Patents

Literature

142results about How to "Prevent weathering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

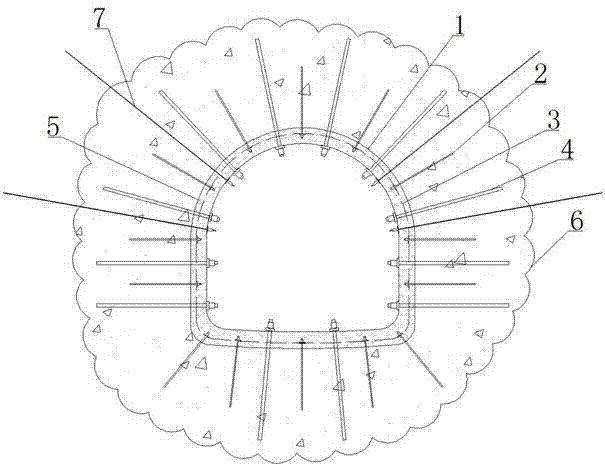

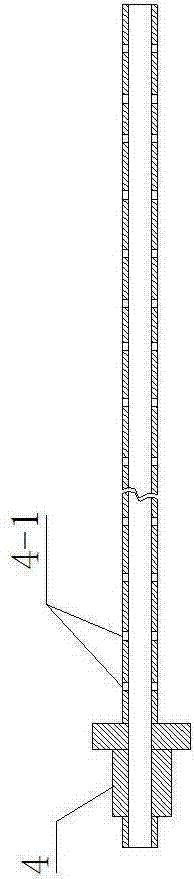

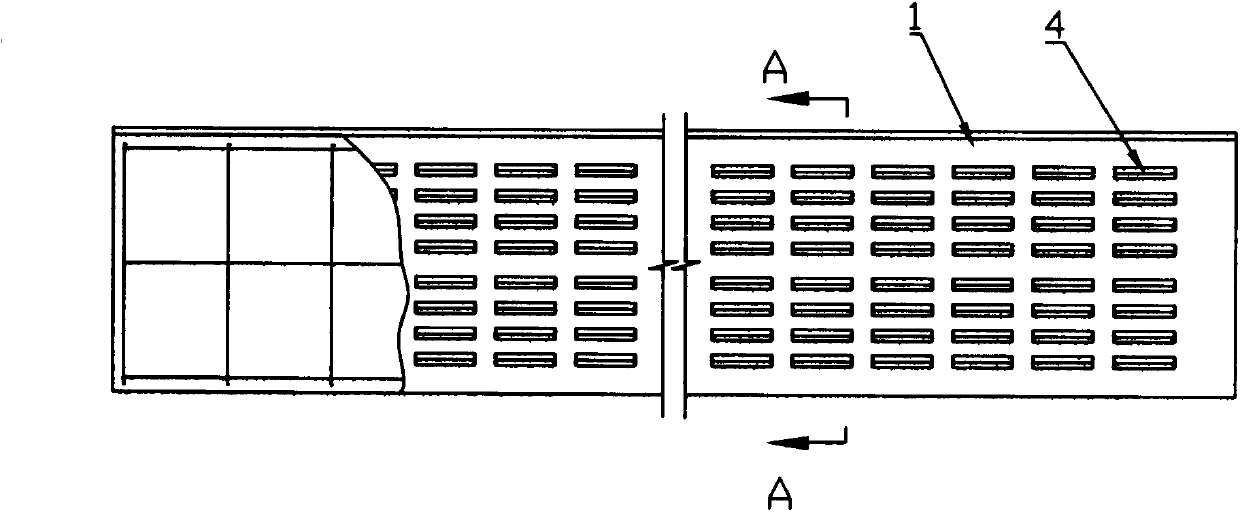

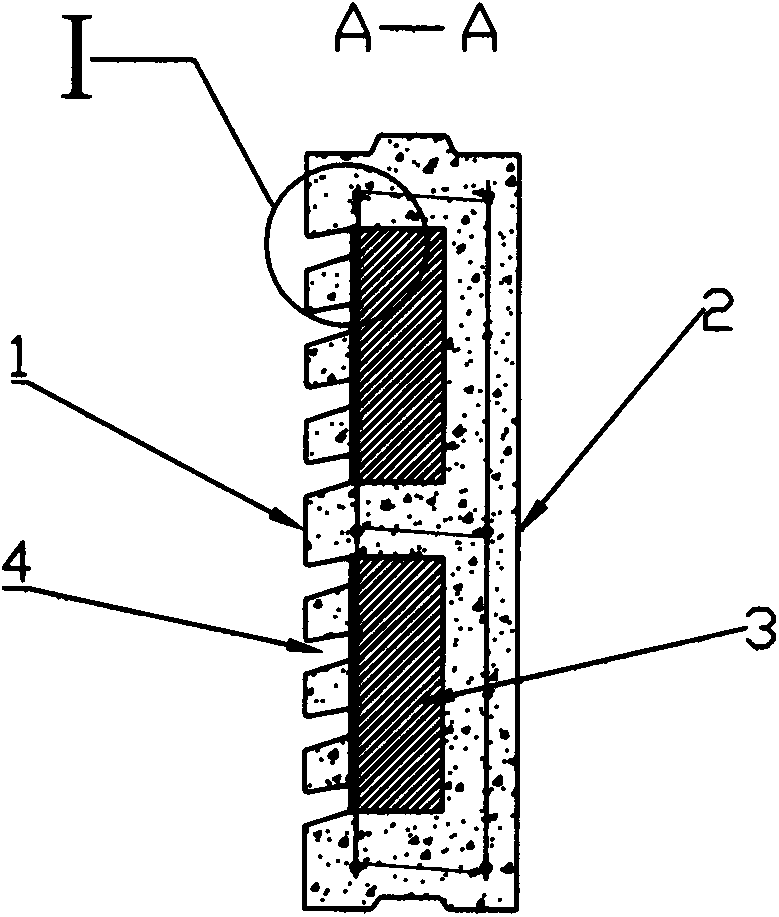

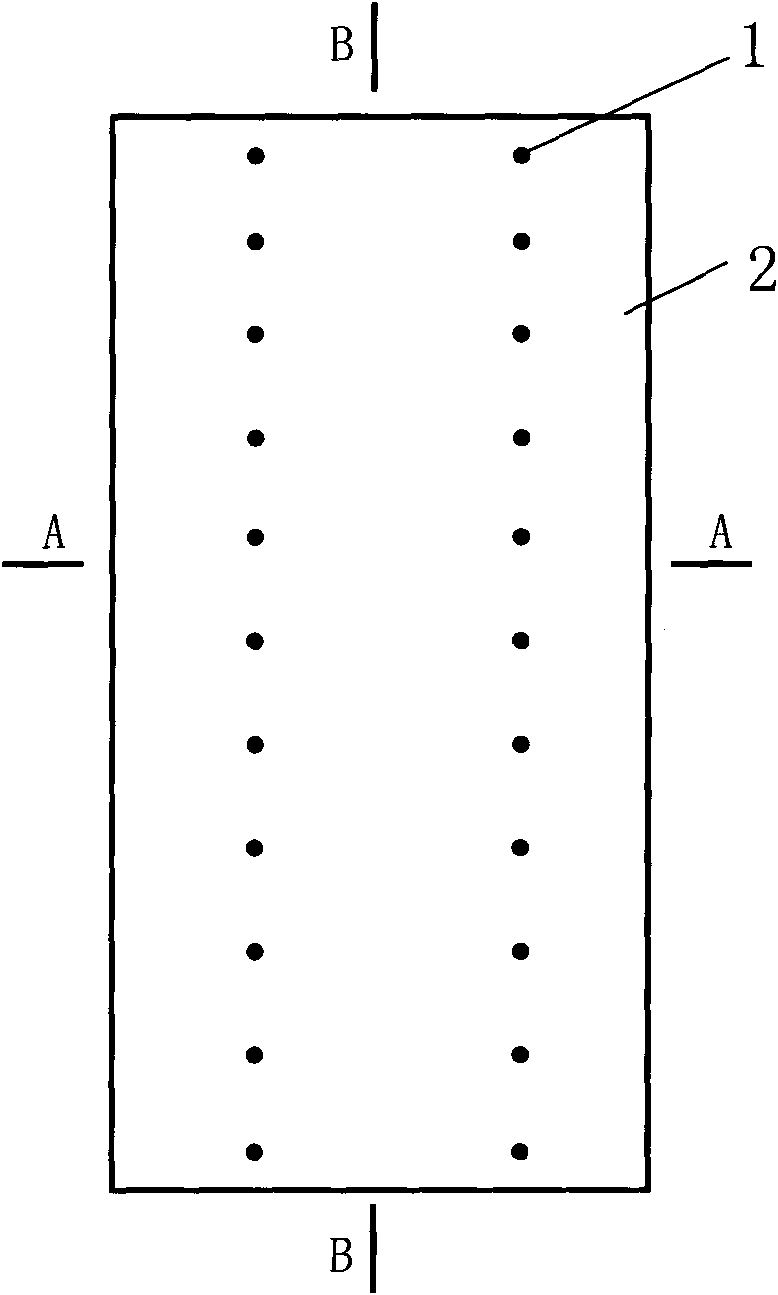

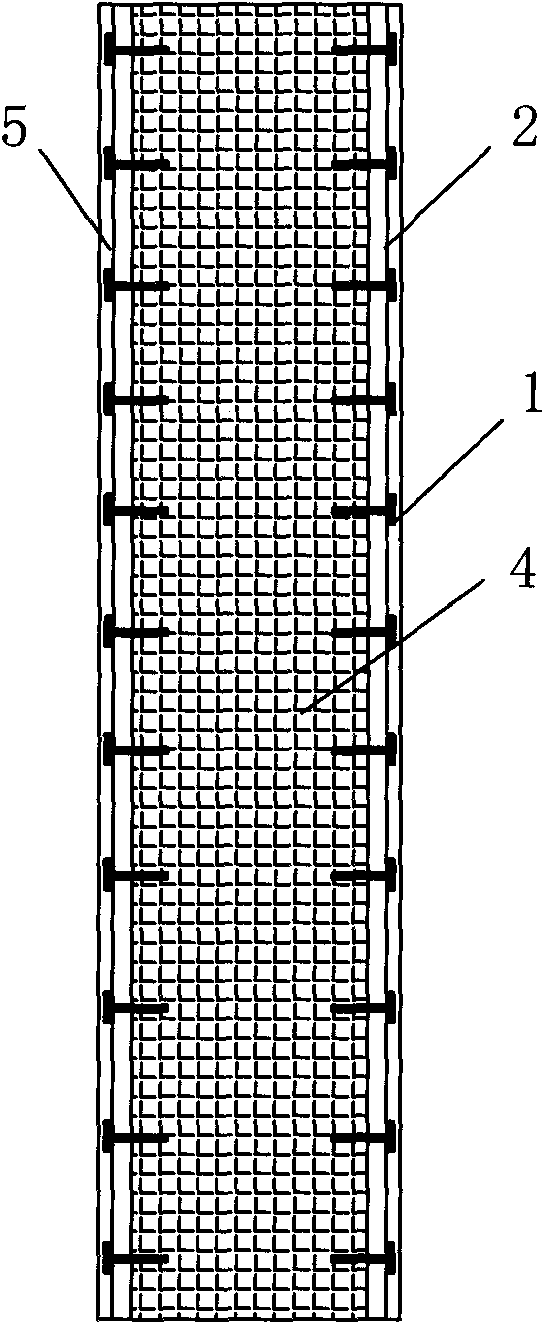

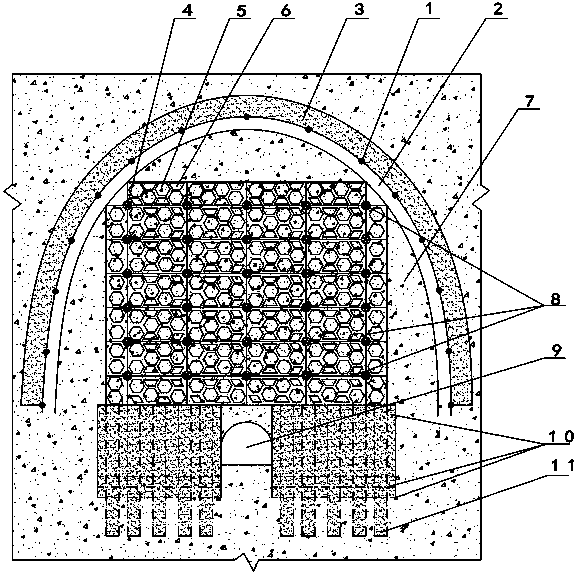

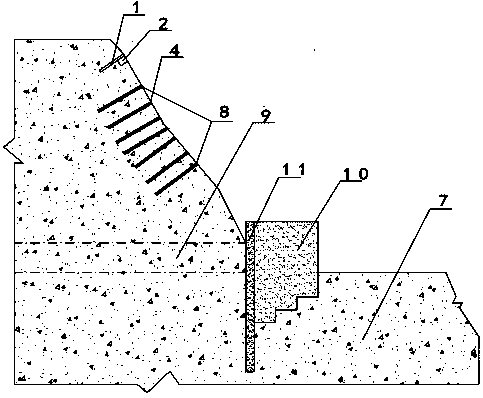

Supporting and reinforcing structure of coal mine tunnel and construction technology thereof

InactiveCN103195441AEven by forcePrevent weatheringUnderground chambersTunnel liningPre stressArchitectural engineering

The invention discloses a supporting and reinforcing structure of a coal mine tunnel and a construction technology thereof. The supporting and reinforcing structure of the coal mine tunnel comprises a lane, wherein a grid-shaped reinforced layer is arranged on the inner wall of the lane, an anchor rod is arranged on the grid node portion of the reinforced layer, the inner end of the anchor rod is anchored in surrounding rock of the lane, and an anchor plate and a nut of the anchor reinforced layer are arranged at the outer end of the anchor rod. A concrete spraying layer covered on the reinforced layer and arranged at the outer end of the anchor rod is further arranged on the inner wall of the lane, a grouting anchor rod is arranged in the surrounding rock of the lane, an anchor cable is further arranged in the surrounding rock of the lane, the inner end of the anchor cable is anchored in the surrounding rock of the lane, and the outer end of the anchor cable is anchored on the outer side of the concrete spraying layer through a tray and a tensioning lock. The supporting and reinforcing structure of the coal mine tunnel integrates the surrounding rock of the lane in cementing mode with the initiative supporting theory as the guidance, prestress is reserved in the rock body, and stress is released and superimposed slowly, so that self integral strength and stability of soft rock and coal body are improved, the surrounding rock in a release ring of the lane can form a structure relatively homogenous and stable, and the aim of reinforcing and protecting the soft rock lane can be achieved within a long time.

Owner:PINGDINGSHAN TIANAN COAL MINING

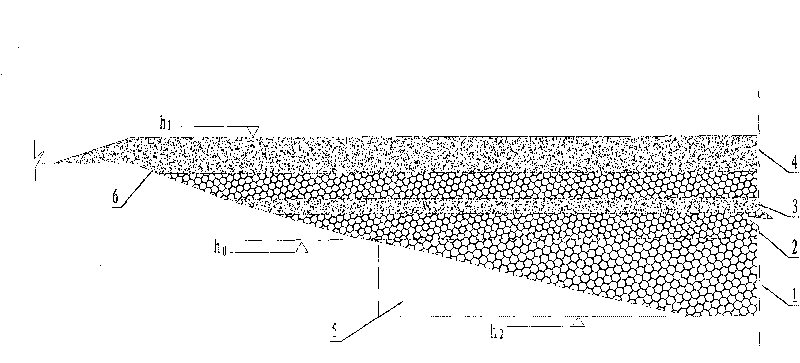

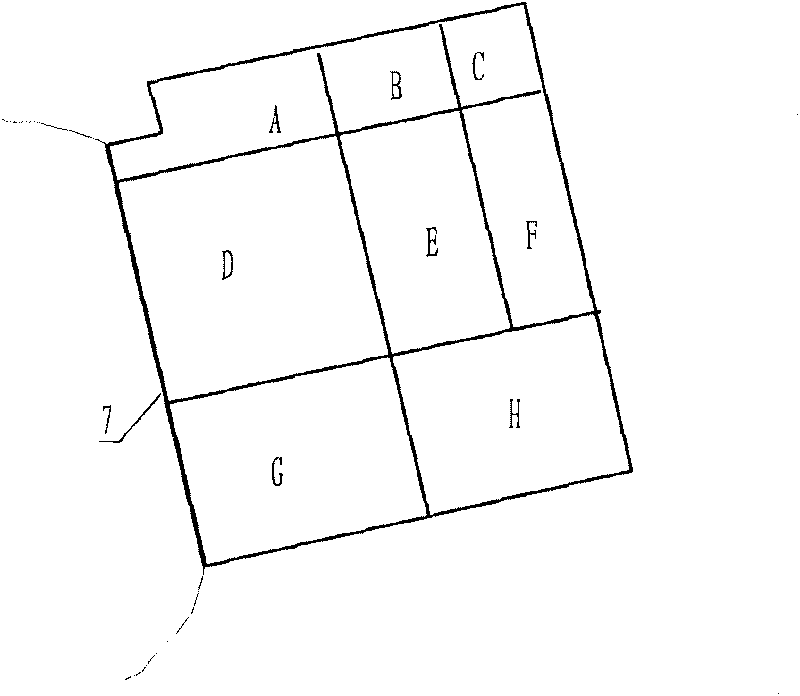

Filling-reclaiming method for building land in coal mining subsidence areas

InactiveCN101713291AEase the growing tensionSave the occupied landUnderground miningSurface miningSpontaneous combustionPorosity

The invention provides a filling-reclaiming method for building land in coal mining subsidence areas, which belongs to the technical field of mining and is used to solve the problem of developing and utilizing coal gangue. The invention adopts a technical scheme that the method is implemented according to the following steps: a, draining accumulated water in reclamation areas and clearing silt; b, striping and stockpiling surface soil; c, determining the thickness and density of coal gangue for hierarchical backfilling through a vibration pressure test; and d, performing hierarchical backfilling compaction on the coal gangue and soil. The method has the following main advantages that: 1, the ways of utilizing the coal gangue are expanded, and environmental pollution caused by stockpiling the coal gangue on ground is reduced; 2, the situation that building land is increasingly short is alleviated by reclaiming subsidence land to be the building land; and 3, the treatment for coal gangue for large-area hierarchical backfilling by a hierarchical vibration-compaction method is economical, reasonable and ideal in compaction effect, can improve the compactness and bearing capacity of coal gangue layers, and can prevent the spontaneous combustion or efflorescence of coal gangue foundations and the separation of harmful substances from polluting local environment because hierarchical compaction greatly reduces porosity and isolates air.

Owner:煤炭科学研究总院唐山研究院

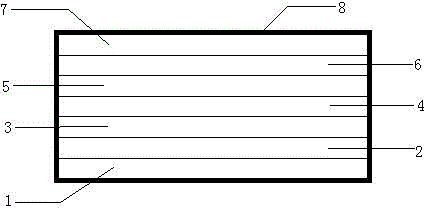

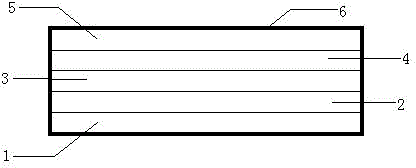

Special floor for magnesium container house and manufacturing method of special floor

ActiveCN104131680APrevent intrusionPrevent weatheringSolid waste managementLaminationGlass fiberEngineering

The invention relates to a special floor for a magnesium container house. The special floor respectively comprises a bottom pulp layer, a lower non-woven fabric layer, a lower glass fiber layer, an intermediate material layer, an upper glass fiber layer, an upper non-woven fabric layer and a decoration layer from bottom to top and is formed through extrusion by a roller, wherein waterproof sealing layers coast the outwards exposed surfaces of the bottom pulp layer, the lower non-woven fabric layer, the lower glass fiber layer, the intermediate material layer, the upper glass fiber layer, the upper non-woven fabric layer and the decoration layer. The special floor has the characteristics that the special floor does not contain formaldehyde at all and achieves a better environment-friendly effect; the weight is light, the intensity is high, dampproof and mildewproof effects are achieved, and the service life is long; the manufacturing cost is low; and the installation, the pavement and the cutting are convenient, and fireproof, smokeless and non-toxic effects are achieved.

Owner:张家港市盛港绿色防火建材有限公司

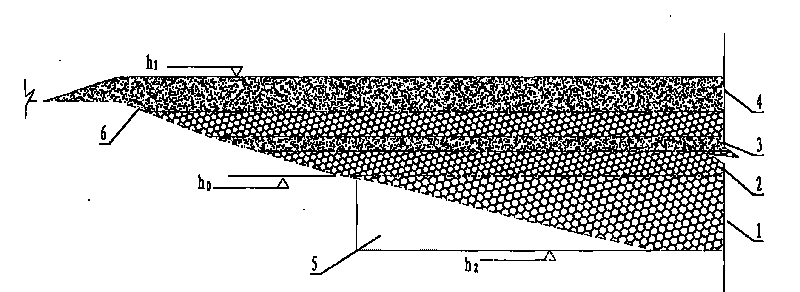

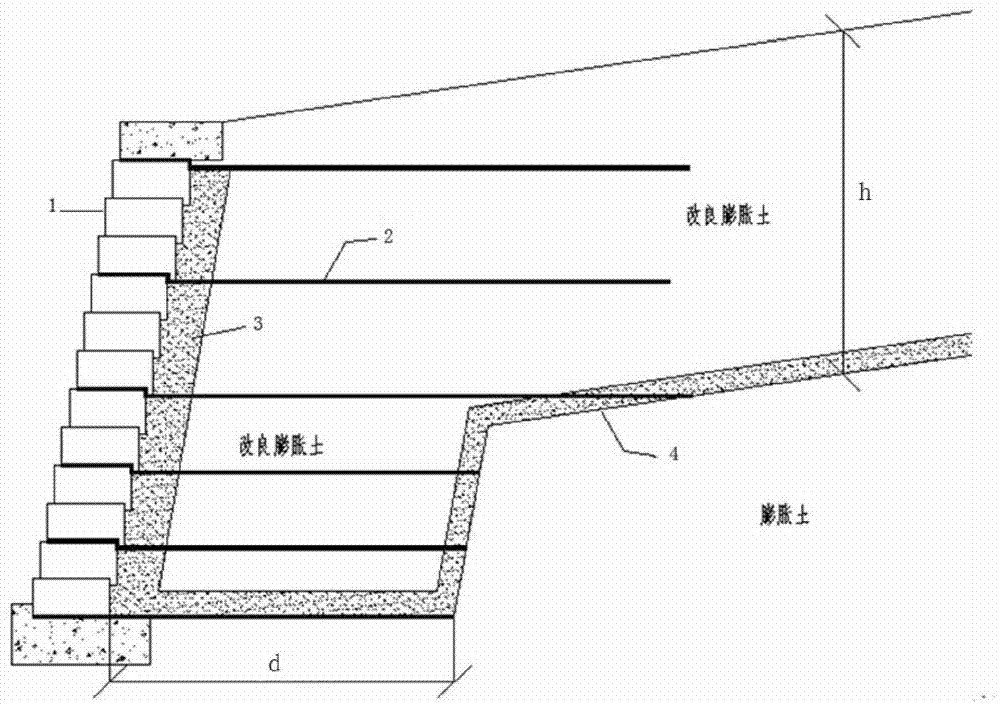

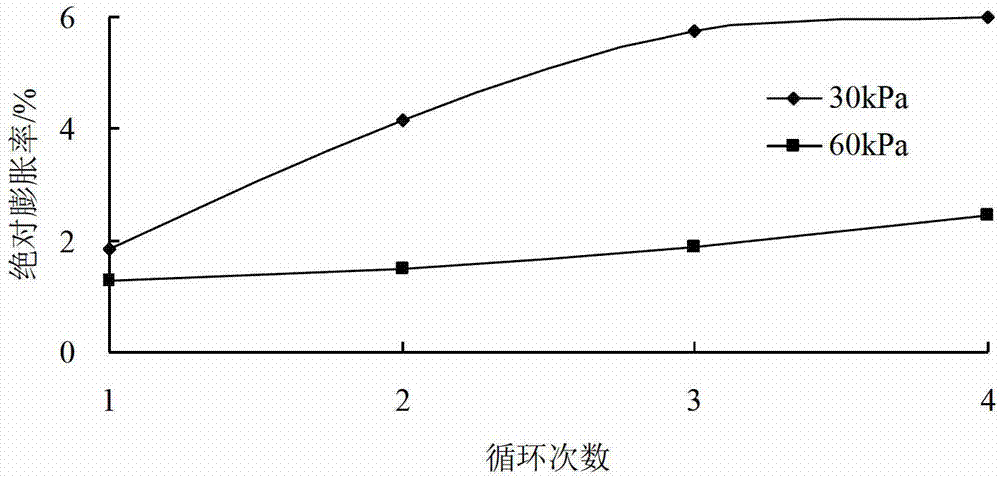

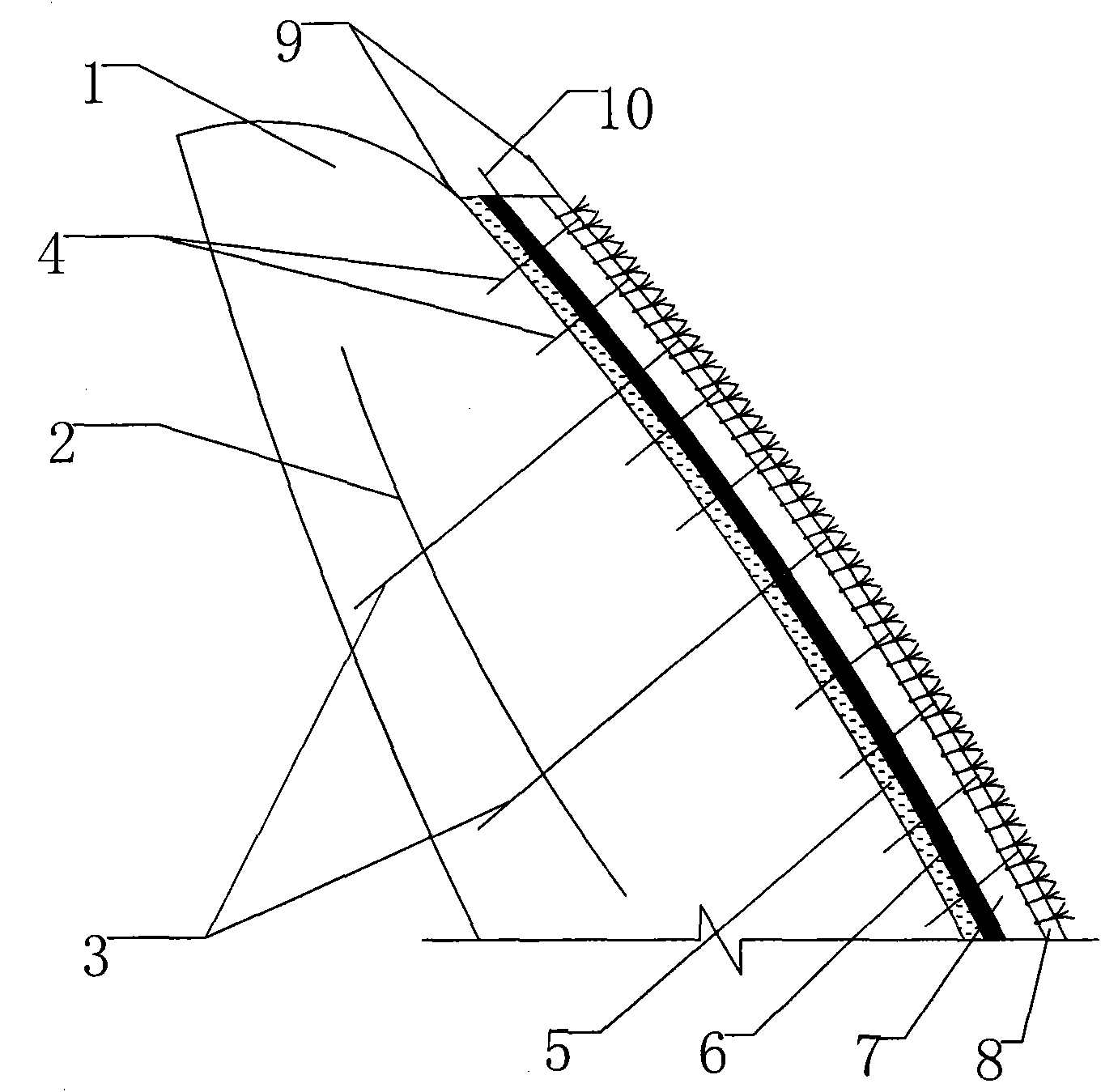

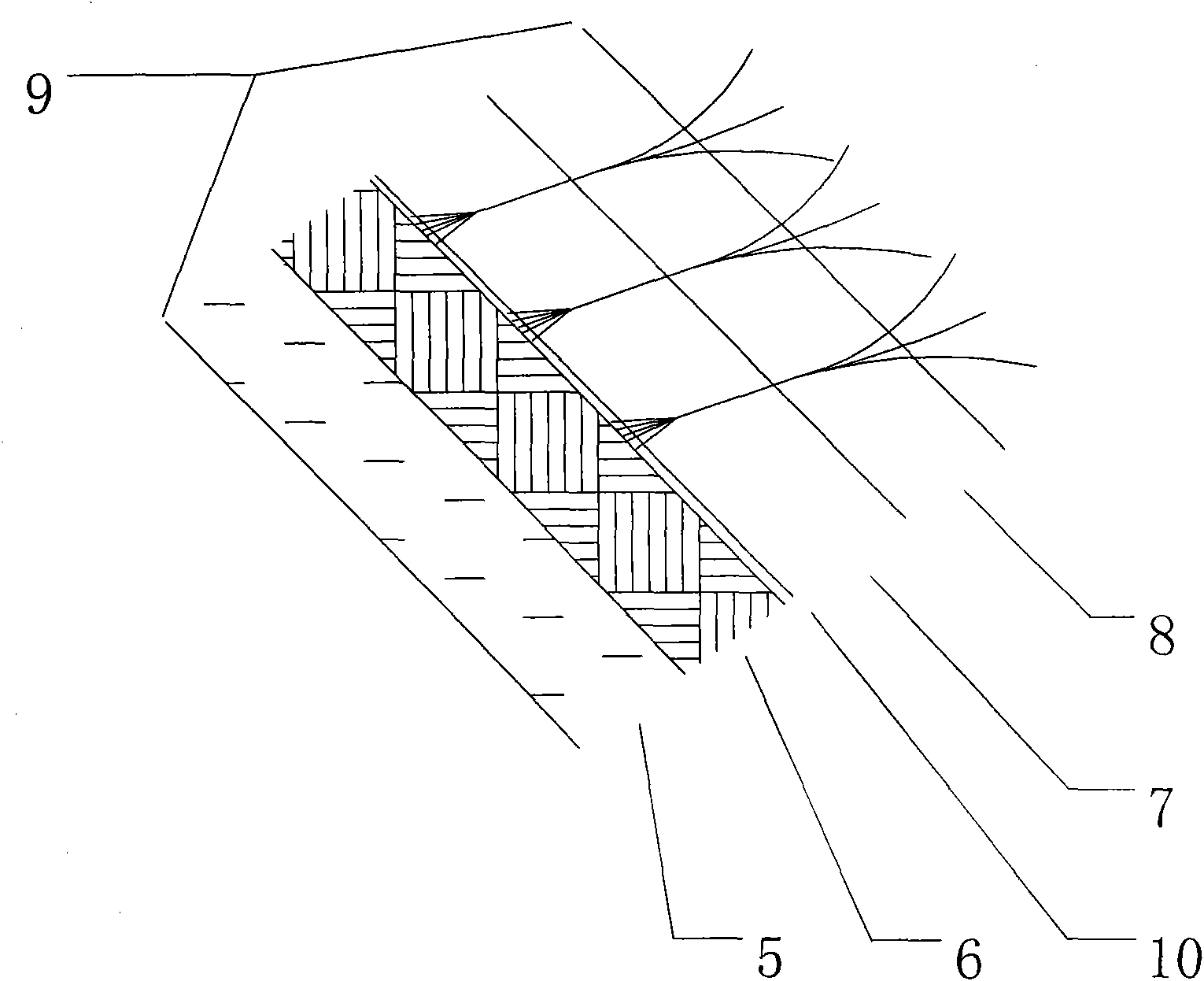

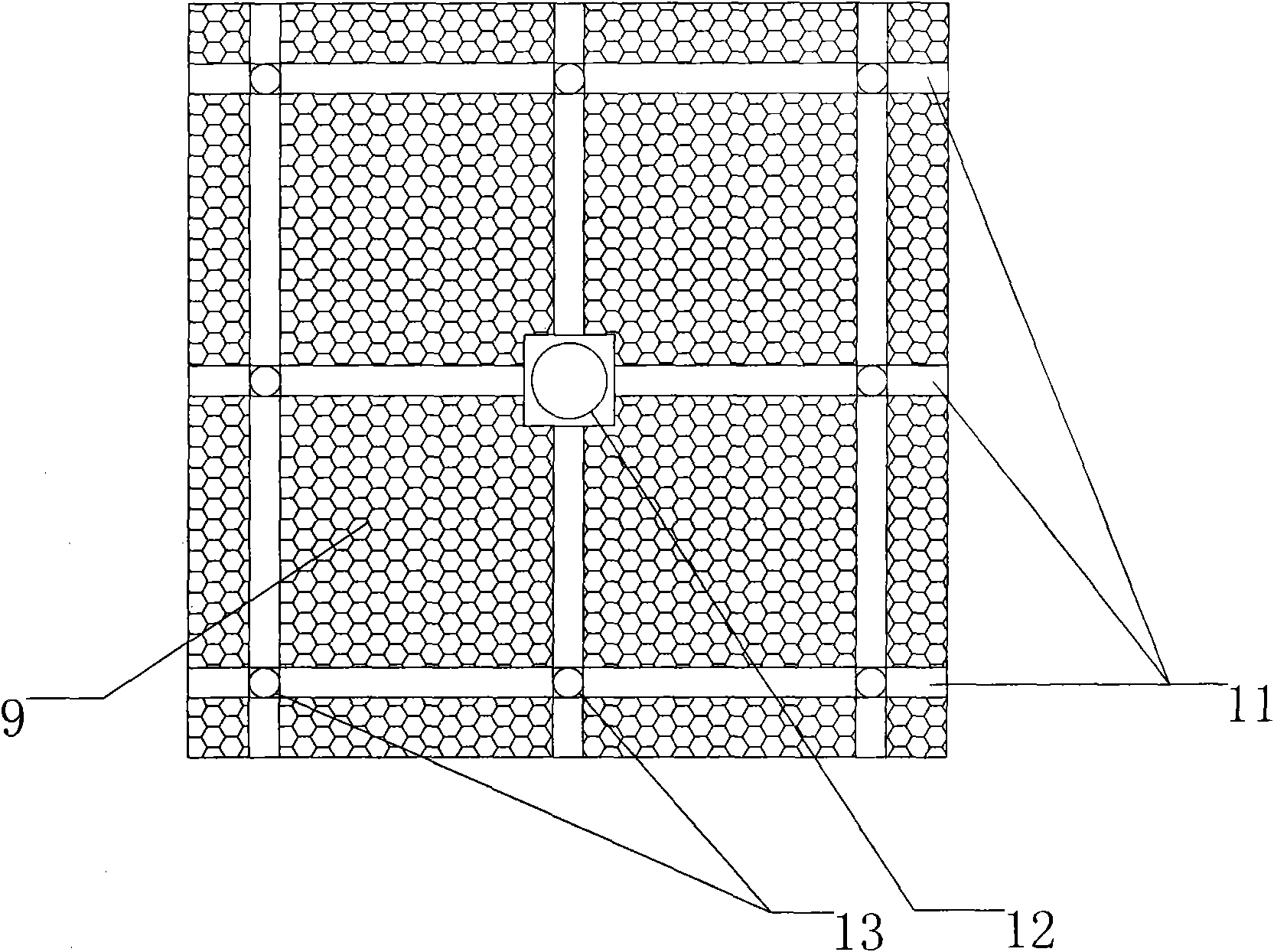

Method for improving slope stability of expansive soil and controlling structural damage of expansive soil

InactiveCN103088834AWeakening rangeReduce expansion and contraction deformationExcavationsIn situ soil foundationSoil scienceGeomembrane

The invention discloses a method for improving slope stability of expansive soil and controlling structural damage of the expansive soil. An expansive soil slope form obtained through the method prevents direct contact of the expansive soil and the atmosphere and effectively avoids weathering of the expansive soil. A water-proof geomembrane is covered on a surface layer of the expansive soil, drainage facility is arranged on the surface layer of the expansive soil, variation range of water-containing rate in the expansive soil can be effectively reduced, and expansive deformation of the expansive soil is reduced. An overlaying load function further limits expansive and shrinkage deformation of the expansive soil and generation and development of fractures, avoids structural damage of the expansive soil, and prevents the structural strength from being reduced, each stagee of stopping wall adopts a flexible protection structure which can avoid damage of the structure caused by discordant deformation between the expansive soil and the structure, so that a slope protection structure has strong capacity to be adapted to deformation and antidumping capacity. The method for improving slope stability of expansive soil and controlling structural damage of the expansive soil is simple and convenient to construct and good in effect.

Owner:HOHAI UNIV

Method for making hydrophobic solution and hydrophobic glass

A process for preparing a hydrophobic solution and a hydrophobic glass used for the windscreen of car is disclosed. Said hydrophobic solution is prepared from CF3(CF2)5C2H4Si(OC2H5)3, Si(OC2H5)4, C2H5OH, deionized water, and hydrochloric acid through proportional mixing, and stirring for 5-20 hr. Said hydrophobic glass is prepared through cleaning glass, preparing said hydrophobic solution, coating it on the surface of glass, and solidifying at 250-350 deg.C for 10 min -72 hr to form a firm hydrophobic film.

Owner:FUYAO GLASS IND GROUP CO LTD

Combined ecological slope protection method for rocky high slope

InactiveCN102146675AAvoid erosion damageMitigation of Physical WeatheringClimate change adaptationExcavationsWeather resistanceWeathering

The invention relates to combined ecological slope protection of a rocky high slope, and belongs to the technical field of rocky high slope reinforcement, weathering resistance and ecological slope protection in rock and earth engineering. The slope protection combined layer comprises a lower grid layer, a temperature change resistant layer, a waterproof layer, a stabilizing layer, a nutritional matrix layer, a plant layer, an upper grid layer and steel battens. A construction method comprises the steps of determining anchoring force and an anchorage cable type and setting the slope protection combined layer. By combination and fixing of a prestressed anchorage cable and a shallow anchorage rod, three effects of reinforcing rocks, preventing weathering and greening the surface can be achieved, the construction process is simplified, and the operation is convenient.

Owner:HOHAI UNIV

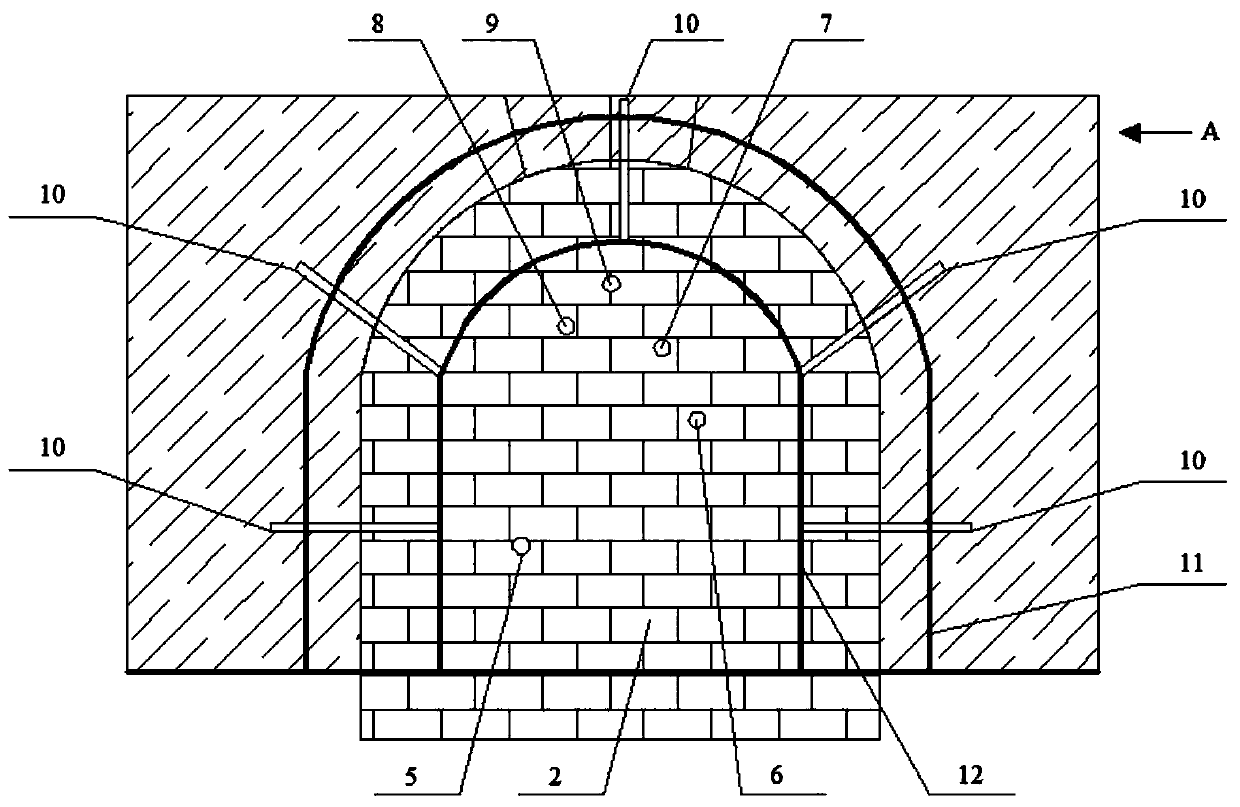

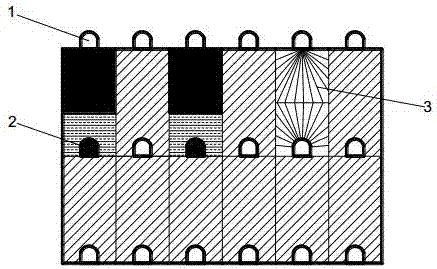

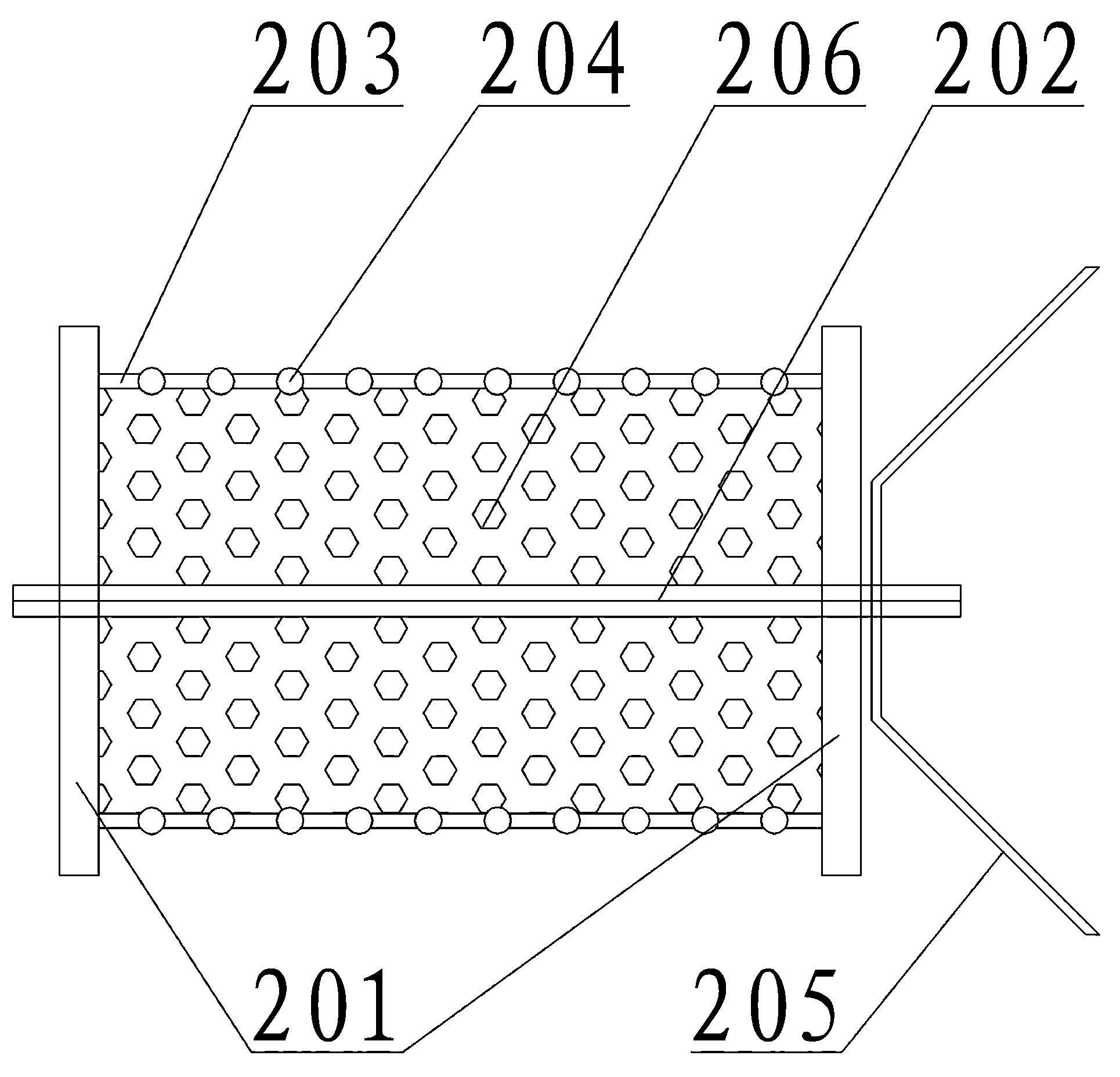

Coal mine explosion-proof sealed wall and construction method thereof

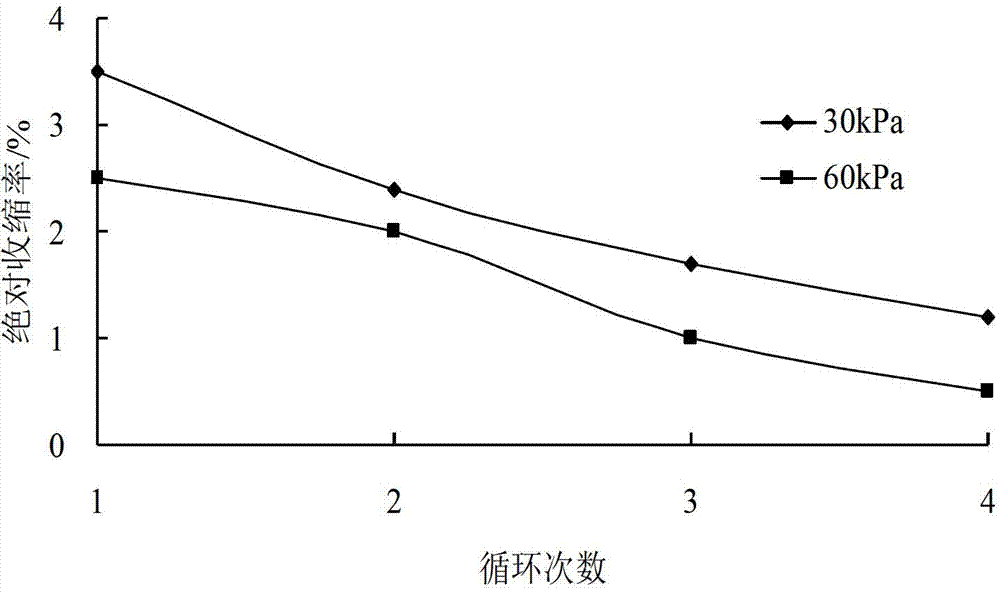

ActiveCN110017167AImprove airtightnessStrong anti-knock abilityMining devicesUnderground chambersWater dischargeShrinkage rate

The invention provides a coal mine explosion-proof sealed wall which comprises a roadway, two sealed walls, a filled wall and two grouting areas, two cutting grooves are formed in the periphery of theinner wall of a roadway sealing section needing to be sealed in parallel in the upward direction, the two sealed walls are arranged in the two cutting grooves respectively, and the filled wall is arranged between the two sealed walls; grouting areas are arranged on the side walls of the periphery of the roadway on the two sides of the two sealed walls respectively, a water discharging pipe, an observation pipe, a filling pipe, a goaf grouting or nitrogen injection pipe and an inspection pipe are sequentially arranged between the two sealed walls from bottom to top, a plurality of grouting pipes are arranged on the surface of the roadway in the circumferential direction of the roadway, one ends of the grouting pipes penetrate into the roadway by 2-5 m, and the other ends of the grouting pipes are connected with grouting equipment, and the filled wall is formed by filling flexible filling materials. The sealed wall constructed by the construction method of the coal mine explosion-proofsealed wall has the advantages of being good in sealing performance and high in explosion-proof capacity, and the strength and air tightness requirements can be met to the maximum degree through material combinations with different properties and different shrinkage rates.

Owner:ANHUI JIATAI COAL MINING TECH

Complete non-coal-pillar continuous depressurized mining method for close-distance coal seam groups

ActiveCN104564072APromote reliefReduce ground stressUnderground miningSurface miningStress concentrationBreather

The invention discloses a complete non-coal-pillar continuous depressurized mining method for close-distance coal seam groups, which is applicable to coal mining engineering. The method comprises the following steps: determining the mining sequence of each coal seam in a coal seam group; when a first coalface of a first mined coal seam is mined, building a filling wall in which a breather pipe is arranged along the edge of a goaf so as to form a gob-side entry retaining, taking the roadway as a transportation roadway when a second coalface is mined, continuing to perform a gob-side entry retaining in a track roadway, breaking and removing a flexible film bag on the surface of the previous gob-side entry retaining behind the coalface, and when the coal recovery of the second coalface is completed, filling carbon dioxide into the breather pipe in the filling wall of the first coalface so as to prompt the filling wall to have a carbonization reaction and then break and disassemble. After a coal seam is completely mined, because a top plate is not supported by a coal-rock pillar, the top plate can move and sink fully, so that the depressurized mining on adjacent coal seams is realized, thereby avoiding the stress concentration produced by the hangover of the filling wall, and facilitating the maintenance for mining spaces, the extraction of gas and the prevention and control of dynamic disasters.

Owner:CHINA UNIV OF MINING & TECH

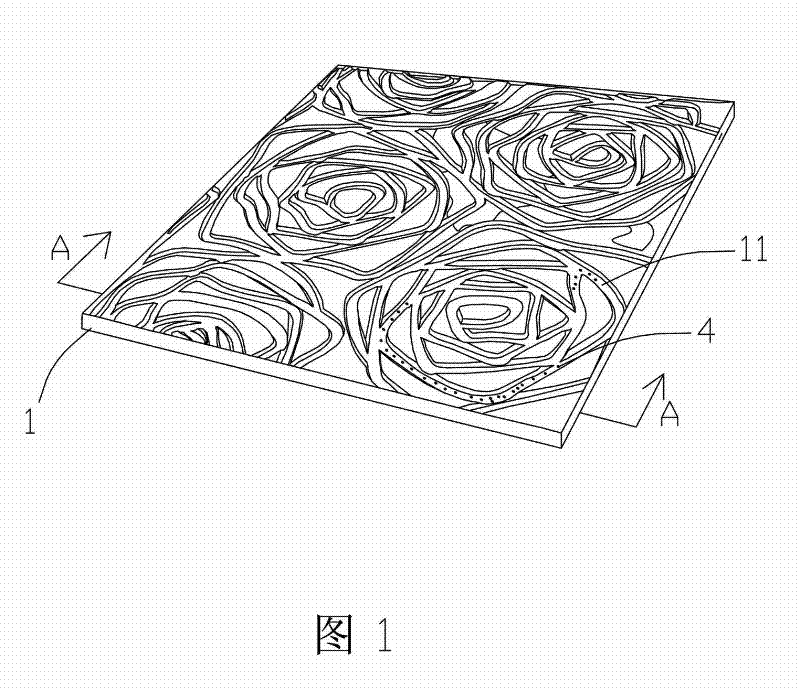

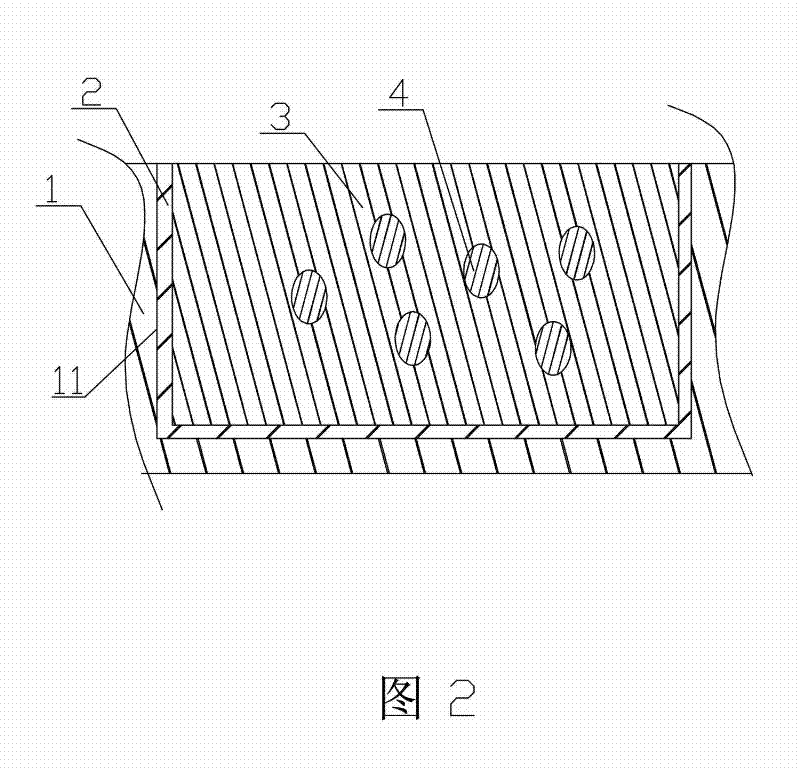

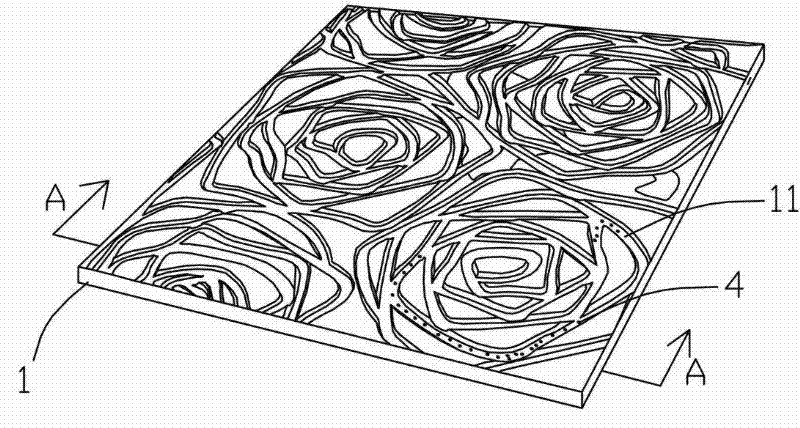

A kind of decorative board and its production process

InactiveCN102259547AExtended service lifeInhibit sheddingDecorative surface effectsData filePulp and paper industry

A decorative board, comprising a decorative board body, the decorative board body is provided with a concave texture engraved by a numerical control engraving machine, and a pattern decorative layer formed by a numerical control inkjet printer is arranged in the concave texture, and the concave texture is filled with Has a transparent protective layer. The decorative board completely covers the pattern in the texture through a transparent protective layer, which can avoid color fading, and can be applied to decorative occasions such as outdoors with harsh natural conditions. Simultaneously, the present invention also provides the production process of the decorative panel, which combines the CNC engraving machine and the CNC inkjet printer well, through the input of data files including patterns, the positioning and data of the CNC engraving machine and the CNC inkjet printer equipment. The CNC engraving machine engraves the corresponding concave texture on the surface of the decorative plate, and the CNC inkjet printer prints the corresponding pattern in the concave texture, which overcomes the limitation that the existing inkjet printer can only print flat patterns and improves production efficiency. Reduced production costs.

Owner:NANAN BESTTIME STONE

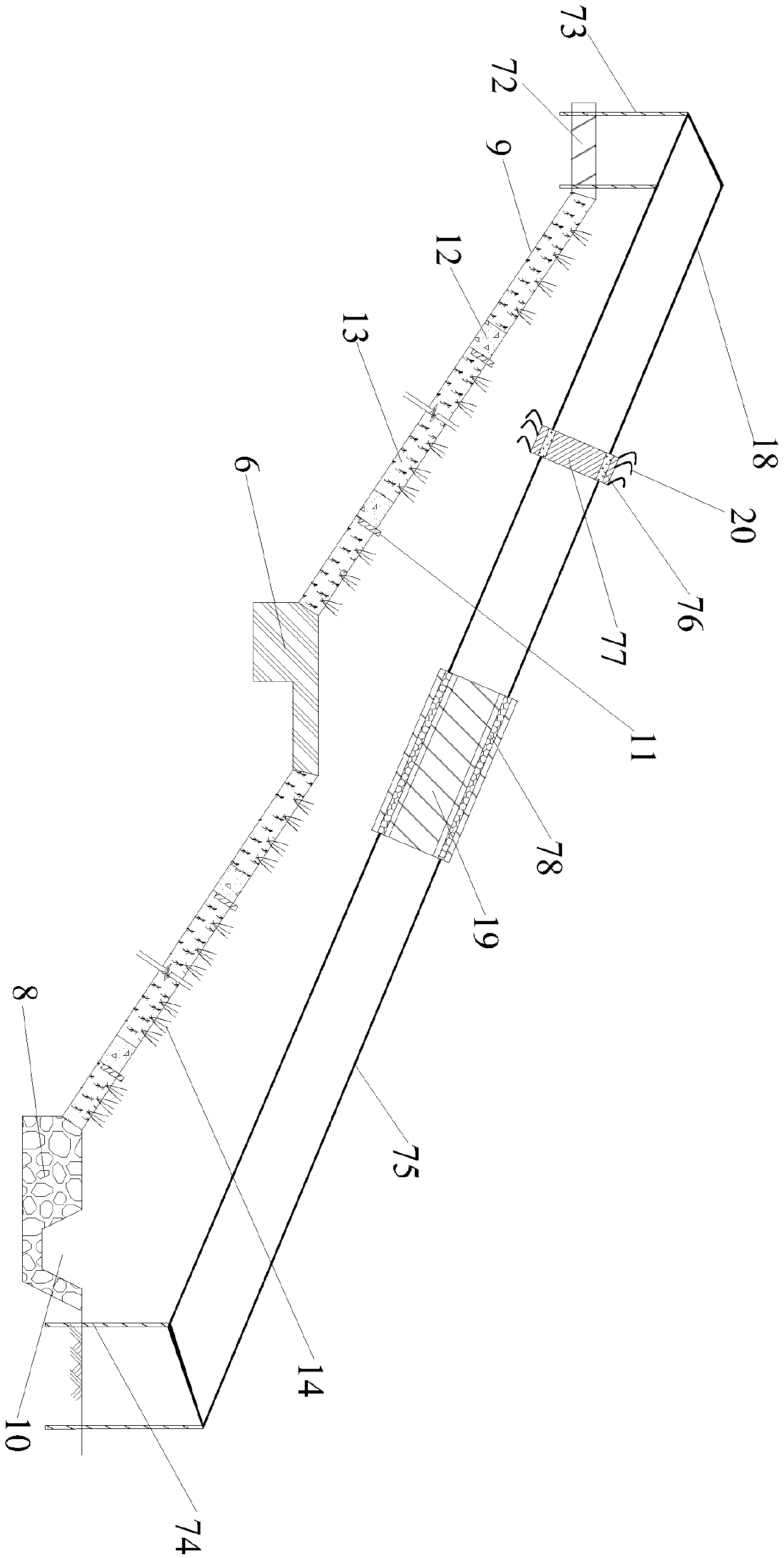

Cut-off embankment side slope ecological protection and construction method

InactiveCN109610484ASimple designSimple and fast constructionBalustradesPaving gutters/kerbsVegetationEngineering

The invention relates to the technical field of civil engineering, in particular to an ecological protection system of a cut-off embankment side slope, and is suitable for ecological protection construction of a cut-off embankment side slope. The ecological protection system for the cut-off embankment side slope comprises a herringbone framework structure, a lining concrete precast block structurewith bottom supporting, pulling and pressing stability, and a shaped sliding type material conveying and curing slope frame structure. The invention deepens the design of the herringbone framework side slope protection system, the slope protection design and construction are simple and convenient, a good side slope protection effect is achieved, natural vegetation is recovered, erosion and weathering of a side slope are prevented, water and soil loss is prevented, and environmental protection is facilitated. Meanwhile, the invention further provides a construction method, the method is convenient to construct, the construction progress is accelerated, devices can be recycled, side slope stair tread can be poured in a segmented mode, the construction progress is convenient to control, meanwhile, the problem of material transportation on the side slope is solved, positioning of an pre-embedded steel plate can be effectively achieved, and a guarantee is provided for installation of an embankment handrail.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Bolt net coal road spraying material

The invention relates to a bolt net coal road spraying material which is added with polyacrylate emulsion and modified on the basis of components such as cement, water reducing agent and accelerating agent. The spraying material can be separately added with 801 adherent and fly ash, silica powder and fly ash, and silica powder and sand for three different injection conditions, namely the normal enclosed environment, small water pouring environment and complicated geological structure environment of the coal road to increase the mechanical properties and using effects. The spraying material has high adhesive strength to the coal wall and the bolt net, high elongation ultimate, high tensile strength, low tensile elastic modulus, small shrinkage, much higher crack resistance, high permeability resistance and much higher compactibility, the spraying material can protect the internal bolt net from erosion and obviously slower the corrosive velocity; the spraying material has good ageing resistance and can reach the aim of delaying the corrosion of the bolt net and the coal wall. In addition, the spray layer is thin and uniform, the construction speed is quick, and the resilience rate, the dust concentration and the cost are low.

Owner:兖矿能源集团股份有限公司 +1

High-performance concrete organic-inorganic composite additive

InactiveCN102643041AReduce permeabilityProtects against weathering and deteriorationSodium silicateSurface-active agents

The invention discloses a high-performance concrete organic-inorganic composite additive. The composite additive comprises the following components by weight percent: 30-90% of active powder, 0-10% of sodium silicate and 5-70% of surface active agent. The additive disclosed by the invention is suitable for long-distance transportation; by using the additive, the compaction is increased, the durability is improved, and concrete can obtain high early strength. The additive is especially suitable for steaming and improvement of early strength.

Owner:SHANGHAI ZHONGJI PILE IND

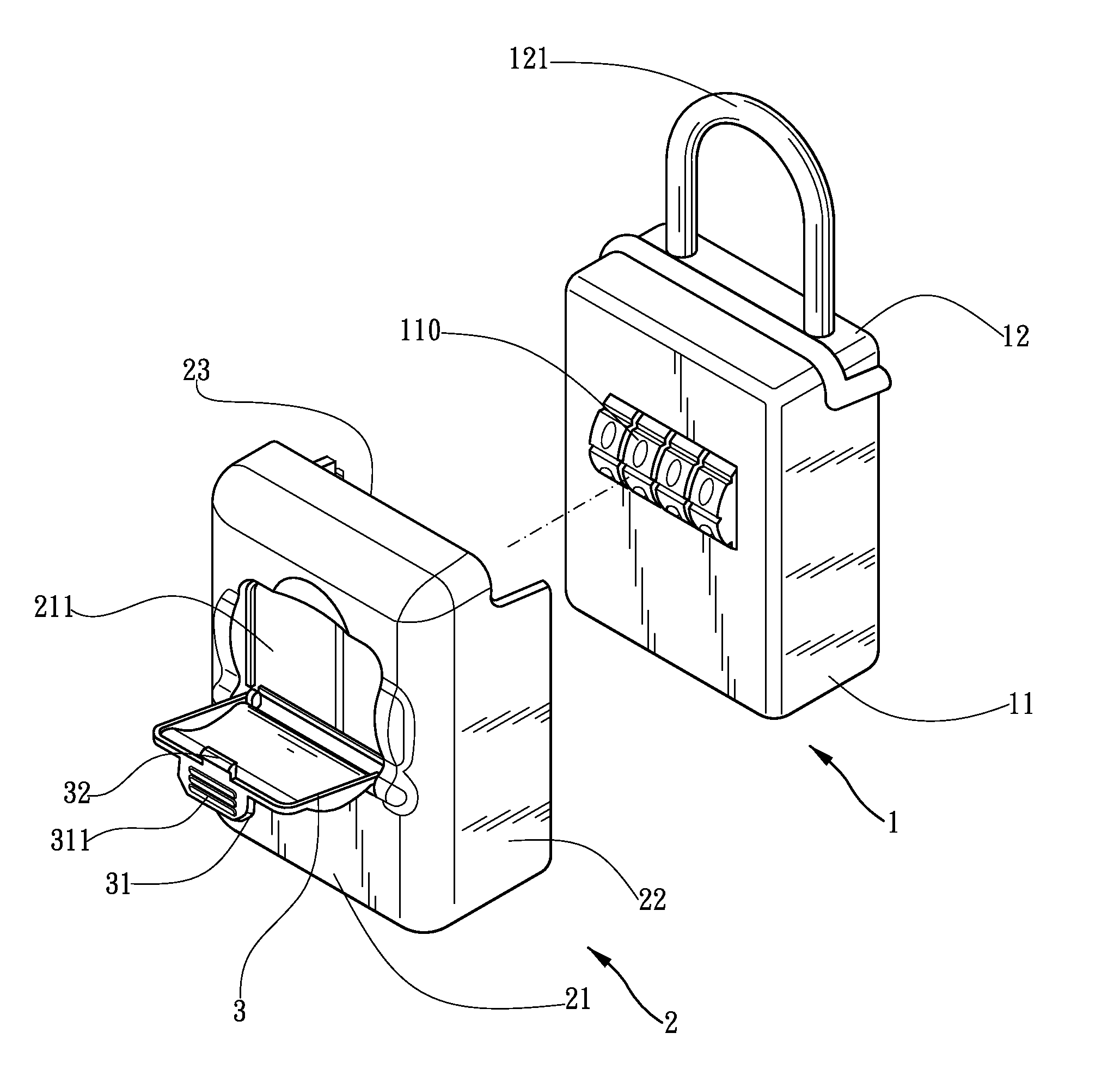

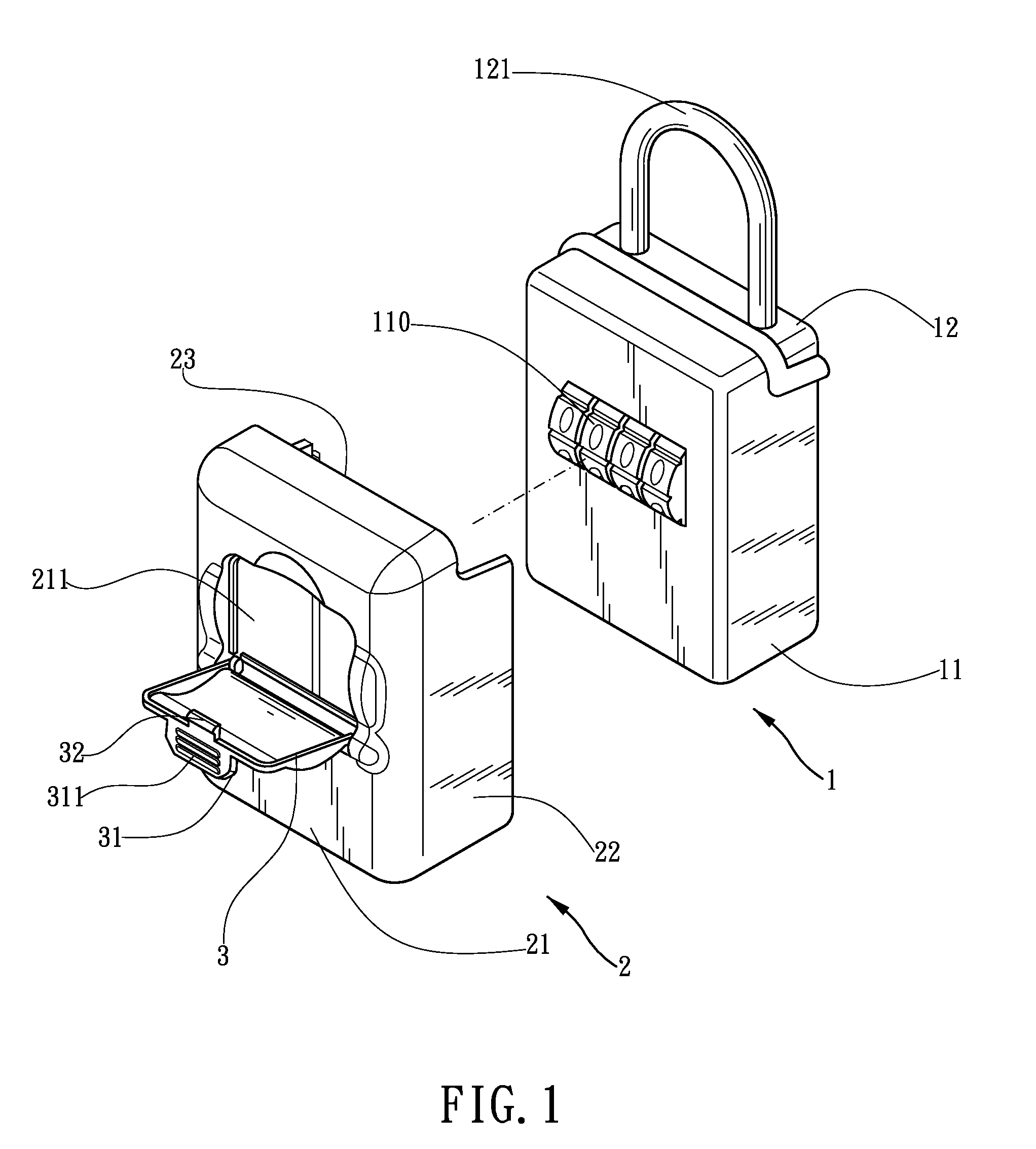

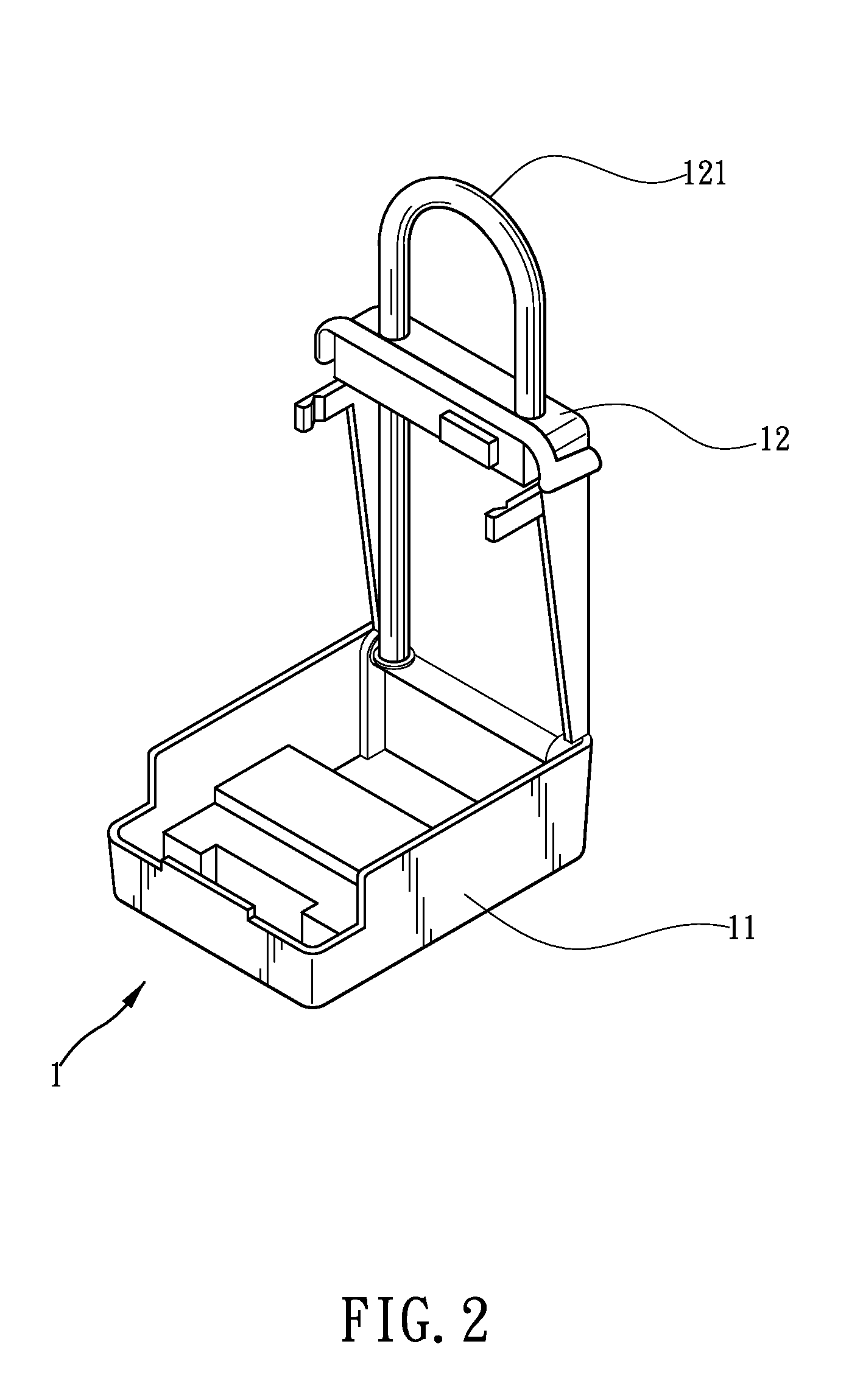

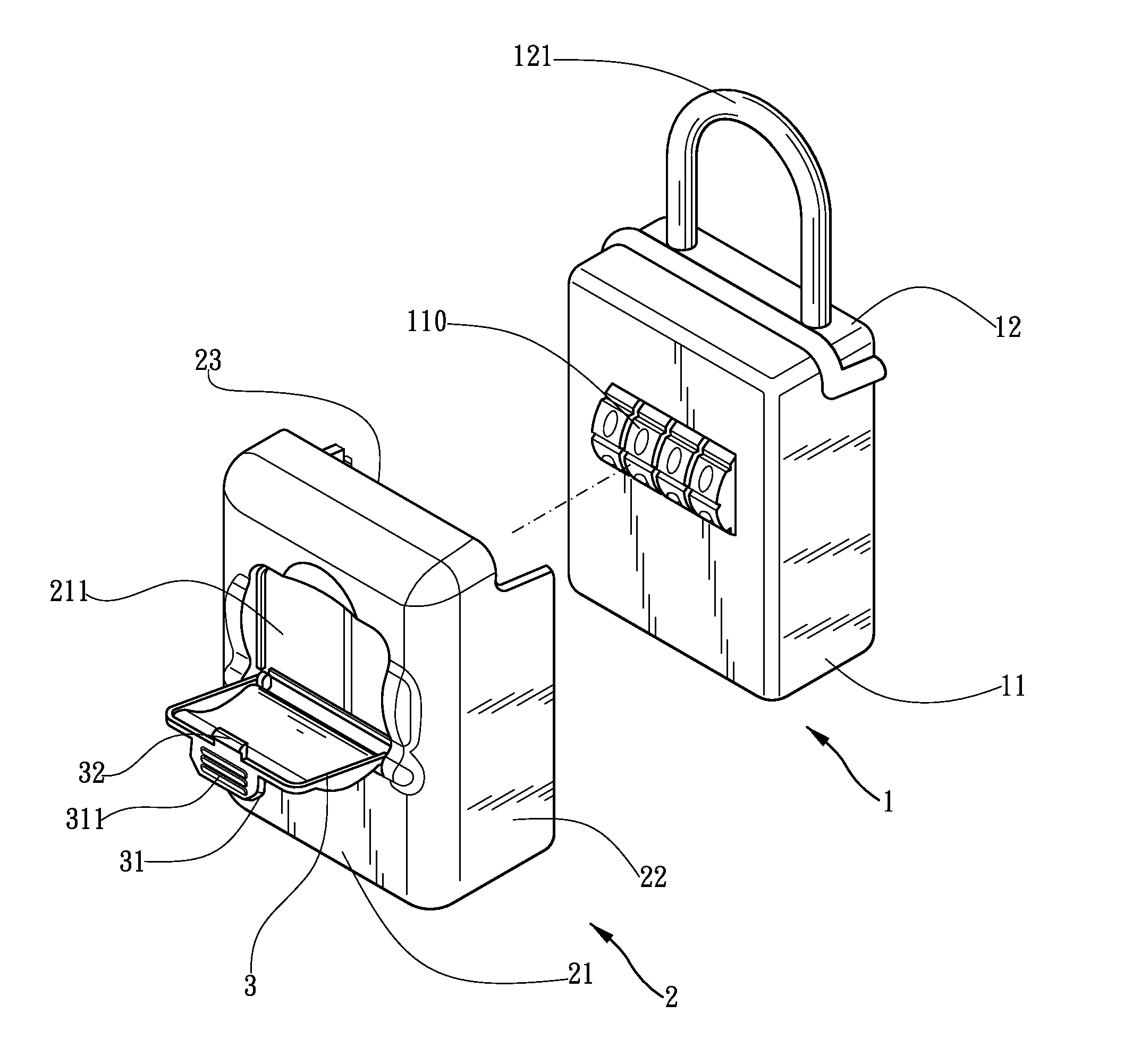

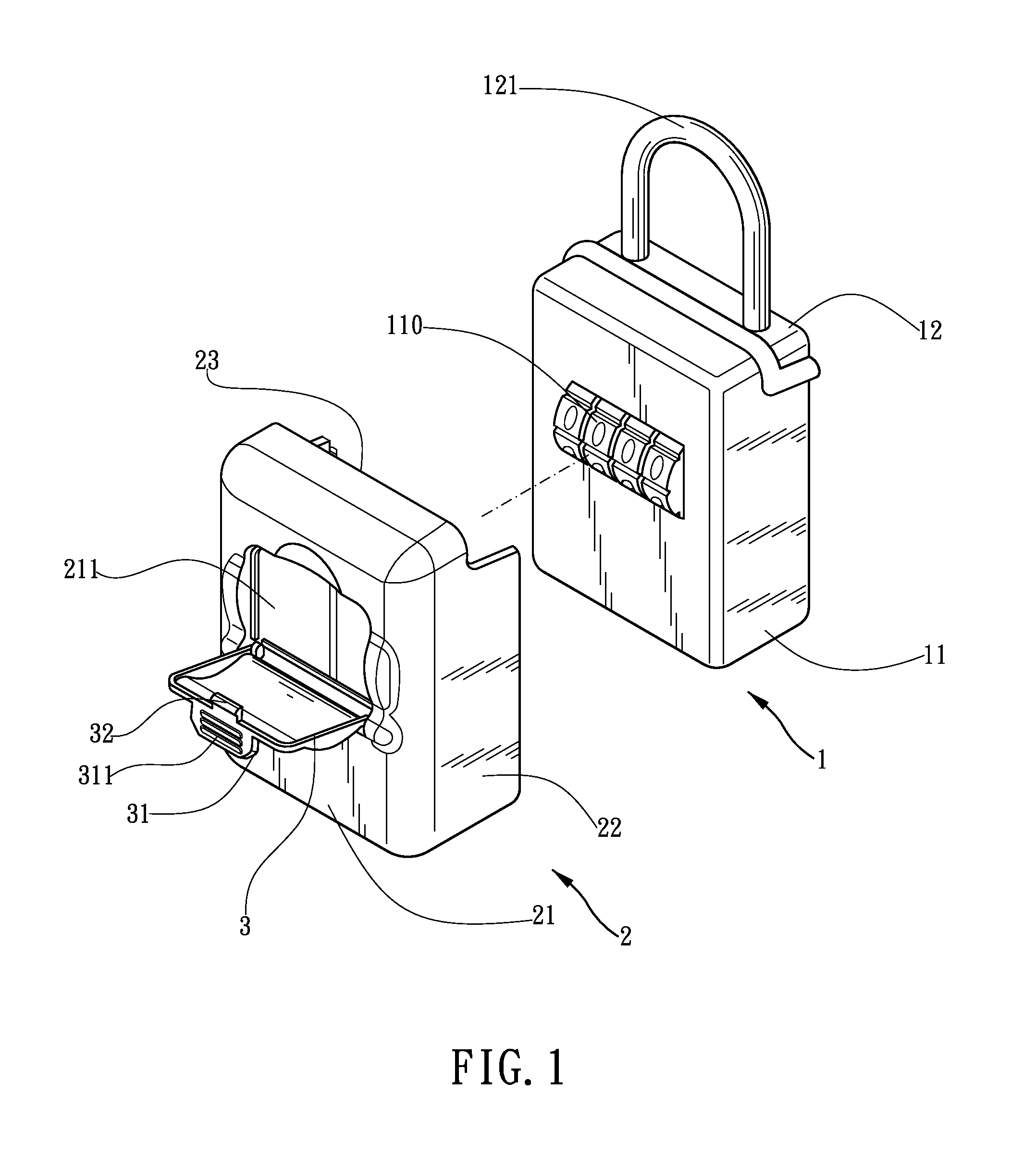

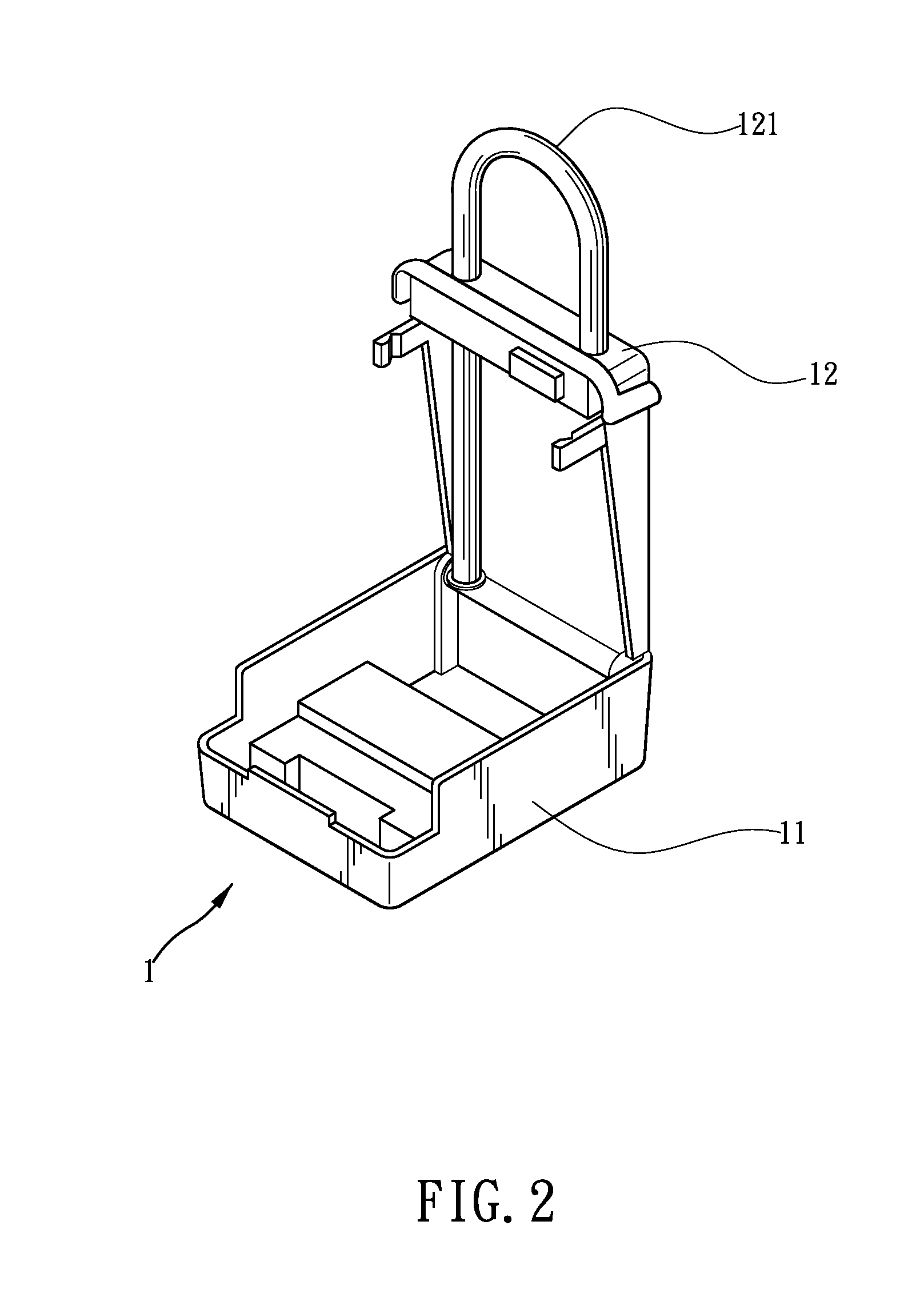

Lock box assembly

Owner:YANG YAO KUN

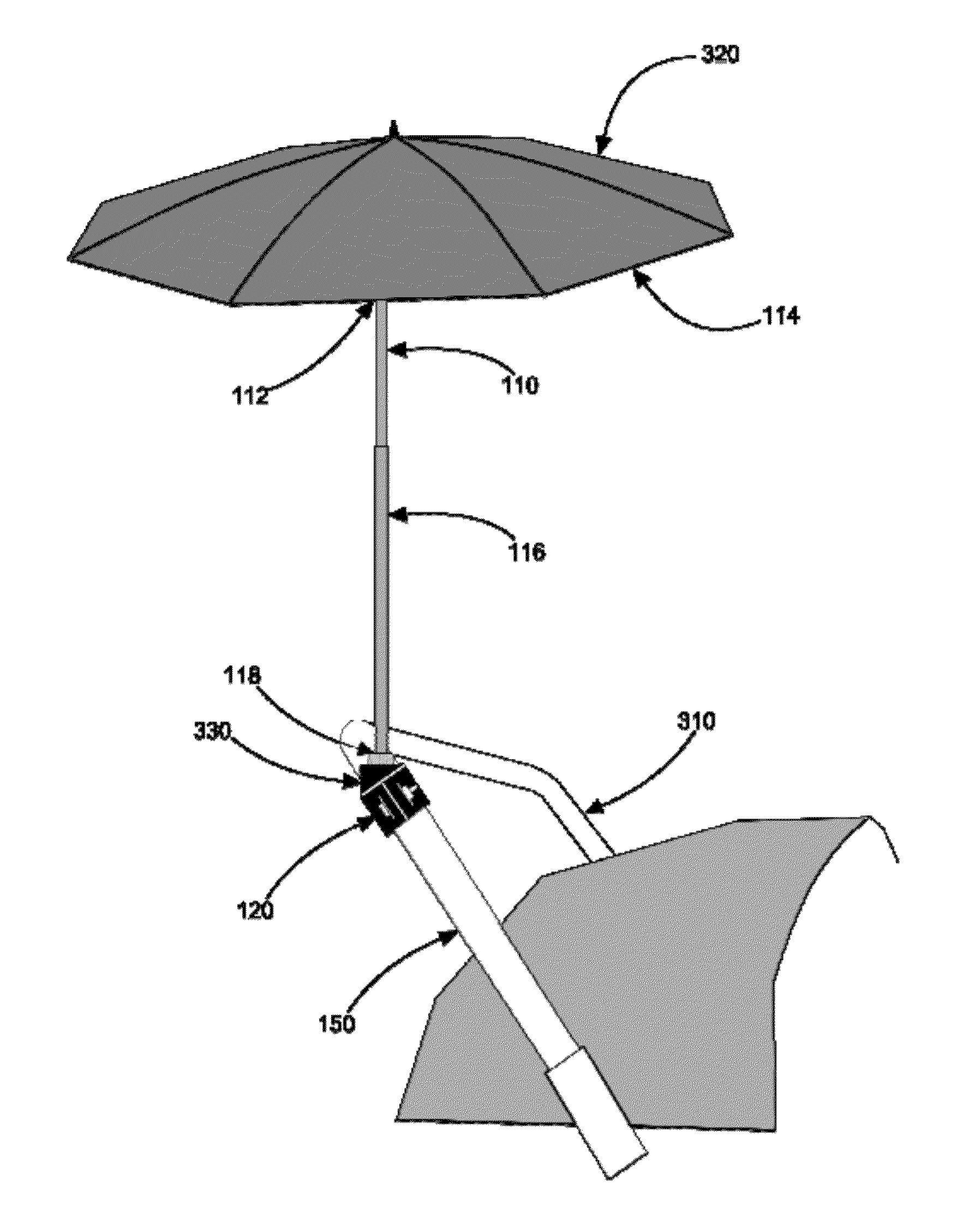

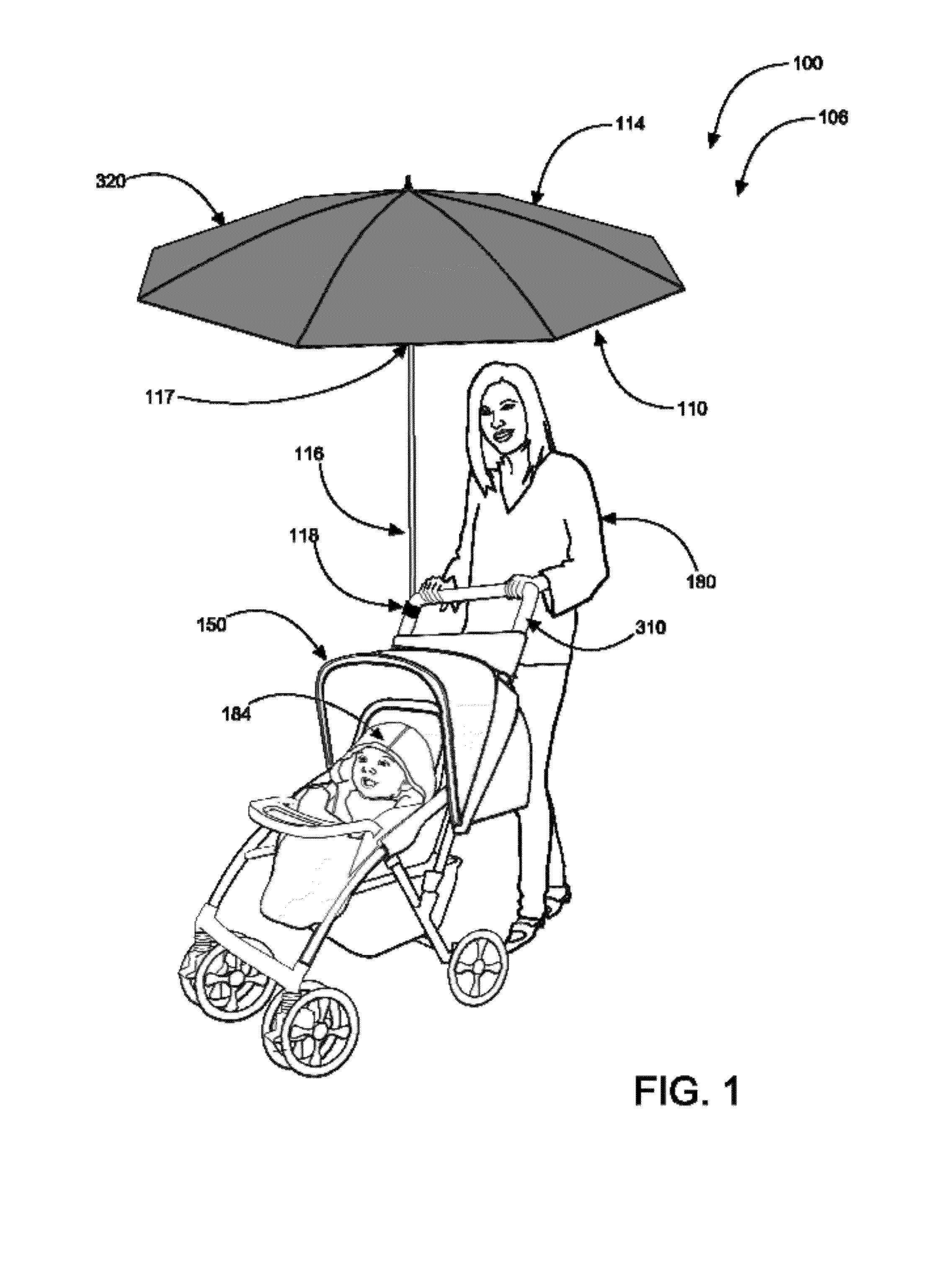

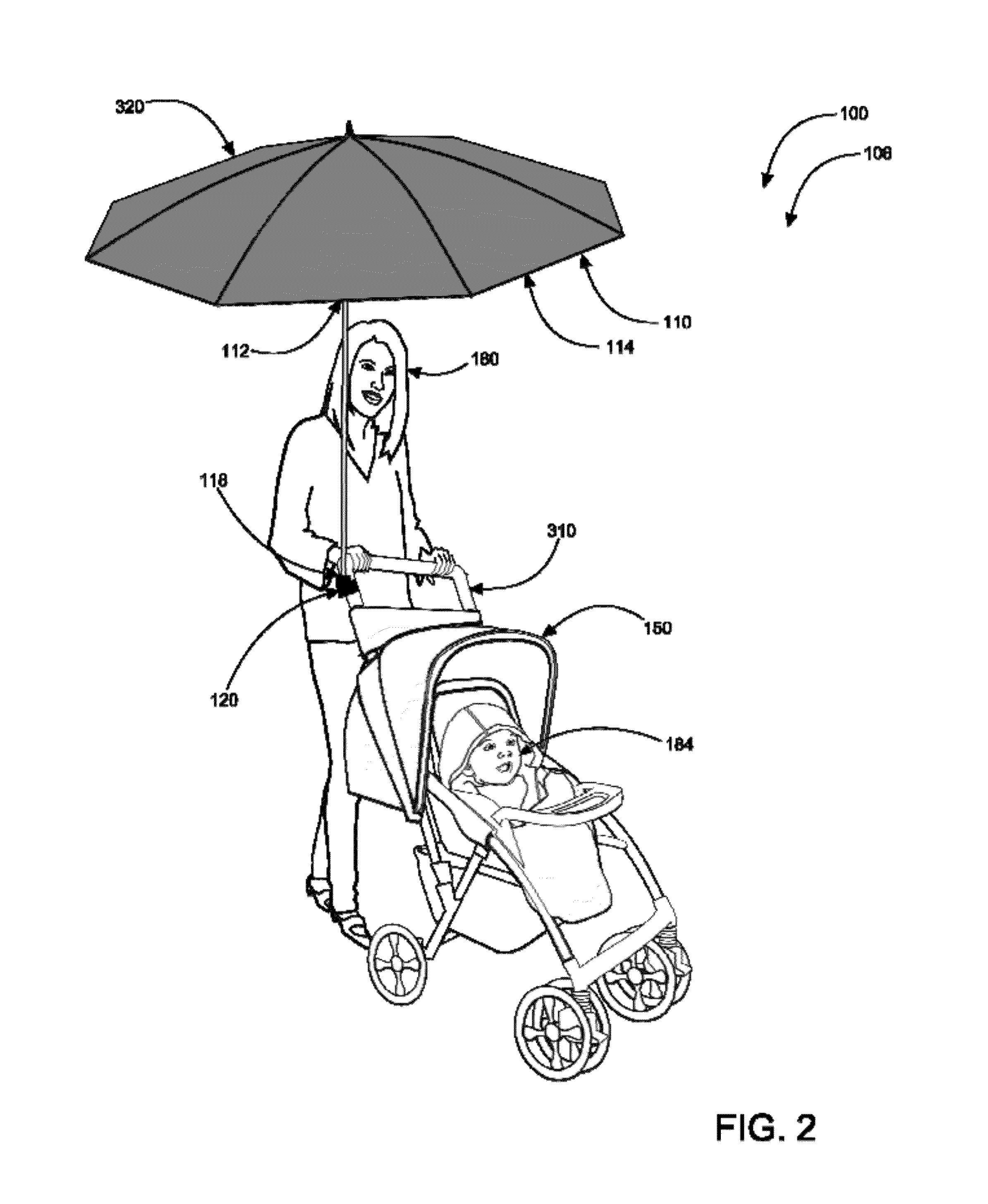

Stroller umbrella systems

InactiveUS20120048316A1Prevent weatheringEasy to disassembleWalking sticksUmbrellasEngineeringWater resistant

A stroller umbrella system comprising a removably-attachable user-adjustable umbrella serving to function as a water-resistant canopy to protect at least one occupant (and or user-pusher); at least one hinged adjustable clamp comprising a ball and socket assembly, and a push button release mechanism located on a tube which permits the user to open and close the water-resistant canopy on demand. The ball and socket assembly enables the occupant to adjust at least one orientation of the water-resistant canopy thereby blocking weather from the occupant from virtually any direction. The adjustable clamp is located on the stroller for removably coupling the removably-attachable user-adjustable umbrella to the stroller.

Owner:FOURNILLIER SOLANGE

High-strength cement sound-absorbing plate

InactiveCN103469739AAvoid enteringPrevent vandalismNoise reduction constructionAccelerated agingFreeze and thaw

The invention relates to a high-strength cement sound-absorbing plate, which comprises a sound-absorbing layer and a sound-insulating layer, wherein a cavity is formed between the sound-absorbing layer and the sound-insulating layer; sound-absorbing materials are filled into the cavity; the surface of the sound-absorbing layer is provided with a plurality of shutter-type sound-absorbing holes communicated with the cavity. The gradient of a shutter-type sound-absorbing hole window is set in such a manner that dust, rain and snow can be prevented from entering the inside of the sound-absorbing plate, and the sound-absorbing material is prevented from being corroded by rain and snow; the surface of the sound-absorbing plate has a hydrophobic effect, so that the problem of accelerated aging caused by freezing and thawing effects can be solved effectively, damages of moisture and cold to the sound-absorbing plate are prevented, and meanwhile weathering can be prevented; the high-strength cement sound-absorbing plate is molded at a time via a mold, and a unit plate has high structural stability and high structural strength; perlite and the like are taken as sound-absorbing materials, so that the structural strength of the sound-absorbing plate is enhanced while the sound-absorbing effect is ensured.

Owner:JIANGSU DONGZE ENVIRONMENTAL PROTECTION TECH

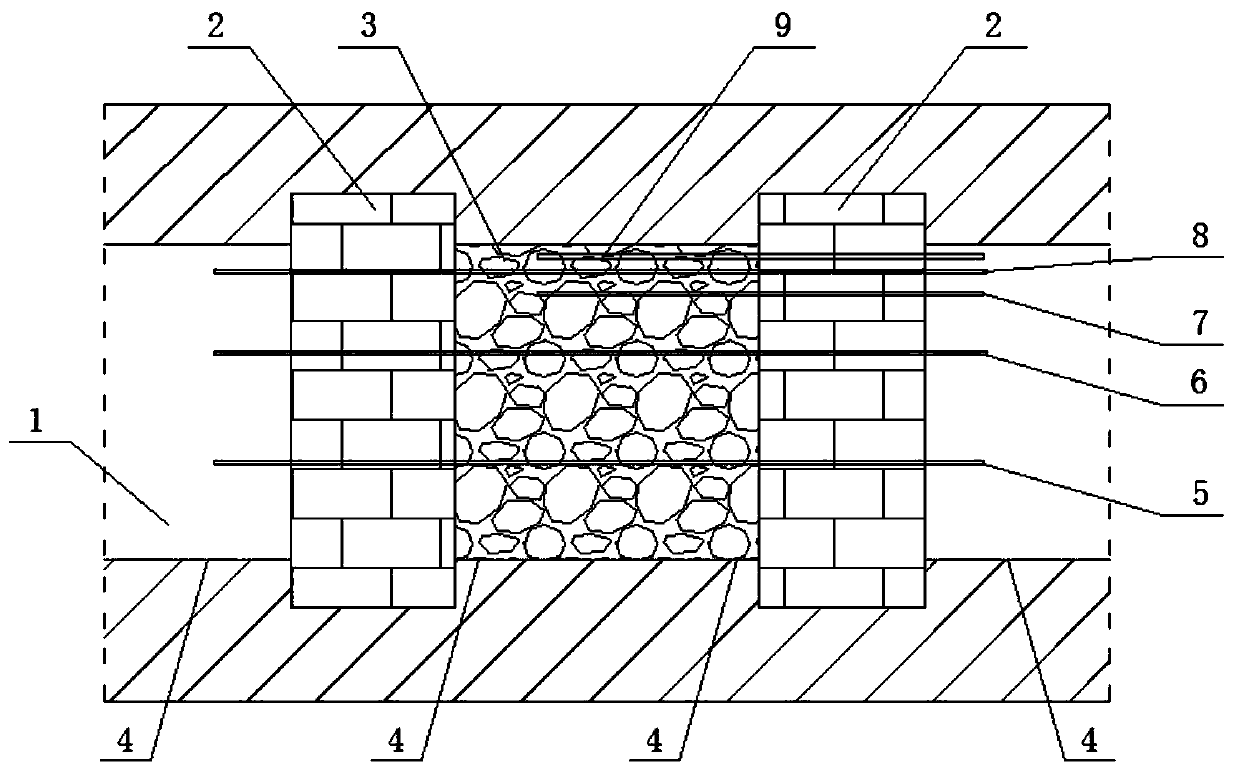

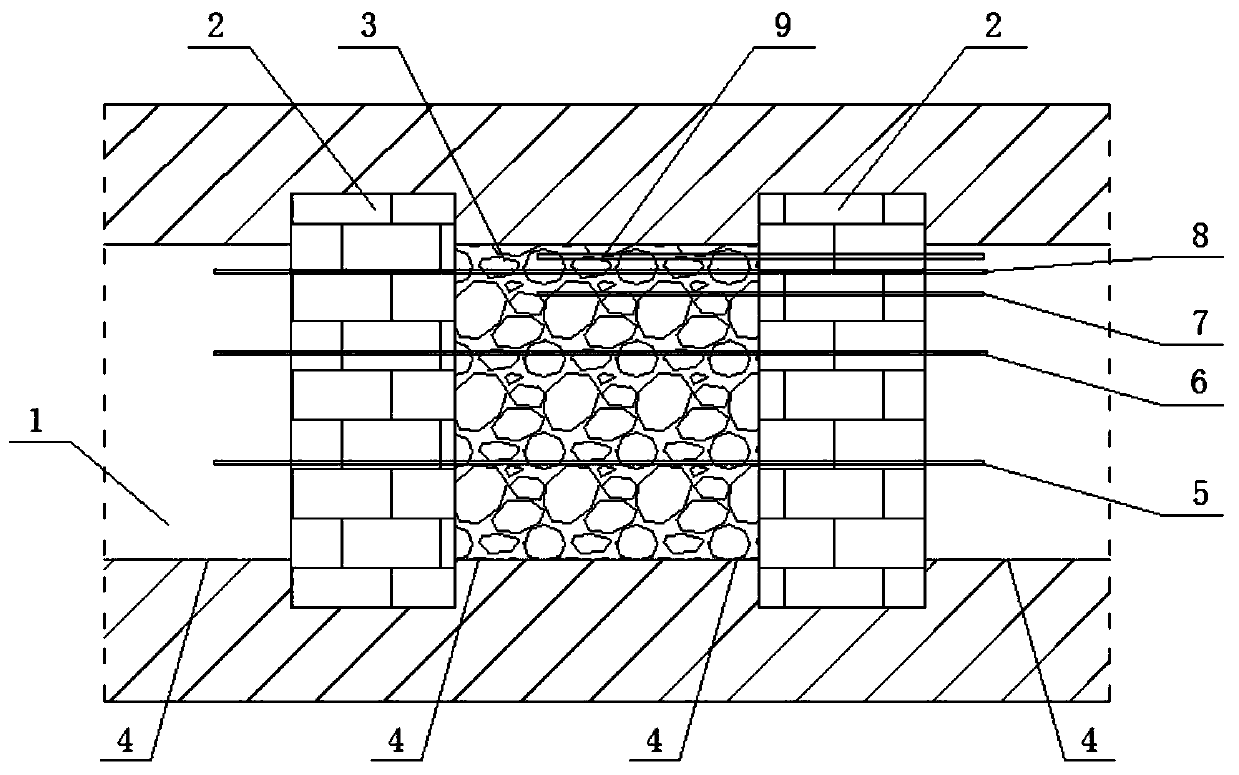

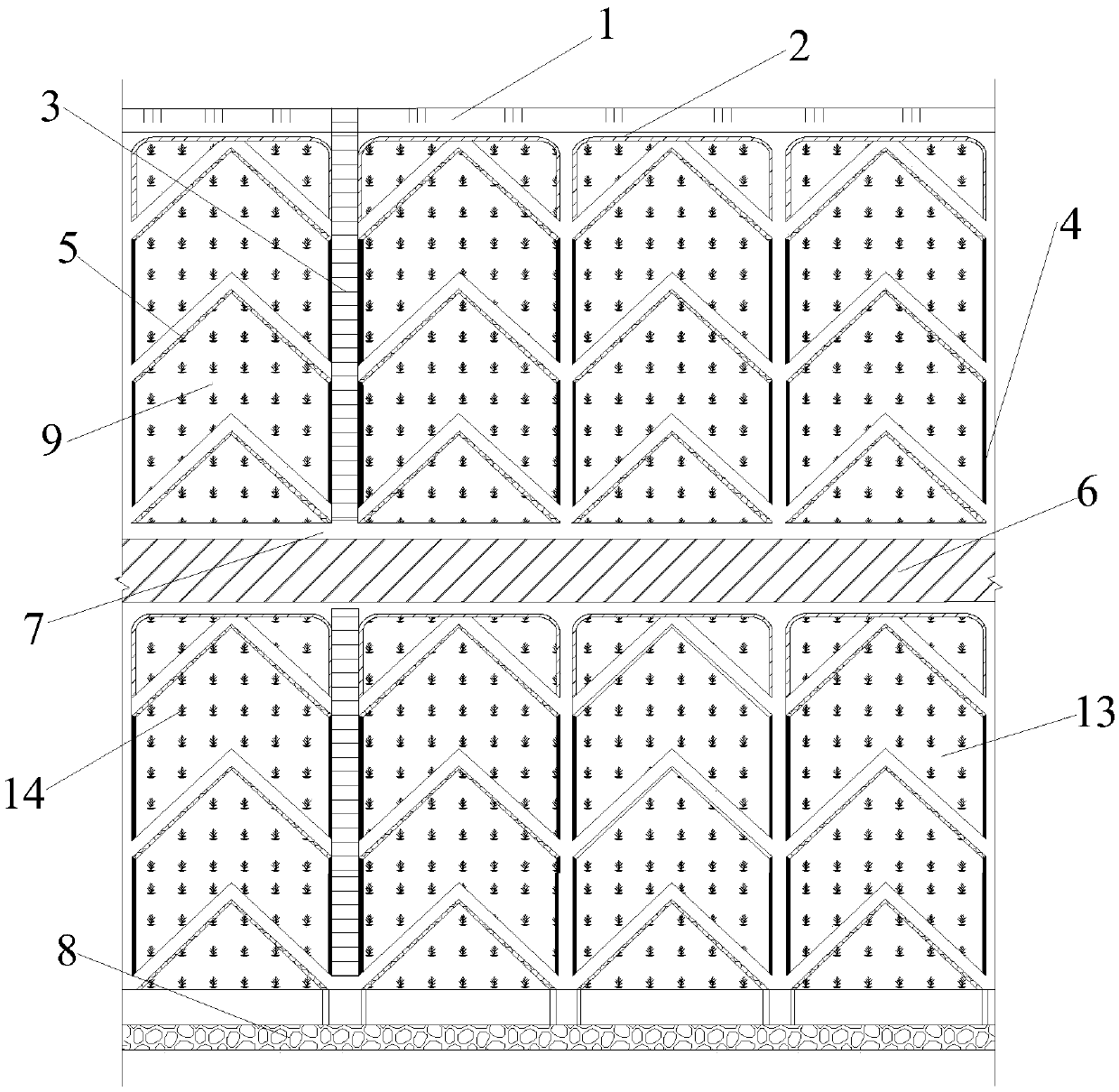

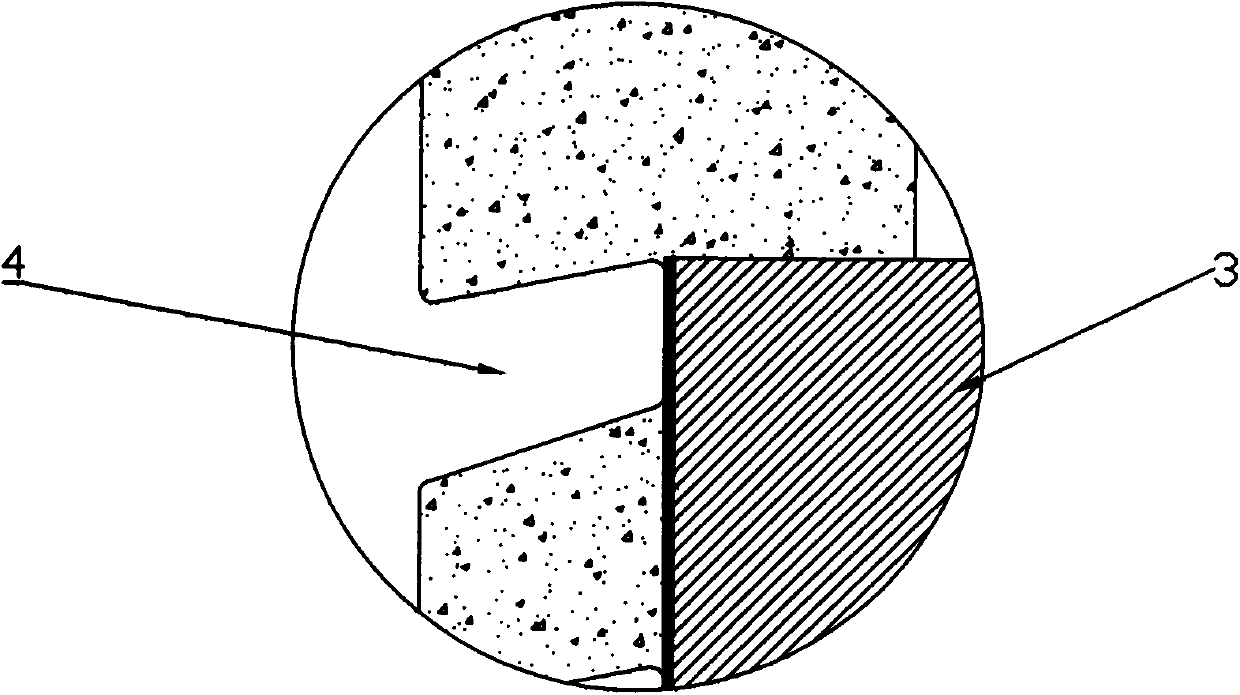

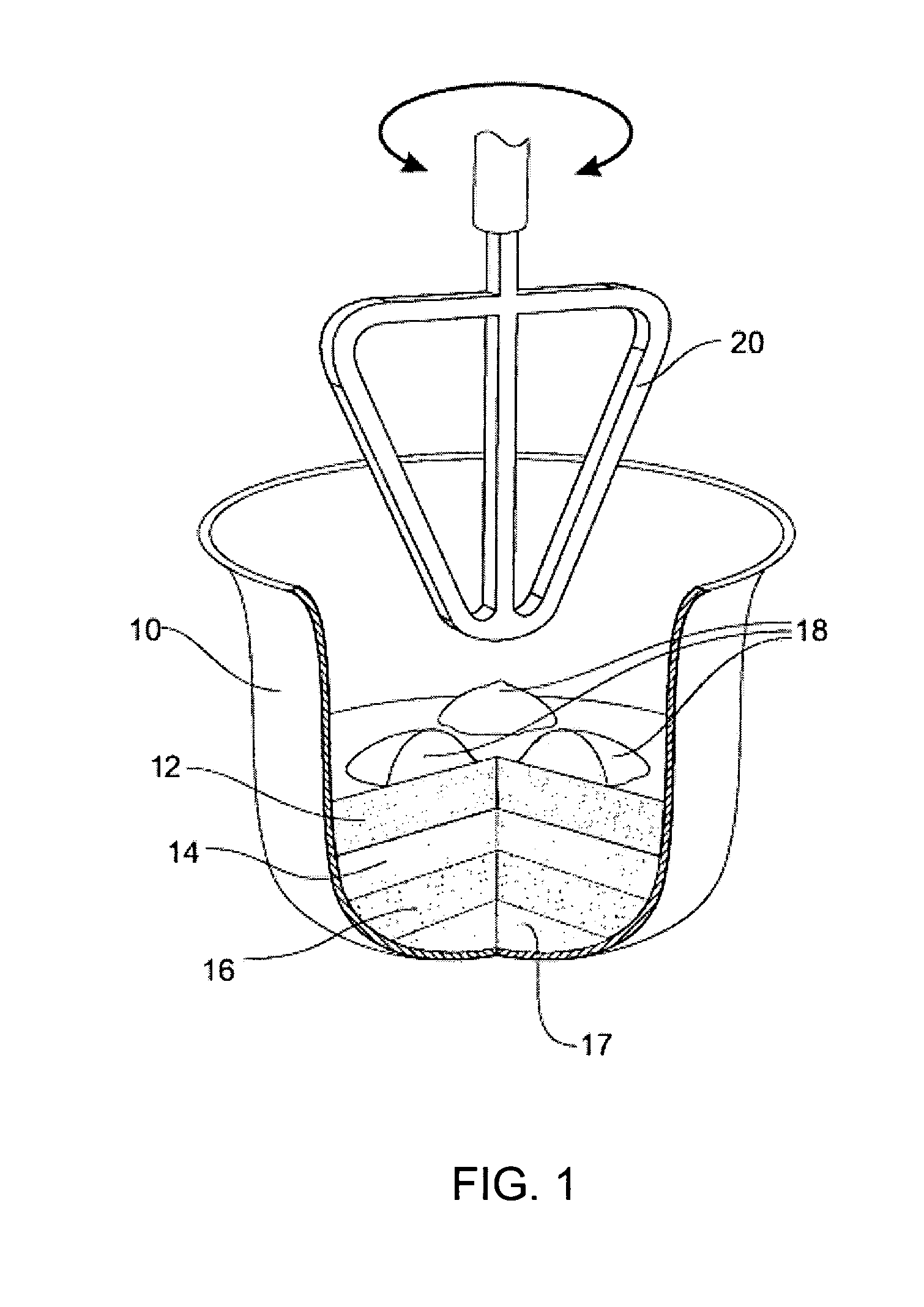

Method for mining thick ore body through segmental ore breaking and subsequent cemented filling

InactiveCN107130962AEnsure safety and stabilityPrevent weatheringUnderground chambersUnderground miningShotcreteMesh reinforcement

The invention discloses a method for mining a thick ore body through segmental ore breaking and subsequent cemented filling. The method comprises the following steps: 1) dividing the ore body into a plurality of segments along the vertical direction of the ore body; 2) dividing the ore body into a plurality of stopes in each segment along the trend of the ore body; 3) arranging rock drilling roadways along a direction perpendicular to the trend of the ore body in each stope, wherein the rock drilling roadways penetrate the ore body and extend to the hanging wall rock of the ore body; 4) supporting the rock drilling roadways formed in the step 3): a, spraying concrete onto the wall surfaces of the roadways; b, knocking anchor poles into the two sides and the tops of the roadways; c, fixedly laying steel mesh reinforcement onto the two sides of the roadways; and d, spraying a 100-mm-thick layer of concrete onto the surfaces of the steel mesh reinforcement; and 5) carrying out mining: a, mining the ore body from hanging segment to footwall segment successively; and b, mining every stope in each segment in such a manner that primary mining is carried out on odd or even stopes at first and then secondary mining is carried out on the rest stopes.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

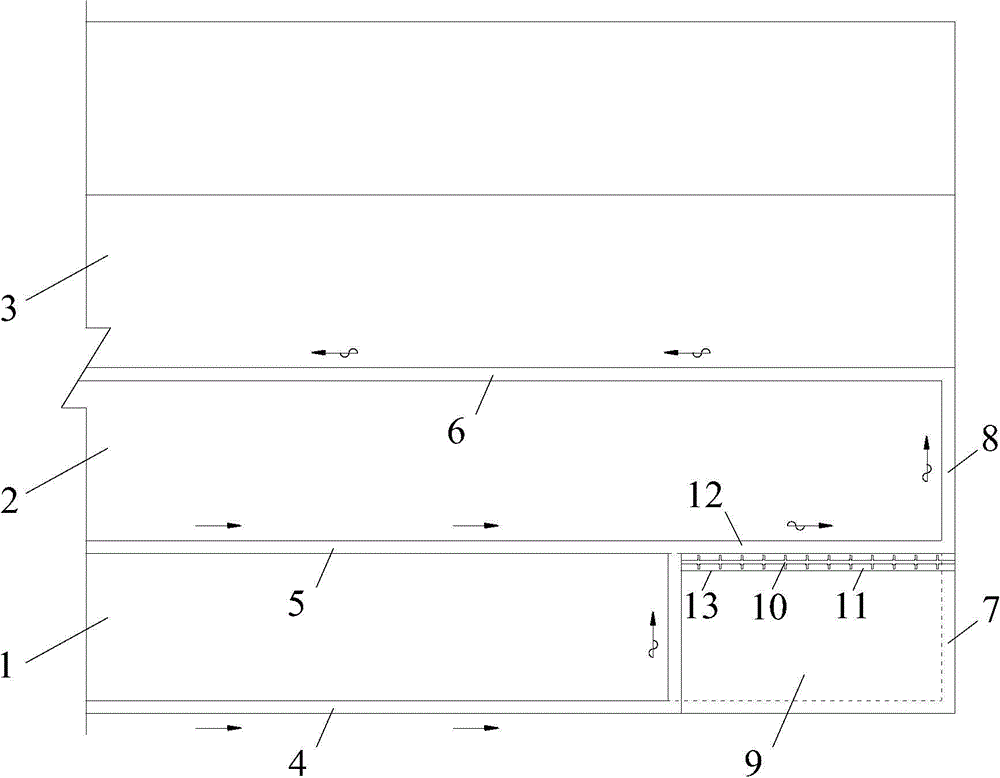

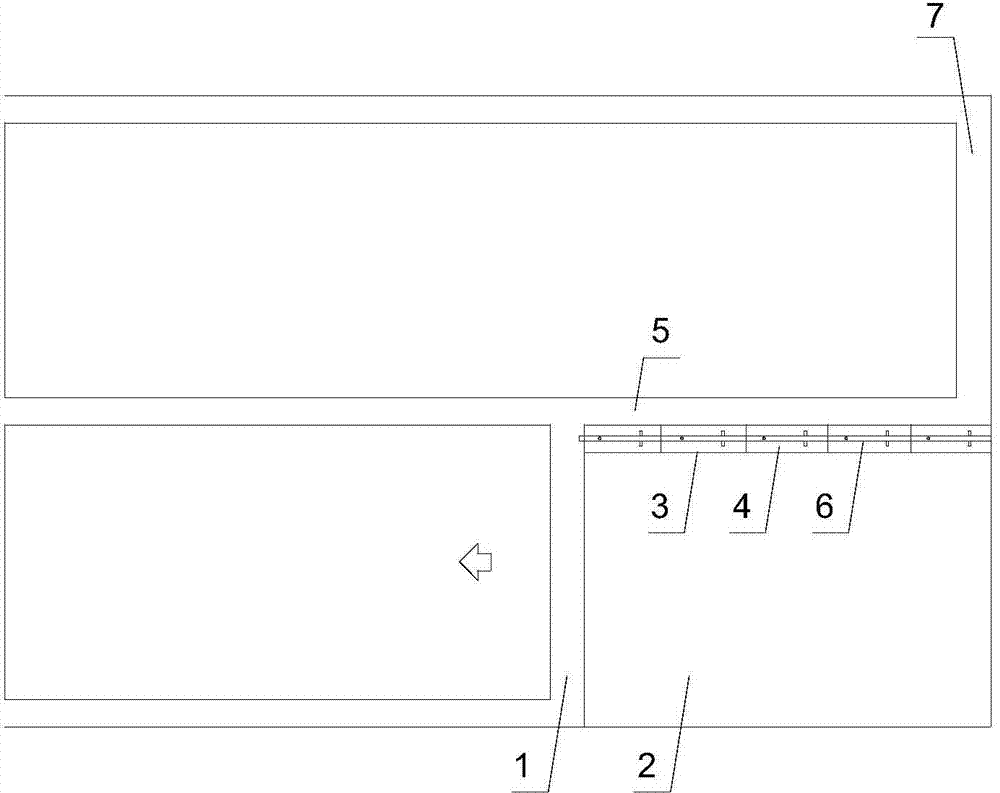

Non chain pillar gob-side entry retaining method with filling wall self-erasure

ActiveCN104727847AGive full play to supportPrevent weatheringUnderground miningSurface miningStress concentrationCarbonization

The invention provides a non chain pillar gob-side entry retaining method with filling wall self-erasure, and applicable to shaft and drift supporting engineering. During the exploitation of an upper section coal face, a high-water material is pumped into a flexible mold bag along the edge of a goaf, a roadside filling wall is formed by construction, and a breather pipe is pre-arranged in the filling wall; during the exploitation of a lower section coal face, the flexible mold bag behind the coal face is cut, after the exploitation is completed, carbon dioxide is injected into the breather pipe, carbonization reaction occurs on the filling wall, and the filling wall is broken and decomposed, so that the self-erasure of the roadside wall is achieved. According to the method, during the gob-side entry retaining service period, the high-supporting performance of a high-water material roadside wall is fully come into play, after the gob-side entry retaining is scrapped, the self-erasure of the filling wall can be achieved, the stress concentration generated by the leftover of the filling wall is prevented, the effect of full pressure relieving on upper and lower adjacent coal beds is achieved, and the method has the positive effect on mining space maintenance, gas extraction and dynamic disaster prevention and treatment.

Owner:CHINA UNIV OF MINING & TECH

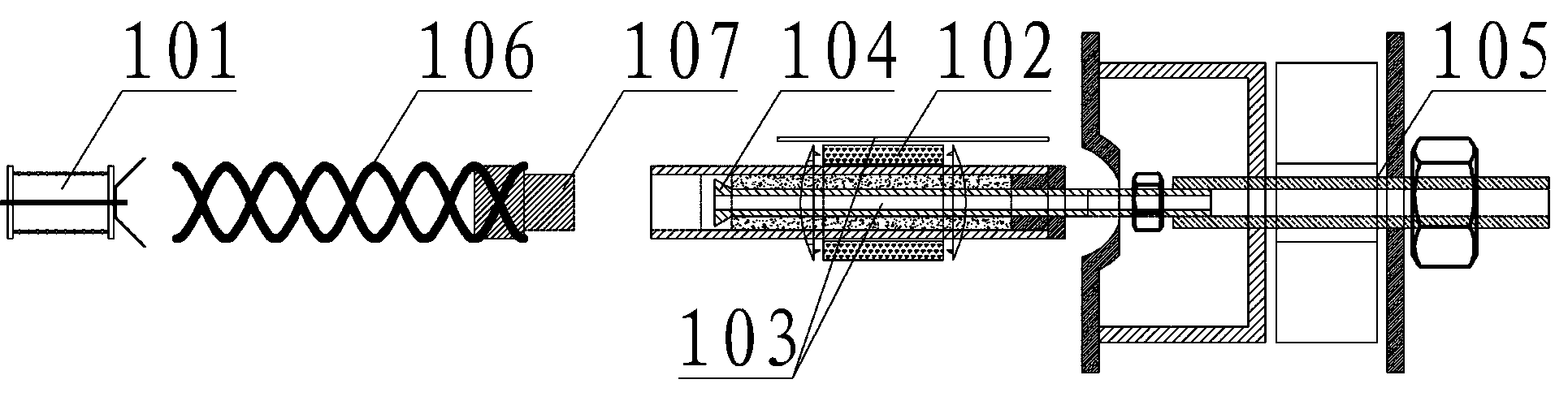

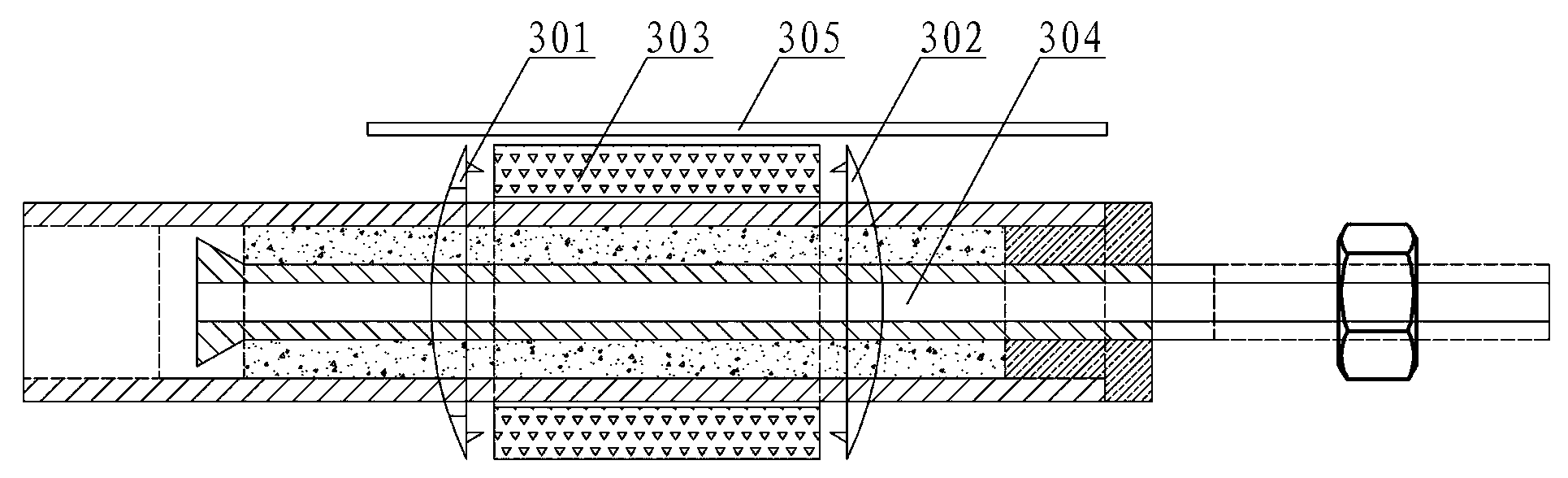

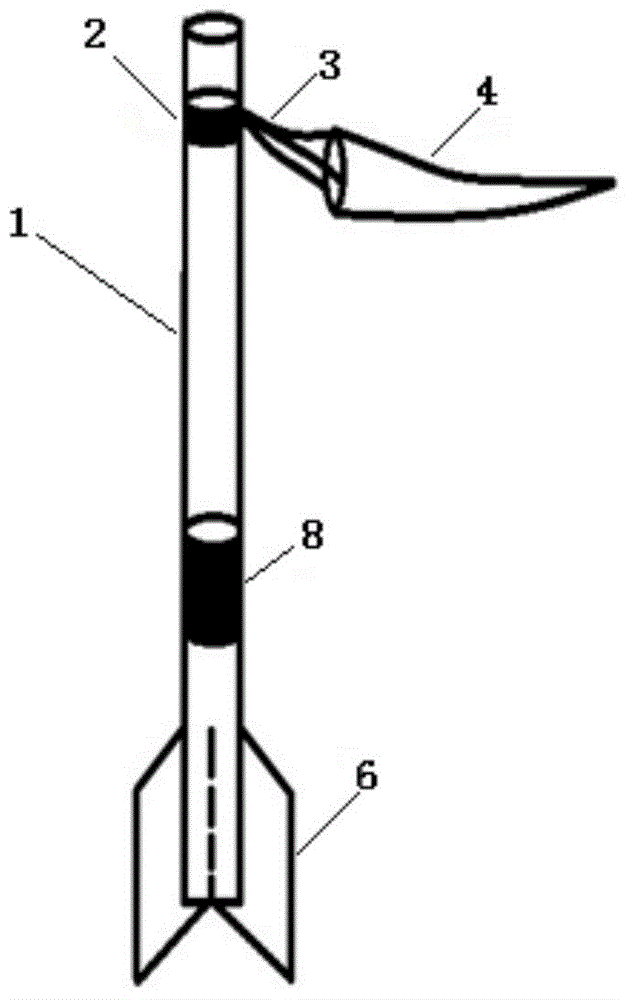

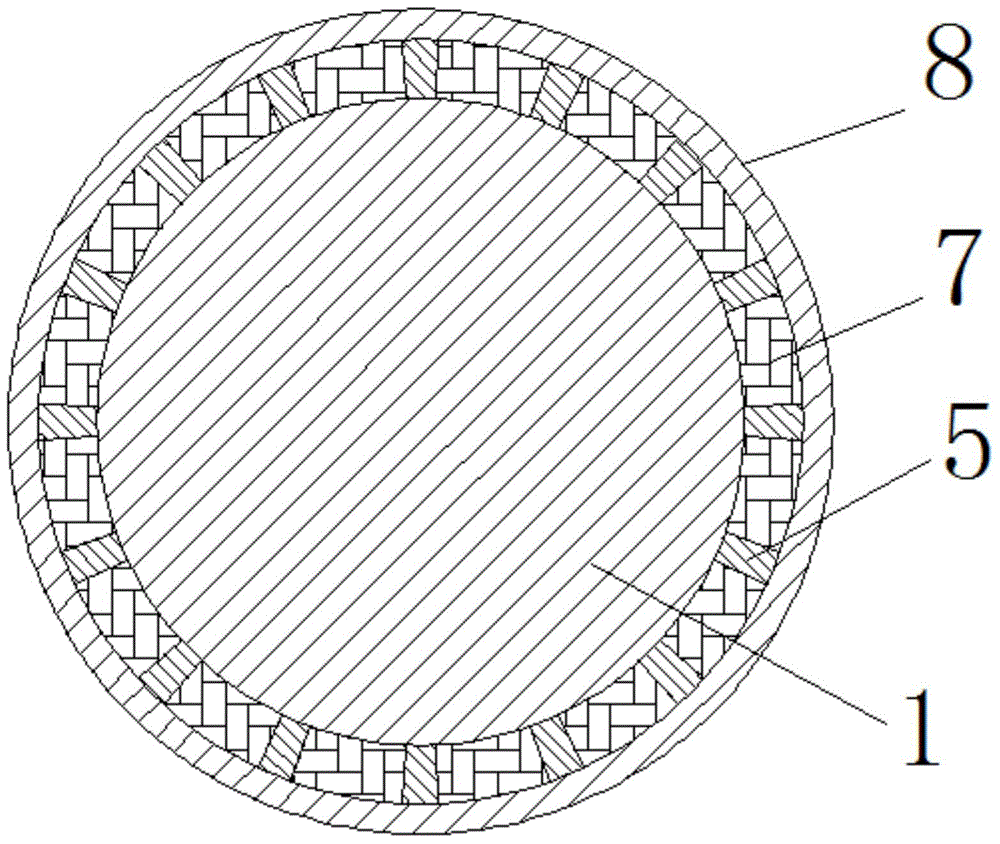

Perforation big head slip casting constant resistant anchor rod

The invention discloses a perforation big head slip casting constant resistant anchor rod in mining tunnel supporting equipment. The perforation big head slip casting constant resistant anchor rod mainly comprises an exploding perforation device, an O-shaped hole sealing power winding device, a high pressure slip casting device, a constant resistance deformation device, a lengthening detection device and an extending anchor rope device. The above-mentioned parts are used for forming a perforation big head slip casting constant resistant anchor rod structure. The exploding perforation device is used for enabling the perforation to be cracked at the end socket of the anchor rod. The O-shaped hole sealing power winding device is used for sealing the perforation and fixing the anchor rod in the middle or any other reasonable positions of the anchor rod. The high pressure slip casting device is used for injecting slurry to form the big head slip casting anchor rod in the end socket of the anchor rod. The constant resistance deformation device is arranged in the middle of the anchor rod. The lengthening detection device is arranged at the tail of the anchor rod. The extending anchor rope device is arranged at the end socket of the anchor rod. The problems that a cone stress structure of the end socket of the anchor rod cannot deform and detecting devices cannot be recycled are solved. The perforation big head slip casting constant resistant anchor rod has the advantages of constant resistance deformability, recycling of the detecting devices and a half-space stress structure of the big head of the end socket of the anchor rod, and build-up arch intensity of anchor rod supporting is strengthened.

Owner:尤洛卡(山东)矿业科技有限公司

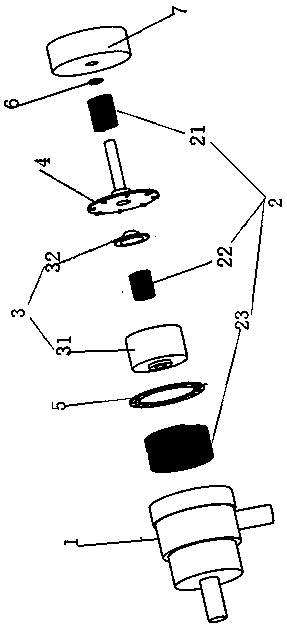

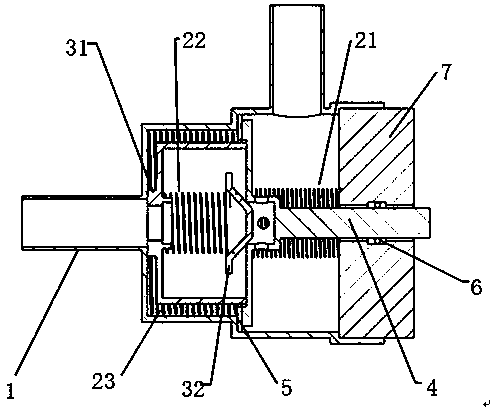

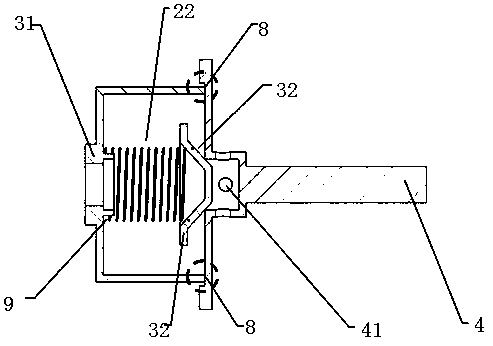

Novel automobile high-pressure-resistant oil tank isolation valve

PendingCN107606179AEmission reductionMeet emissionsOperating means/releasing devices for valvesNon-fuel substance addition to fuelIsolation valveFuel tank

The invention relates to a novel automobile high-pressure-resistant oil tank isolation valve. The novel automobile high-pressure-resistant oil tank isolation valve is characterized in that the oil tank isolation valve comprises an isolation valve body, a spring assembly, a valve core assembly, a supporting rod, a restrictor ring, a sealing ring and an electromagnetic valve; the spring assembly, the valve core assembly, the restrictor ring, the supporting rod and the sealing ring are all arranged in the isolation valve body; and the electromagnetic valve is arranged at the end of the isolationvalve body. According to the technical scheme, the novel automobile high-pressure-resistant oil tank isolation valve is simple and ingenious in structure, and the complex functions of high-pressure air exhausting, negative-pressure air supplementing, oil charging air exhausting and the like are achieved by means of a few of parts including plastic parts, springs, the electromagnetic valve, rubberparts and the like; by adjusting the diameter of a hole and the sizes of the springs, the requirements of different customers can be met; only one electromagnetic valve is adopted for the isolation valve of the structure, so that electric energy is saved; and the isolation valve of the structure is small in size and does not occupy the space of a chassis.

Owner:YAPP AUTOMOTIVE PARTS

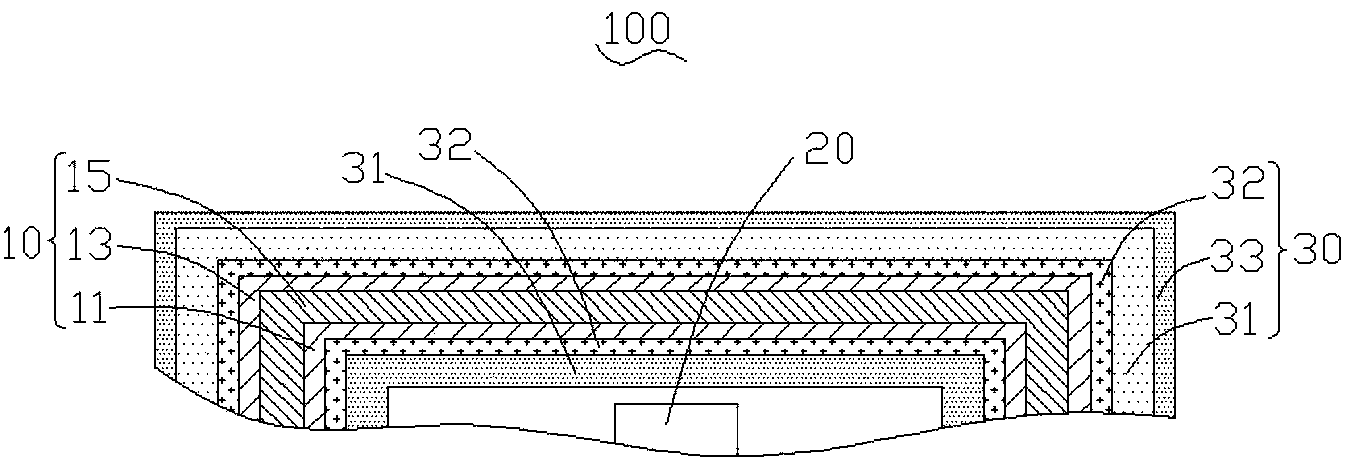

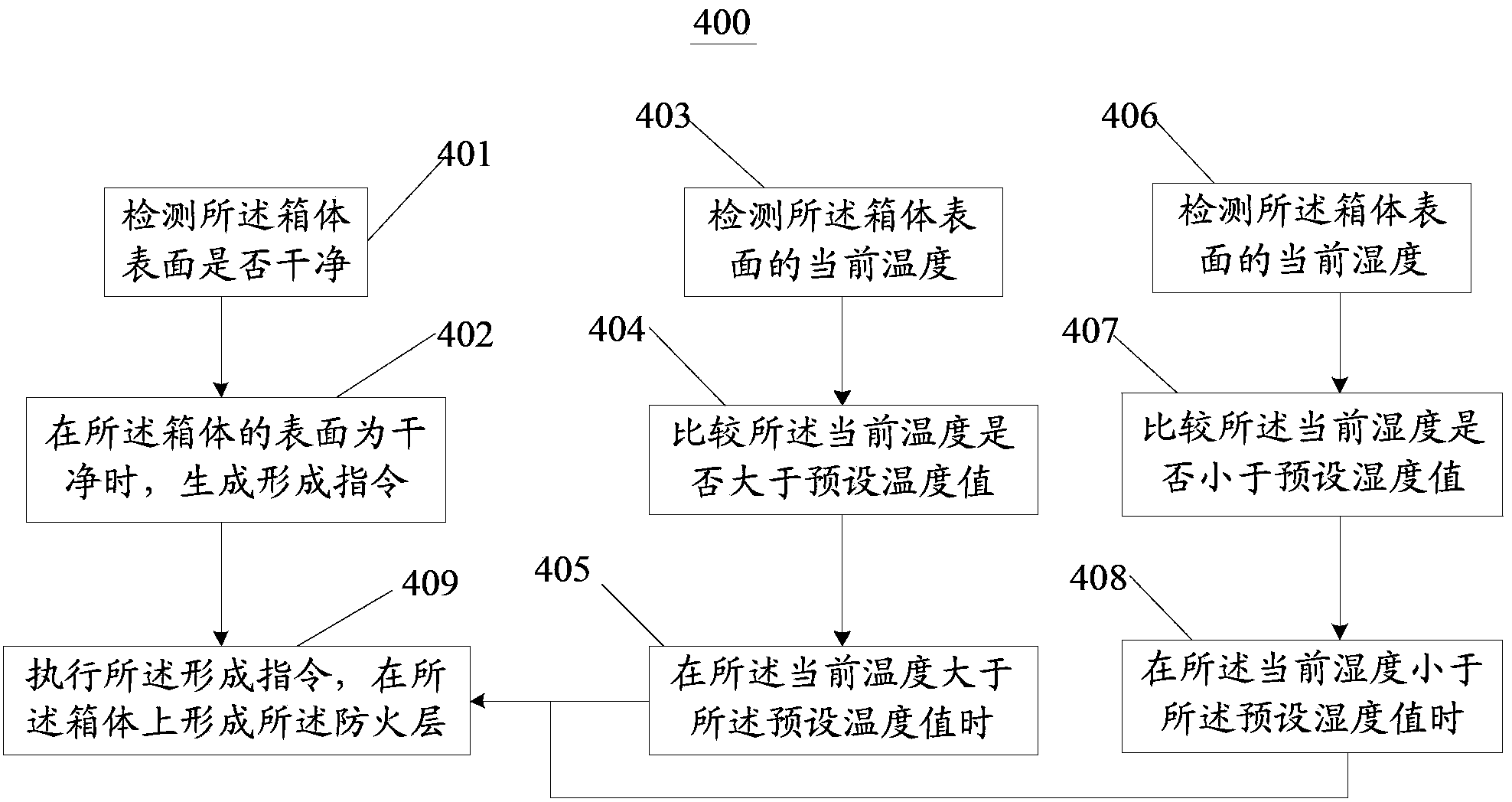

A container and fire-proof layer fabrication method thereof

InactiveCN104302141AAvoid fireImprove securityCasings/cabinets/drawers detailsMetal casingsState of artCombustion

The present invention discloses a container and a fire-proof layer fabrication method thereof. The container includes a box body containing metal plates; computing equipment, set in the box body; and a fire-proof layer, formed on the metal plates. By forming the fire-proof layer on box body, the fire-proof layer forms a uniform compact cavernous expanded thermal insulation layer immediately when encountering fire, and prevents flame from spreading effectively, thereby accomplishing the purpose of fire-proof and flame-proof and reducing toxic smoke which generated by the flame combusting. Therefore, the invention solves the technical matters of poor fire-proof, combustion, serious security risk in box body the container in the prior art, thereby accomplishes box body fire-proofing of container, and improves the technical effects in safety of the box body of container.

Owner:EMERSON NETWORK POWER CO LTD

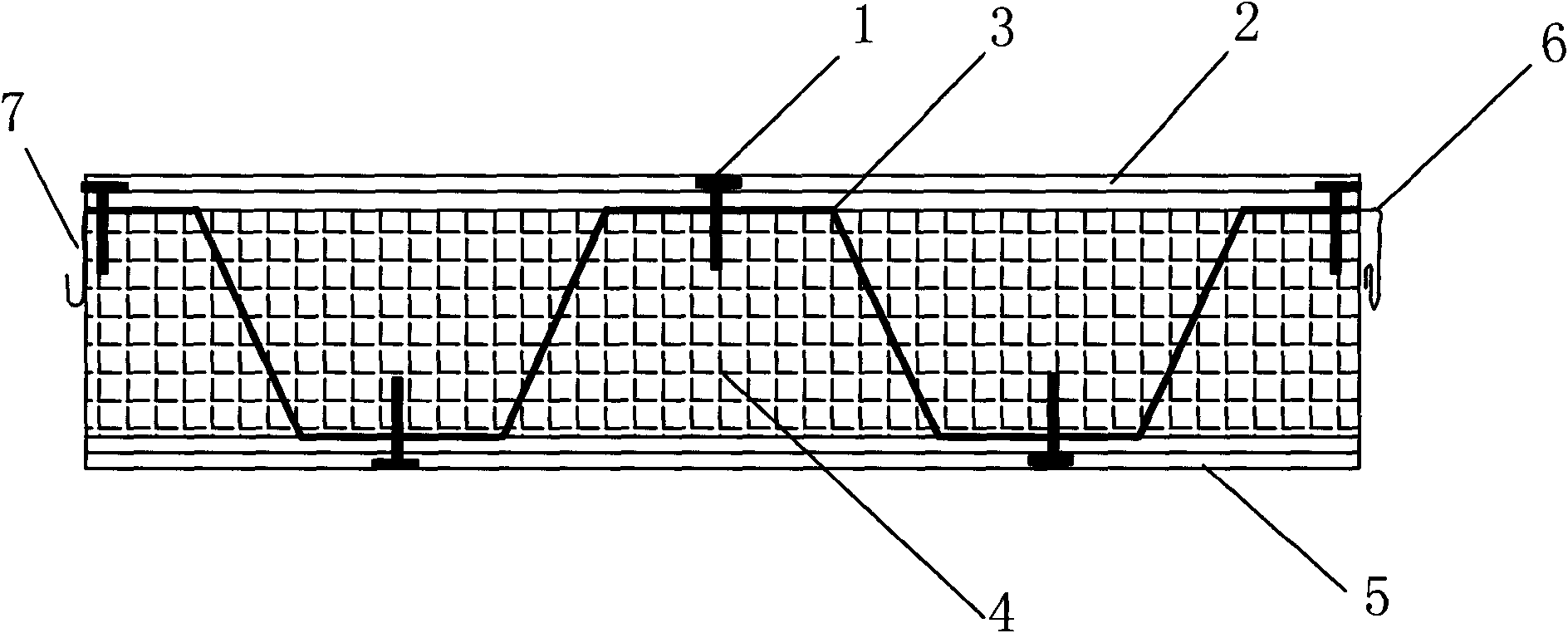

Open hollow steel section-thermal insulation core material-thin panel composite energy-saving external wall panel

InactiveCN101831967AEasy constructionSave human effortWallsHeat proofingThermal insulationEngineering

The invention discloses an open hollow steel section-thermal insulation core material-thin panel composite energy-saving external wall panel, which comprises a wallboard supporting member and a filling layer, and is characterized in that: the wallboard supporting member is formed by connecting an open hollow steel plate and two side plates through a fastening connector; the thickness of the open hollow steel plate is 0.4 to 2.0mm, and the thickness of the two side plates is 6 to 12mm; and the filling layer is made of the thermal insulation core material, which is filled in a closed space formed by enclosing the open hollow steel plate and the two side plates. Compared with the prior art, the open hollow steel section-thermal insulation core material-thin panel composite energy-saving external wall panel has light weight and convenient transportation and installation; and the thin panel plays a role in effectively protecting the open hollow steel plate and the thermal insulation core material so as to prevent the open hollow steel plate and the thermal insulation core material from mechanical damage, prevent the thermal insulation core material from weathering, isolate water from steam, prevent fire and resist corrosion.

Owner:HOHAI UNIV

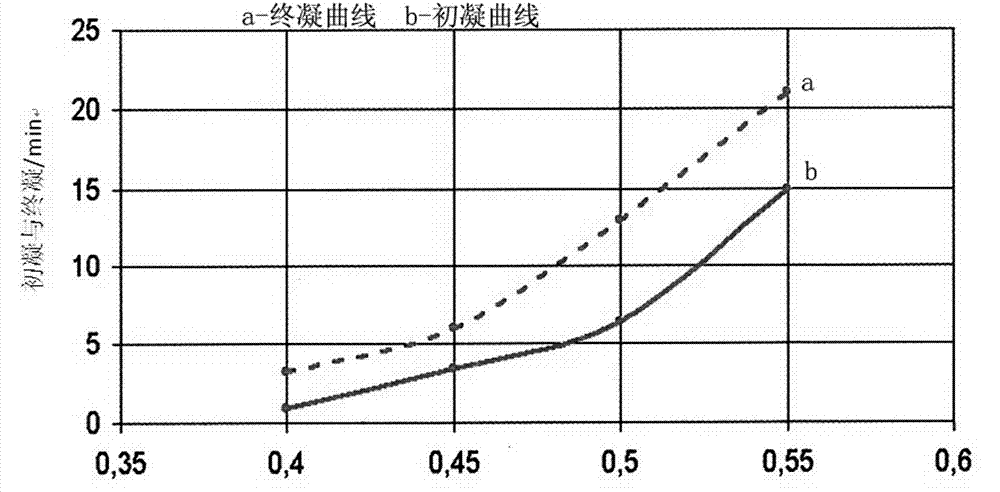

Poor-quality surrounding rock concrete wet-spraying method

The invention relates to an underground coal mine supporting method, particularly relates to a roadway surrounding rock concrete wet-spraying method, and in particular relates to a poor-quality surrounding rock concrete wet-spraying method. The poor-quality surrounding rock concrete wet-spraying method comprises the following steps: respectively sieving stones and sand with a dedicated standard stone sieve and a dedicated standard sand sieve, then mixing cement, stones and sand through a batching machine according to the mass ratio of 1:(1.5-3):(1.5-3); conveying the batched mixed materials to an agitator; adding water in the agitator according to the water-cement ratio of (0.4-0.5):1, agitating to obtain concrete, adding a water reducing agent and a hydrated agent into the concrete, wherein the addition amount of the water reducing agent is 0.8%-1wt% of the cement, and the addition amount of the hydrated agent is 0.3%-2.0wt% of the cement; transporting the concrete to a wet spraying machine, arranged underground, through an anti-explosion tank car; adding an alkali-free liquid-state accelerator into the to-be-sprayed concrete at the spray nozzle of the wet spraying machine by a peristaltic pump through a regulating valve, wherein the addition amount of the alkali-free liquid-state accelerator is 1%-3wt% of the cement, and the concrete is sprayed out from the spray nozzle of the wet spraying machine. According to the poor-quality surrounding rock concrete wet-spraying method, the problem that the supporting effect of the surrounding rock, especially poor-quality surrounding rock is poor by adopting concrete dry spraying can be solved.

Owner:DATONG COAL MINE GRP

Lock box assembly

A lock box assembly includes a lock box which includes a first casing and a second casing pivotally coupled to the first casing. The first casing has a combination lock disposed thereon. A protective shell is coveringly and detachably assembled with the first casing. The protective shell includes a cover panel shielding the first casing. A plurality of side panels extend from the cover panel for enclosingly forming a receiving space adapted for accommodating the first casing. At least one buckle is formed on the plurality of side panels. The cover panel has an opening defined therein and corresponds to the combination lock of the first casing. A lid is pivotally hinged to an edge of the opening for selectively shielding the opening. The protective shell and the lid protectively prevents the first casing the combination lock from exposing to weathering.

Owner:YANG YAO KUN

Ecological fireproof interior trimming plate and manufacturing method of ecological fireproof interior trimming plate

ActiveCN104131668AWaterproofFlame retardantCovering/liningsSolid waste managementIsolation effectGlass fiber

The invention provides an ecological fireproof interior trimming plate, which respectively comprises a bottom material layer, a middle material layer, a glass fiber layer, a non-woven layer and an interior trimming layer from bottom to top, wherein waterproof sealing layers coat outwards exposed surfaces of the bottom material layer, the middle material layer, the glass fiber layer, the non-woven layer and the interior trimming layer; the bottom material layer is a non-woven-cloth-covered PVC plate or a non-woven-cloth-covered TOB ceramic plate; and the interior trimming layer is formed by a PVC plate and an aluminum foil through hot pressing. The ecological fireproof interior trimming plate provided by the invention has the characteristics that the flame-retardant and fireproof effects are good; the sound isolation effect is good; the heat insulation performance is excellent; and the weatherability is high.

Owner:张家港市盛港绿色防火建材有限公司

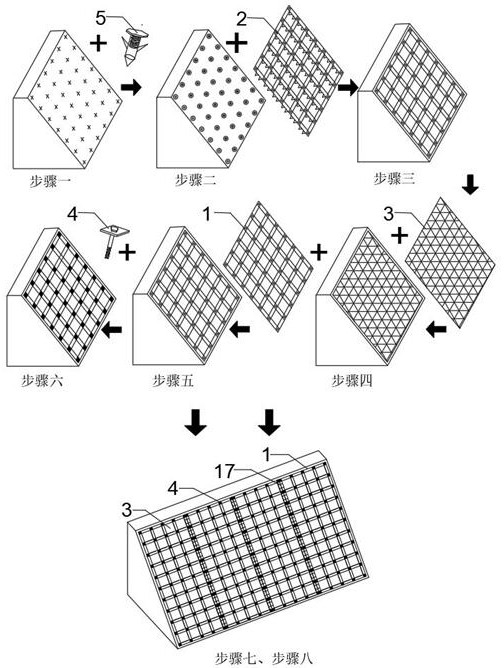

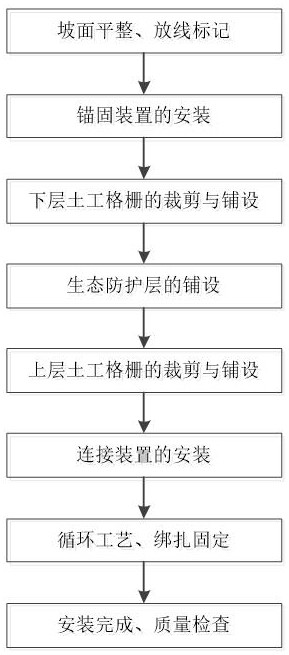

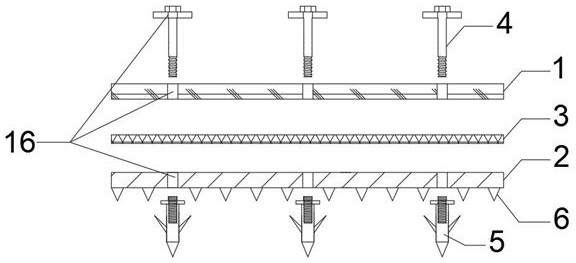

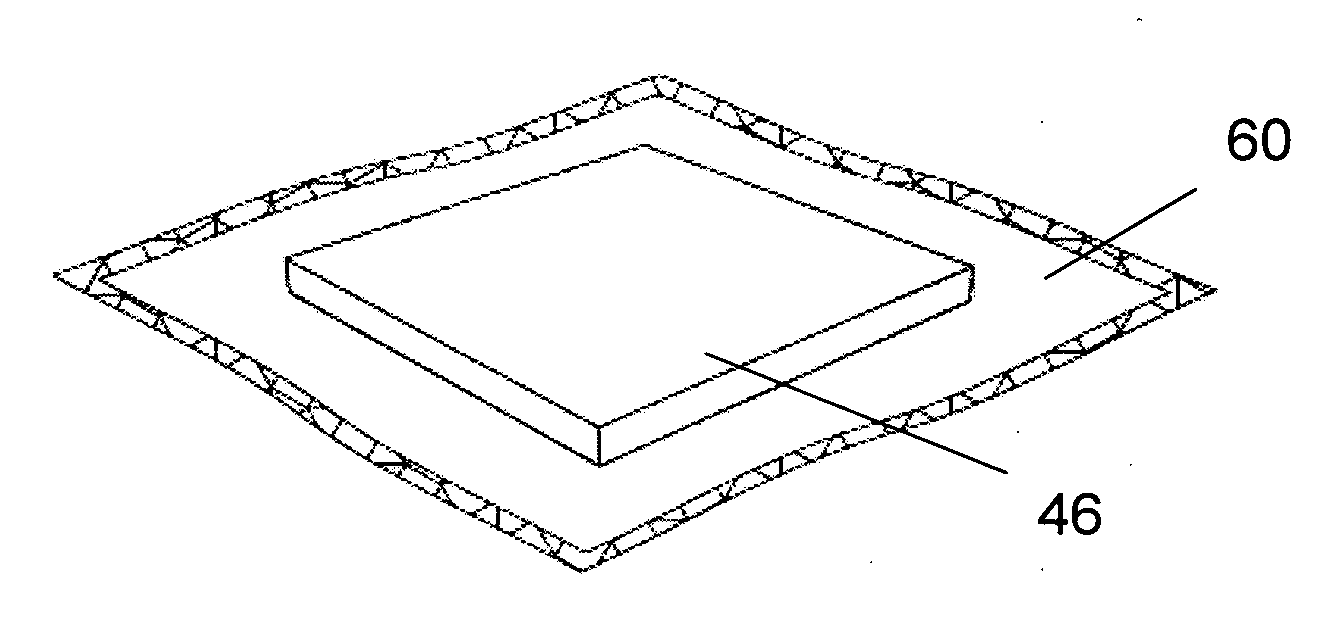

Construction method based on interlocking type ecological geogrid

ActiveCN112281876AHigh tear strengthGuaranteed reinforcement effectHops/wine cultivationTurf growingSoil scienceLap joint

The invention discloses a construction method based on an interlocking type ecological geogrid. The interlocking type ecological geogrid is composed of an upper layer geogrid, a lower layer geogrid, an ecological protection layer, a connecting device and an anchoring device, the upper layer geogrid is a biaxial tension polypropylene geogrid, the ecological protection layer is turf or an ecologicalbag filled with nutrient soil and grass seeds, the lower layer geogrid is a steel-plastic geogrid, the upper layer geogrid and the lower layer geogrid are the same in size and specification except for materials, and circular through holes consistent in size and specification are formed in rib belt lap joint positions. The construction method based on the interlocking type ecological geogrid comprises eight steps. The structure is simple, the construction method is convenient, the reinforcing effect and greening effect of the geogrid on a rock-soil side slope can be effectively improved, waterand soil loss can be effectively treated, meanwhile, double benefits of side slope reinforcing and ecological protection can be achieved, the requirement for modern green engineering development is met, and important engineering significance is achieved.

Owner:SHANDONG UNIV OF SCI & TECH +1

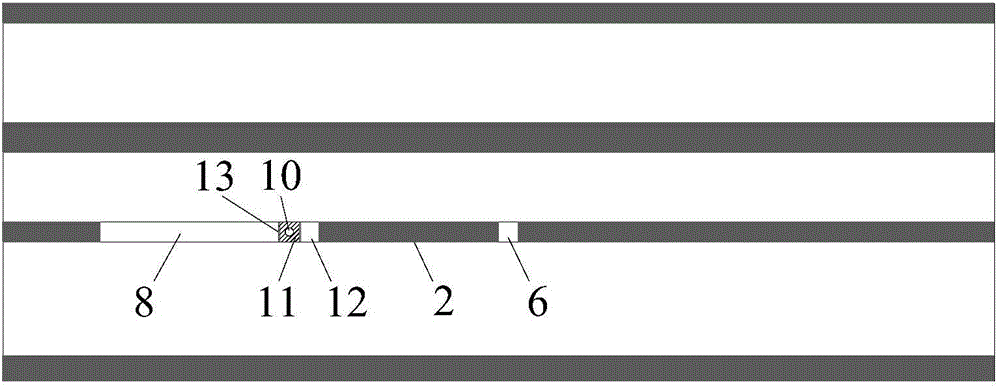

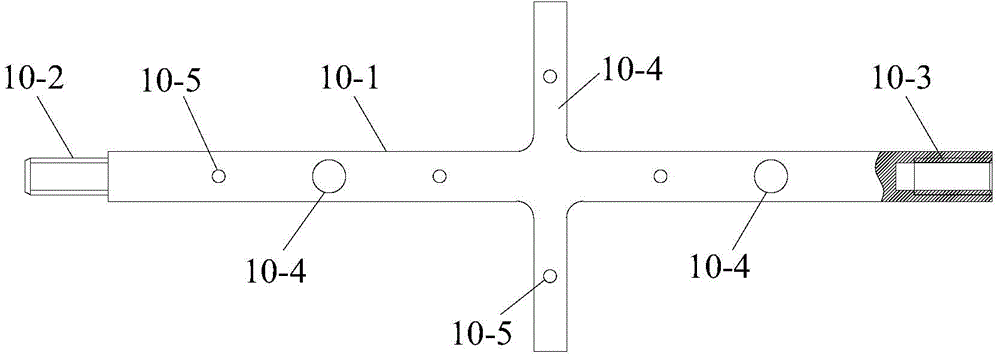

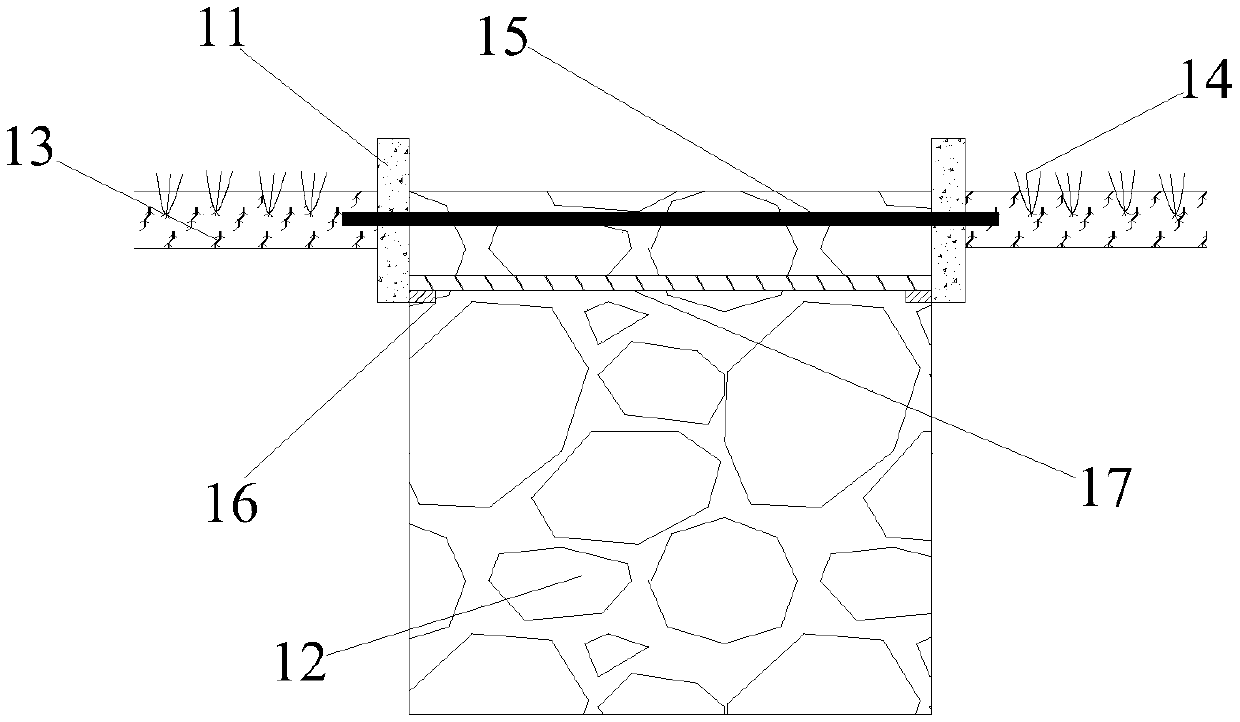

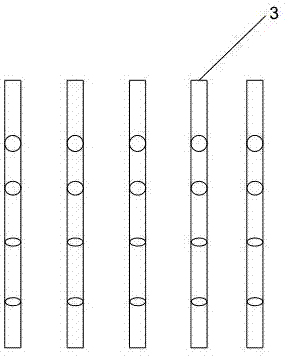

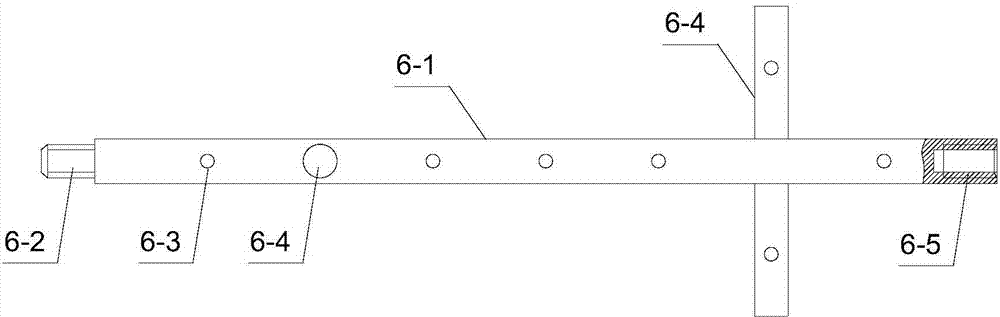

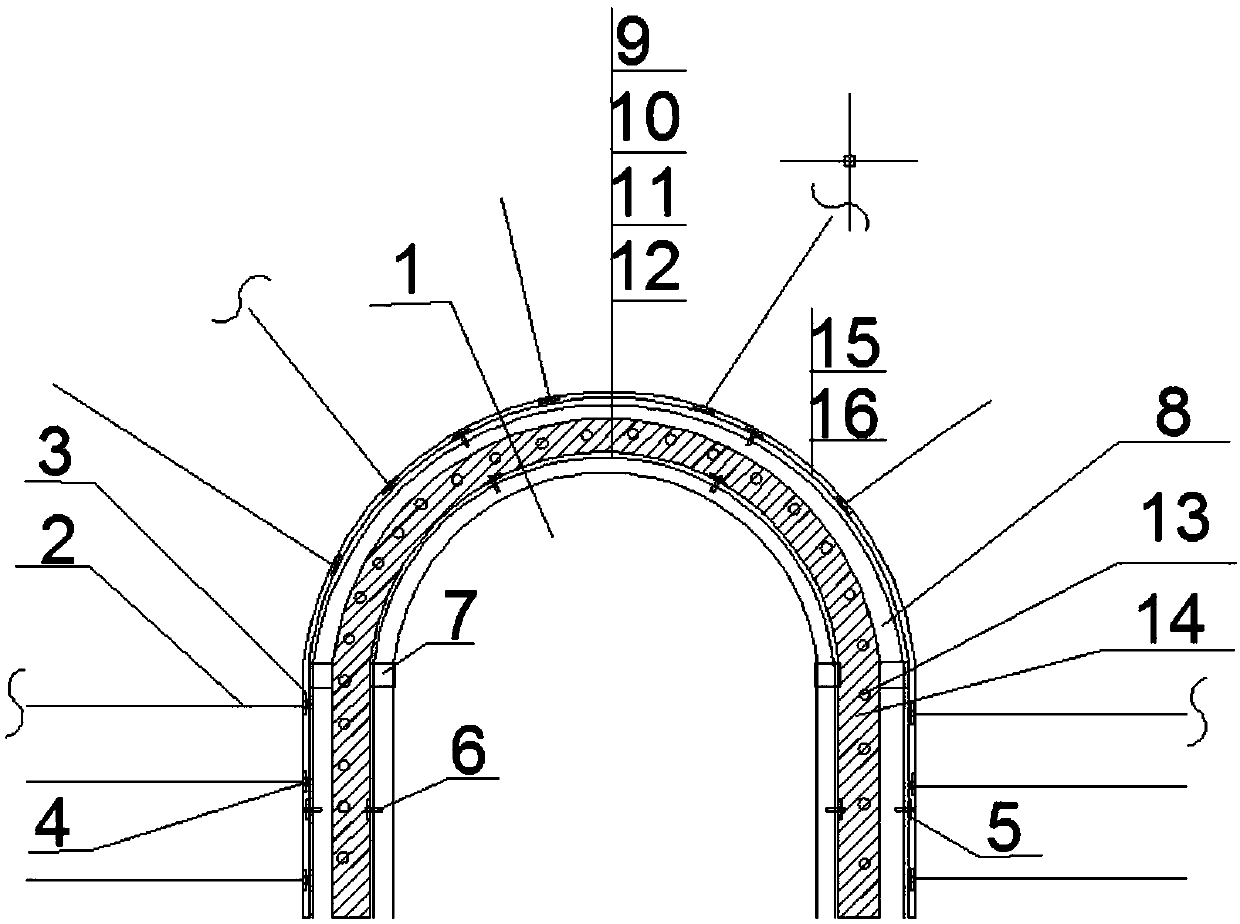

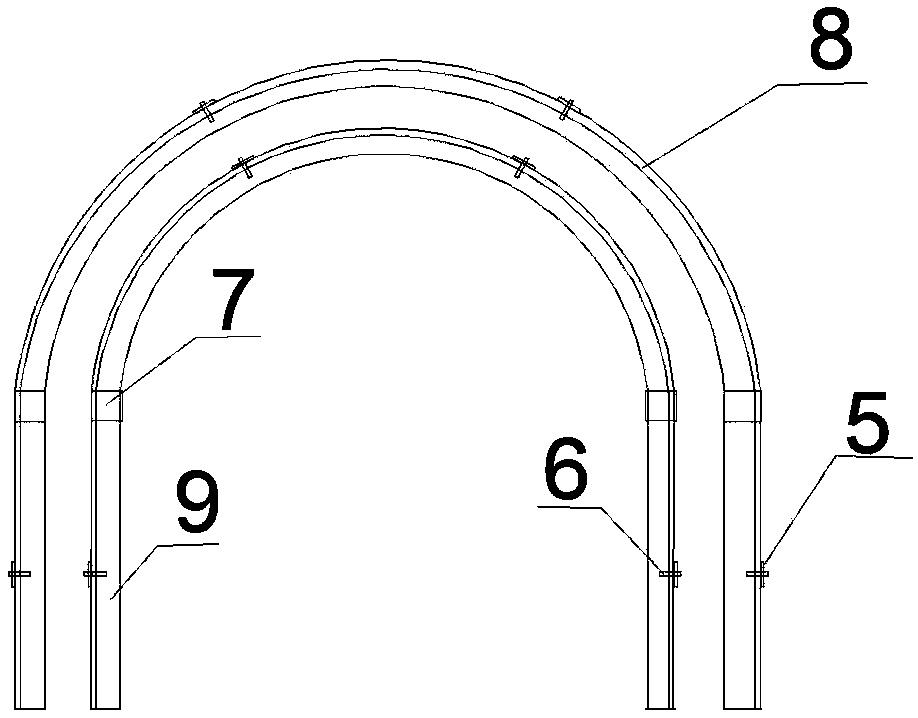

Roadway U-shaped steel sleeving shed supporting structure

PendingCN107939419APrevent weatheringPrevent deliquescenceUnderground chambersTunnel liningStress concentrationArchitectural engineering

The invention discloses a roadway U-shaped steel sleeving shed supporting structure. The supporting method that anchor cables and a metal net are arranged, mortar spraying is conducted, a U-shaped steel sleeving shed is arranged, and grouting is conducted is adopted; firstly, an anchor net spraying layer is formed, the anchor net spraying layer has the effect of preventing surrounding rock from further weathering and deliquescing, the loads on the two sides and a roof of a roadway evenly act on supports so as to avoid stress concentration, thus, rapid press-deformation and roof caving which are caused by crushing of the surrounding rock at the initial excavation period of the roadway can be controlled effectively, and finally an anchor net spraying combination isolation arch on the surfaceof the roadway is formed; secondly, a supporting rigid layer is formed between every two layers of U-shaped steel; the roadway U-shaped steel sleeving shed supporting structure can be resistant to compression with high strength and can conduct yielding moderately, and a hardness and softness double-layer supporting structure is formed; and the stability and supporting strength of the surroundingrock of the crushed soft rock roadway are promoted greatly, a certain guarantee is provided for safe production of a coal mine, meanwhile, a certain amount of roadway maintenance cost is also reducedfor an enterprise, great benefits are achieved for development of the coal enterprise, and thus the roadway U-shaped steel sleeving shed supporting structure can be used and popularized on a large scale.

Owner:GUIZHOU UNIV

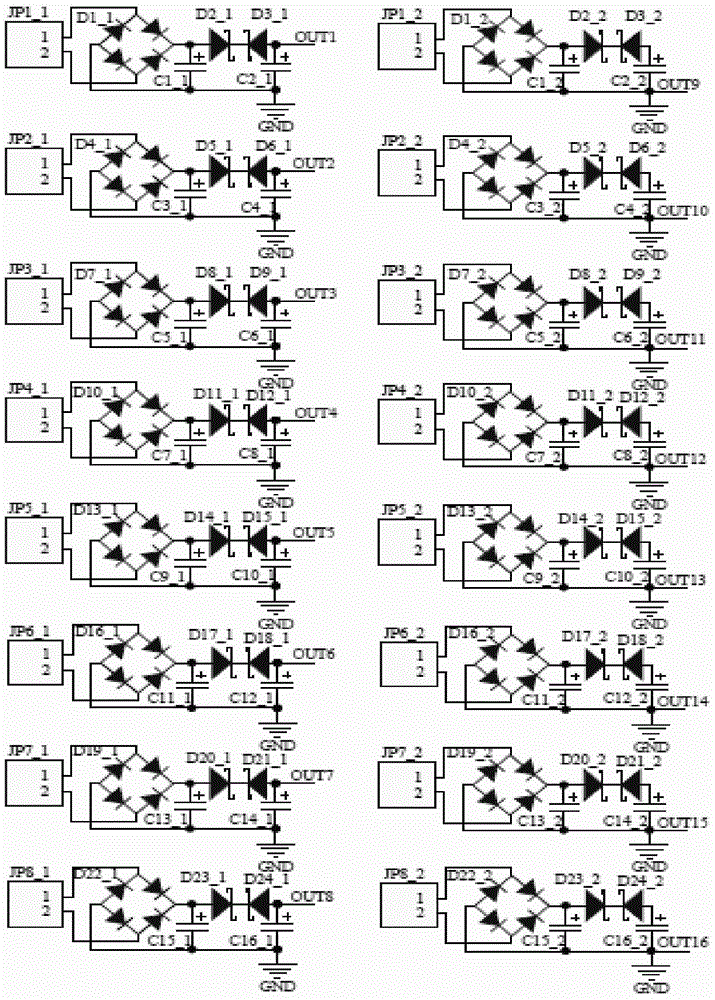

Wind speed and direction detection device

InactiveCN104535790AInvasion freeHigh precisionIndication/recording movementFluid speed measurementRubber materialElectricity

The invention discloses a wind speed and direction detection device, and particularly relates to a wind speed and direction detection device based on the piezoelectric effect. The wind speed and direction detection device comprises an induction system and a measuring system. The induction system comprises a vertical rod made of rubber materials, sixteen piezoelectric ceramic pieces, a rotating device and a wind receiving device. The piezoelectric ceramic piles are symmetrically attached to the portion, between the top end and the bottom end, of the outer wall of the rubber vertical rod on the same horizontal height. The rotating device is located at the top end of the rubber vertical rod. The wind receiving device is connected with the rotating device through a nylon rope. The two ends of each piezoelectric ceramic pile are connected with the measuring system. The wind speed and direction detection device is installed on the top of a building, the wind receiving device swings along with wind, the piezoelectric ceramic tiles on the vertical rod are driven to generate output voltage, the output voltage is input to a display circuit to be displayed out, the wind direction and speed can be detected at the same time, and the higher precision is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

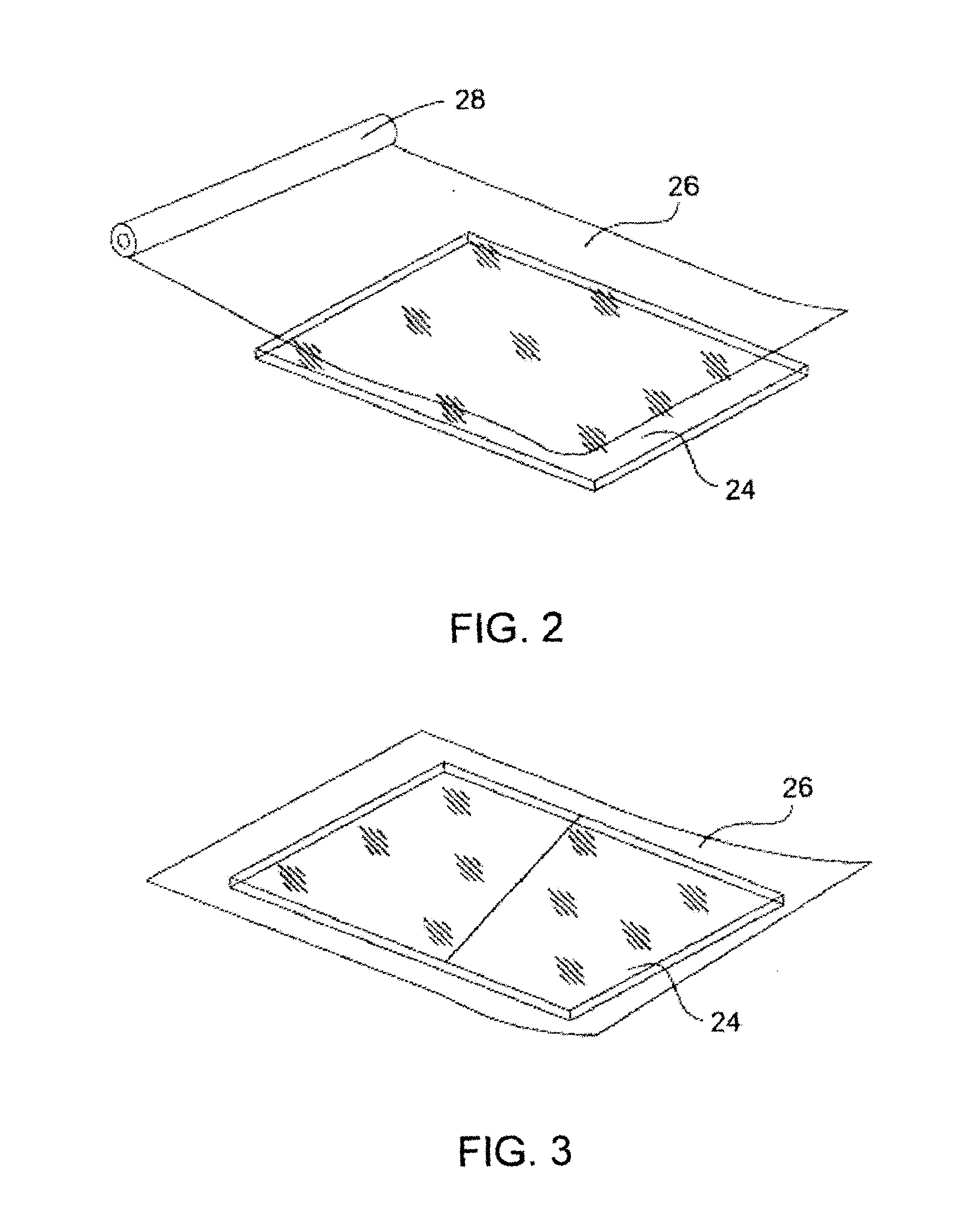

Packaging cementitious products

InactiveUS20130216761A1Prevent weatheringReduce the possibilityPretreated surfacesShock-sensitive articlesPlastic materialsThin sheet

The present invention provides a method of processing cementitious products to substantially reduce or eliminate efflorescence. The method includes applying a protective layer to at least one surface of a slab product at the time of pouring cementitious mix into a mould and retaining the protective layer in place. The protective layer is a relatively thin sheet of plastic material.

Owner:ABBEY & PRIDE IP

Supporting treatment construction method for high and steep side slopes of tunnel portal bedding strong weathered rocks

ActiveCN109610481AIncreased risk of landslidesGood drainageExcavationsReinforced concreteEngineering

The invention discloses a supporting treatment construction method for high and steep side slopes of tunnel portal bedding strong weathered rocks. The method comprises the following steps: (1) densely-arranged steel pipe piles which are distributed in an approximate semicircular arc mode are arranged outside a design boundary of a main slope, U-shaped drainage grooves are constructed and formed along the inner sides of the densely-arranged steel pipe piles, geogrids are paved within the range of 1-2 m along the outer sides of the densely-arranged steel pipe piles, and a layer of concrete is sprayed to the surfaces of the grids; (2) an anchor cable frame beam structure is arranged on the surface of the side slope on the inner sides of the densely-arranged steel pipe piles, a concrete layerslightly higher than a frame beam is built along the inner side of each frame, and hollow polygonal edge blocks are evenly arranged in the frames; (3) a plurality of reinforced concrete piles are evenly arranged on the left side and the right side of the tunnel portal design boundary at intervals; and (4) a foundation pit is excavated along the outer side of the reinforced concrete piles, and a reinforcement cage is built along the foundation pit and around the reinforced concrete piles to form a retaining wall structure. The method can effectively solve the problem of treatment of the high and steep side slopes of the bedding strong weathered rocks, and has the advantages of efficient construction, safe structure and the like.

Owner:XIANGTAN UNIV

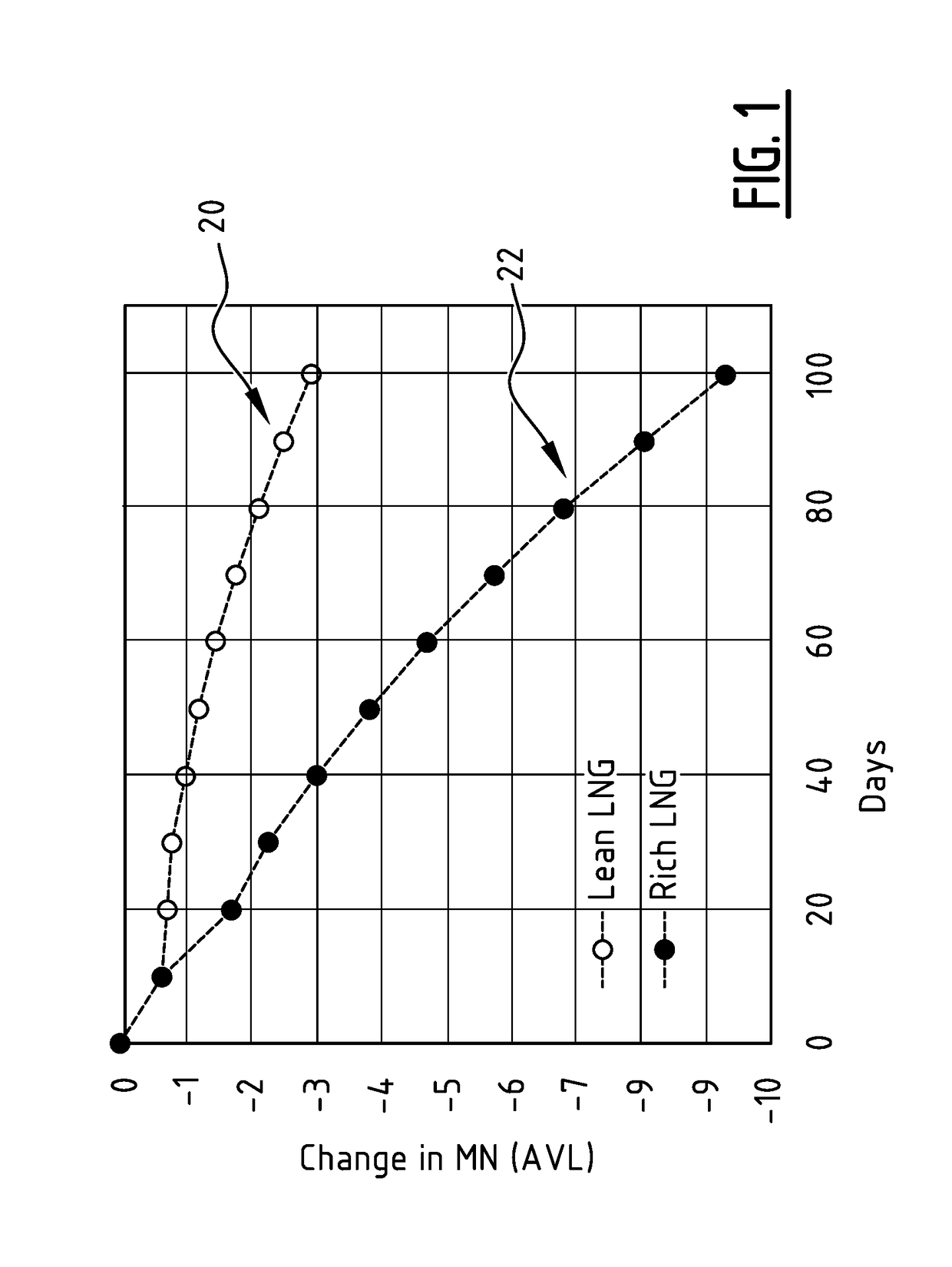

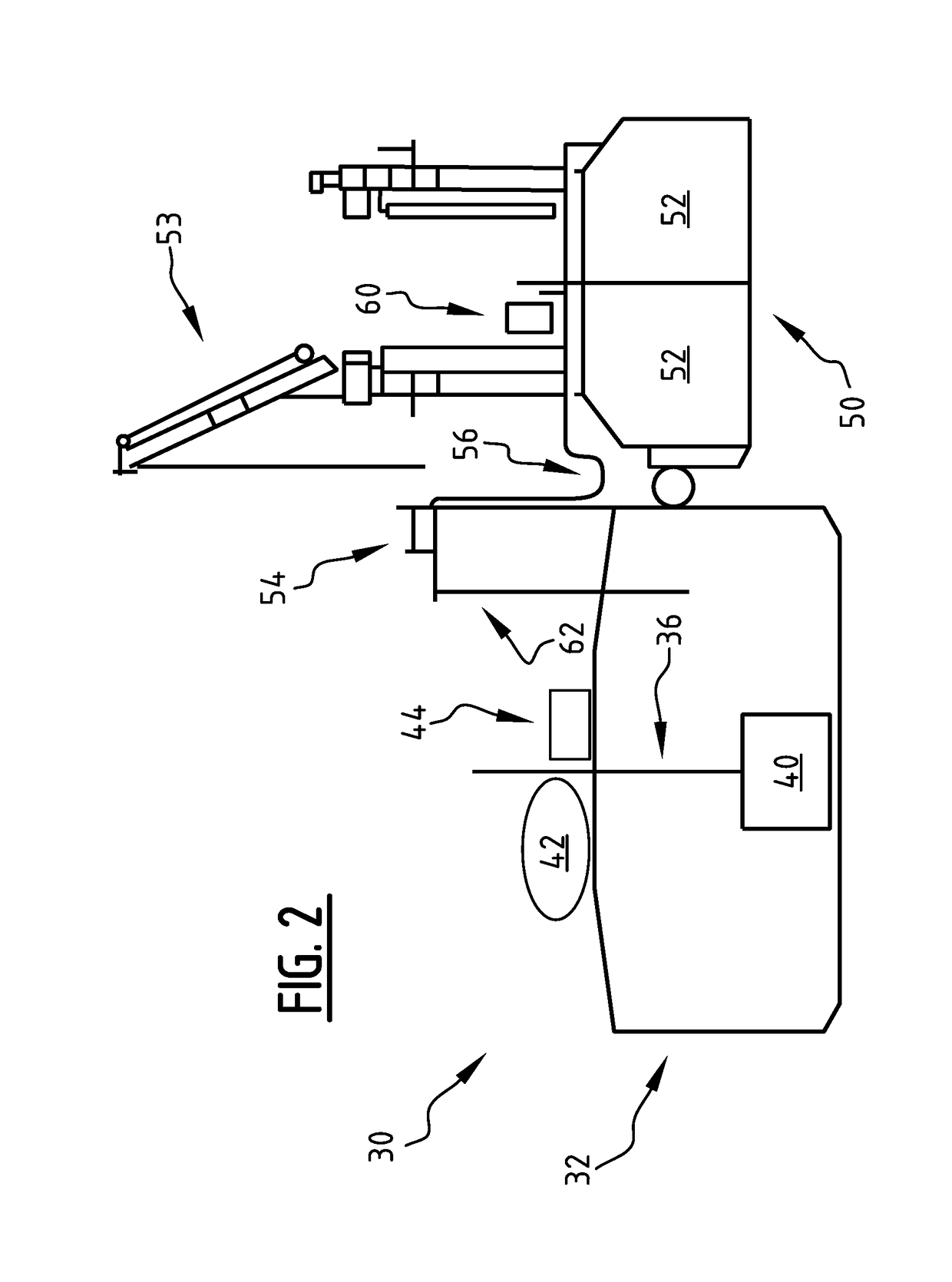

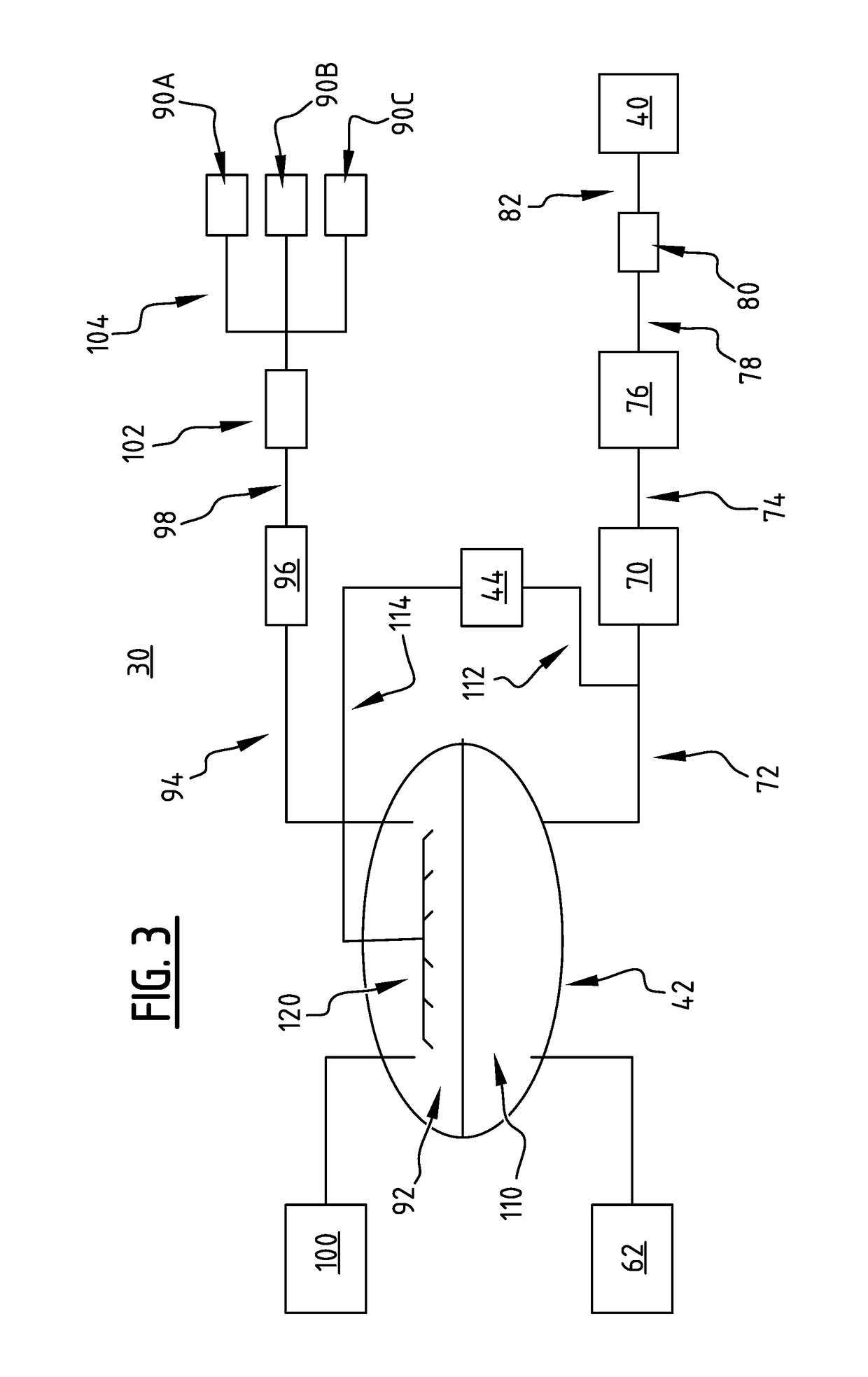

Liquefied fuel gas system and method

PendingUS20190024847A1Improve efficiencyImprove securityContainer filling methodsRailway vehiclesAutomotive engineeringChiller

A method of fueling a transporter with liquefied fuel gas includes providing a transporter having a fuel gas storage tank for holding a liquefied fuel gas, a sub-cooler fluidly connected to the fuel gas storage tank, and a consumer. Liquefied fuel gas from the fuel gas storage tank is pumped into the subcooler to create subcooled liquefied fuel gas. The subcooled liquefied fuel gas may then be introduced into the fuel gas storage tank, for example by spraying into a vapor space of the fuel gas storage tank. Liquefied fuel gas is pumped from the fuel gas storage tank to provide pressurized liquefied fuel gas, the pressurized liquefied fuel gas is vaporized and the vaporized fuel gas is provided to the consumer for propelling the means of transport using the vaporized fuel gas as a fuel.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com