Complete non-coal-pillar continuous depressurized mining method for close-distance coal seam groups

A mining method and coal seam group technology, which is applied in the field of continuous pressure relief mining with no coal pillars in close coal seam groups, can solve problems such as insufficient pressure relief, hidden safety hazards, high concentration of coal pillar stress, and safety hazards in adjacent coal seams. Fully relieve pressure, promote gas overflow, and facilitate the maintenance of mining space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

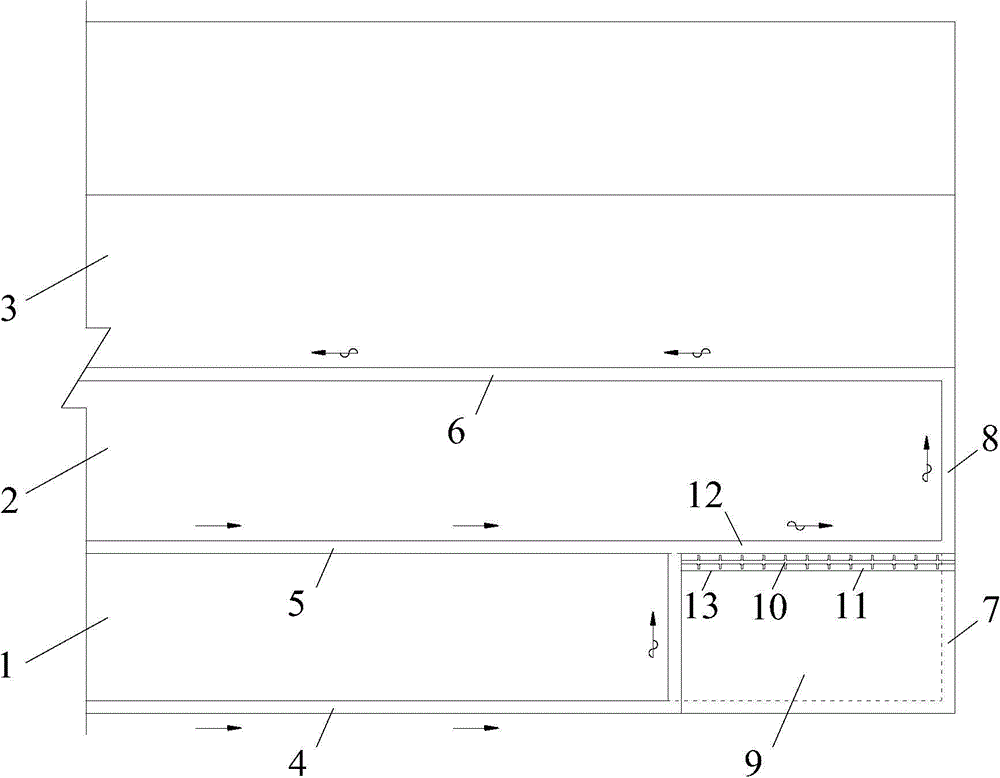

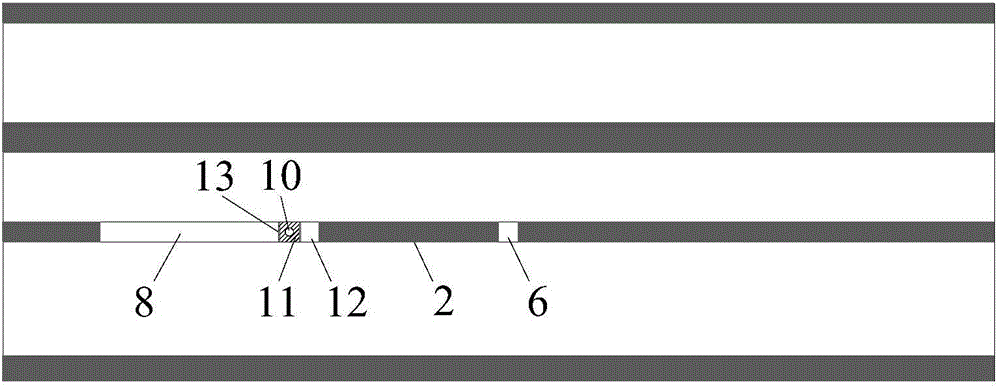

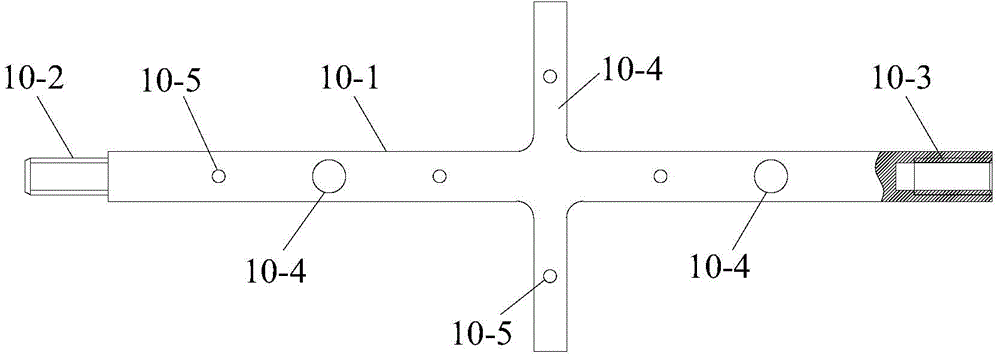

[0035] Such as figure 1 As shown, the method for continuous pressure relief mining without coal pillars in the short-distance coal seam group of the present invention first determines the mining sequence of each coal seam in the coal seam group, and when mining the first coal mining face 1 of the first mining coal seam, excavate the second coal seam. The second track lane 6 and the second cutout 8 of the first coal mining face 2, together with the transportation lane 4, the first track lane 5 and the first cutout 7 of the first coal mining face 1, constitute the first mining face. The ventilation system of the coal face 1; when mining the coal face 1, a filling wall with a flexible mold bag 13 and a built-in ventilation pipeline 10 is built along the edge of the gob 9 to form a gobside entry retention 12. When the second coal mining face 2 is mined, the go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com