen, etc., to achieve The assembly process saves time and effort, and the splicing precision is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

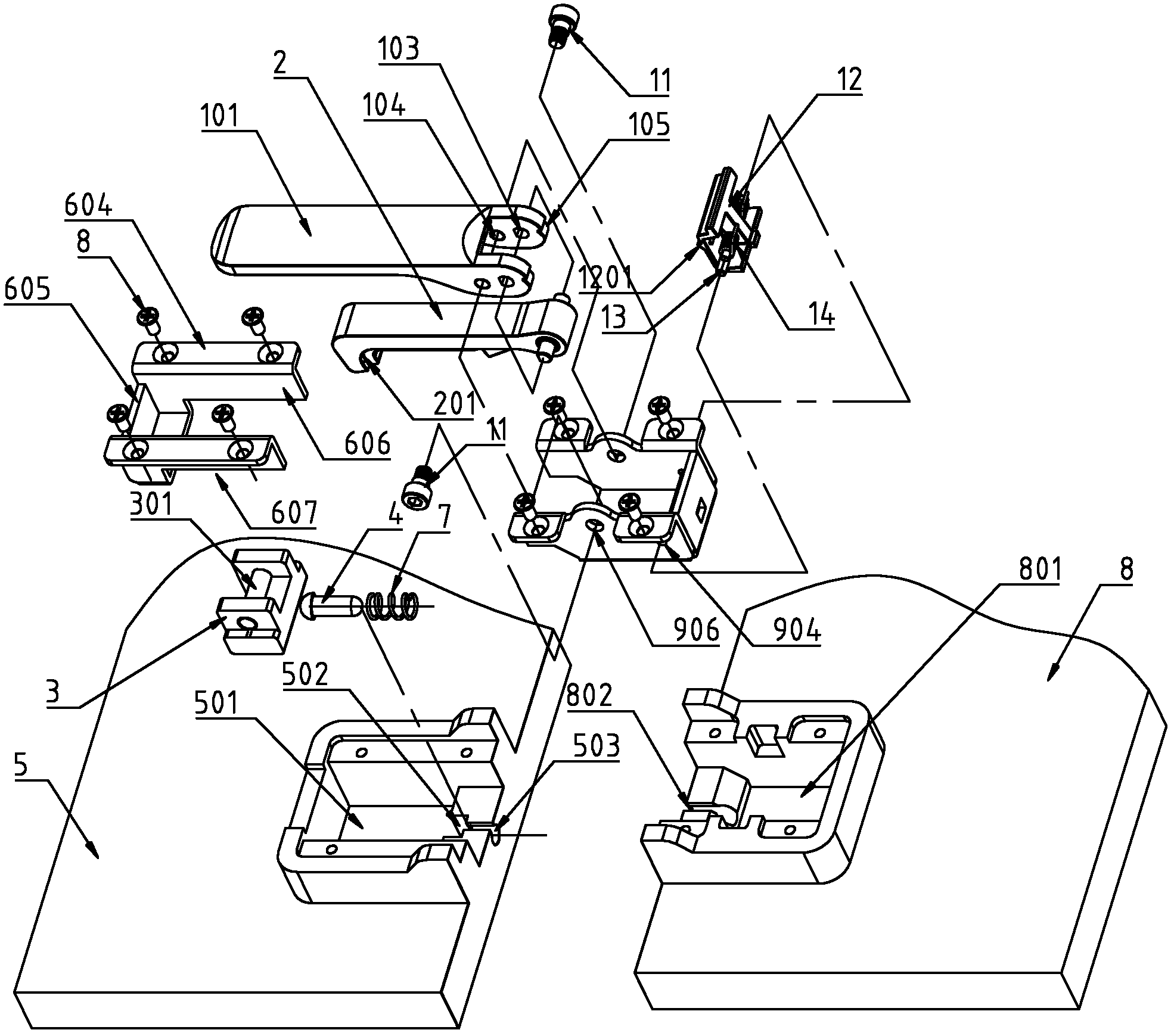

[0035] like Figure 1 to Figure 5 As shown, the locking mechanism of the LED combined screen according to Embodiment 1 of the present invention includes a first connecting portion and a second connecting portion.

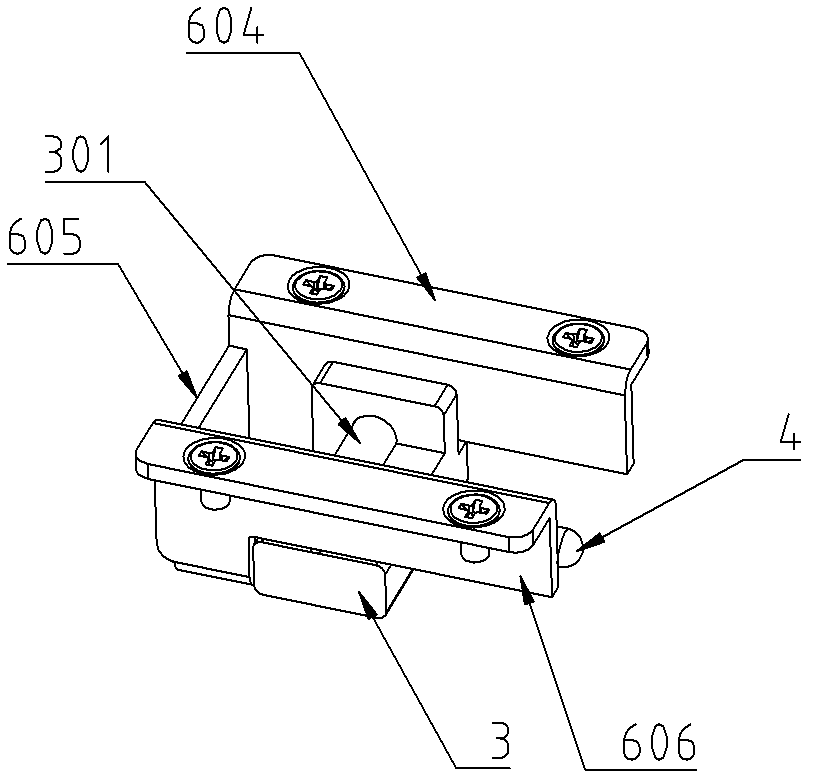

[0036] The first connecting part includes a slider 3, a positioning pin 4 and a first screen.

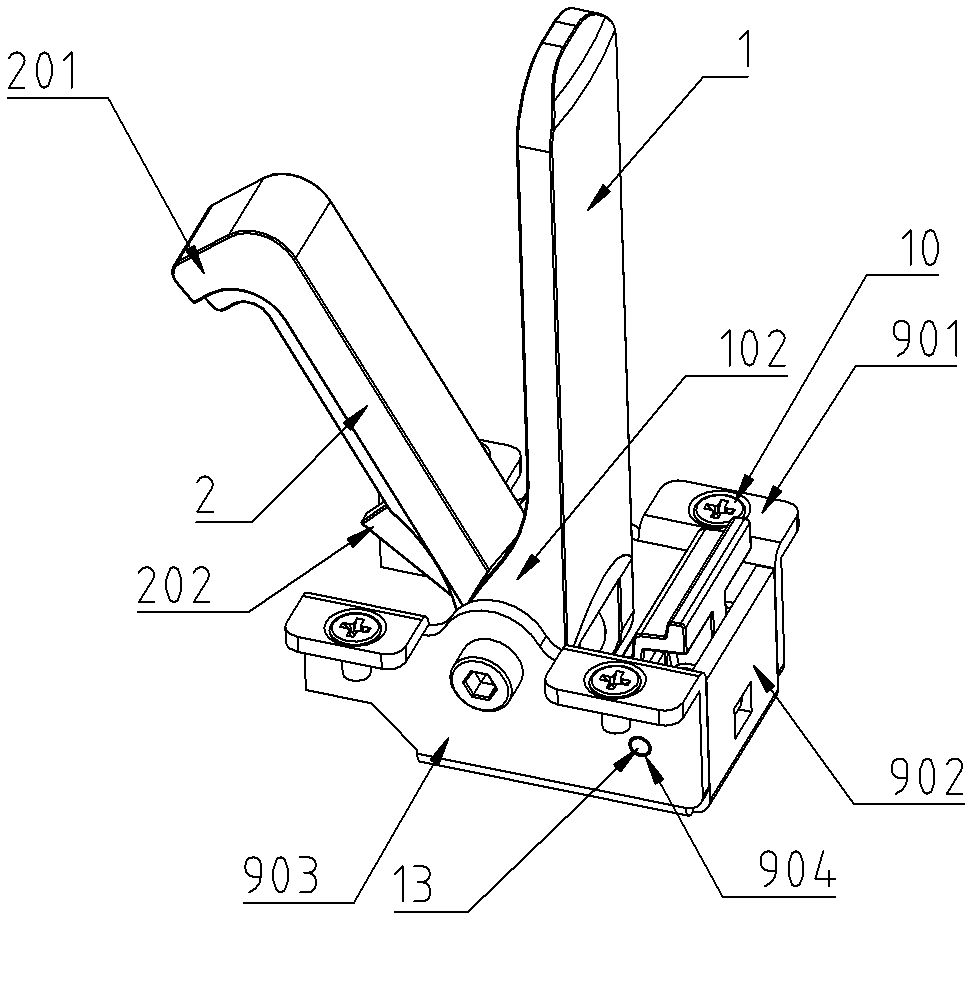

[0037] The second connecting part includes a locking hook 2, a wrench 1 and a second screen. The lock pin is installed on the first screen plate, and the wrench 1 is hinged with the second screen plate. The rear end of the lock hook 2 is hinged with the wrench 1 , and the hinge point between the wrench 1 and the second screen is located in front of the hinge point between the lock hook 2 and the wrench 1 . The front end of the lock hook 2 has a hook head 201 .

[0038] The first screen plate includes a first plate body 5 and a groove-shaped first installation seat 6 , and the first plate body 5 has a sliding groove 501 , a spring seat 502 and a shaft hole 503 . The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com