Method for blasting construction of upper and lower fracture surfaces in IV/V-class surrounding rock through three-arm jumbo drill

A rock drilling jumbo and cross-section technology, which is applied in blasting and other directions, can solve the problems of easy instability of the side wall, low anti-disturbance ability, and large energy consumption, and achieves easy control of the extrapolation angle, fast blasting and drilling time, and improved The effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

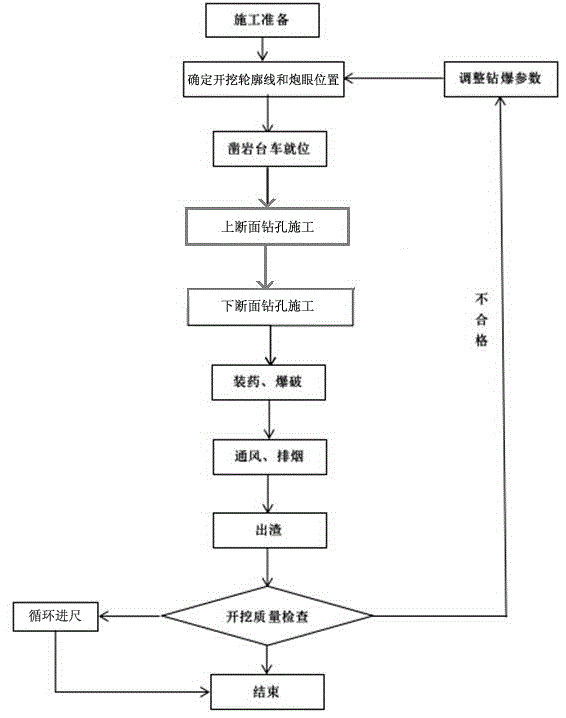

[0017] In this embodiment, the method of using the three-arm rock drilling jumbo to blast the upper and lower sections in the surrounding rocks of grades IV and V is as follows: image 3 shown, follow the steps below:

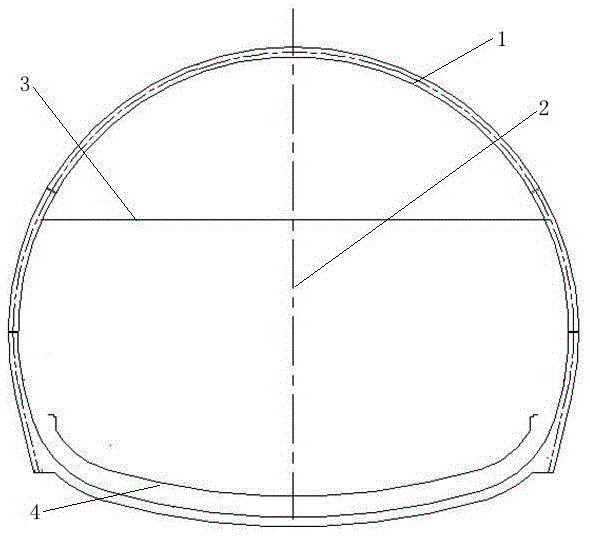

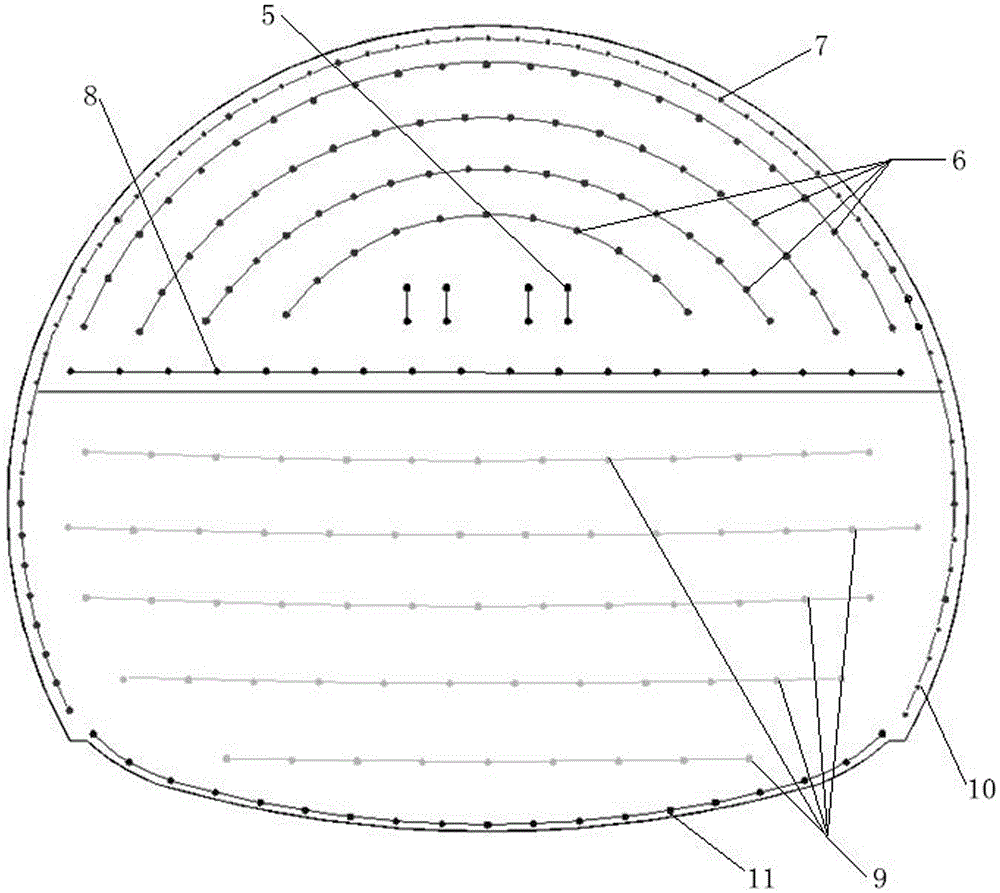

[0018] (1) Set out the line according to the tunnel construction design drawing, and the setting out error of the surrounding contour line should not be greater than ±2cm, such as figure 1 As shown, determine the tunnel excavation contour line 1 and the tunnel center line 2, according to the layout of the blasting hole, as shown in figure 2 As shown, the positions of the blastholes are marked on the upper section 3 and the lower section 4; the distance between the cutting holes 5 in the upper section is 50-80 cm, and there are a total of 8 cutting holes 5 in the upper section, and the auxiliary holes 6 in the upper section are in four rows. The spacing of the first row is 70cm, the spacing of the last three rows is 90cm, a total of 73 auxiliary eyes 6 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com