Landfill leachate multi-membrane treatment process

A landfill leachate and membrane treatment technology, applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Depreciation costs and other issues, to achieve the effect of improving sedimentation efficiency, saving membrane cleaning chemicals, and improving influent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

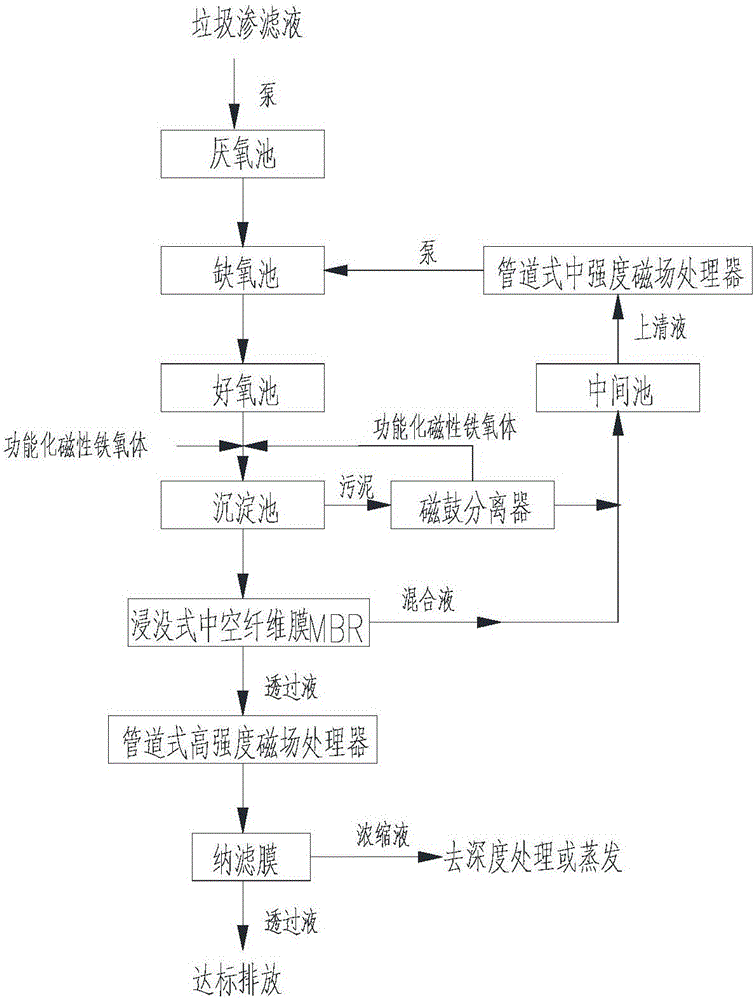

[0031] For a 250t / d landfill leachate treatment project, the overall process adopts UBF anaerobic / two-stage AO nitrification and denitrification / magnetic particle enhanced precipitation / hollow fiber ultrafiltration membrane / NF process.

[0032] Depend on figure 1 As shown, the landfill leachate is sequentially pumped into the anaerobic pool, anoxic pool and aerobic pool for treatment, functionalized magnetic ferrite is added to the effluent of the aerobic pool, and then enters the sedimentation tank for solid-liquid separation; the sedimentation tank gets The supernatant of the supernatant enters the submerged hollow fiber membrane membrane bioreactor for secondary solid-liquid separation; the sludge obtained from the sedimentation tank enters the magnetic drum separator for separation to obtain magnetic ferrite-containing slurry and return sludge, which contains The slurry of magnetic ferrite flows back into the outlet of the aerobic tank, and the return sludge enters the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com