Method for preparing fried snack food at low temperature

A low-temperature frying and low-temperature vacuum frying technology, applied in the field of fried food, can solve problems such as carcinogenicity, achieve the effects of wide application, eliminating carcinogenic defects, and improving freezing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

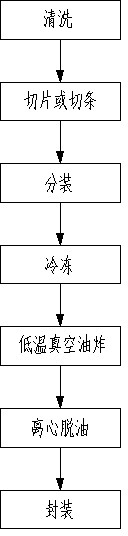

[0032] Such as figure 1As shown, a method for frying snacks at low temperature, the method comprises: washing carrots or pumpkins as food raw materials to obtain washed food raw materials; slicing or cutting the washed food raw materials to obtain Flake or strip-shaped food raw materials; steam and boil the flake or strip-shaped food raw materials, because carrots or pumpkins have high moisture content and are easy to steam and boil, so the steaming and boiling time is kept between 5 minutes and 6 minutes. Get eight mature semi-finished products, that is, semi-finished products; after the semi-finished products are cooled, the semi-finished products are divided into small bags. Because carrots or pumpkins have a high moisture content and are not easy to freeze through, so the weight of each bag is kept at 35 grams, and then divided into small bags The semi-finished product is frozen for 48 hours, and the temperature during freezing is kept between -19°C and -20°C to obtain a f...

Embodiment 2

[0034] Such as figure 1 Shown is a method for frying snacks at low temperature, the method comprising: washing potatoes or sweet potatoes or purple potatoes or lotus roots as food raw materials to obtain washed food raw materials; slicing or slicing the washed food raw materials Cut into strips to obtain sheet or strip food raw materials; steam and boil the sheet or strip food raw materials, because sweet potatoes or purple potatoes or lotus roots are easier to steam and boil, so the steaming and boiling time is kept at 7 minutes to 8 minutes. Within minutes, eight mature semi-finished products are obtained, that is, semi-finished products; after the semi-finished products are cooled, the semi-finished products are divided into small bags, because sweet potatoes, purple potatoes or lotus roots have moderate moisture content and are easier to freeze through, and the weight of each bag is kept at 50 grams , and then freeze the semi-finished products that are divided into small b...

Embodiment 3

[0036] Such as figure 1 Shown is a method for frying snacks at low temperature, the method comprising: washing beans or white beans or peas or walnuts as food raw materials to obtain washed food raw materials; slicing or Cut into strips to obtain food raw materials in flake or strip shape; steam and boil the food raw materials in flake or strip shape, because peas or white beans or peas or walnuts are not easy to steam and boil, so the steaming and boiling time is kept at 9 minutes Between 10 and 10 minutes, eight mature semi-finished products are obtained, that is, semi-finished products; after the semi-finished products are cooled, the semi-finished products are divided into small bags, because the moisture content of soybeans or white beans or peas or walnuts is low, and they are easy to freeze through, and the weight of each bag remains In 70 grams, the semi-finished product packed into small bags is frozen for 24 hours, and the temperature during freezing is kept between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com