Patents

Literature

192 results about "Drill site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

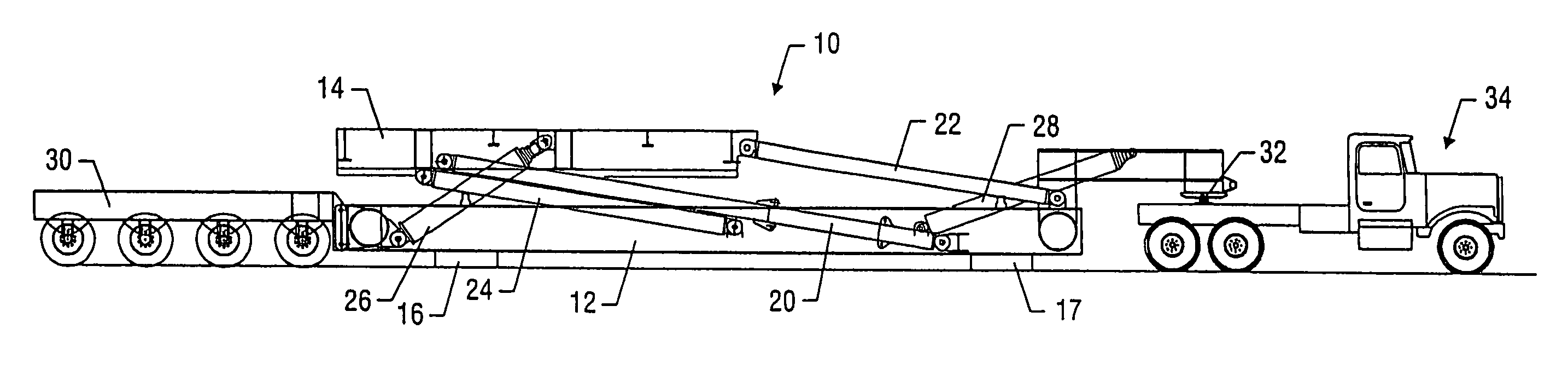

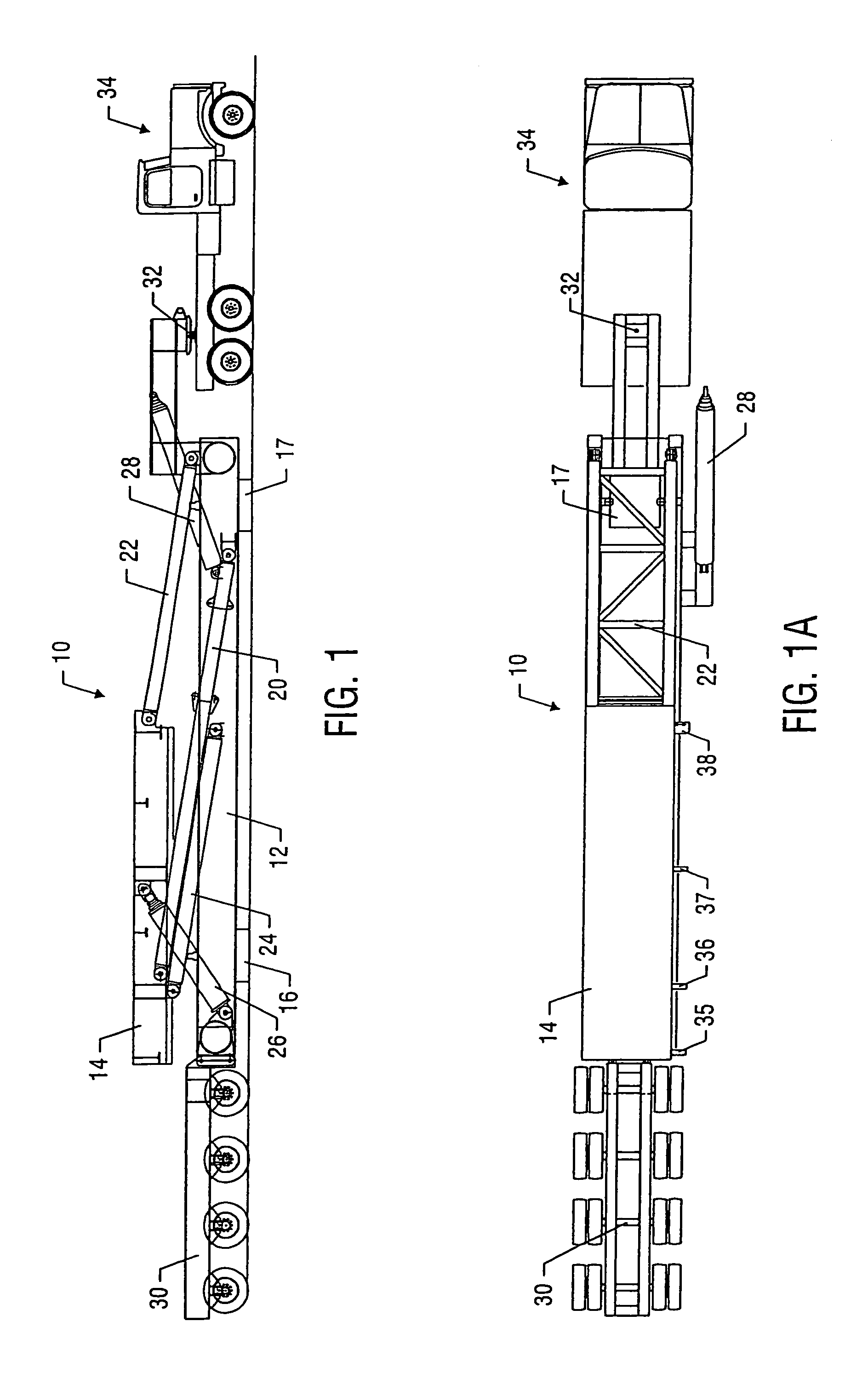

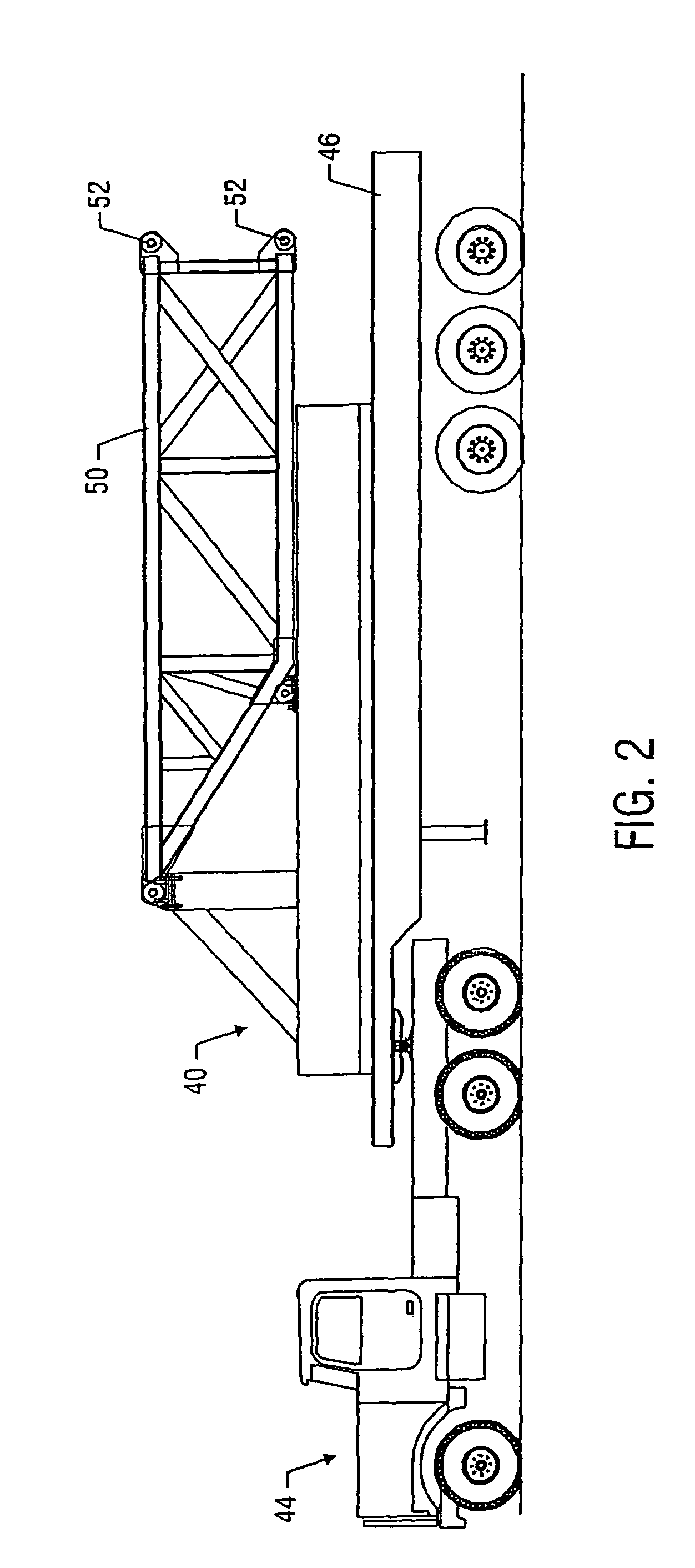

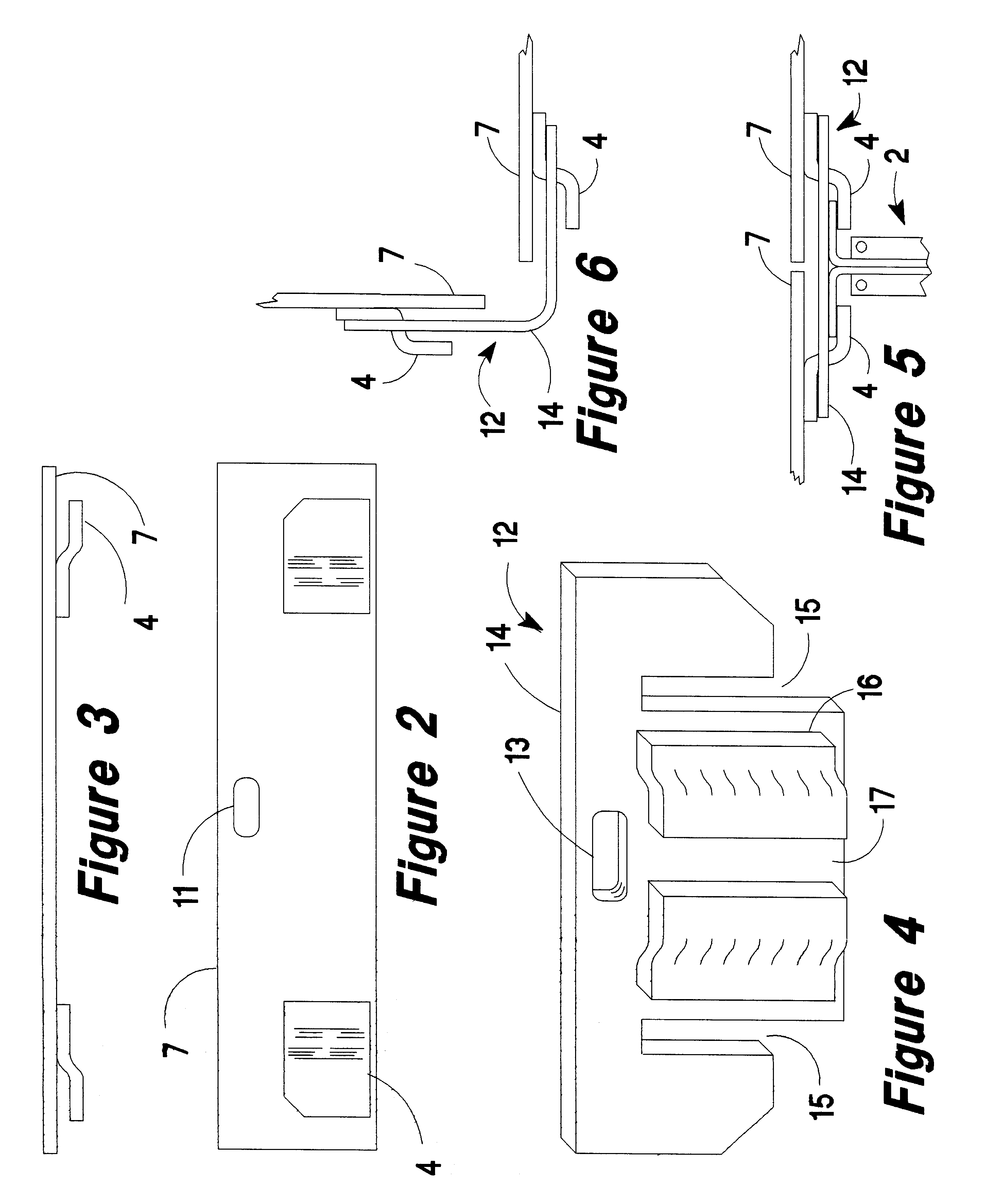

Fast moving drilling rig

A method and apparatus for transporting and assembling a drilling rig is disclosed. The drilling rig of a preferred embodiment of the present invention utilizes specialized positioning pads integral to the side boxes of the drilling rig to facilitate the connection of the center drill floor of the drilling rig to the side boxes of the rig. A preferred embodiment of the present invention may also utilize a specialized positioning dolly and an adjustable fifth-wheel truck connection for transporting the mast to the drill site, assembling the mast sections together, and positioning the mast for connection to the drill floor of the rig. The result is a unique drilling rig design and sequence for assembly that significantly reduces the time required to transport the rig from location to location and to assemble the rig at the drill site.

Owner:NAT OILWELL DHT

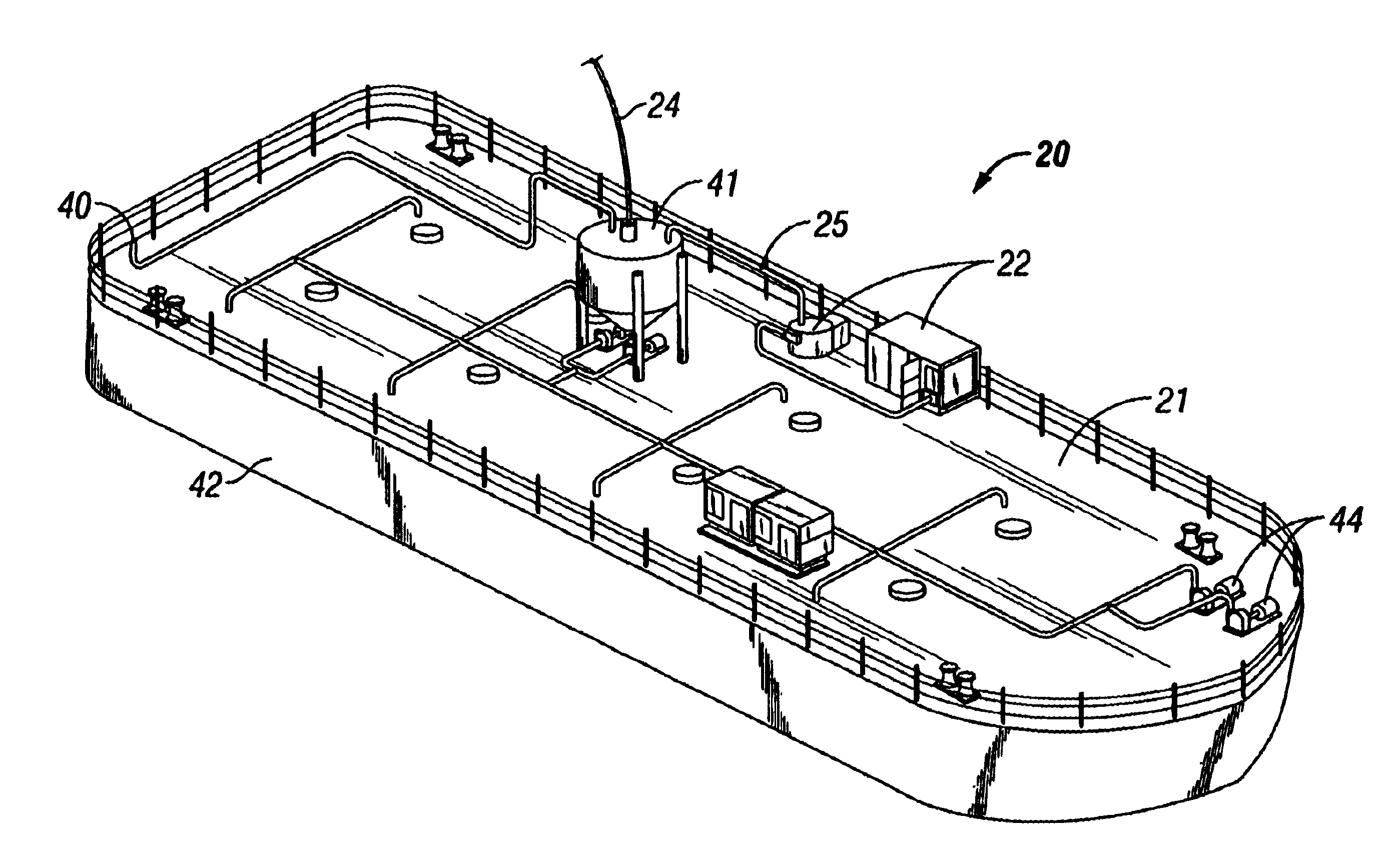

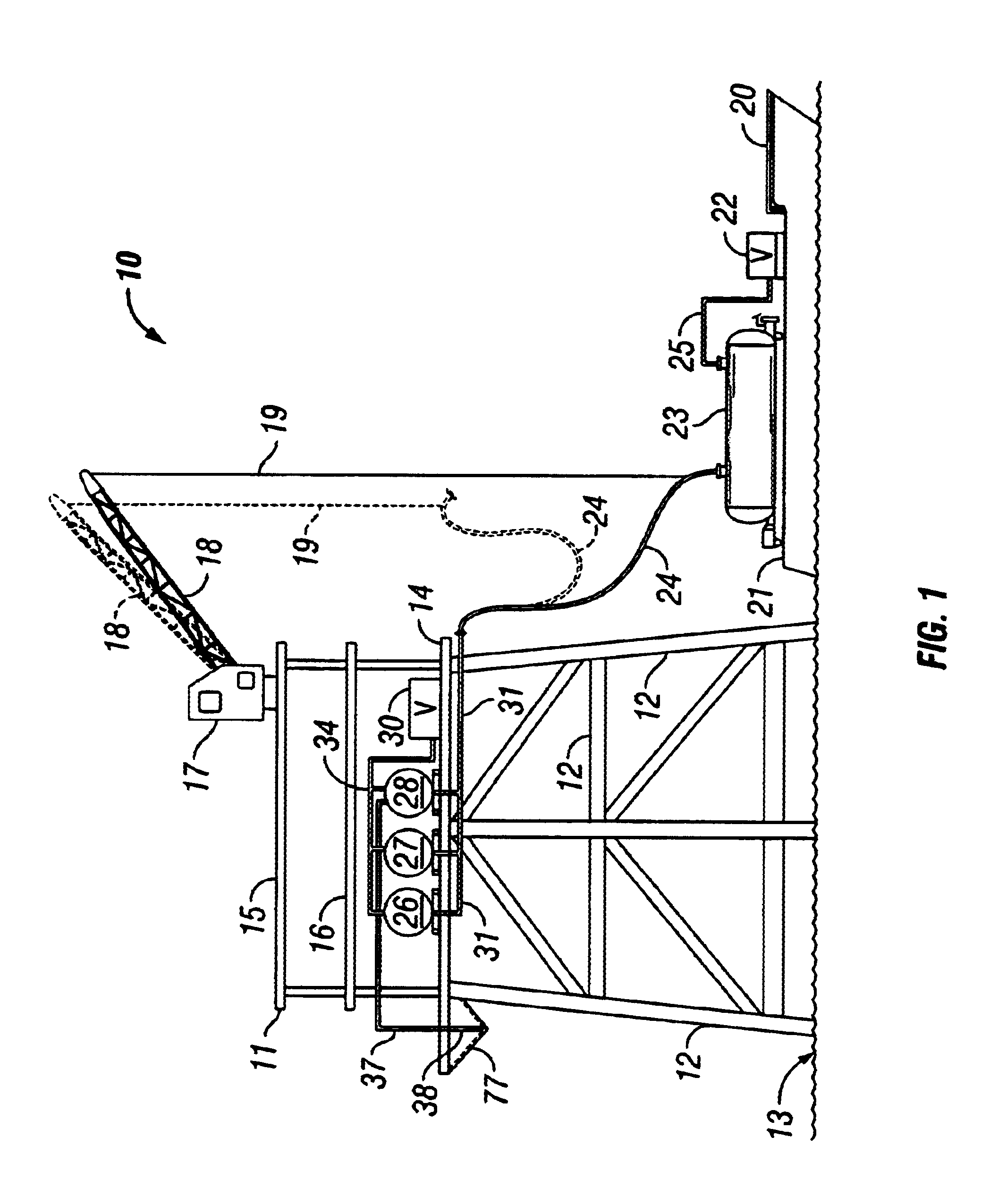

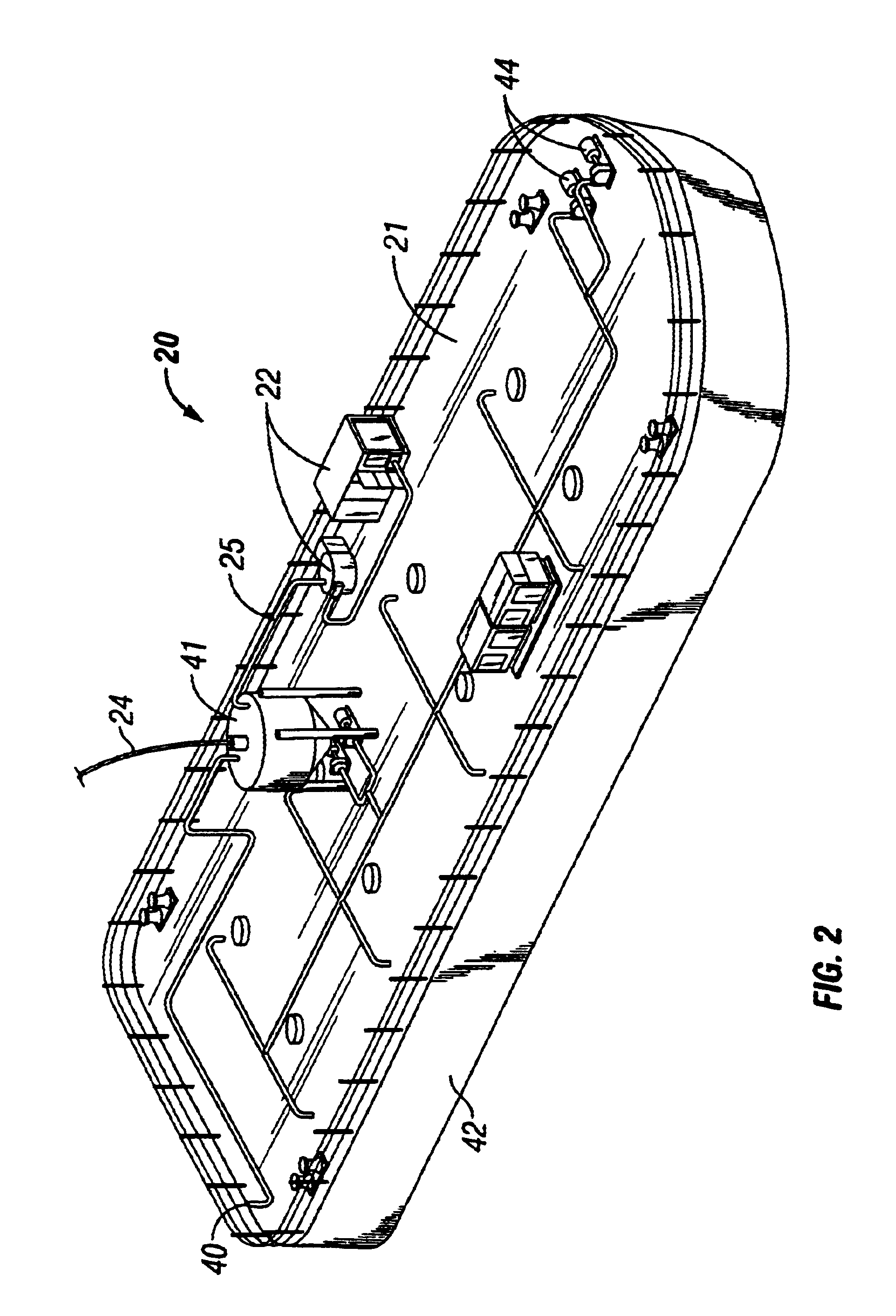

Methods and apparatus for disposing of deleterious materials from a well

InactiveUS6745856B2Save spaceSave equipmentCargo handling apparatusAuxillariesDrill siteHazardous substance

An improved method and apparatus for processing deleterious material on a floating vessel during transportation from a well to a disposal site. The vessel contains equipment for the slurrification and agitation of the deleterious material. Such equipment includes storage tanks, slurrification units, and agitation units, as well as transfer equipment such as flow lines and vacuum or pump means. The deleterious material is transferred from the drill site to the storage tanks on the vessel. The vessel then transports the material to a disposal site, such as an injection well. During transportation, the deleterious material is processed. Such processing can include slurrification and / or agitation of the deleterious material to maintain the slurry, adding fluid if necessary. Once at the disposal site, the deleterious material slurry is then transferred from the vessel to the disposal site.

Owner:MI

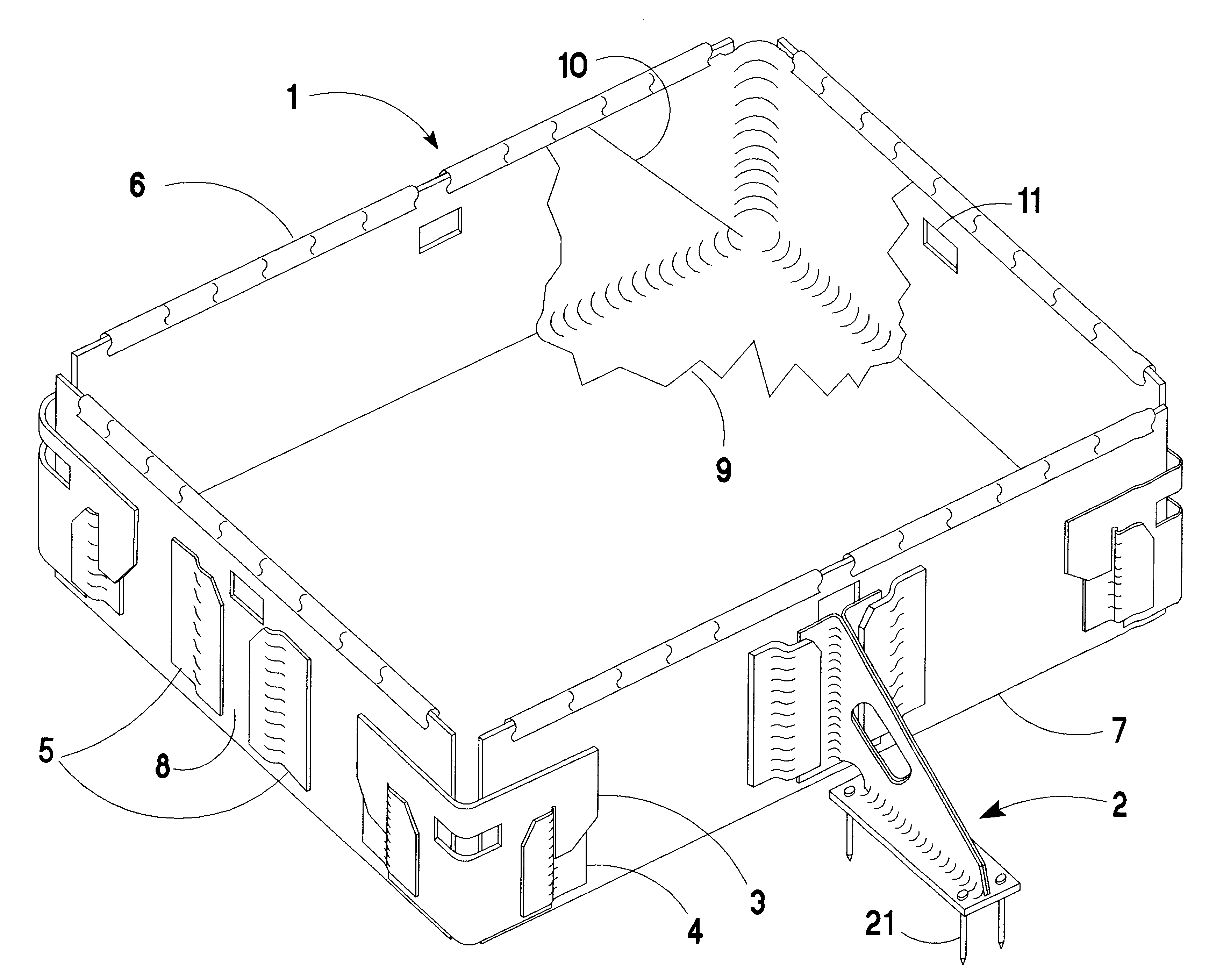

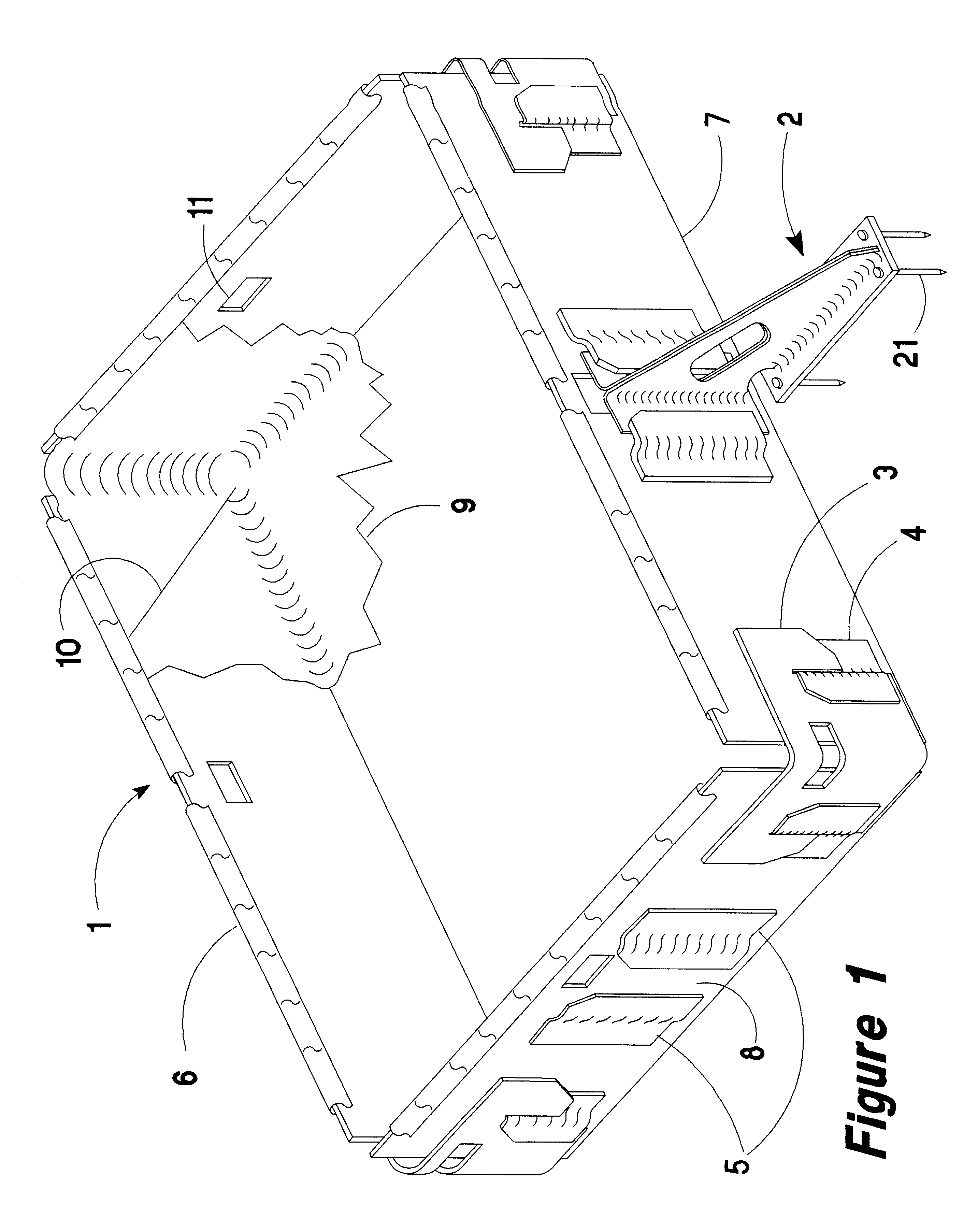

Portable environmental containment system

InactiveUS6315495B1Easy to replaceEasy to disassembleSolid waste disposalProtective foundationDrill siteEngineering

A temporary berm or bin system, easily transported, erected without tools, and easily dismantled. A set of panels or planks is joined with sliding clips to form a bin having vertical or near vertical sides. The bin is lined with an impervious sheet of geocloth to form a containment berm for use in controlling the dispersal of hazardous material spilled from storage or work facilities. Spring loaded clamps hold the geocloth securely to the uppermost plank without nailing, sewing, or other labor consuming and / or tear prone methods. The berm is particularly suited to protect oil well drilling sites in environmentally sensitive environments such as arctic tundra. No excavation or other disturbance of the soil is required to erect the protective berm. The berm is secured to the ground by spildng through triangular support gussets. In the arctic, securing may be accomplished by freezing ice or mud as an "ice mortar" over the gusset feet and along the lower edge of the planking. The berm system may be transported by ordinary truck, specially adapted transport / laying truck, or on a portable drilling platform.

Owner:KONKIN HLDG INC

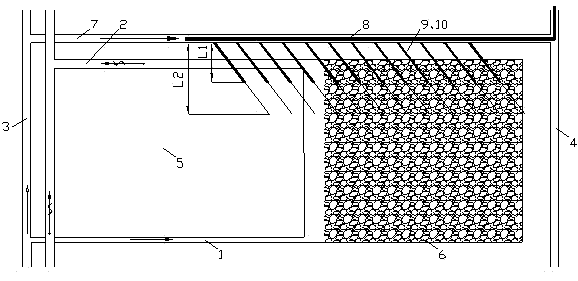

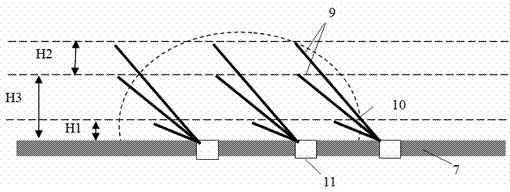

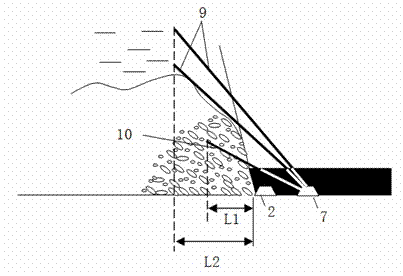

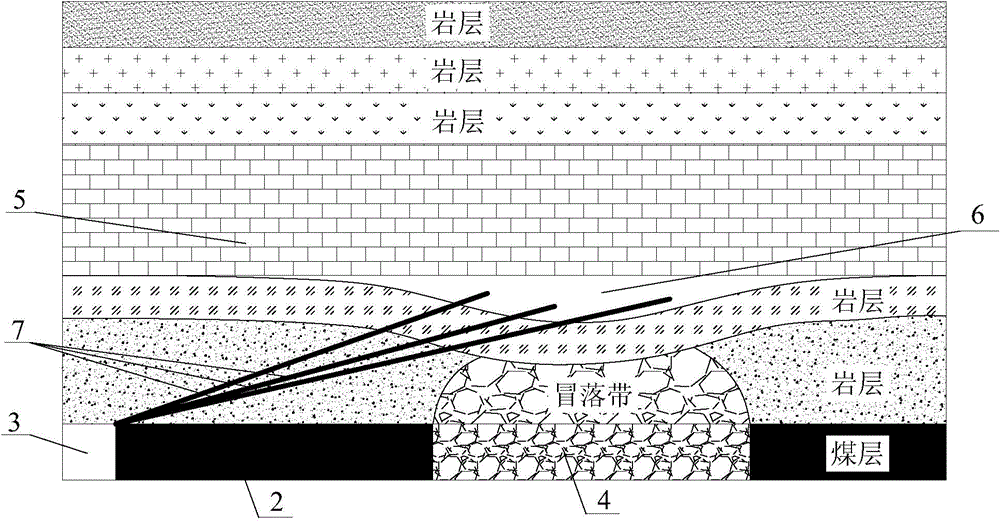

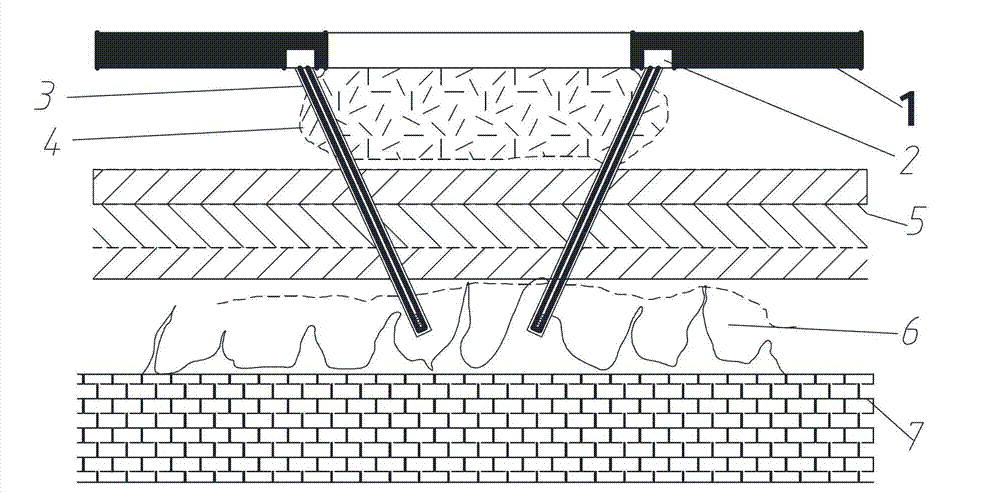

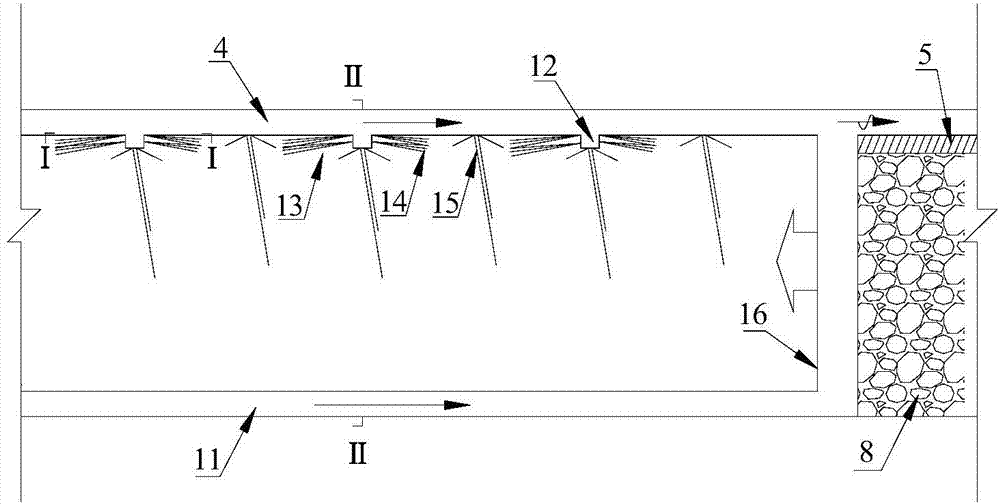

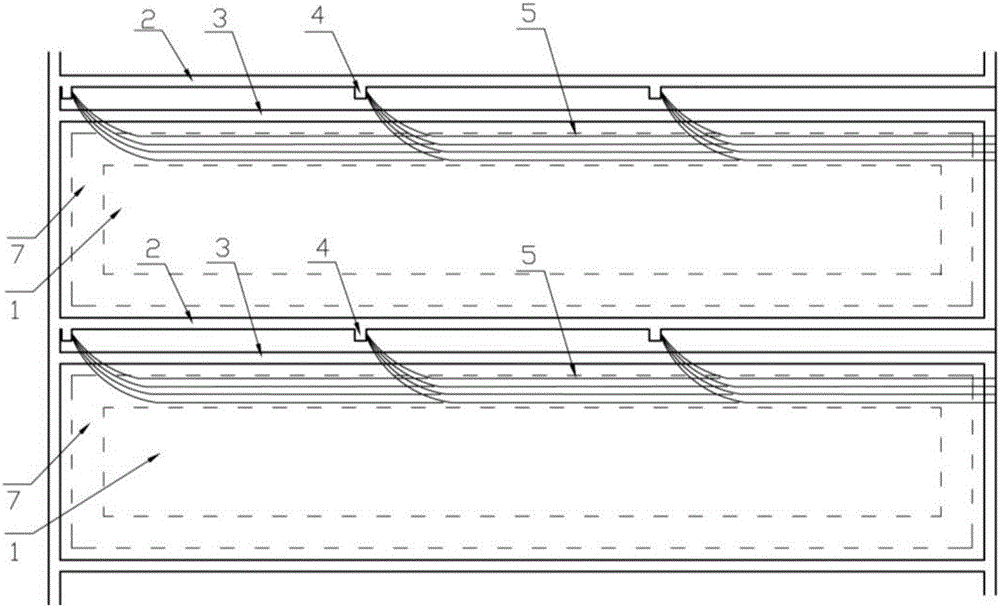

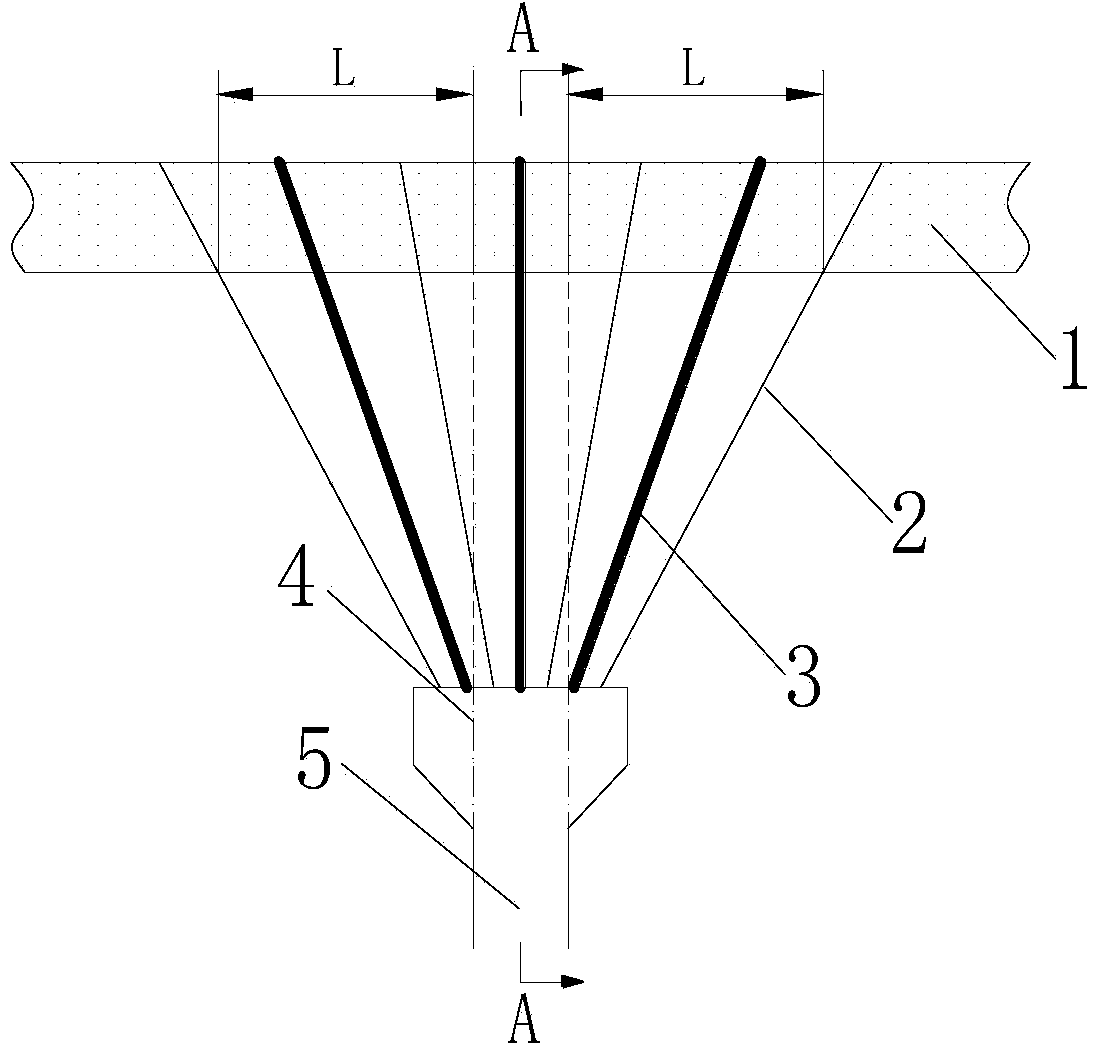

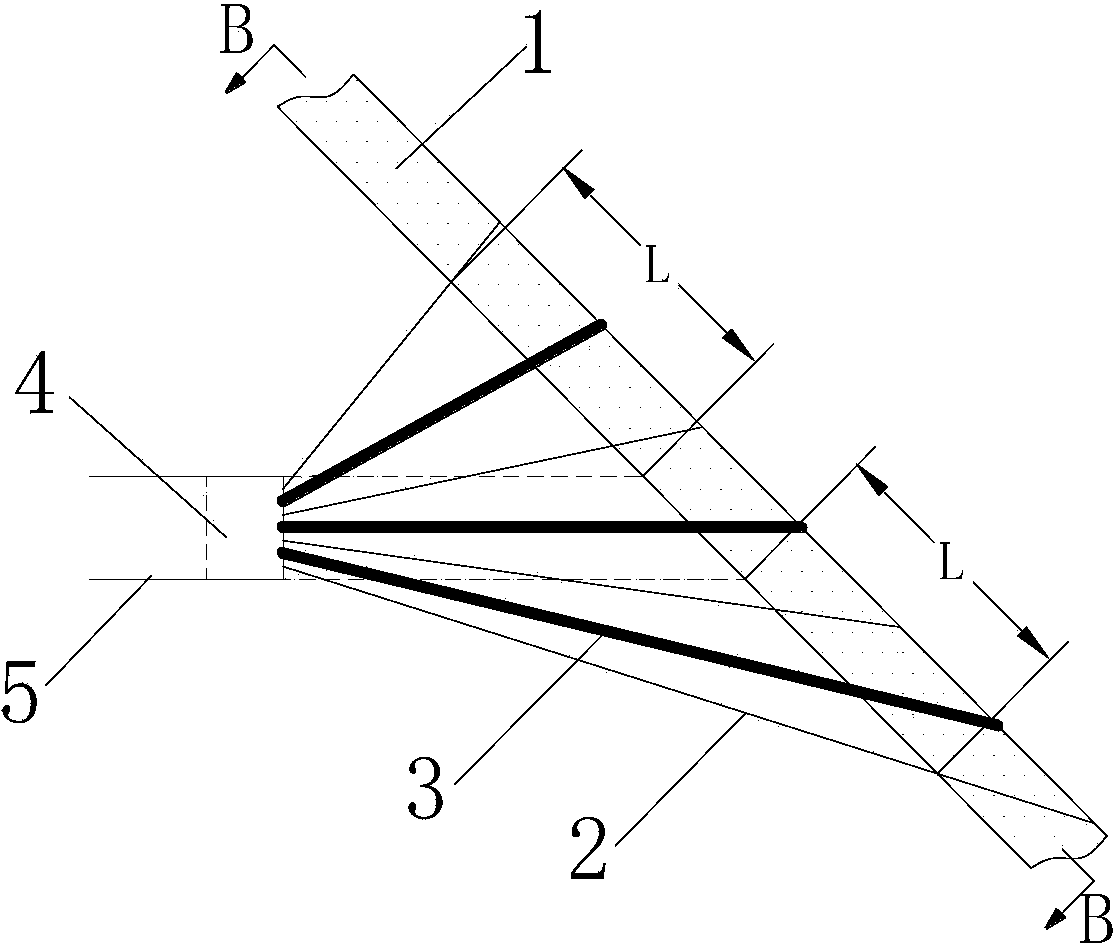

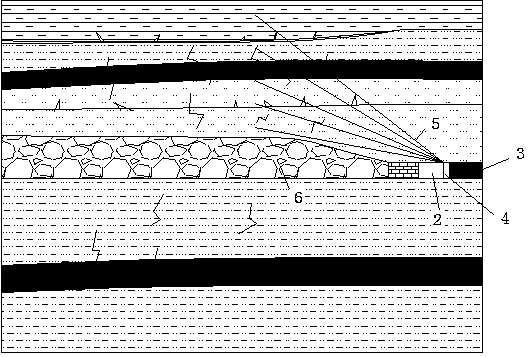

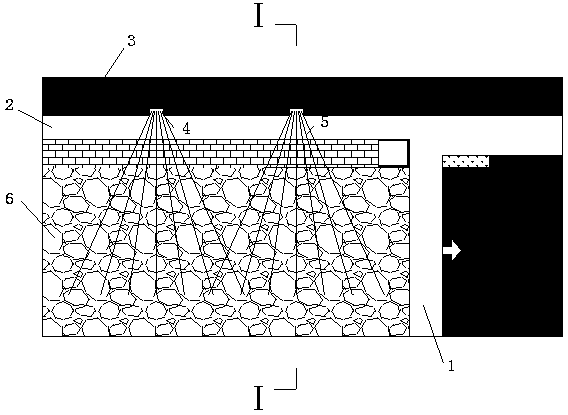

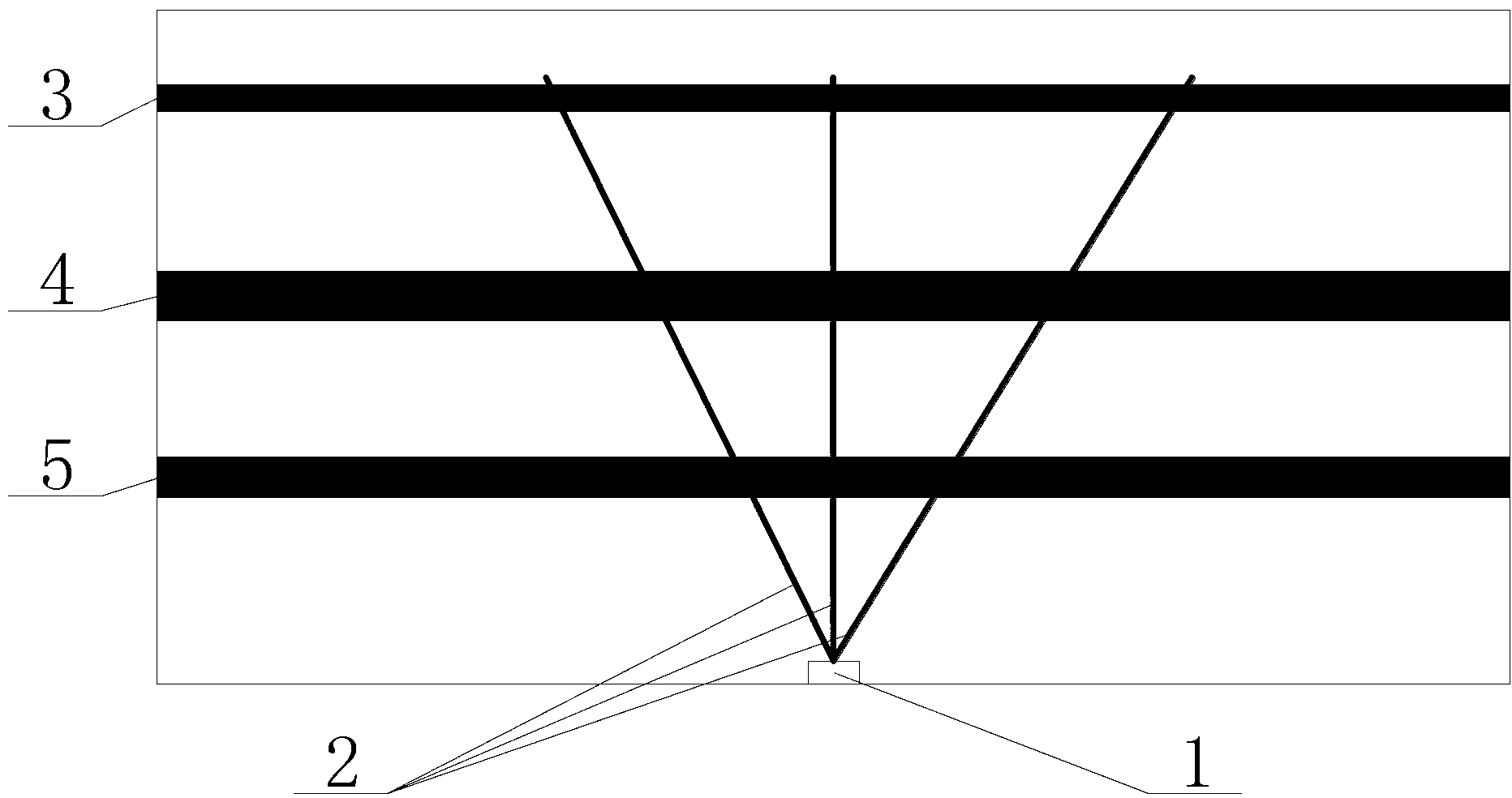

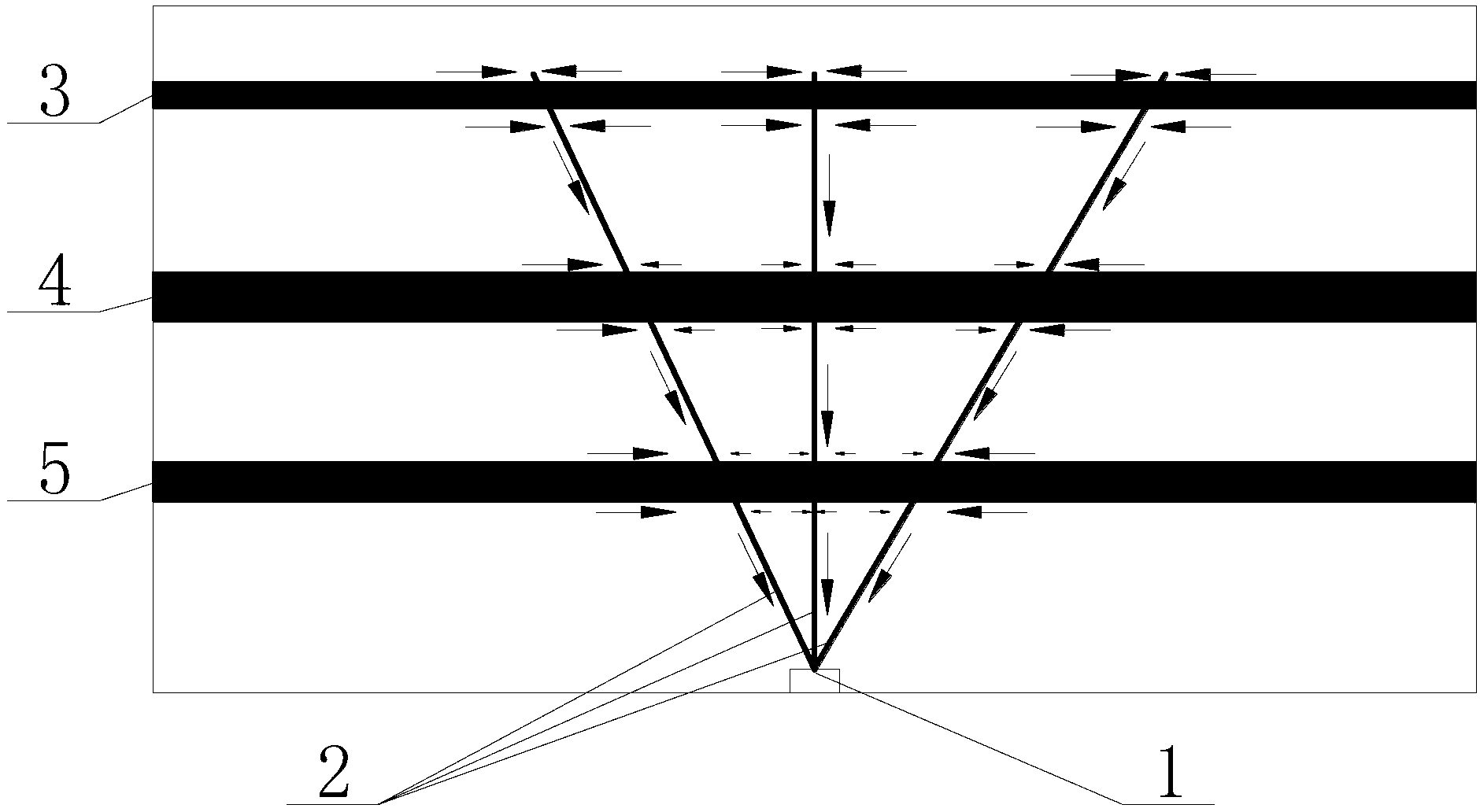

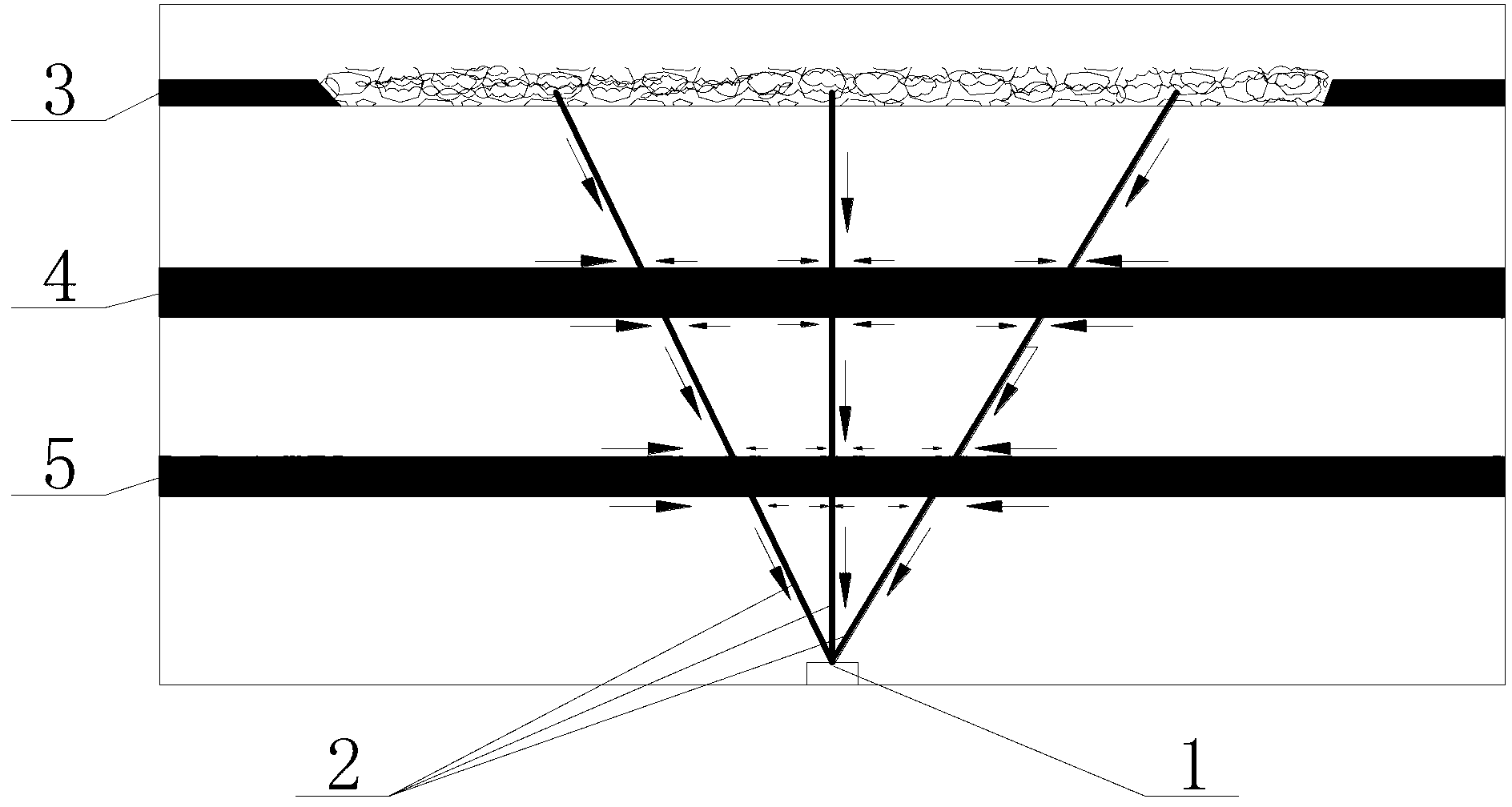

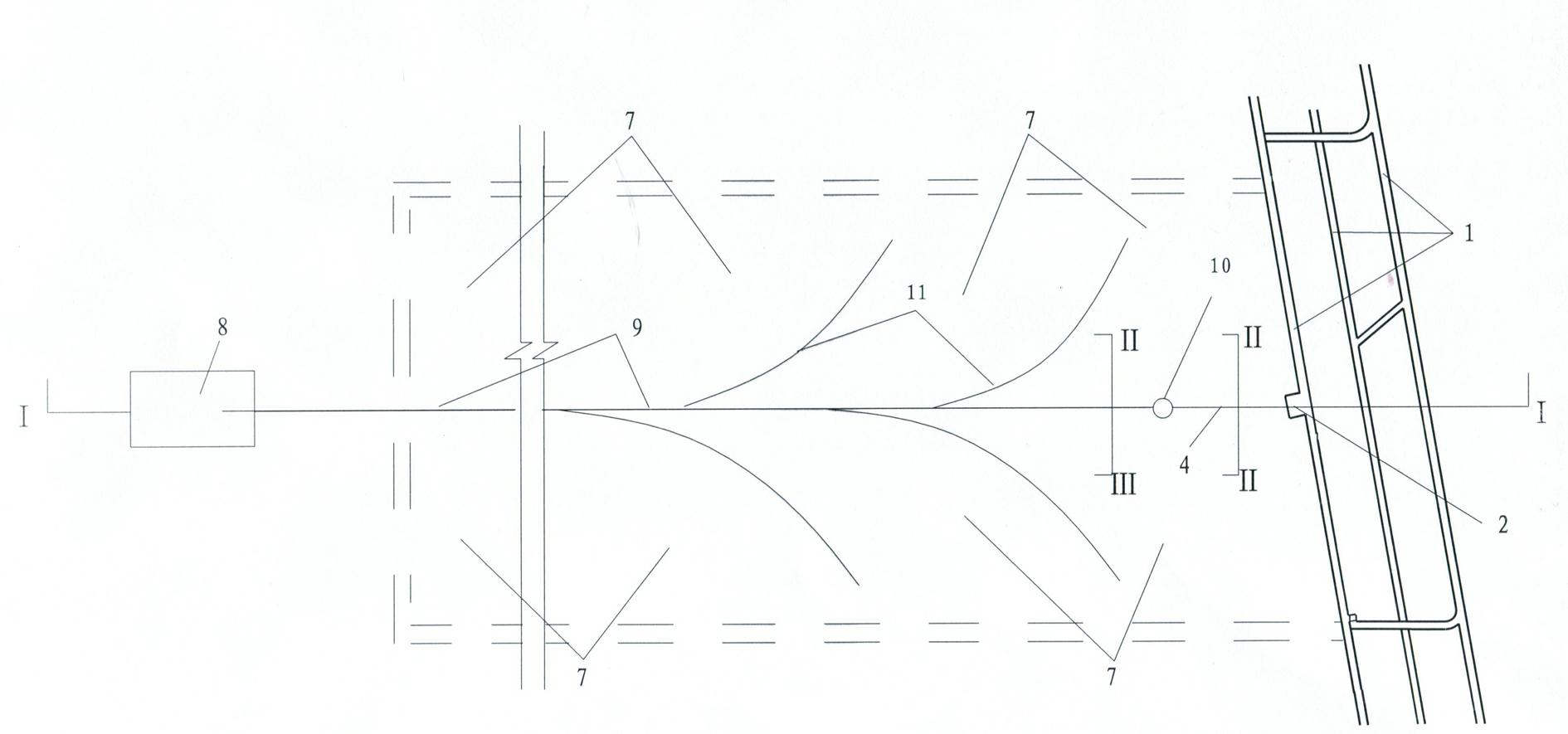

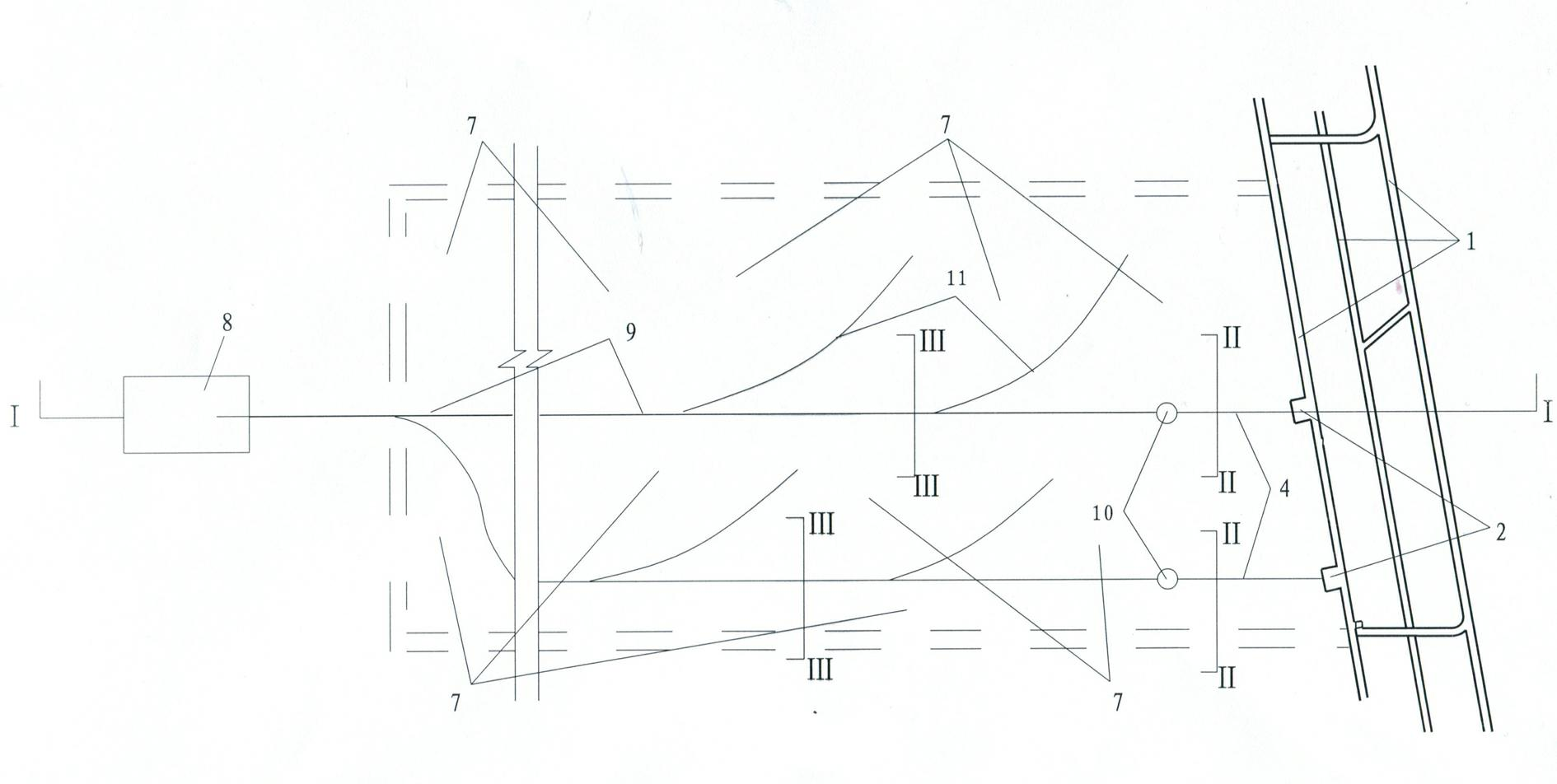

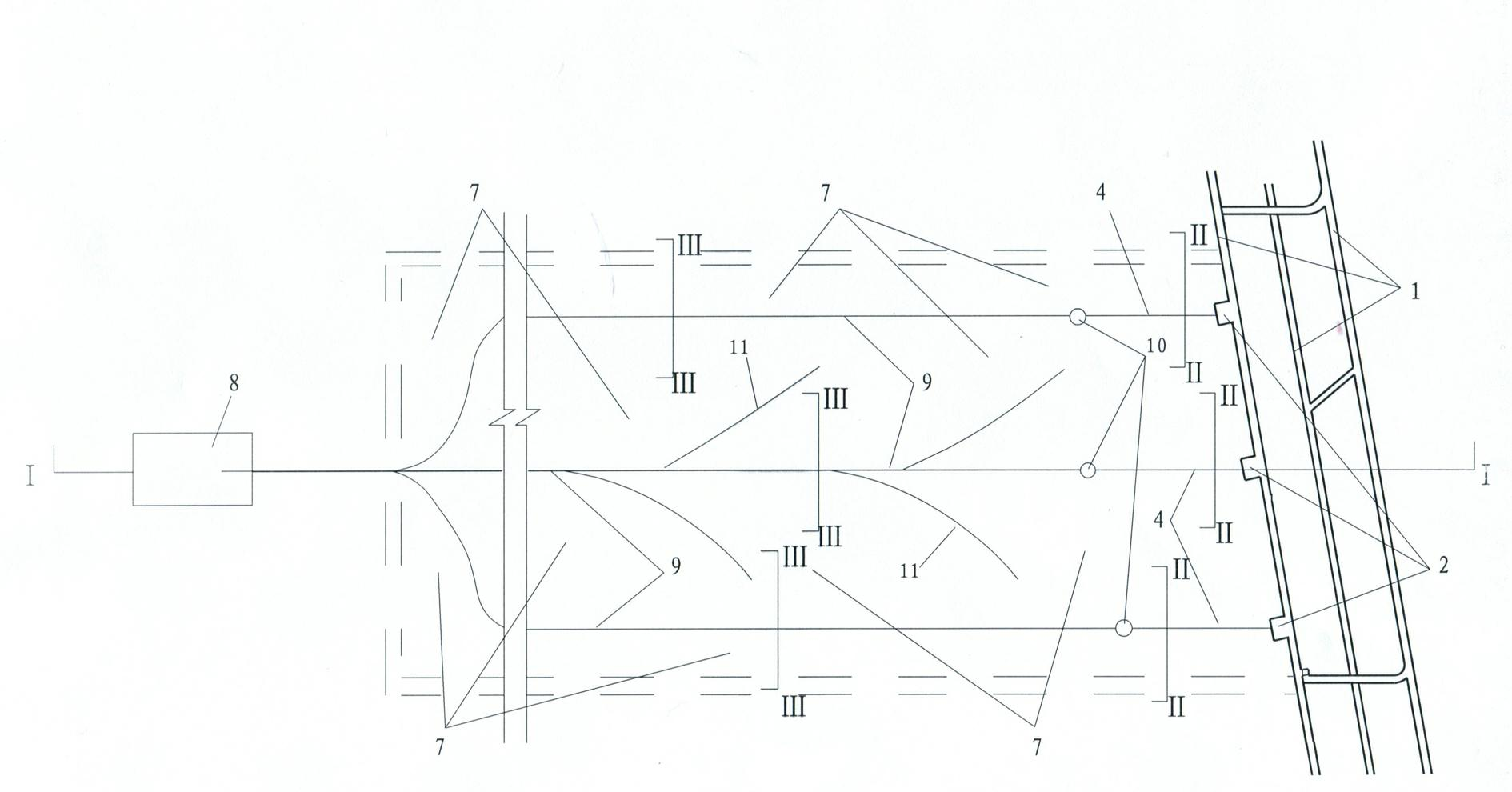

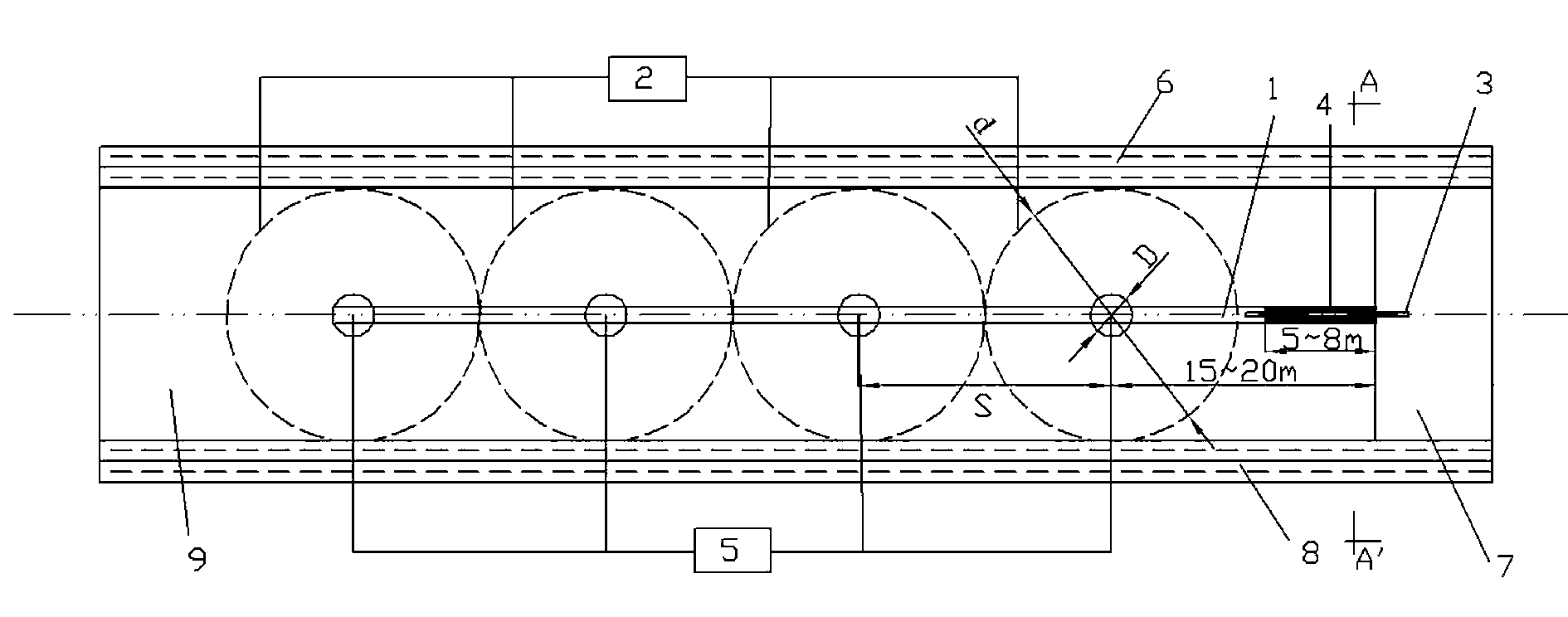

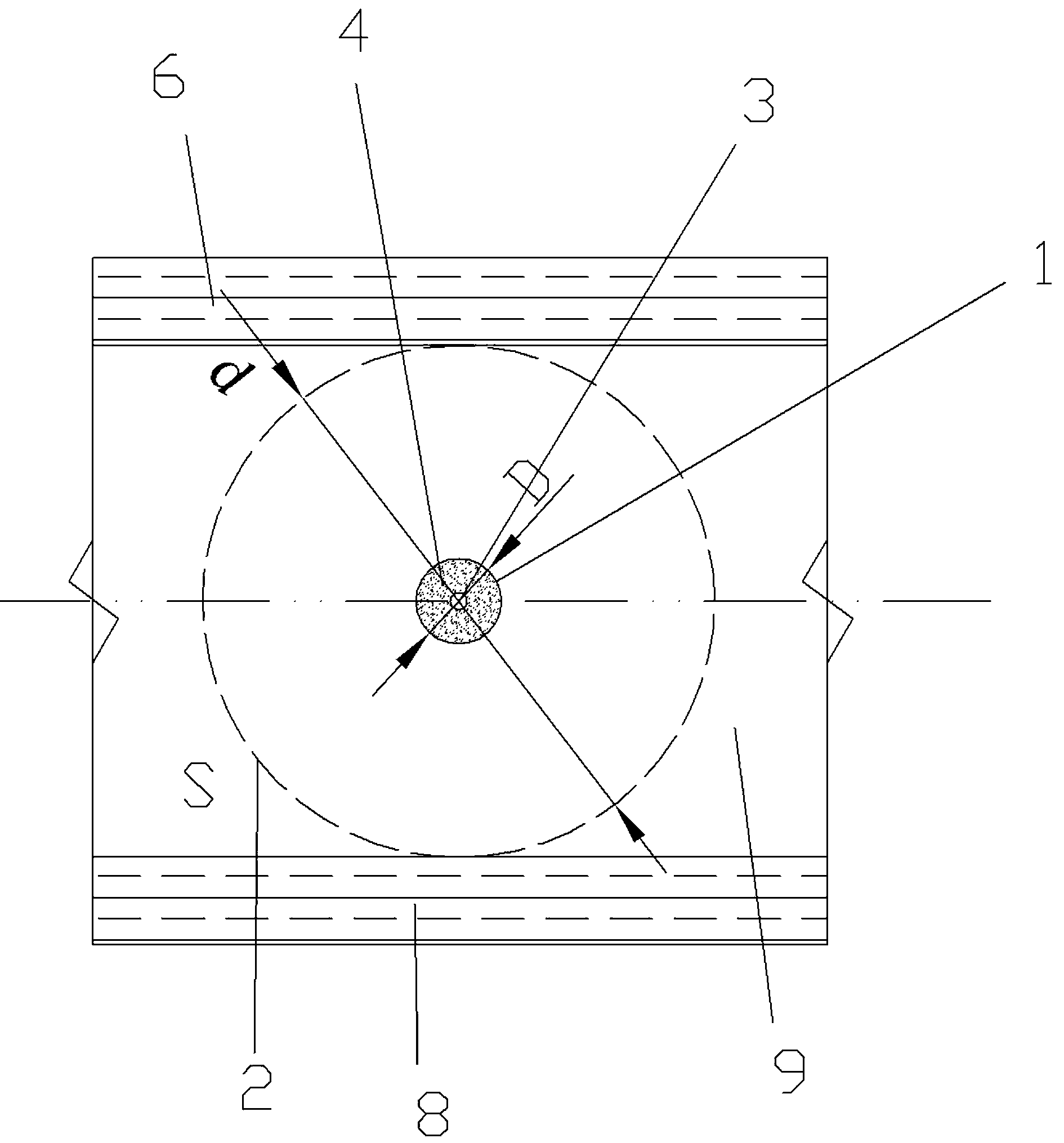

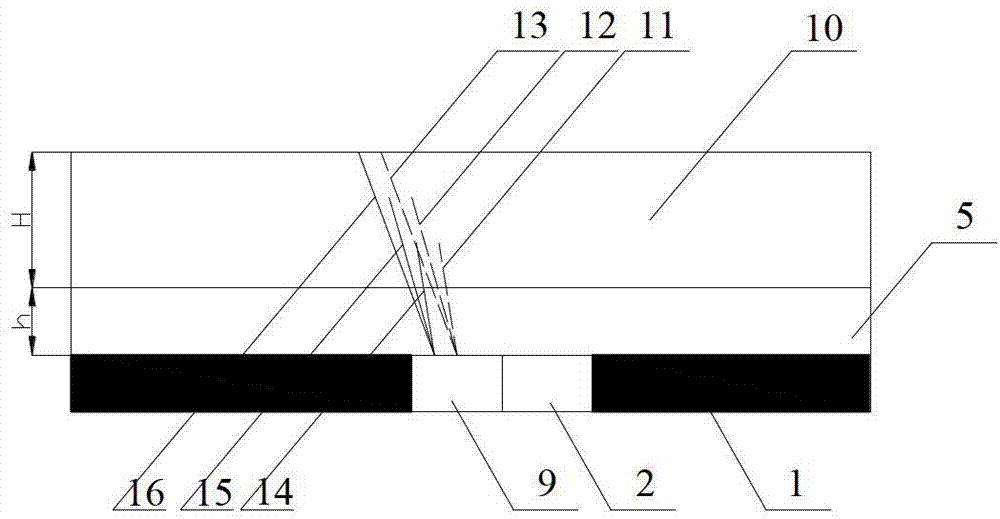

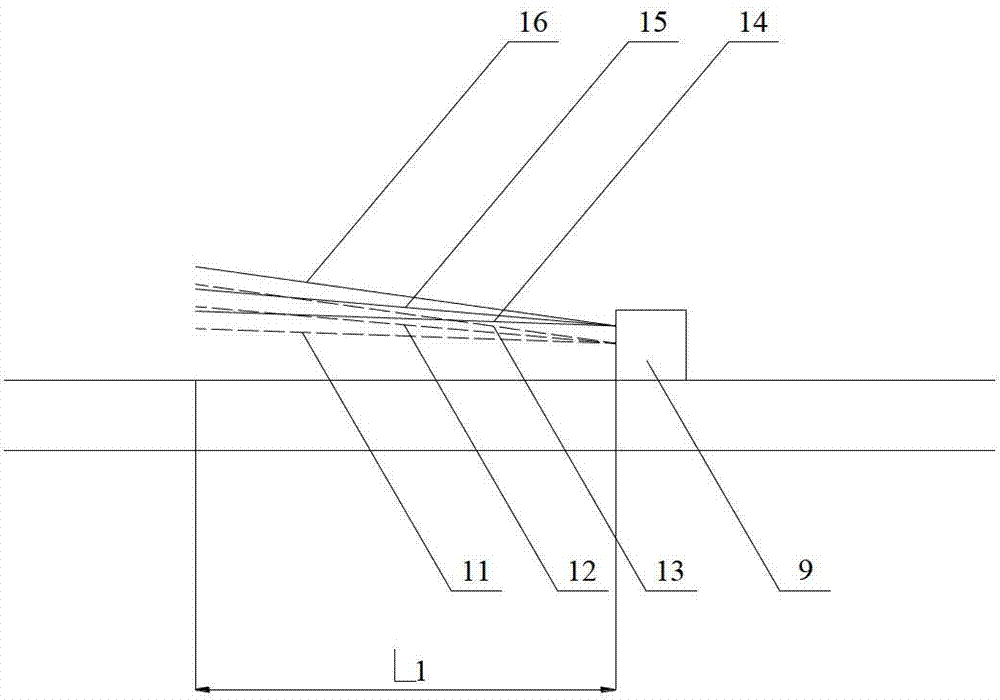

Gas extraction method of cross hole drilling area of gas discharge laneway

ActiveCN102226413AEffective interceptionEffective gush controlDirectional drillingGas removalDrill siteOblique angle

The invention discloses a gas extraction method of a cross hole drilling area of a gas discharge laneway, comprising the following steps: tunnelling an mining area return airway parallel to a mining area track roadway at the tail part of the gas discharge laneway; arranging drill sites on the gas discharge laneway along the roof of a coal seam at intervals; respectively constructing multiple high-level drilling holes with different oblique angles and different lengths and a low-level hole in a worked out area direction in the middle and upper part of each drill site; arranging an extraction pipe after hole drilling construction in each drill site is finished; sealing the holes; and connecting the drilling holes in each drill site into the extraction pipe of the gas discharge laneway through an upper confluence pipe and a lower confluence pipe for extraction, thus realizing the safe production of a gas coal seam group. The method is safe and reliable, can effectively intercept pressure relief gas at an upper neighbor layer, effectively controls the gas from flowing out from a stope face, lowers the gas concentration of an upper corner, and ensures the safe production of the stope face.

Owner:CHINA UNIV OF MINING & TECH

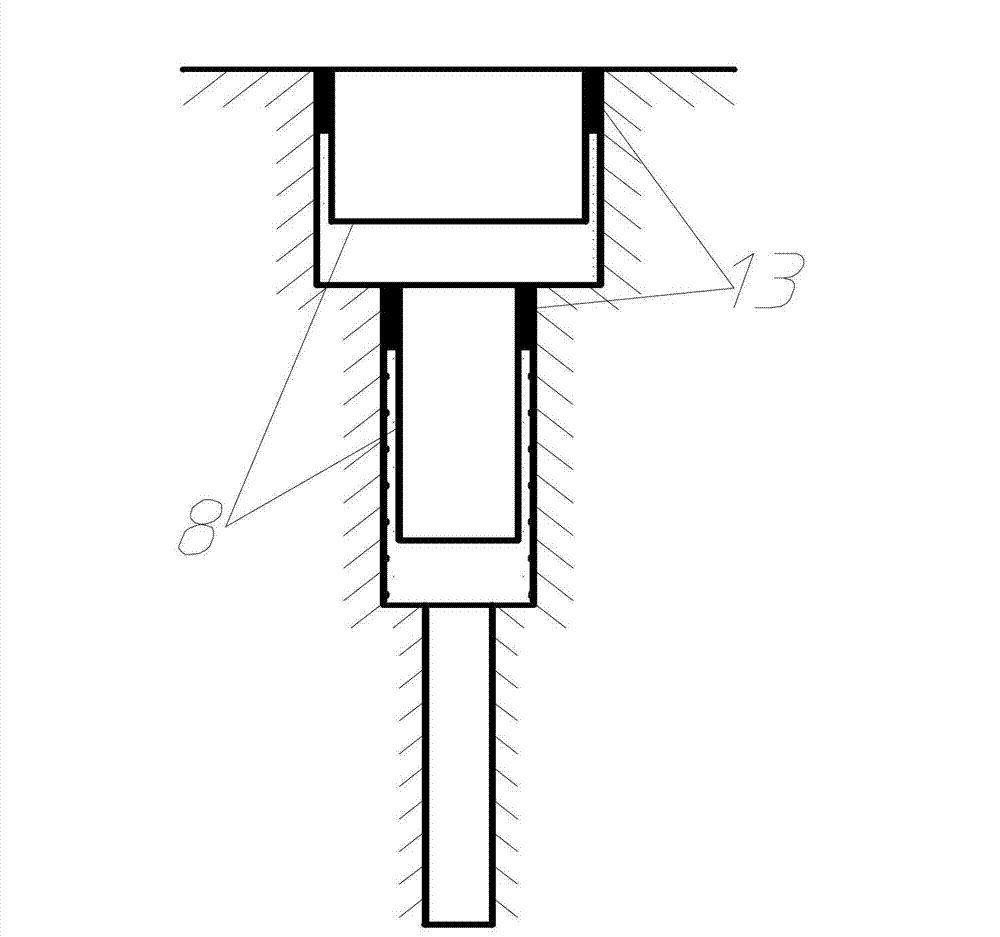

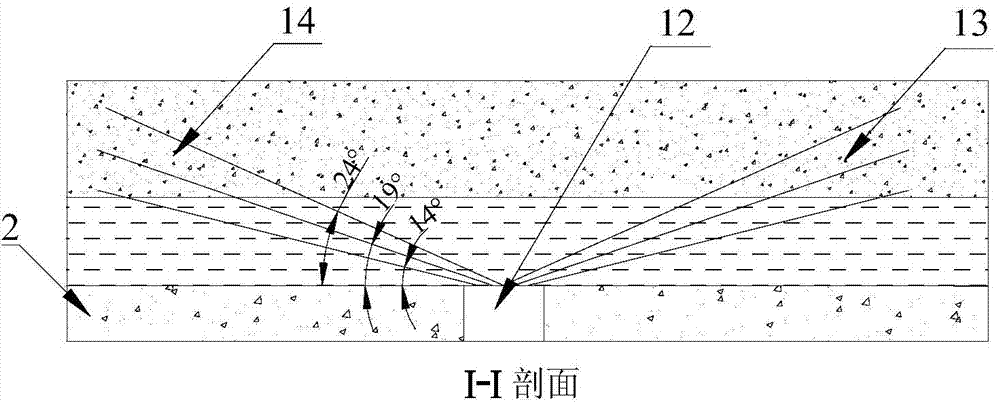

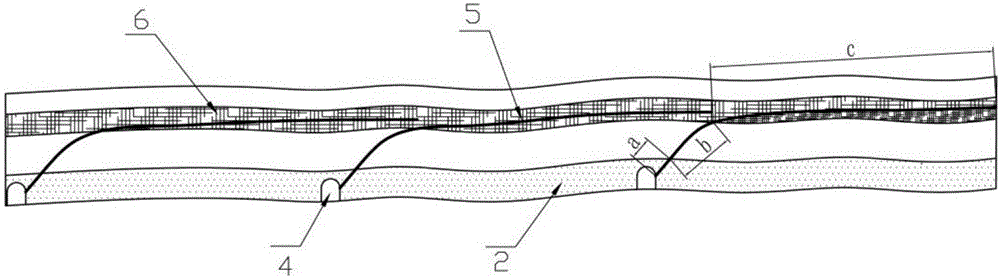

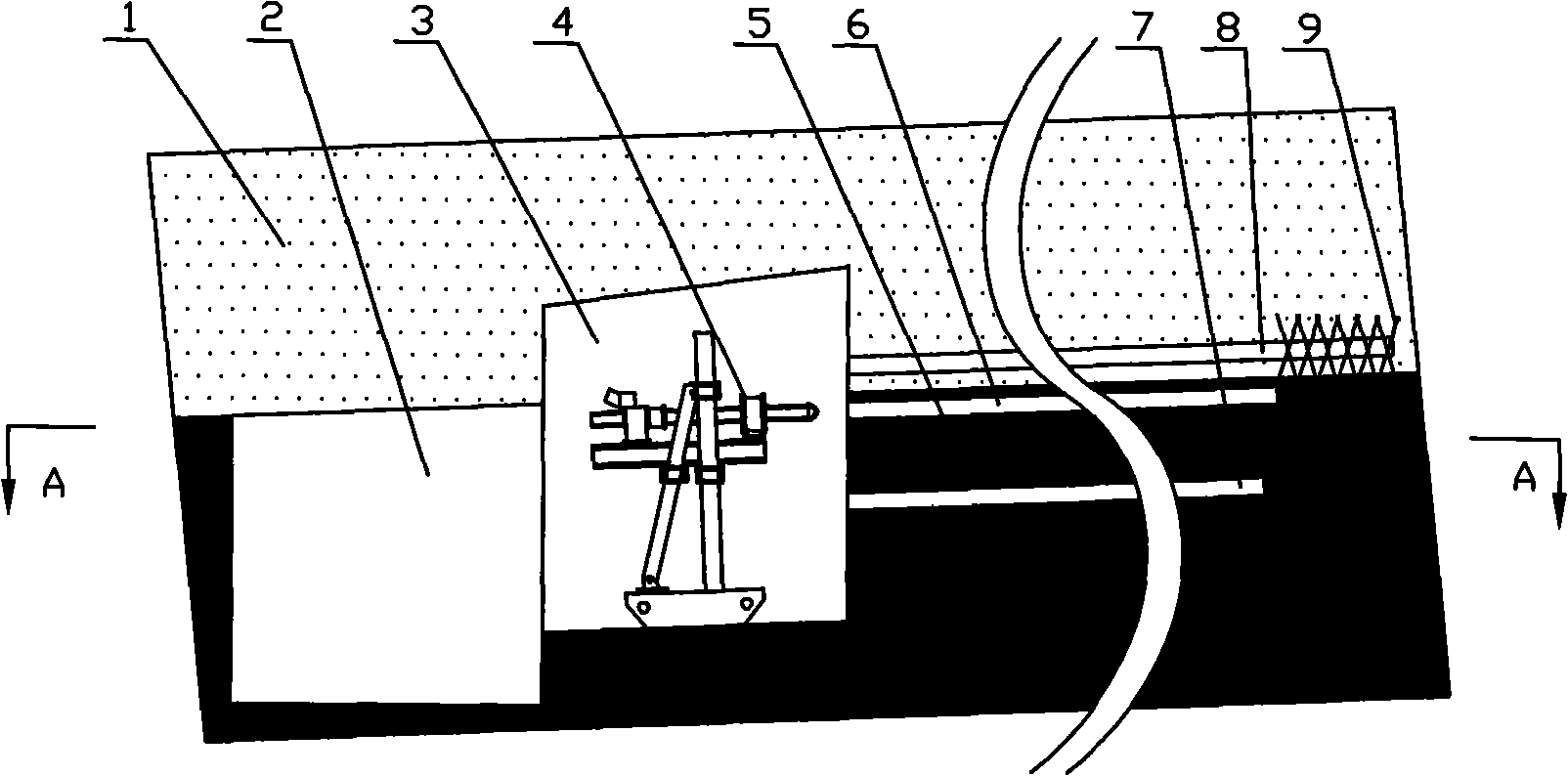

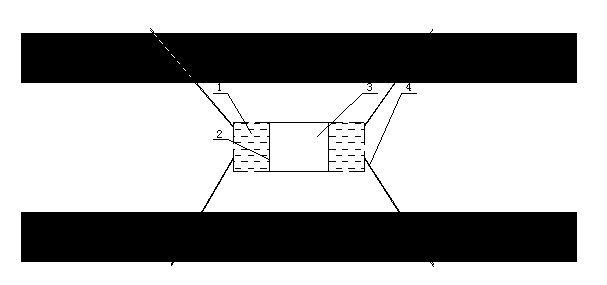

Method for extracting gas from separation layer below overlying strata, draining water and grouting through combined drill hole

ActiveCN104863629AHigh extraction rateImprove grouting effectMaterial fill-upDrainageDrill siteCement paste

The invention discloses a method for extracting gas from a separation layer below an overlying strata, draining water and grouting through a combined drill hole and belongs to a mine disaster prevention method. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole includes that installing a drill site at a transportation roadway of a preparatory work face adjacent to a coalface, constructing the combined drill hole in the part about to generate the separation layer below the overlying strata above the gob of the coalface in a mode of keeping away from a caving zone, wherein the combined drill hole is composed of an inside gas extraction pipe and a water draining-grouting pipe; after the separation layer is generated, preventing the mine disaster according to the stages that firstly, draining water from the separation layer through the combined drill hole; secondly, after the gas is gathered in the separation layer after the water in the separation layer is emptied, using the primary combined drill hole to extract the gas from the separation layer; finally, after the water and gas are completely drained and extracted from the separation layer, filling cement paste to the separation layer through the primary combined drill hole. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole is capable of solving the mine disasters of water bursting in mine, gas outburst (gas emission), rock burst, surface subsidence and the like through the combined drill hole, the separation layer water and gas extraction rate is high, and the grouting effect is good.

Owner:CHINA UNIV OF MINING & TECH

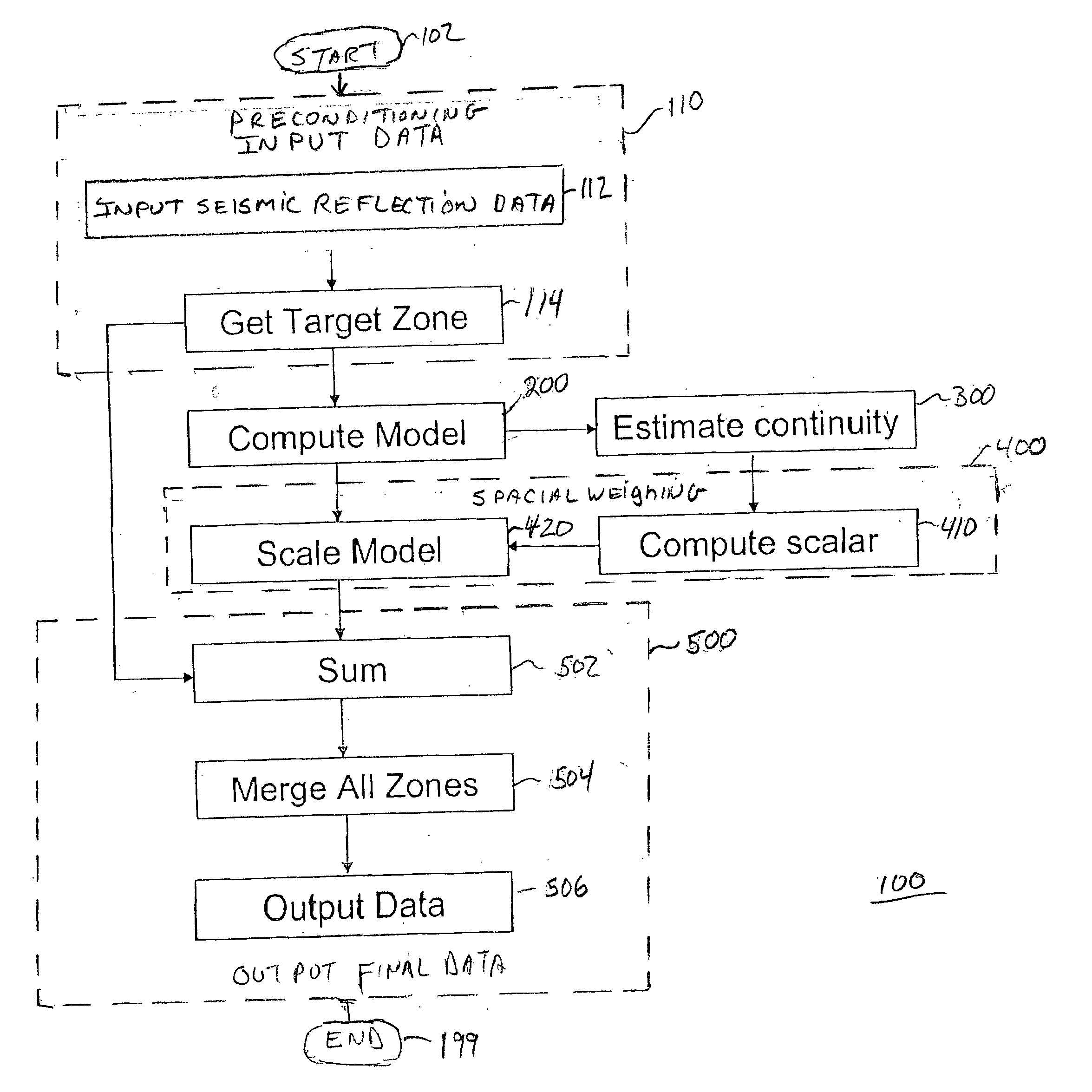

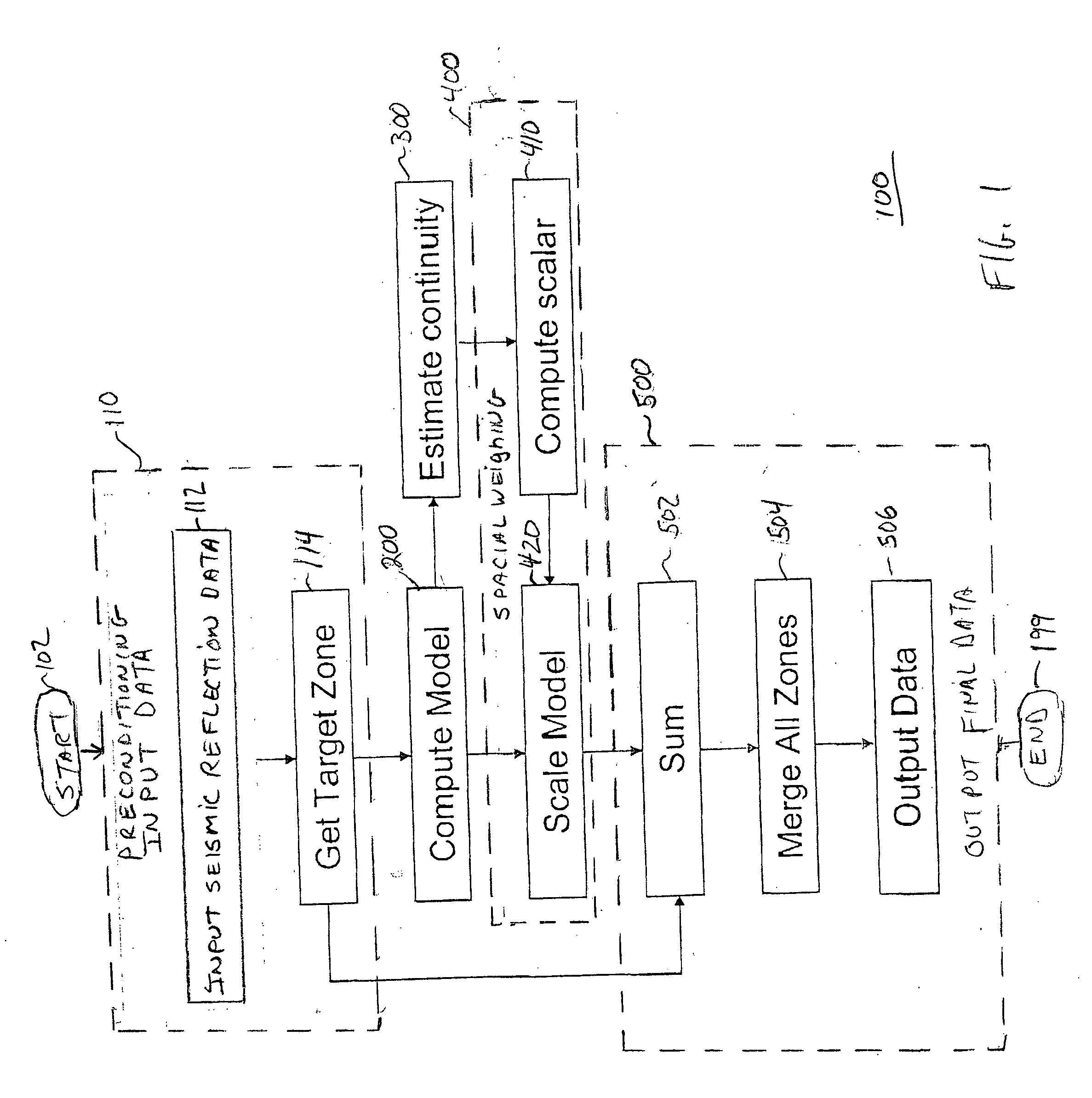

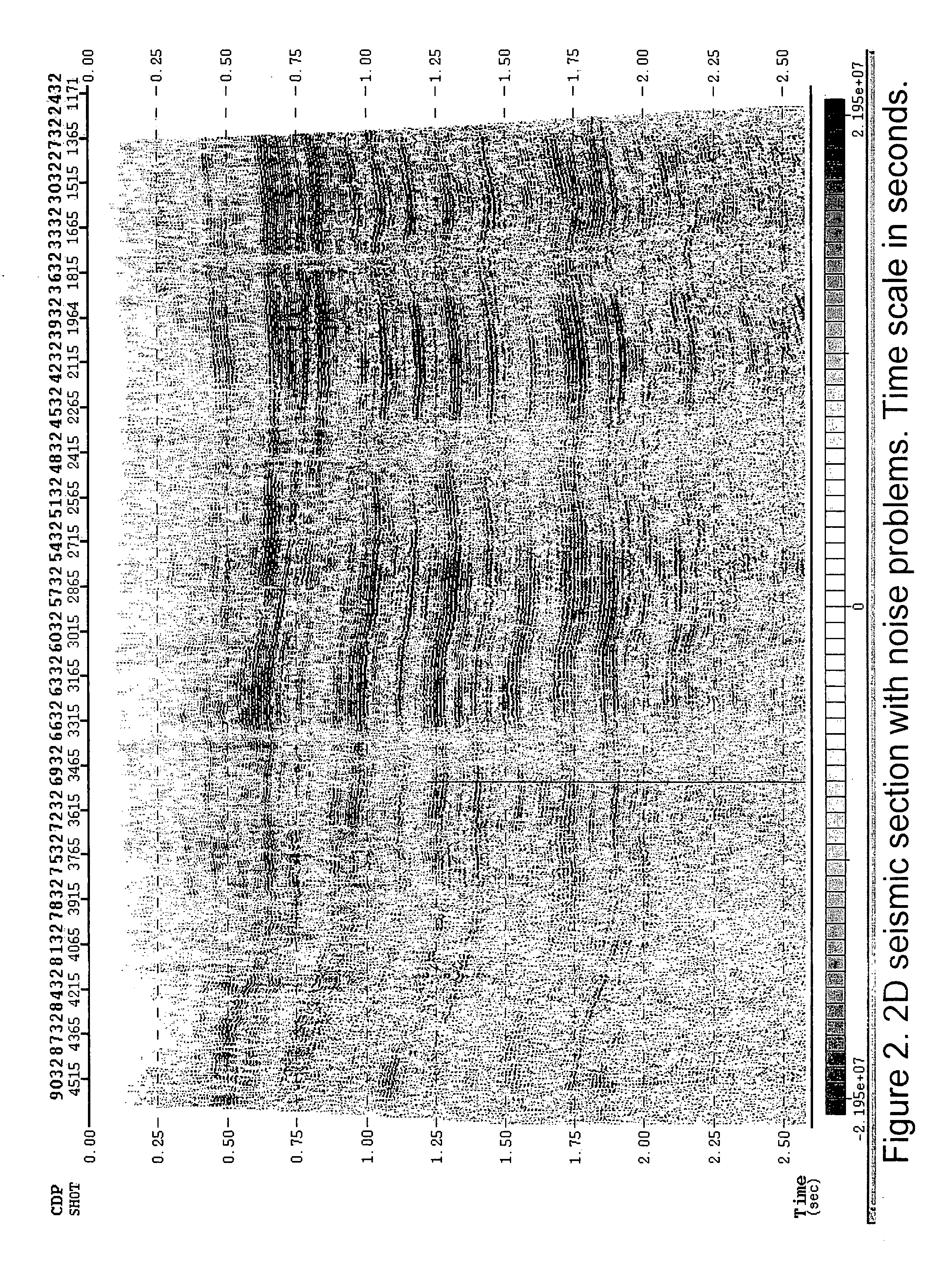

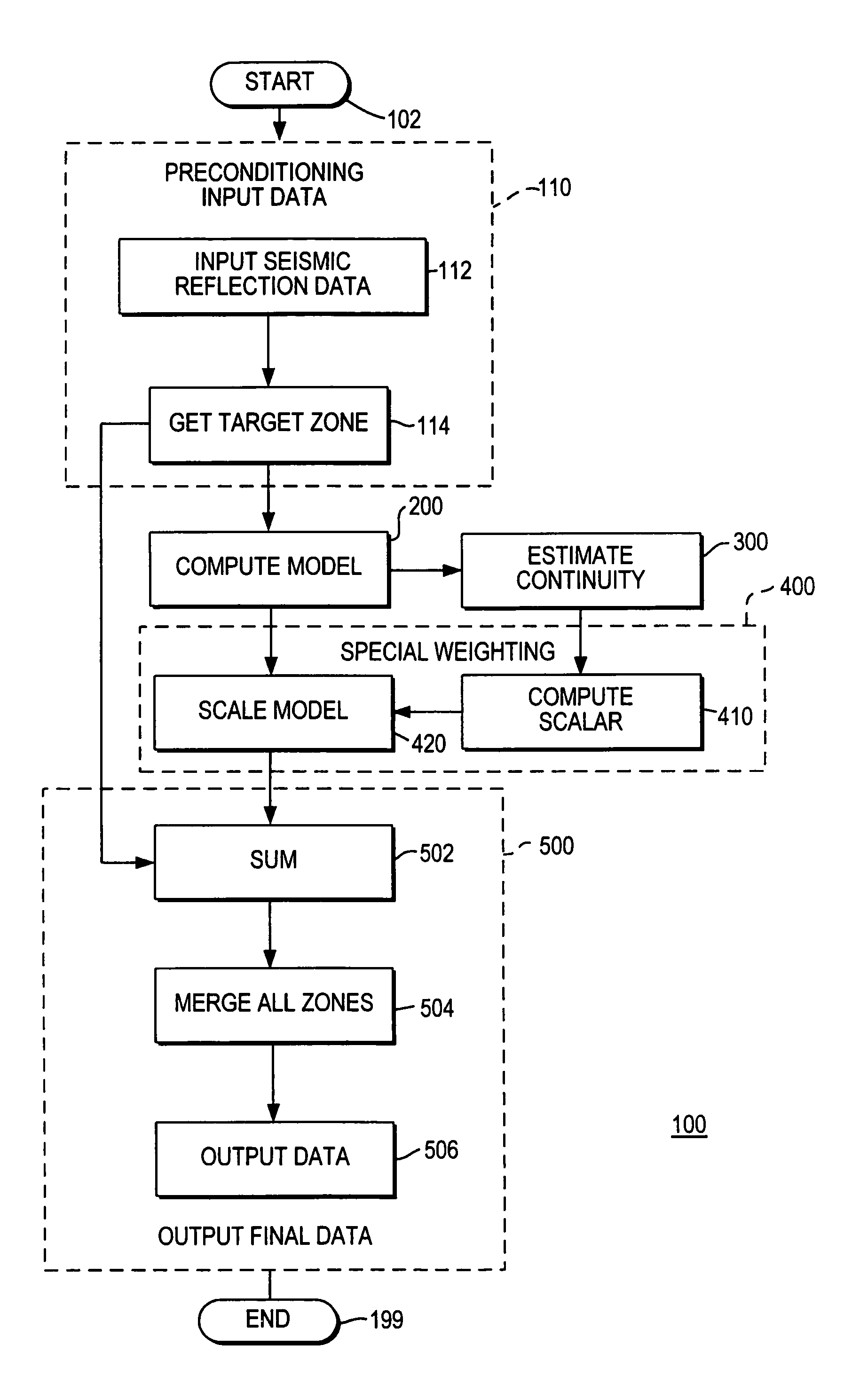

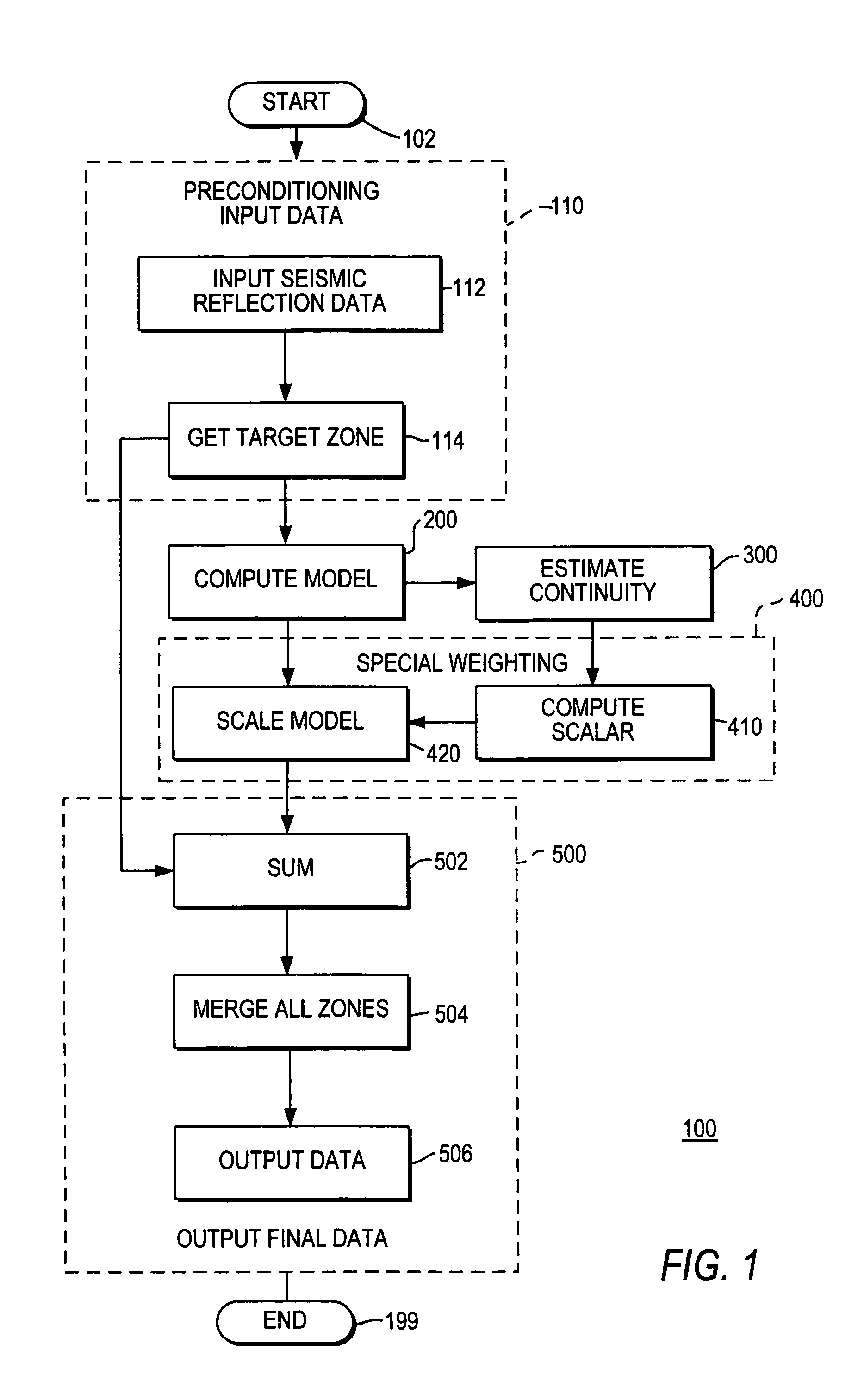

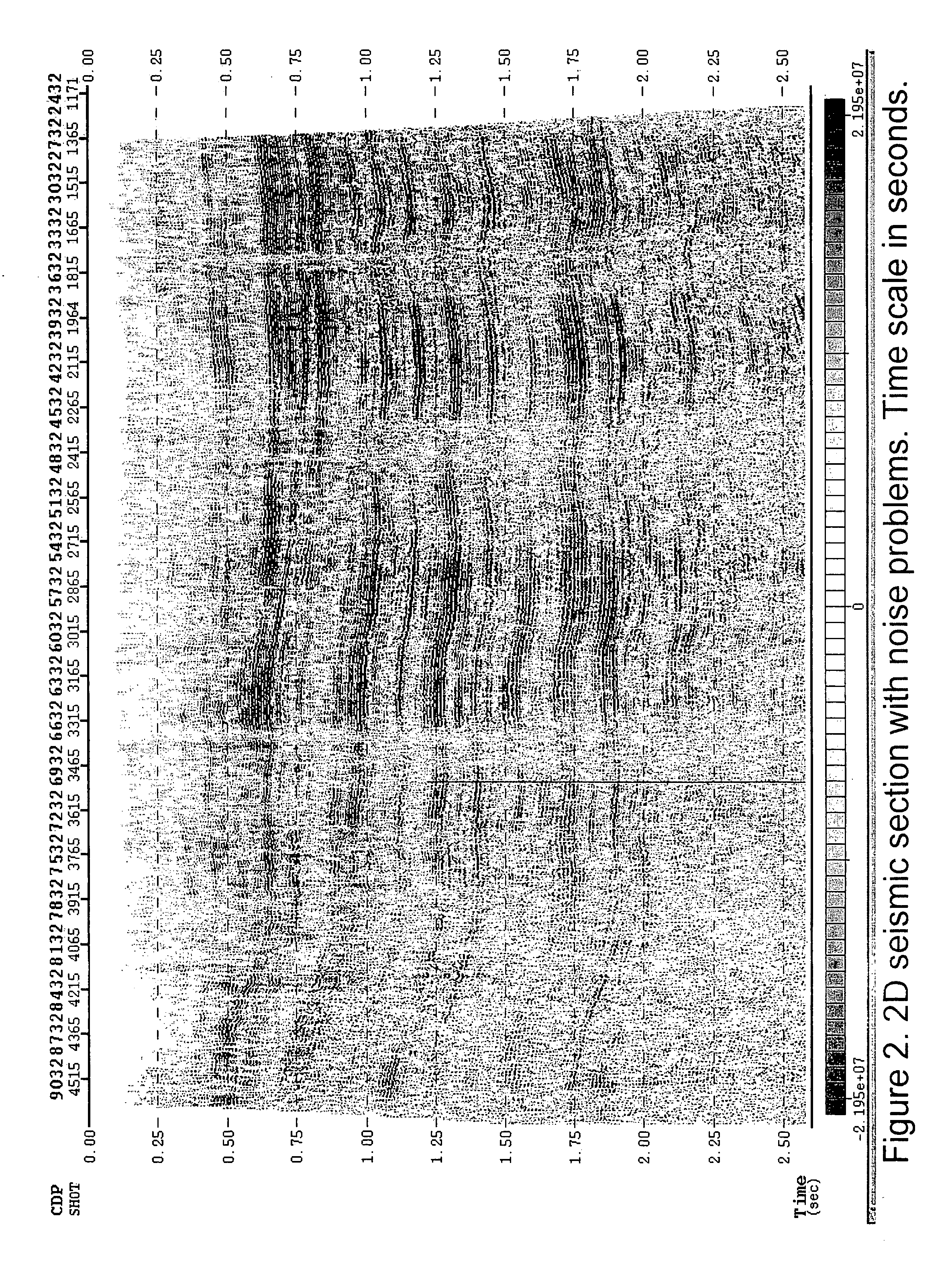

Method for estimating and reconstructing seismic reflection signals

ActiveUS20070064535A1Avoid a lotImprove resolutionSeismic signal processingSeismology for water-covered areasFeature vectorSignal-to-noise ratio (imaging)

A method for reconstructing seismic data signals of poor quality to improve the signal-to-noise ratio of the data for display and analysis in connection with the selection of drilling sites for recovery of hydrocarbons. The method includes providing a signal model by applying a Karhunen-Loeve transform to selected input seismic data collected for the target zone, to form a co-variance matrix from the dot products of all pairs of input data. Eigenvalues and eigenvectors for the matrix are computed, and the most significant eigenvectors are inversely transformed to provide a coherent estimate of the signal. The input data is combined with the model data based on the determination that the model data lacks continuity, wherein the good quality signal-to-noise ratio data experiences little change and discontinuous data is enhanced by a contribution of the signal estimate data. The reconstructed seismic data of the target zone can be displayed for analysis.

Owner:SAUDI ARABIAN OIL CO

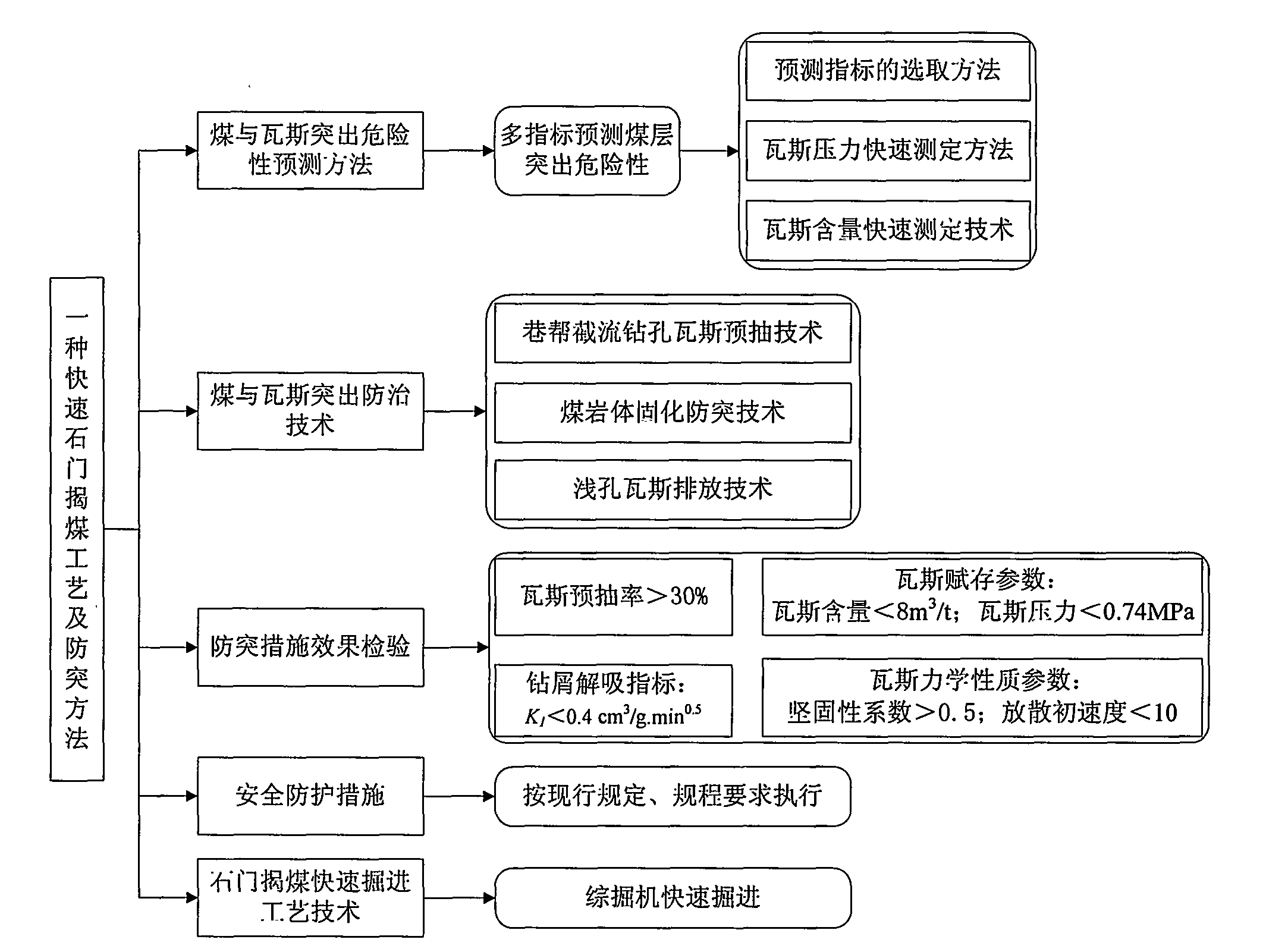

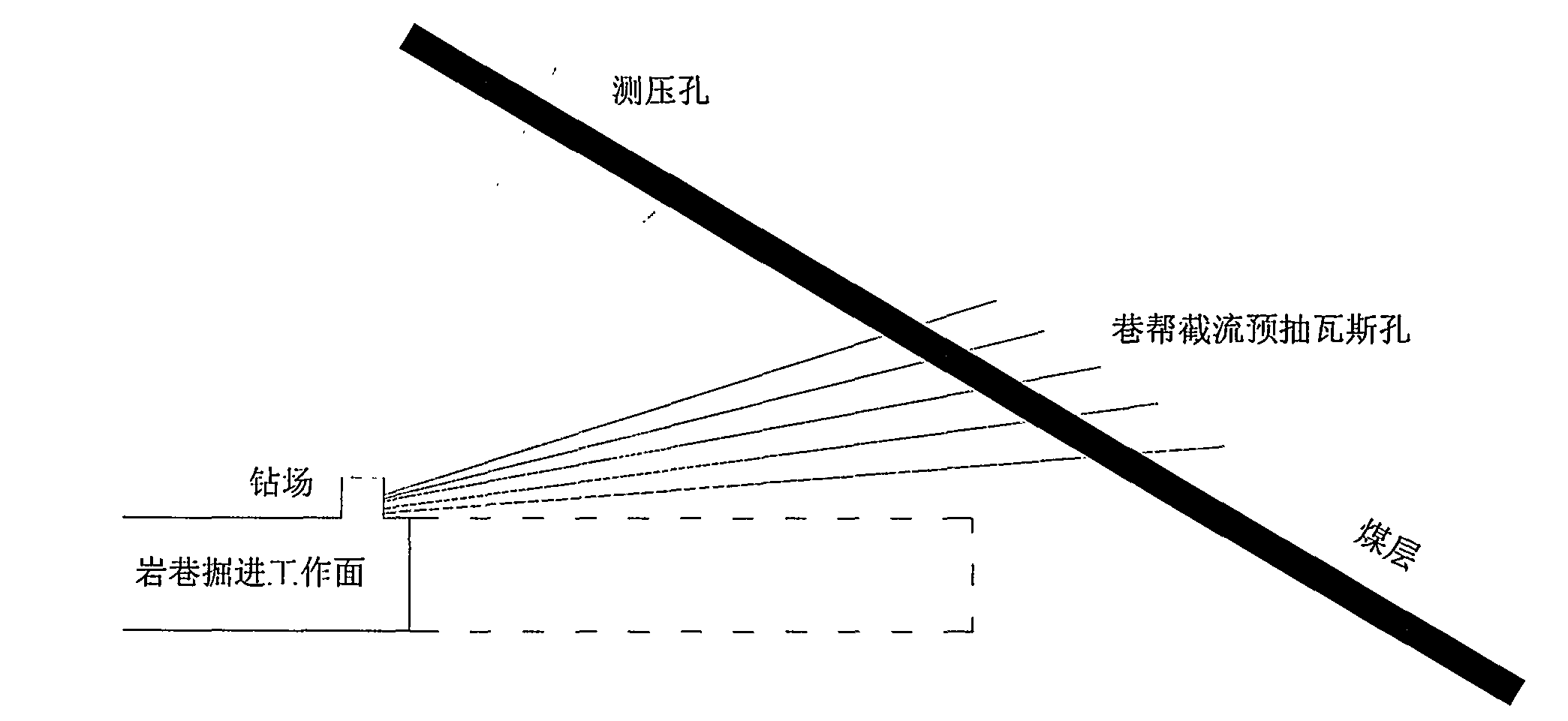

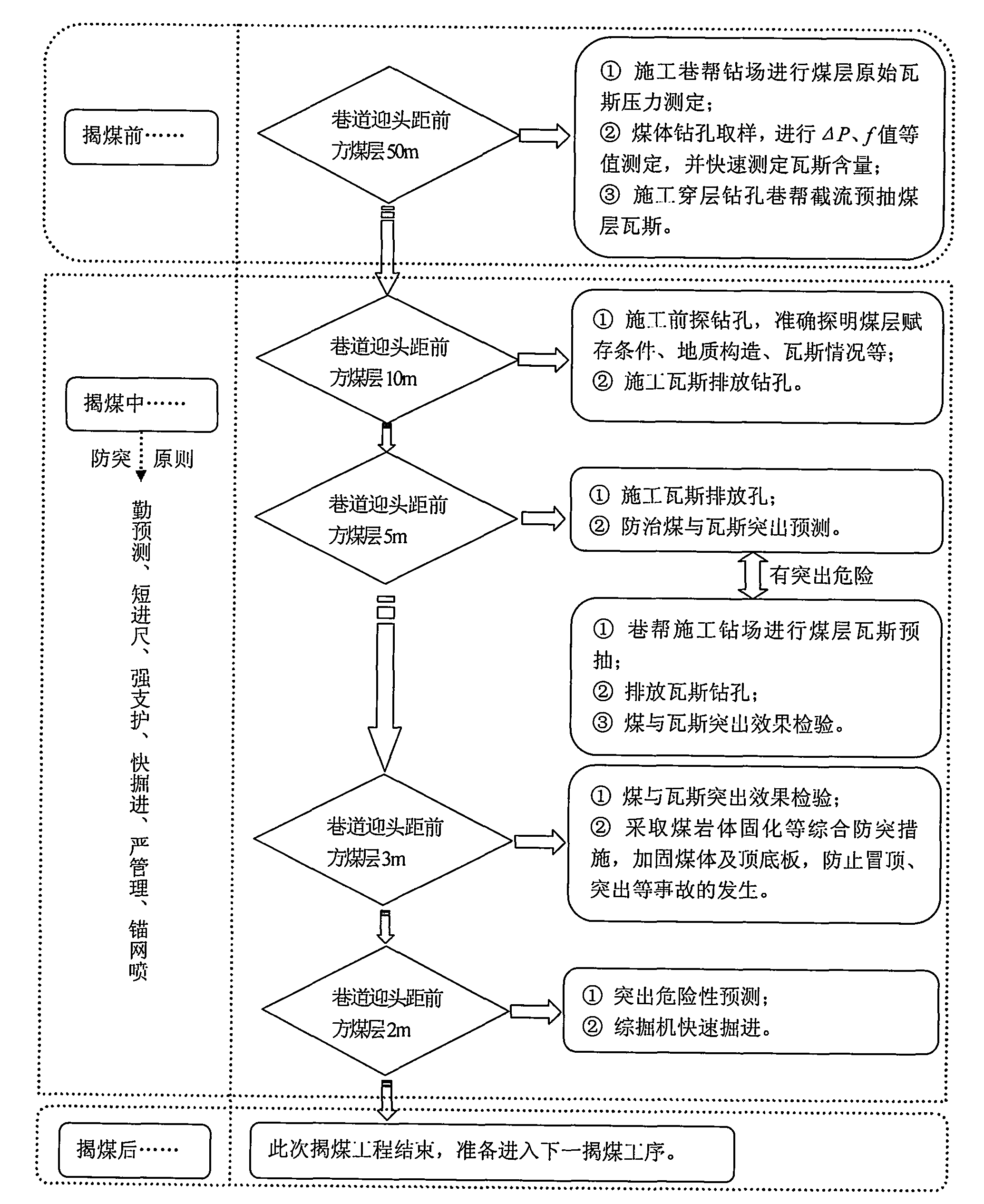

Rapid rock cross-cut coal uncovering process and outburst prevention method

InactiveCN103306677AImprove accuracyShorten the timeUnderground miningSurface miningDrill siteCross cut

The invention relates to a rapid rock cross-cut coal uncovering process and an outburst prevention method. The rapid rock cross-cut coal uncovering process comprises the following steps: performing lane drill site construction advance borehole during rock drivage period, performing penetration drilling to measure the gas pressure of the coal seam and rapidly measuring the gas content, the mechanical property of the coal and other parameters by utilizing extraction drilling and sampling under the conditions that the rock gangway construction is not influenced and the coal seam to be uncovered is subjected to gas interception and extraction in advance, and realizing the outburst danger of the multi-index prediction coal seam; increasing the specific coal and rock mass curing measures in addition to the gas outburst prevention measures with the uncovering related regulations and standard requirements, so that the rock cross-cut is excavated by employing an integrated excavator after the rock cross-cut uncovering working face is subjected to complete outburst removal, and rapid rock cross-cut coal uncovering is realized. The whole set of coal uncovering process and the outburst prevention are used for the experimental coal mine 937m roadways, and 18 layers of coal are uncovered totally, so that the whole construction period is shortened by 1.63 years and is only 1 / 3 of the expected coal uncovering time. The method is easy and convenient to operate, safe in construction, short in overall coal uncovering time and good in outburst prevention effect and has wide practicability.

Owner:GUIZHOU INST OF COAL SCI

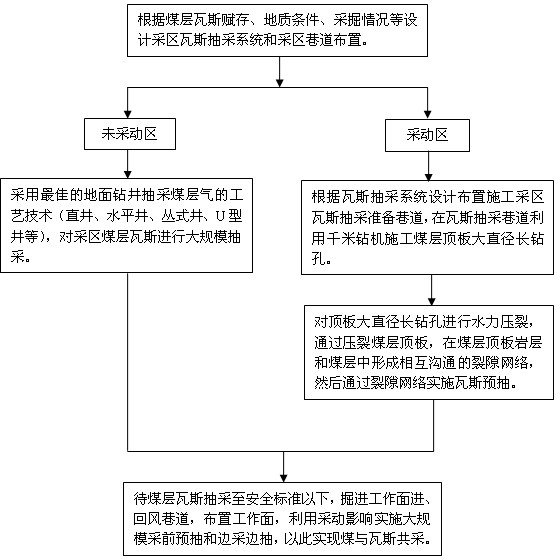

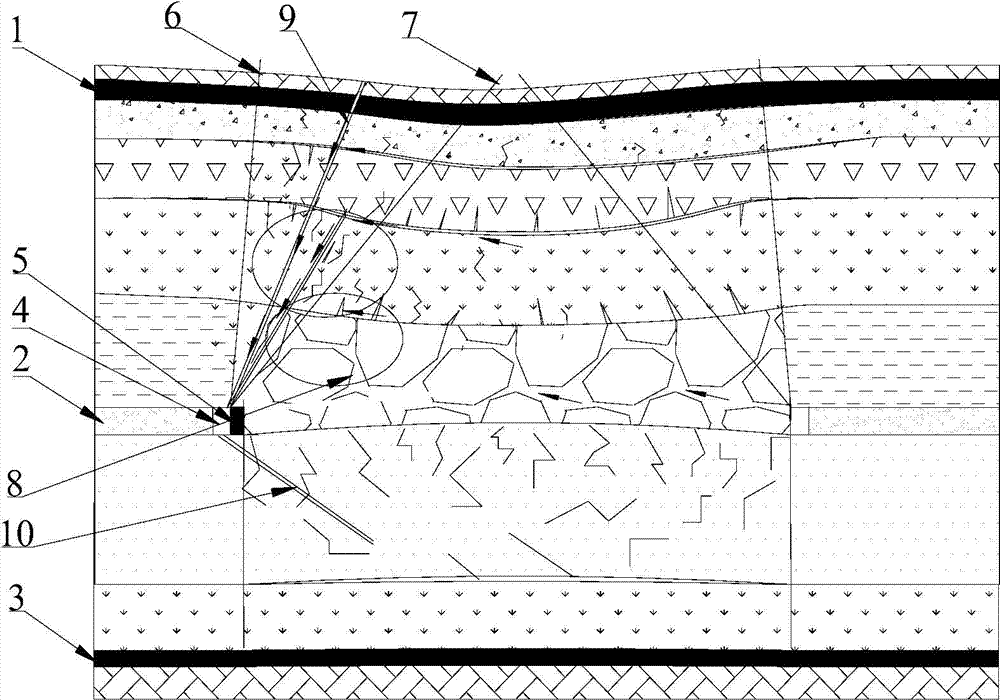

Integrated mining method for commonly mining coal and gas of high mine

The invention discloses an integrated mining method for commonly mining coal and gas of a high mine. The integrated mining method comprises the following steps of: adopting a process technology which utilizes ground drilling to drain coal bed gas for carrying out gas drainage on unmined areas, and carrying out coal mining on drainage areas when the safety standard is met; for mined areas, utilizing the space of the existing roadways and gas drainage special preparation roadways under the coal mine or additionally opening large-diameter long drilling holes which have different distances from a drill site to a coal bed top plate; selecting corresponding fracturing pump stations and fracturing process technologies to carry out fracturing treatment, forming a fracture network system communicated with the coal bed in the coal bed top plate to preextract the coal bed gas; when the preextraction meets the safety standard, firstly adopting a tunneling process to tunnel an intake airway and a return airway of a work surface; distributing a stopping work surface, then carrying out construction of the conventional drainage and drilling at the intake airway and the return airway of the work surface; and by utilizing the mine pressure rule caused by the stopping of the work surface, implementing the preextraction before mining and simultaneous mining and extraction with fracturing holes, and realizing integrated mining of the coal and the gas. In the integrated mining method, the safe high-efficiency common mining of the coal and the gas can be realized and the application prospect is wide.

Owner:HENAN COAL CHEM IND GROUP INST

Method for preventing and controlling water burst of coal mining base board rock stratum on pressure bearing water body

InactiveCN103291325ASolve the problem of low pulp intakeSolve the problem of water inrushUnderground chambersTunnel liningDrill siteSlurry

The invention relates to a method for preventing and controlling water burst of a coal mining base board rock stratum, in particular to a method for preventing and controlling water burst of a coal mining base board rack stratum on a pressure bearing water body. The method comprises the following steps that firstly, a coalface is detected; secondly, drill sites are exploited at the two sides of a lead conveying smooth groove and the two sides of a air returning smooth groove respectively so as to perform drilling according to a detected result in the first step; thirdly, slurry filling casing pipes are arranged at drilling openings of lower three belts of the coal layer base board, and a freezing casing pipe is arranged at the bottommost layer section; fourthly, after drilling is finished, slurry is filled into drill holes, the slurry is sequentially filled, starting from the bottom end and going upwards layer by layer, before the slurry is filled into the bottommost layer and in the slurry filling process, liquid nitrogen is used for performing quick-freezing treatment. According to the method for preventing and controlling water burst of the coal mining base board rack stratum on the pressure bearing water body, the principle that the procedures of detection, slurry filling, freezing and digging are sequentially performed is utilized, slurry filling and freezing are respectively performed on the lower three belts sequentially from bottom to top layer by layer, and therefore water disasters in the excavating process of a deep coal layer base board of a complex geological structure can be effectively prevented from happening.

Owner:SHANDONG UNIV OF SCI & TECH

Coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of working face of first mining total rock pressure relief

InactiveCN104712358ALayer selection is flexibleSolve the outstanding problem of safe miningFluid removalGas removalLithologyPlate pressure

The invention discloses a coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of a working face of first mining total rock pressure relief. When a first mining pressure relief coal seam can not be selected, the coal and rock seams are moved and broken through the working face of first mining total rock pressure relief, an upper covered coal seam with high gas and a lower covered coal seam which high gas are subjected to pressure relief and swollen, fractures of a surrounding rock mass are developed, the gas permeability is increased, the gas is subjected to desorption and transportation, and finally a top plate pressure relief annular fracture area and a bottom plate pressure relief annular fracture area are generated. To create a favorable stress environment of retained roadway surrounding rock, retained roadway mining empty side cantilever crest truncation is conducted to first advance mining drill site toward and backward the working face in a bi-directional mode, according to the top plate lithologic characters, the first advance is subjected to top plate deep hole pre-splitting and cover caving so that it is guaranteed that the top plate is sufficiently collapsed to fill a worked out section. By means of the method, the prominent problems of exhausting and mining of coal seam group pressure relief gas and safe mining when the first mining pressure relief coal seam of the coal seam group with high gas content is difficult to select are solved.

Owner:CHINA UNIV OF MINING & TECH

Stope face roof water pre-drainage construction method

The invention relates to coal mine underwater treatment technology, in particular to a stope face roof water pre-drainage construction method, which solves the technical problem of treatment of a water-bearing bed on a coal seam of a stope face. As the process of stoping on the stope face includes down stoping firstly and up stoping secondly, stope face roof water is drained in advance through roadways beside the stope face before stoping, a drill site chamber and a water bin are constructed at the lowest position of each of the roadways, two drainage pipelines are paved on each of the roadways, an independent drainage system is utilized, drainage holes are drilled in the drill site chamber towards the stope face roof, and water for drilling is led into the water bin through hoses directly and is drained by the drainage system of the roadways. Since roof water is drained in advance, water inflow during the stoping process is reduced effectively, troubles to production of coal mines due to the roof water are eliminated, affection of flood disaster to production is avoided, a safe and comfortable working environment is provided for the stoping operation, and conditions for stability and high yield of the stope face are created.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

High-efficiency tunneling gas control method for high outburst mine coal roadway

The invention discloses a high-efficiency tunneling gas control method for a high outburst mine coal roadway, which comprises the following steps: before the working surface of the outburst mine coal roadway is used for tunneling, respectively forming a drill site at two sides of the coal roadway, perforating overlong deep holes from each drill site along the tunneling direction of the coal roadway, and carrying out grouting treatment so that gas in the grouting range along the tunneling direction of the coal roadway is relatively isolated from the surrounding environment, thereby forming a relatively closed roadway tunneling space, eliminating the potential safety hazard of outburst in the roadway tunneling process, and overcoming the original defect that as the time for pumping and discharging the gas is too long, the whole tunneling efficiency is very low; meanwhile, the method of the invention realizes high-efficiency tunneling in the premise of safety and has simple operation of construction processes; and the method is suitable for being popularized and utilized under various conditions of occurrence of high outburst coal seams.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Construction method for coal mine downhole mining gas extraction roof plate pitch-up through stratum directional hole

ActiveCN106285477ASave recovery preparation periodIncrease the effective hole segmentDrill bitsDirectional drillingFracture zoneDrill site

The invention relates to a construction method for a coal mine downhole mining gas extraction roof plate pitch-up through stratum directional hole. By using a drill site in a tunneled air inlet roadway of a working face adjacent to a working face to be mined, equipment such as pilot directional drill tools and impact composite reaming drill tools, a multi-stage revolving reaming process, a sliding directional drilling process, a composite directional drilling process and an impact composite reaming process, the roof plate pitch-up through stratum directional hole is obtained. The roof plate pitch-up through stratum directional hole enters a roof plate mining fissure zone and a separation area in advance and extends for a long distance at a large diameter. After drilling construction and during recovery of the working face to be extracted, an upward fracture formed in a roof plate stratum under the influence of mining communicates with the roof plate pitch-up through stratum directional hole, gas generated during mining enters the roof plate pitch-up through stratum directional hole, and therefore extraction and use of mining gas is realized. The defects that an existing mining gas extraction drilling hole is small in aperture, the extension distance of a fracture zone is short, the drilling efficiency is low, the cost is high, and the construction period is long are overcome, and the mining gas extraction effect is improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

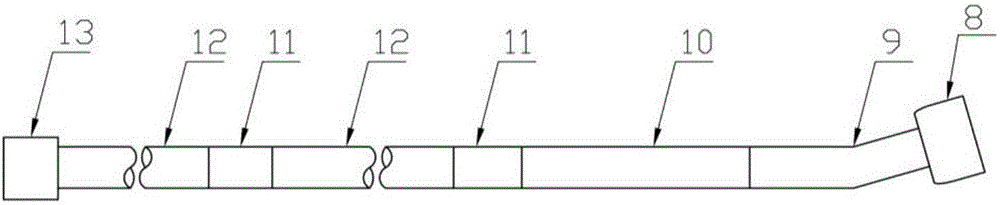

Mine MWD exploration system and measurement method thereof

ActiveCN106194159AShorten the timeReduce the amount of workConstructionsWater resource assessmentLithologyAction spectrum

The invention discloses a mine MWD (Measurement While Drilling) exploration system and a measurement method thereof. The mine MWD exploration system comprises a measurement module, a communication device and a handheld terminal, wherein the measurement module is mounted at the back of a drill bit, is propelled by a drill rod, directly utilizes vibration generated when the drill bit breaks rocks as a vibration source, and comprises a measurement probe tube as well as non-magnetic rods mounted at the front end and the back end of the measurement probe tube; the measurement probe tube is used for collecting signals in a hole, and meanwhile plays the transmission and water flowing functions; the non-magnetic rods are used for isolating the magnetic interference generated by the drill rod to the measurement probe tube, and also have the transmission and water flowing functions; the communication device is mounted in a drill site outside the hole to realize communication between the measurement probe tube and the handheld terminal. According to the mine MWD exploration system and the measurement method thereof, the occurrence of the drill hole and a rock dynamic action spectrum of the drill bit can be measured while drilling, a drilling space trajectory and the drilling meeting rock property are provided, meanwhile the purpose of exploration while drilling can be realized, and the fact that various conditions can be measured in one hole can be realized.

Owner:ANHUI HUIZHOU GEOLOGY SECURITY INST

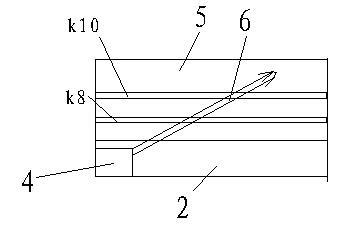

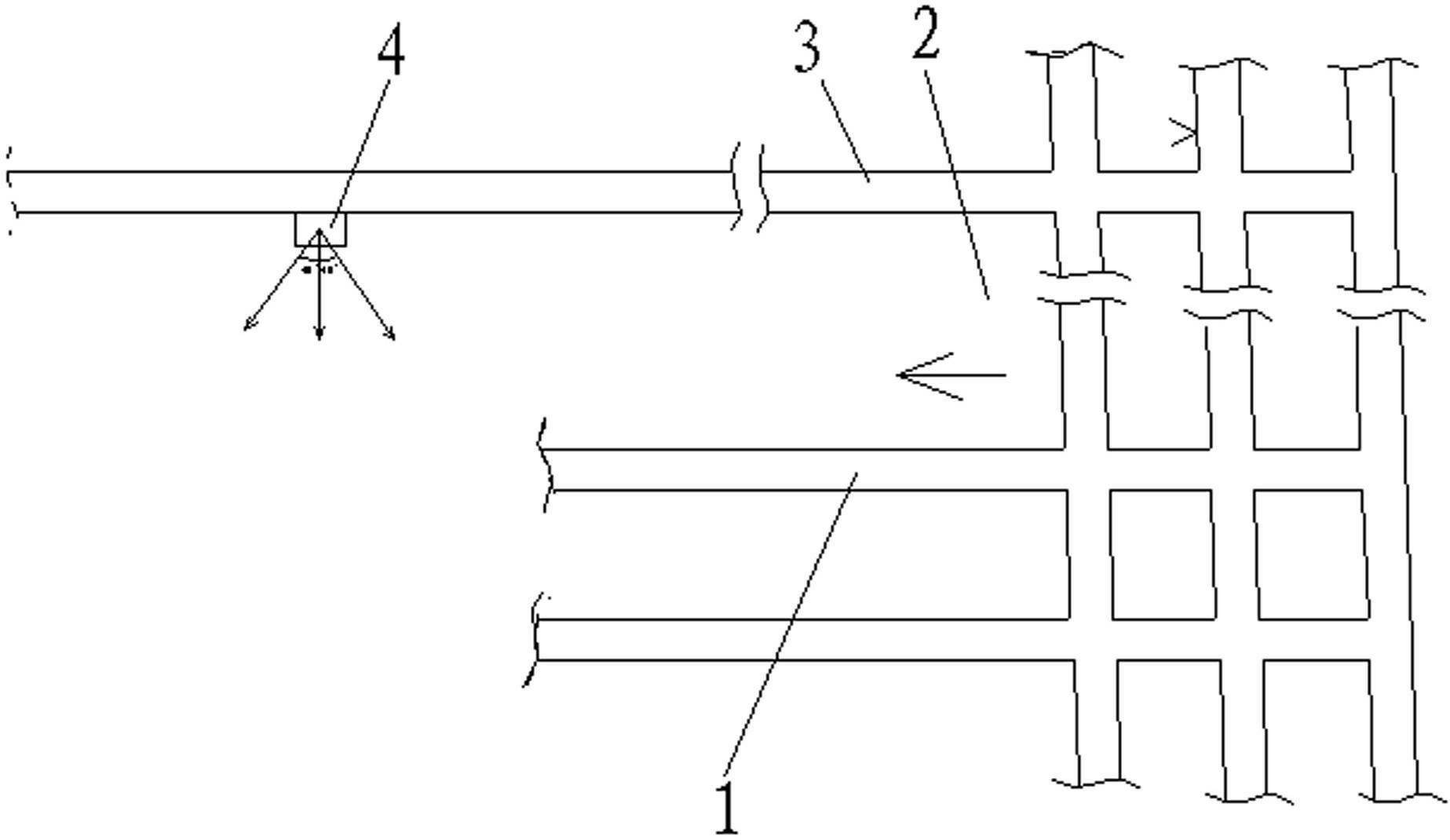

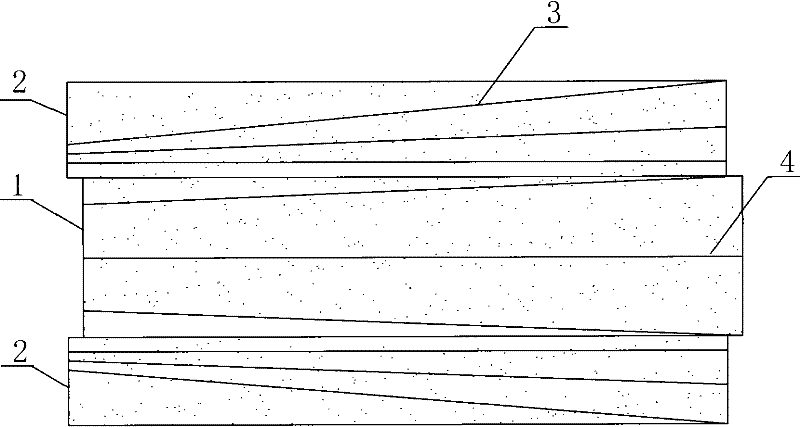

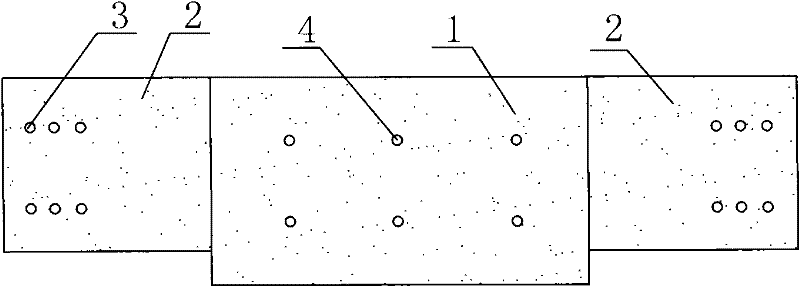

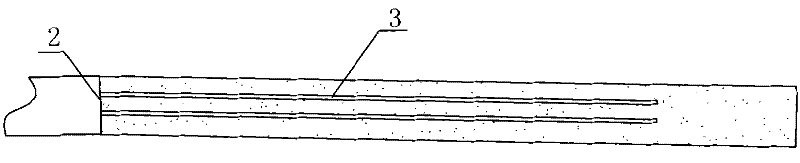

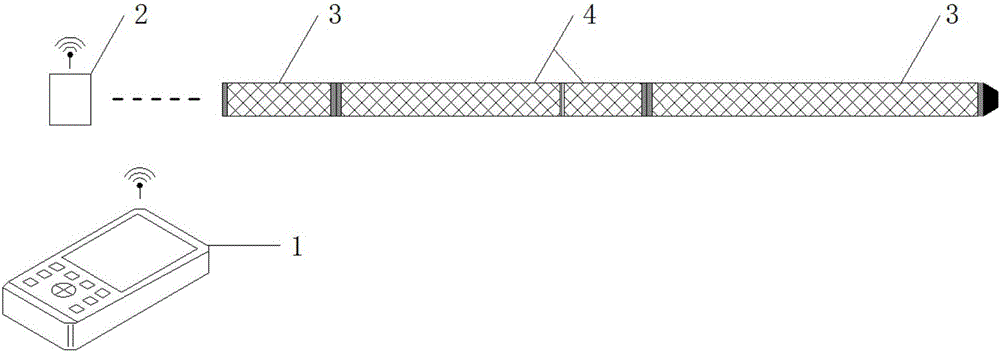

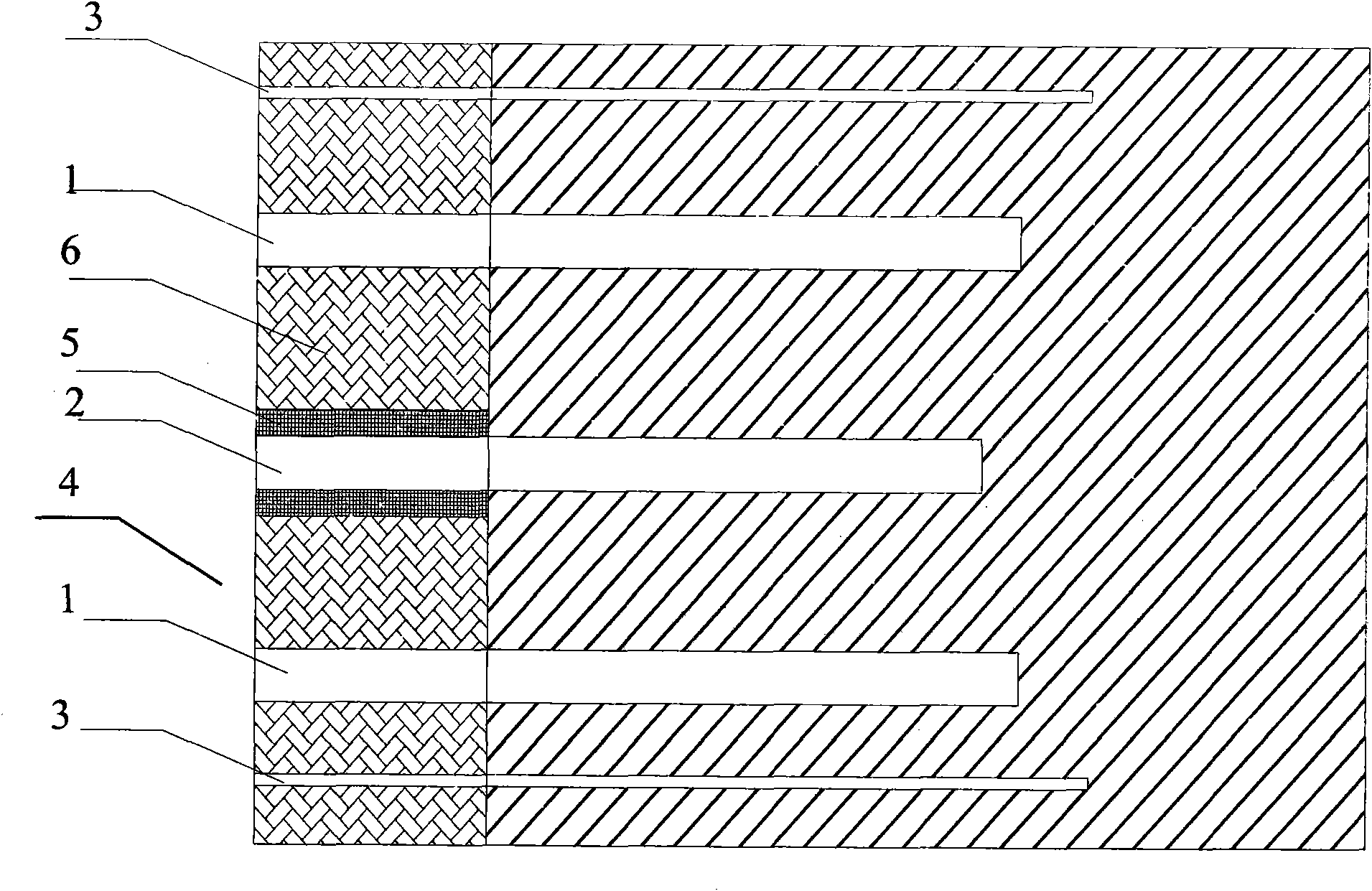

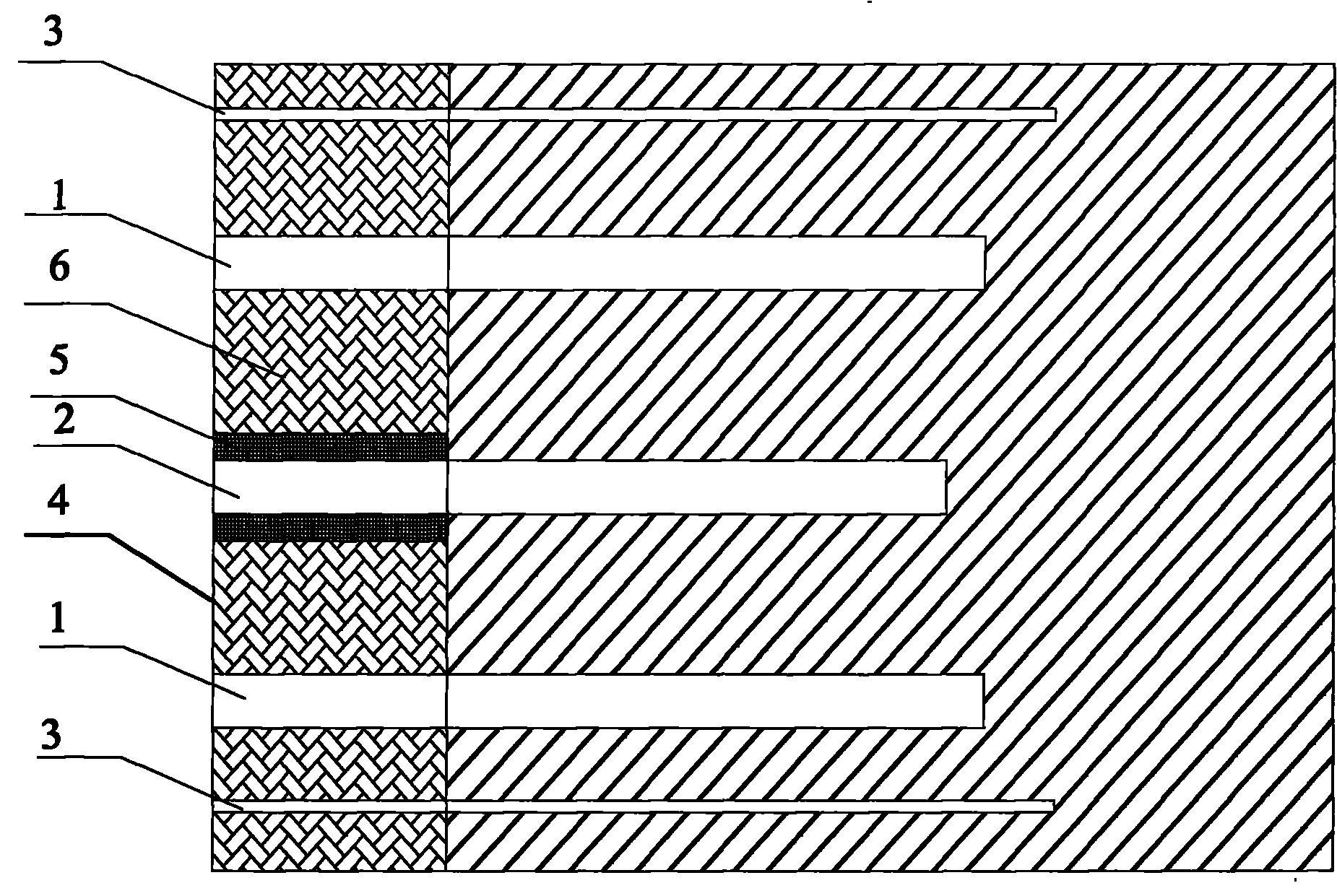

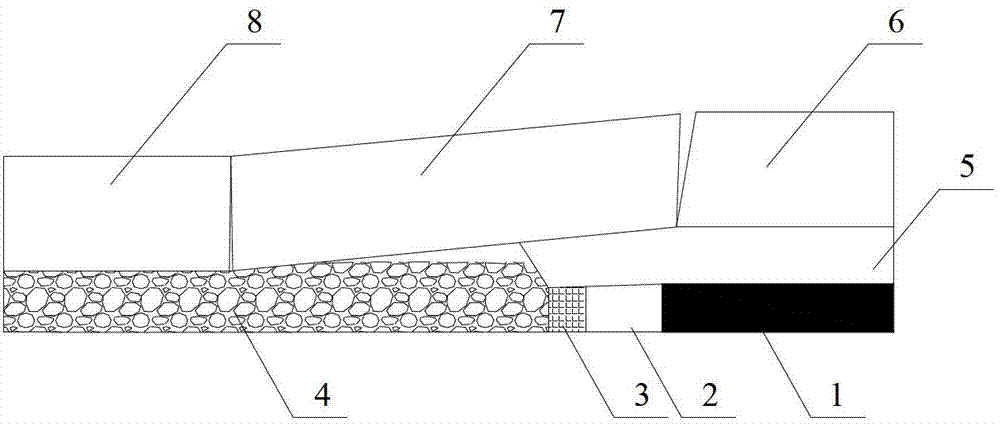

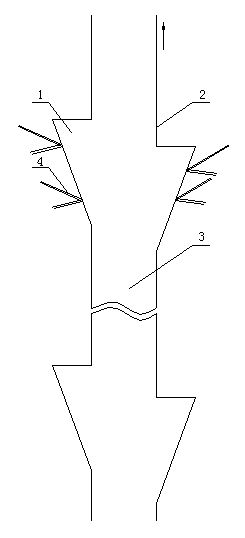

Method for draining gas by heating coal bed through drilling

InactiveCN102400669AEasy to crackIncrease pressureFluid removalGas removalDrill siteProcess engineering

The invention discloses a method for draining gas from an underground coal bed. The method comprises the following steps of: firstly, establishing a drill site in the coal bed to be drained; then, punching an anchor net (4) and anchor rods (3) in the surface of and around the coal bed to reinforce the coal bed; selecting at least one of the drill holes to serve as a heat source hole (2); performing negative pressure drainage of the gas through other drainage drill holes (1) by using drainage equipment; protecting a protective layer coal bed (6) by using a heat insulating material (5) to prevent a protective layer from being heated; heating the coal bed except the protective layer coal bed (6) by using heating equipment; heating the coal bed to 80-200 DEG C; and after the coal bed is heated, quickly desorbing the adsorbed gas into free gas. The volume of the free gas is increased, the gas pressure in the coal bed is increased, the development of fractures in the coal bed is promoted due to the increased gas pressure of the coal bed, the flow of the coal bed gas is facilitated, and the aim of quickly and efficiently draining the coal bed gas can be fulfilled under the action of the negative pressure drainage drill holes (1).

Owner:田力龙

Combined rock cross-cut coal uncovering method

ActiveCN103510957AUniform pressure relief and anti-reflectionShorten prepumping timeUnderground miningSurface miningDrill siteCross cut

The invention discloses a combined rock cross-cut coal uncovering method which is particularly suitable for quick rock cross-cut coal uncovering of outburst dangerous coal seams in underground coal mines. When a cross cut is tunneled to be at a vertical distance of 10 m from coal seams, a drill site is directly constructed in the cross cut; the coal seams are constructed and holes are drilled in the drill site; the drill holes are arranged at intervals by slotting drill holes and general drill holes; the uniform pressure relief of coal bodies is realized through the combined arrangement of the slotting drill holes and the general drill holes. After the drilling operation is finished, pipes are connected for extraction and drainage to reduce the gas content and the gas potential in the coal seams. After the gas extraction is qualified, the slotting drill holes are used as slurry injecting drill holes to inject cement mortar in the coal bodies for strengthening the coal bodies, so that the combination of slotting pressure relief and reinforcement is realized. Under the condition of guaranteeing safe coal uncovering, through the adoption of the method, the outburst removing engineering amount can be reduced by 30-40%, the gas extraction time and the coal uncovering period can be shortened, and the safe coal uncovering speed is increased by 40-50%.

Owner:CHINA UNIV OF MINING & TECH

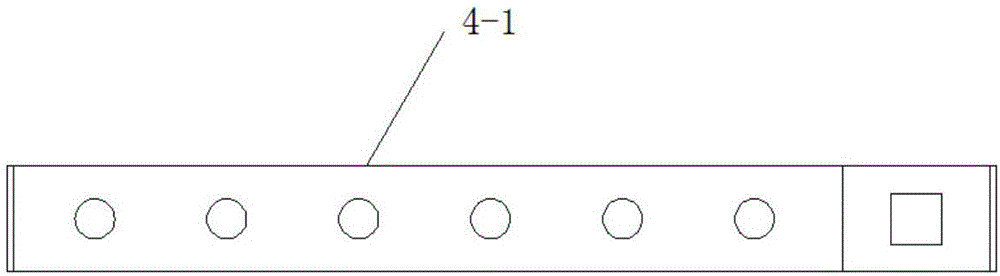

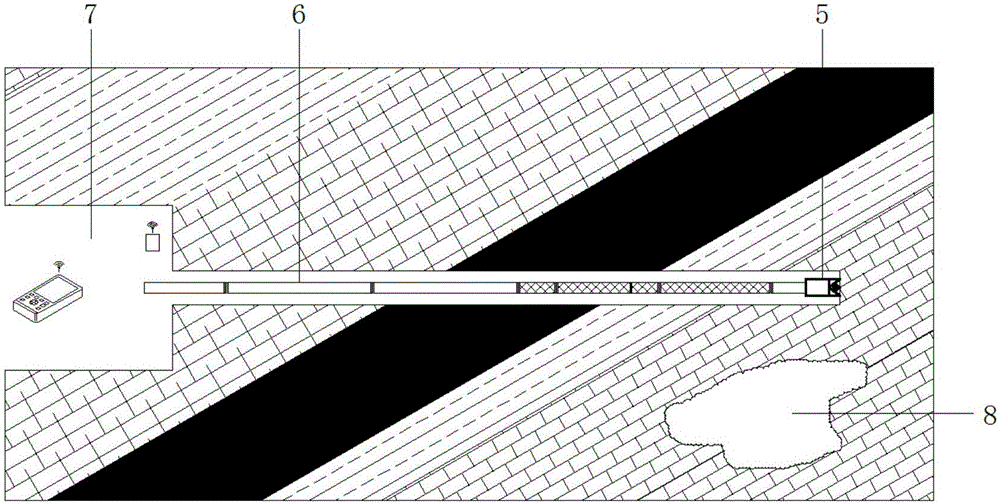

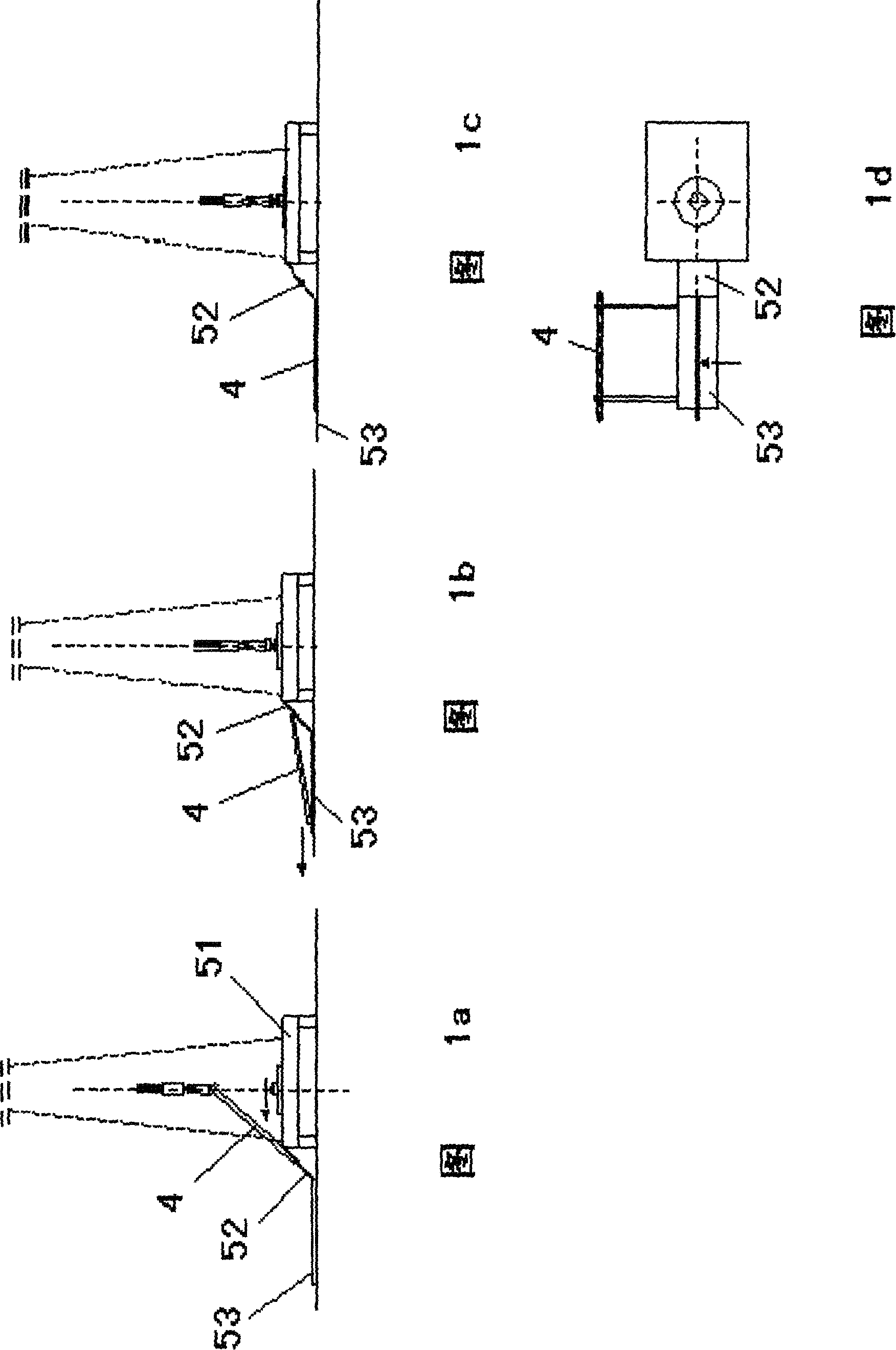

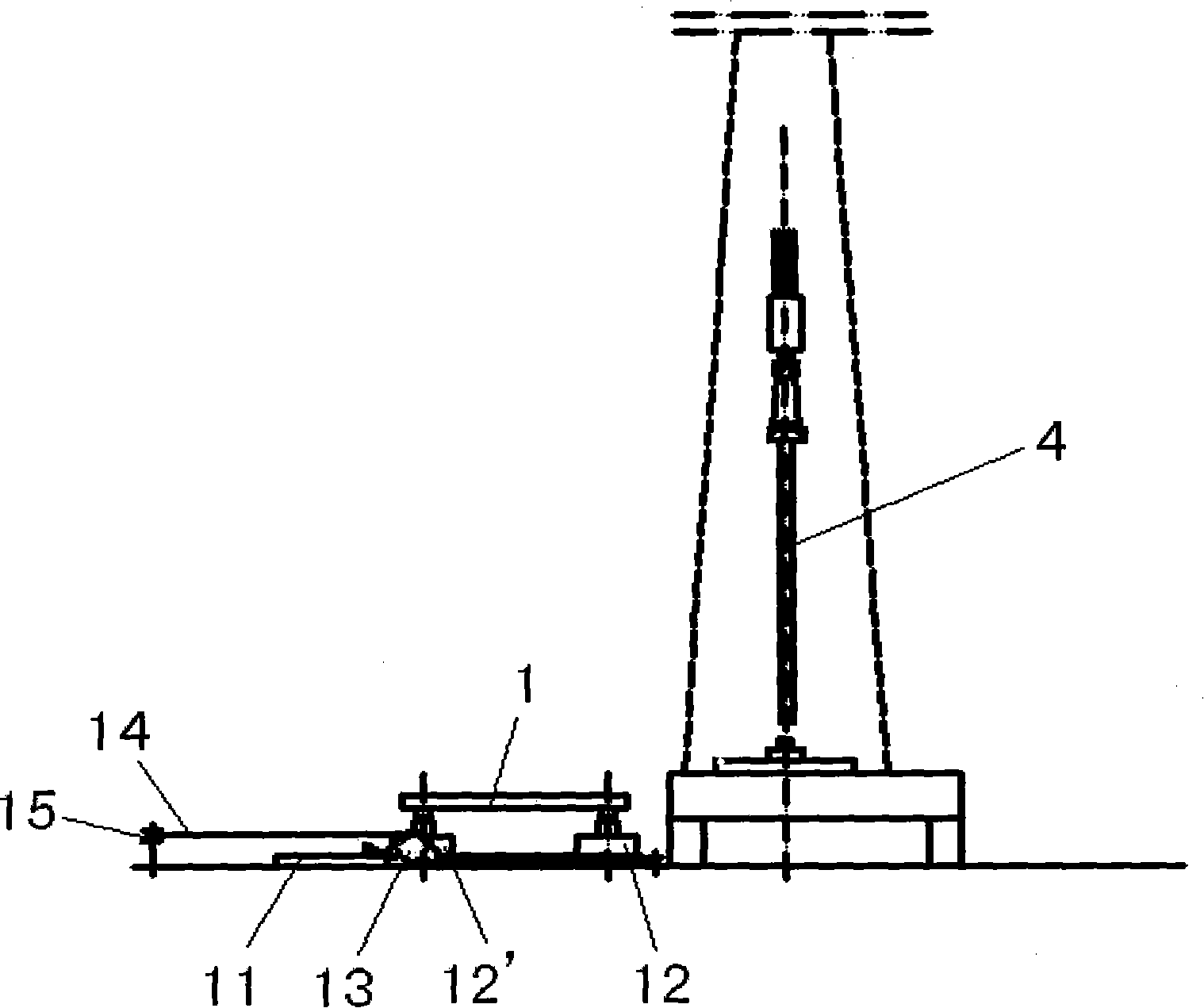

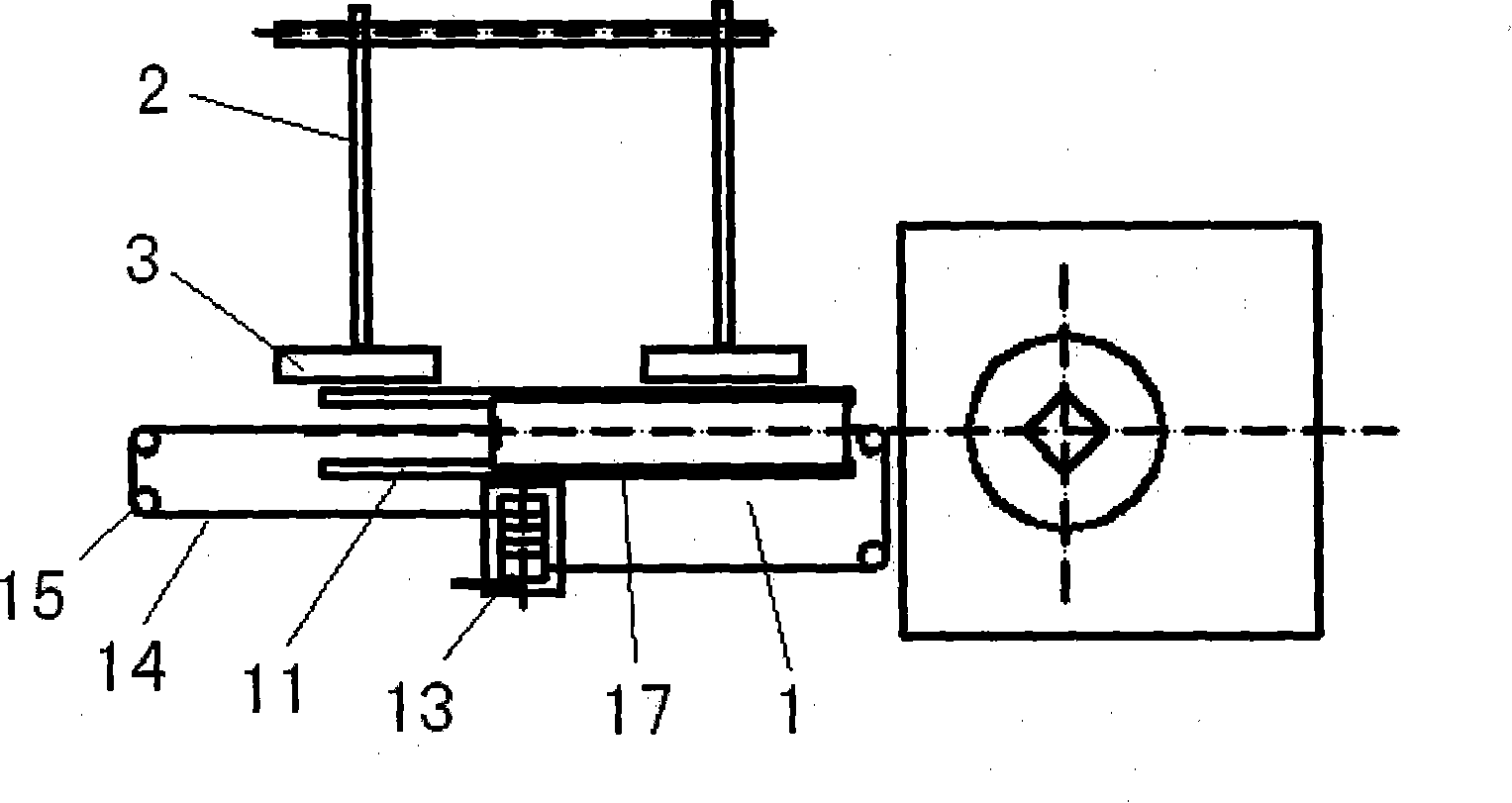

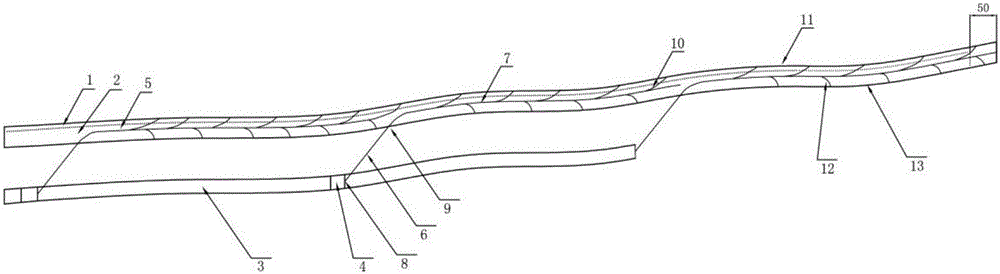

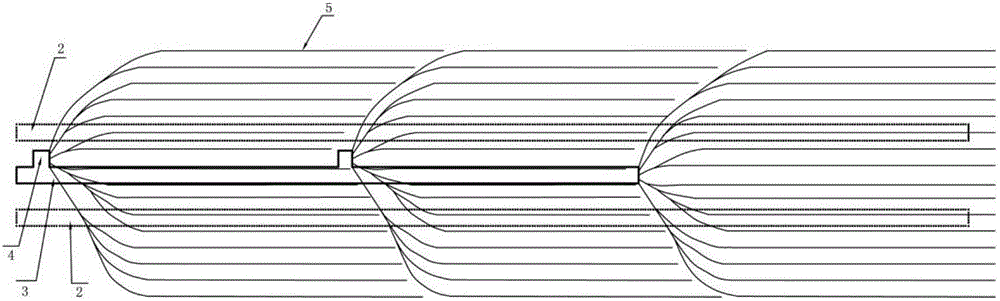

Drill site tubular pile automatic discharging device

ActiveCN101250986AEasy to transport horizontallyEasy to removeDrilling rodsDrilling casingsDrill sitePiston

The invention relates to an automatic string handling device in well fields, being characterized in comprising a movable lifting device and a multi-layer pipe rack, the movable lifting device comprises a rail on which two lifting cylinders are arranged in a sliding way and one side of which a dragging device used to drag two lifting cylinders is arranged, the tops of plunger pistons of the two lifting cylinders are respectively connected with a set of runners rotationally through a driving device; one side of the movable lifting device is provided with the multi-layer pipe rack. The automatic string handling device in well fields can also be provided with a lifting pipe bridge between the movable lifting device and the multi-layer pipe rack; realizes the automation of the link of handling strings, is strongly applicable and can be used in similar automatic handling operation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

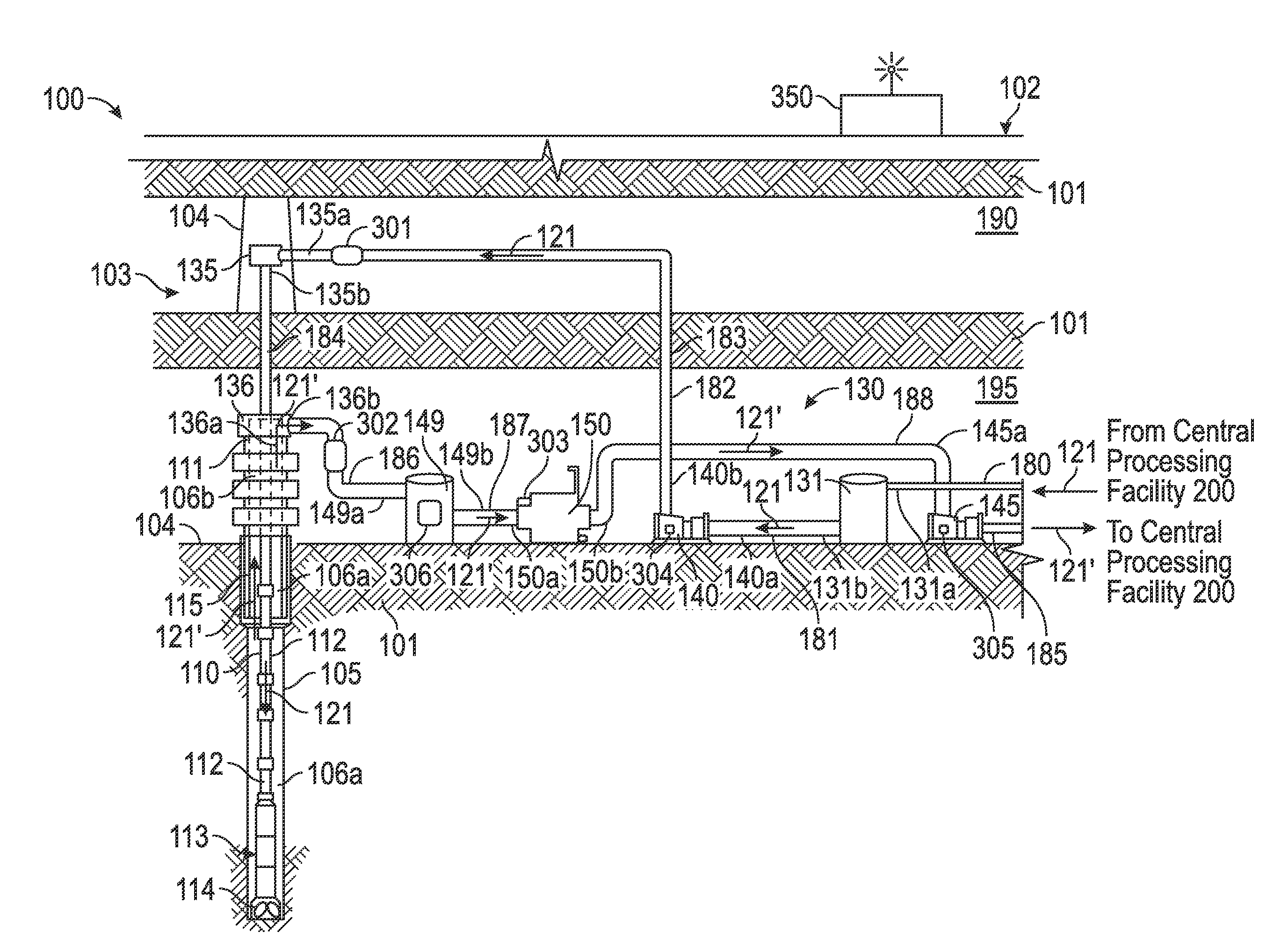

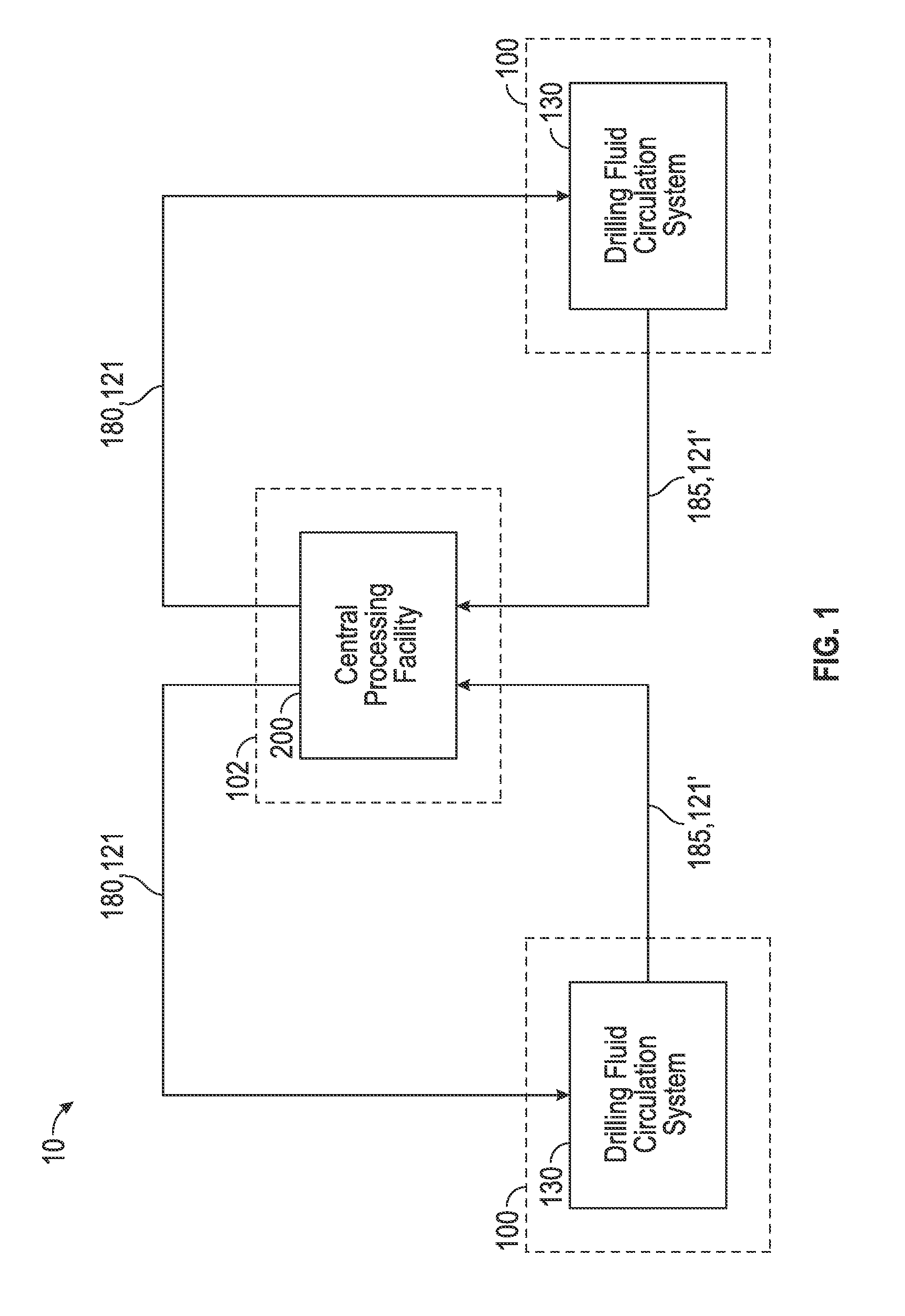

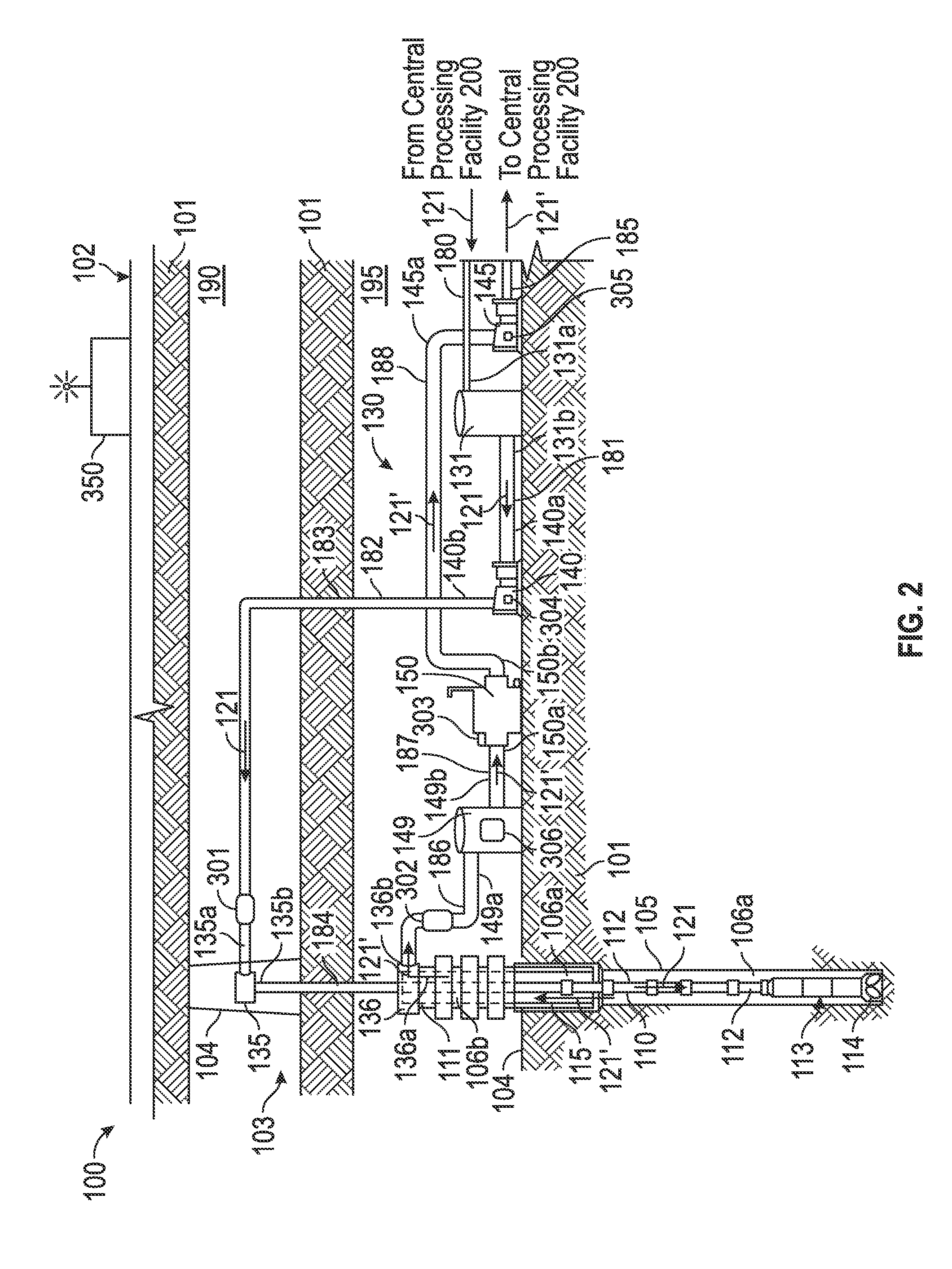

Closed loop drilling fluids circulation and management system

A closed loop drilling fluids circulation system includes a first drilling fluid circulation system disposed at a first subterranean drill site. The first drilling fluid circulation system includes a supply tank for holding clean drilling fluid and a solids control device configured to separate solids from used drilling fluid. In addition, the system includes a central processing facility disposed at a location remote from the first drill site and configured to receive used drilling fluid from the solids control device and supply clean drilling fluid to the supply tank.

Owner:BP CORP NORTH AMERICA INC

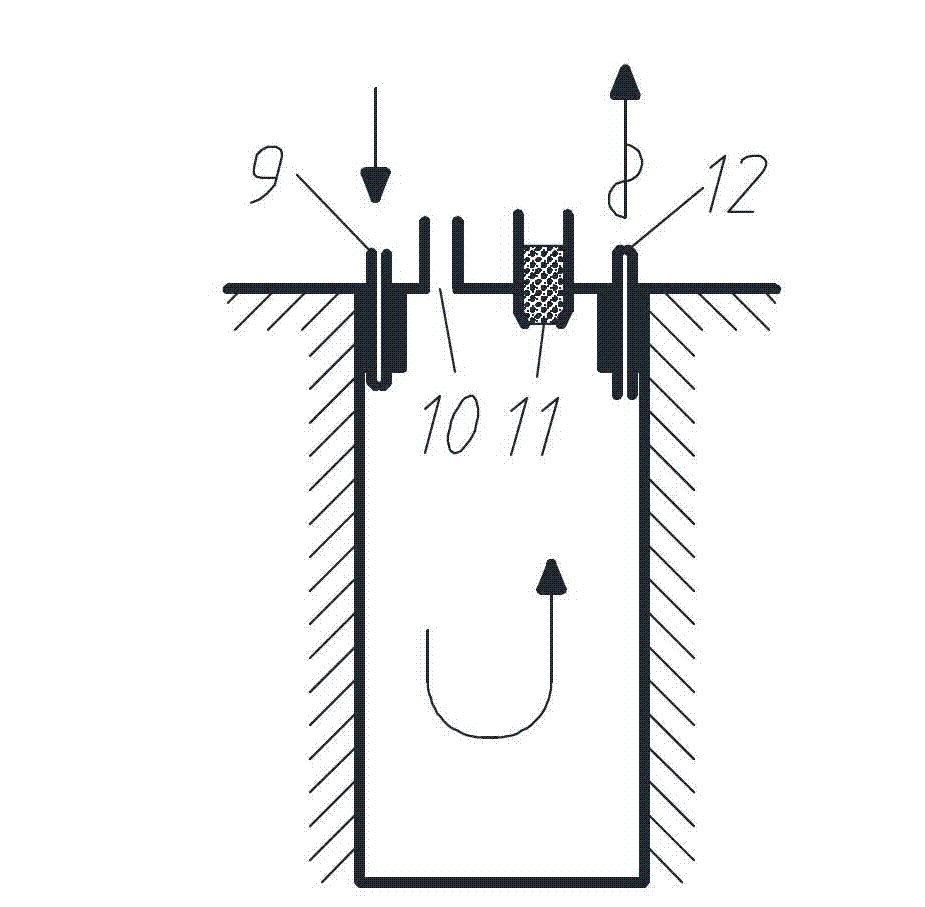

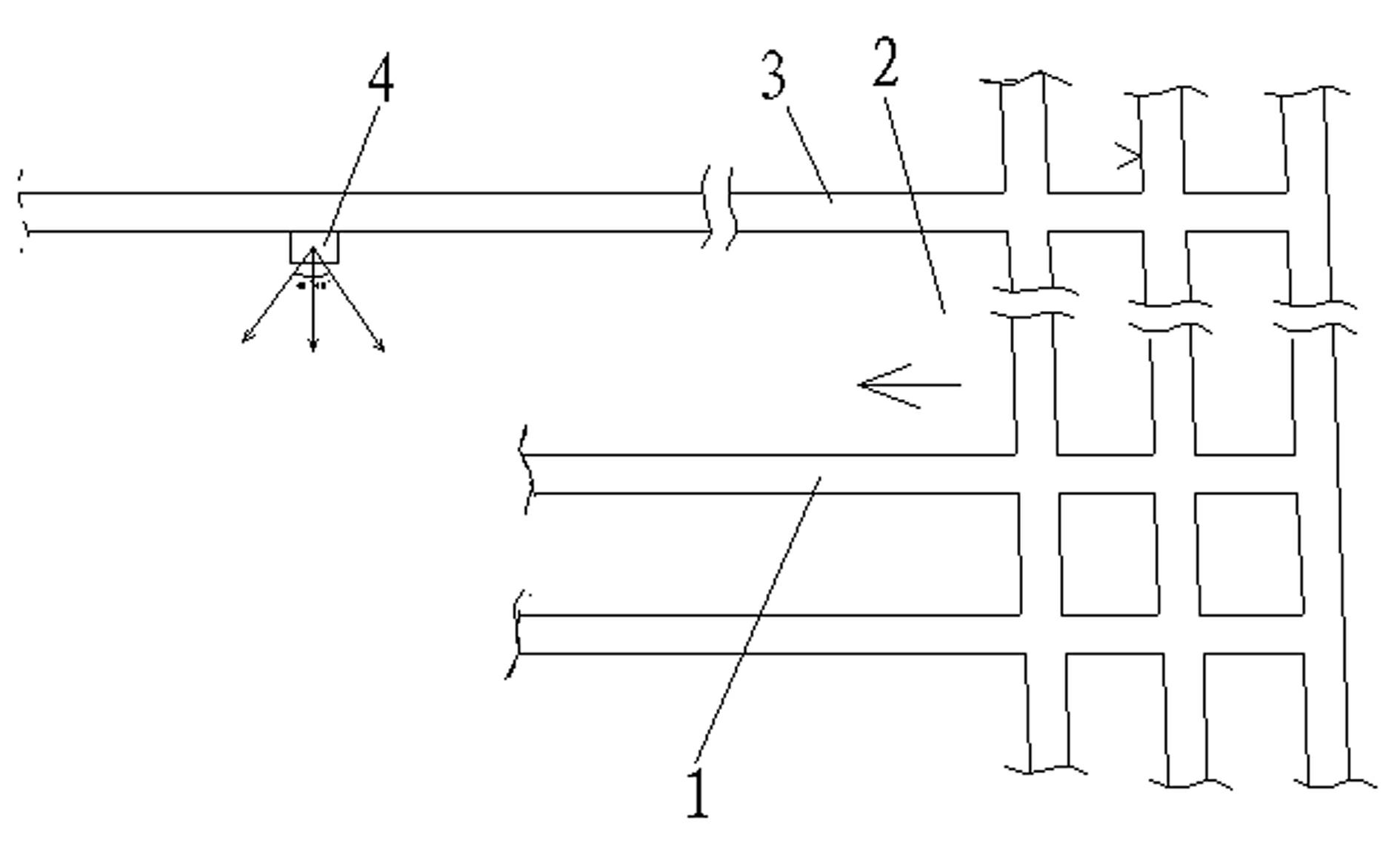

Method for extracting pressure relief gas by retained roadway drill site drilling

The invention discloses a method for extracting pressure relief gas by retained roadway drill site drilling, aiming at solving the problem that gas extraction drilling cannot be constructed since hole collapse occurs easily during gas extraction drilling in construction of an advance coal face of a retained roadway along a goaf of a deep well and the section of a retained roadway of a lag coal face shrinks seriously. The method comprises the following steps: constructing drill sites on one side of solid coal of a lag coal face in a retained roadway to provide an operation space for constructing extraction drilling; constructing extraction drilling in the drill sites towards a fissured zone of the roof of the goaf; and finally sealing extraction drilled holes and performing gas extraction after connecting an extraction pipeline. According to the method, the technical problems that hole collapse occurs easily during gas extraction drilling of the advance coal face and the extraction drilling of the lag working face is difficult to construct are solved, the operation space is provided for the gas extraction drilling construction, and smooth implementation of gas extraction is guaranteed.

Owner:CHINA UNIV OF MINING & TECH

Gas control method for triple-purpose use of drilled holes in coal floor of close distance seam group

The invention discloses a gas control method for triple-purpose use of drilled holes in a coal floor of a close distance seam group, and belongs to coal mine gas control methods. In the coal floor of a mine, drilled holes in the same drill site are used, and gas extraction is performed according to the steps as follows: firstly, before coal mining, gas in a coal seam is extracted in advance through the drilled holes in the coal floor of the mine, and danger of the outburst of coal in the coal seam at the upper part and the gas is eliminated; secondly, the coal at the upper part is mined, when the coal seam at the upper part is mined, mining pressure relief and stress relief are caused to coal seams at the upper part and in the middle, the drilled holes of the original drill site are used, and gas in the coal seams at the upper part and in the middle in a mining pressure relief zone is extracted in a negative pressure manner; and finally, the coal seam in the middle and the coal seam at the lower part are mined, and simultaneously, the original drilled hole is used again, and gas in a mining layer is extracted in the negative pressure manner. The work efficiency can be improved, the gas extraction efficiency is high, the cost is saved, the concentration of the extracted gas is high, and the utilization of the gas is facilitated. The gas control method comprises the control of gas in close distance seam groups of two or more coal seams.

Owner:CHINA UNIV OF MINING & TECH

Projecting coal bed edge top drill construction technique and method for eliminating pumping blind zone

The invention discloses a construction method for outburst coal seam by drilling along the top and a method for eliminating mining blind areas, which are operated according to the steps: first, the construction of a top brushing drill site is carried out in the wall of a mining tunnel; second, a drilling machine is put in the top brushing drill site and the height of the drilling machine is adjusted so as to enable the drilling machine to construct coal holes along the top in the outburst coal seam; third, a group of coal holes is constructed in the top brushing drill site, and the hole opening angle of each coal hole is consistent with the obliquity or the pseudo obliquity of a coal seam roof at the upper part. The coal holes along the top are led to reach or run through the mining blind areas and even run through the width of sections or the width of straps of a coal mining working face; in complicated geological conditions or a tectonic zone, when the coal holes along the top are difficult to run through the mining blind areas, rock bores along the top can be constructed to reach above the mining blind areas, and then a blasting method or a hydraulic fracturing method is applied to the rock bores, so as to enable the rock bores along the top to be communicated with the mining blind areas by manual cranny; when the coal seam is relatively thick, strengthened coal holes can be constructed below the coal holes along the top.

Owner:HENAN POLYTECHNIC UNIV

Method for draining coal seam gas

The invention relates to a method for draining coal seam gas, belonging to a method for pre-draining coal seam gas in coal mines. According to the invention, the technical problem that the existing methods for draining coal seam gas are low in drainage efficiency is solved. The technical scheme of the method for draining coal seam gas comprises the steps of: firstly opening at least one butt hole drill site in a coal mine underground preparation roadway, constructing a 30-50m long butt drill hole from the butt hole drill site to a target coal seam, lowering a seamless steel sleeve to the butt drill hole and solidifying the hole by high-quality cement, then opening a ground drill site at the far end of a designed drainage area, horizontally and directionally drilling a horizontal directional main branch hole along the target coal seam toward the underground butt drill hole, butt-jointing the horizontal directional main branch hole with the underground but drill hole, enclosing the ground orifice, arranging an orifice control valve on the head of the seamless steel sleeve, connecting the control valve with a coal mine underground gas drainage pipe network, and carrying out gas drainage by using a coal mine gas drainage pump.

Owner:华晋煤层气综合利用有限责任公司 +1

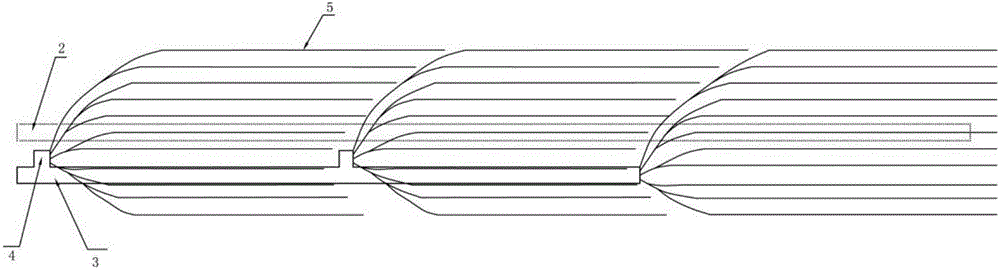

Method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building

ActiveCN103061798AImprove drilling single-hole drainage production capacityImprove extraction efficiencyDrill bitsGas removalDrill siteCoal

The invention relates to a method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building and a hydraulic mechanical drill with the diameter changed and enlarged while drilling. A coal bed bedding long borehole is combined with a cave building technology, and the permeability of low-permeable coal reservoirs and the coal bed borehole extraction capacity are improved. A hole is opened at 1 / 3 coal thickness or 1.5m upwards away from the coal heading floor on the extracting drill site coal wall of an underground coal mine along with the coal bed, the hydraulic mechanical drill with the diameter changed and enlarged while drilling performs cave building on the borehole from inside to outside successively after the borehole reaches the preset depth, and the cave diameters and distances can be calculated through formulas. Coal bed stresses around the cave are released and coal bed prior cracks are widened and lengthened after the caves are completed, tensional and shear failures occur to the coal bed, novel cracks are produced, and accordingly, the coal bed crack connectivity is increased, the permeability is improved, the coal bed methane can be depressurized and desorbed rapidly, the coal bed methane extracting efficiency is improved dramatically, and the coal bed methane extracting time is shortened.

Owner:ZHONGBEI UNIV +1

Gob-side entry retaining adjoining rock stabilizing method based on lateral rock formation pre-splitting control

ActiveCN103321642AStress Field Distribution OptimizationEliminationUnderground miningSurface miningDrill siteInduced stress

The invention provides a gob-side entry retaining adjoining rock stabilizing method based on lateral rock formation pre-splitting control. The stabilizing method is used for pre-splitting an upper roof above the gob-side entry retaining. The method comprises the steps as follows: constructing a drill site in a roadway stoping lateral coal wall; stoping a lateral top plate in the drill site; constructing two groups of six advanced pre-splitting blasting holes which take the shape of a small horizontal rotational angle in the trending direction of the roadway; loading the explosive for blasting in the position which is 10 to 40 meters to an advanced working surface. According the method provided by the invention, a top cover rock formation can be pre-split, the fracture of the top cover rock formation in an assigned position outside a wall body is guaranteed, and the contact of the turning submerged upper roof to the gob-side entry retaining adjoining rock is separated, so that the bearing pressure of the gob-side entry retaining adjoining rock is reduced, and the action time of the mining-induced stress is shortened; the method has the effects of simple operation, high efficiency of construction and fast speed.

Owner:CHINA UNIV OF MINING & TECH

Method for estimating and reconstructing seismic reflection signals

ActiveUS7333392B2Increase contributionOptimize dataSeismic signal processingSeismology for water-covered areasFeature vectorSignal-to-noise ratio (imaging)

A method for reconstructing seismic data signals of poor quality to improve the signal-to-noise ratio of the data for display and analysis in connection with the selection of drilling sites for recovery of hydrocarbons. The method includes providing a signal model by applying a Karhunen-Loeve transform to selected input seismic data collected for the target zone, to form a co-variance matrix from the dot products of all pairs of input data. Eigenvalues and eigenvectors for the matrix are computed, and the most significant eigenvectors are inversely transformed to provide a coherent estimate of the signal. The input data is combined with the model data based on the determination that the model data lacks continuity, wherein the good quality signal-to-noise ratio data experiences little change and discontinuous data is enhanced by a contribution of the signal estimate data. The reconstructed seismic data of the target zone can be displayed for analysis.

Owner:SAUDI ARABIAN OIL CO

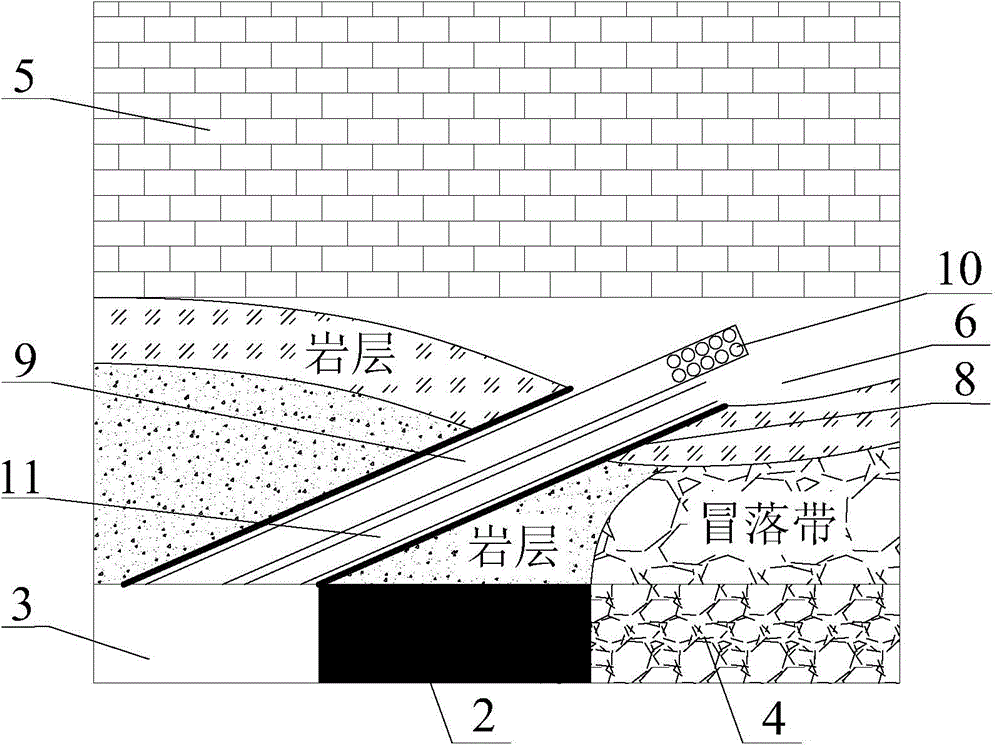

Top plate high-position boring large-diameter long-drill-hole gas extraction method based on directional drilling

InactiveCN104975868AReduce concentrationHigh extraction rateFluid removalDirectional drillingDrill siteLap joint

The invention particularly relates to a top plate high-position boring large-diameter long-drill-hole gas extraction method based on directional drilling. The method solves the problems of great engineering quantity of the existing high-drainage roadway extraction and poor extraction effect of ordinary drill high-position hole drilling. The method comprises the following steps that: a, a plurality of drill sites are constructed at intervals at a ventilation connection roadway of an extraction working face, and drill holes constructed in the two adjacent drill sites are in lap joint; b, four drill holes are totally constructed in each drill site, and each drill hole passes through a working face crossheading position part and is positioned above a top plate; c, before the drill hole construction, a hole opening pipe is installed, and a hole opening gas-liquid separator is connected; d, rotary drilling is performed in a hole forming section, then, a hole sealing pipe is put at a hole sealing section, and a drilling machine directionally drills to a terminal hole and performs whole-process hole reaming after the grouting hole sealing; e, the outer end of the hole sealing pipe is connected with a snake-shaped pipe through a flange, and the other end of the snake-shaped pipe is connected with a gas collecting opening of a drainage pipe; and f, when a working face is pushed to a position passing through the hole bottom of a drill hole, the drainage operation is carried out. The top plate high-position boring large-diameter long-drill-hole gas extraction method improves the mine gas extraction rate, and has the advantages that the extraction concentration is high, and the flow rate is great.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

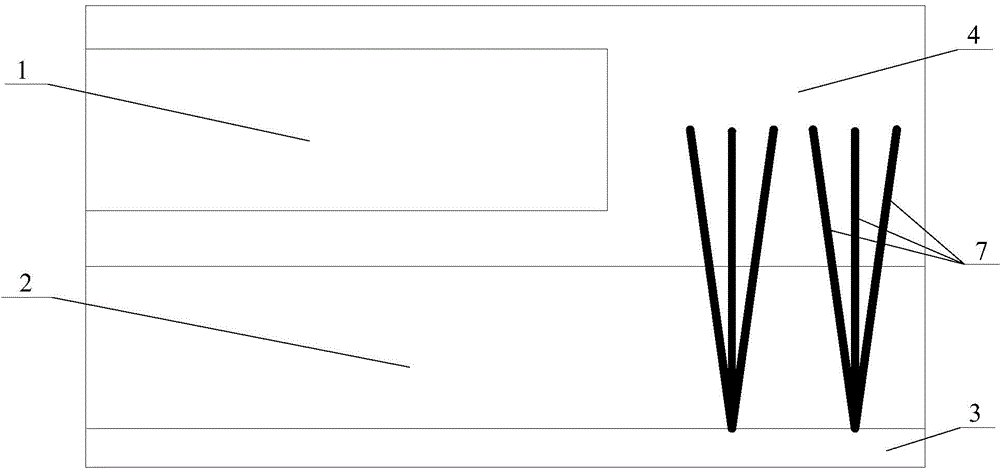

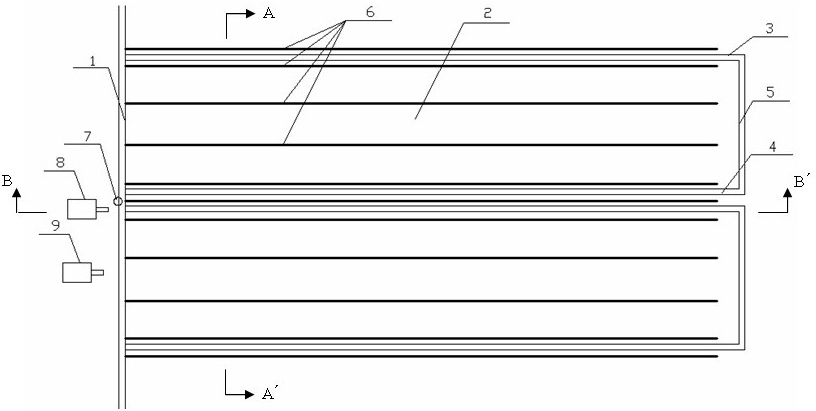

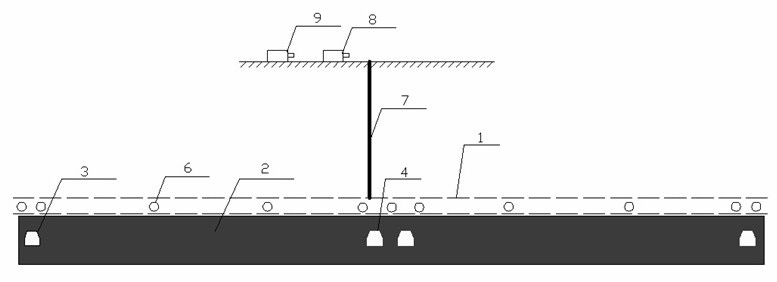

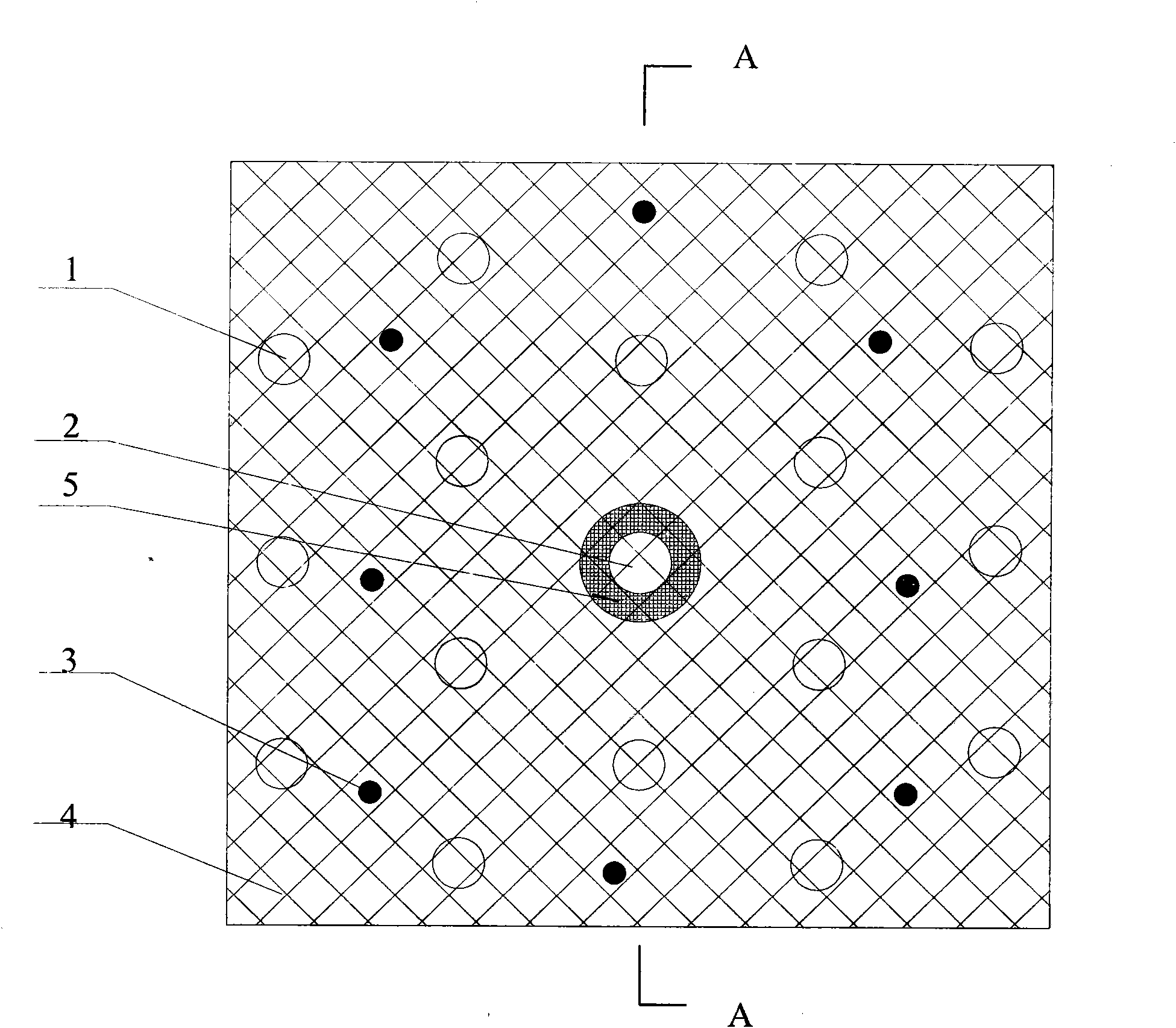

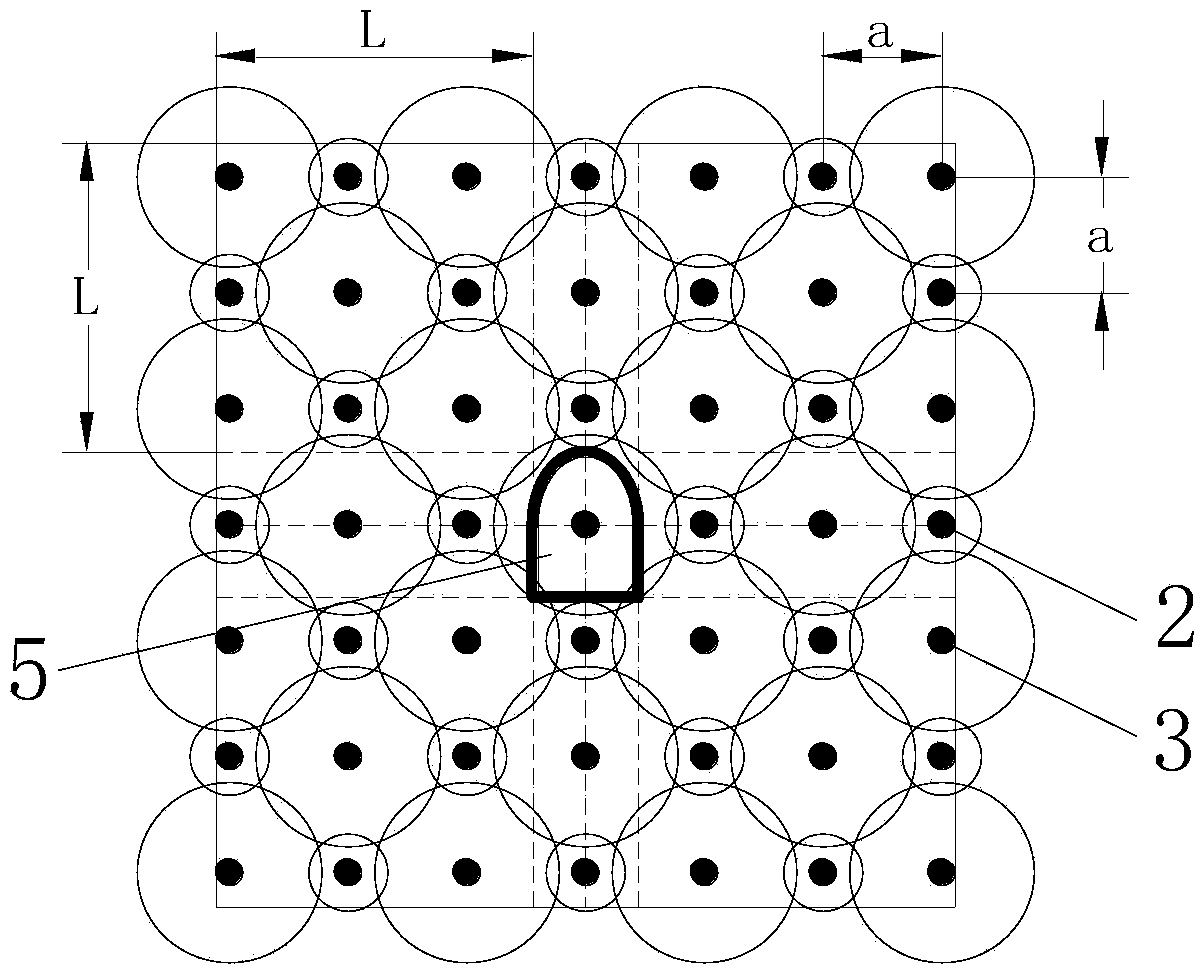

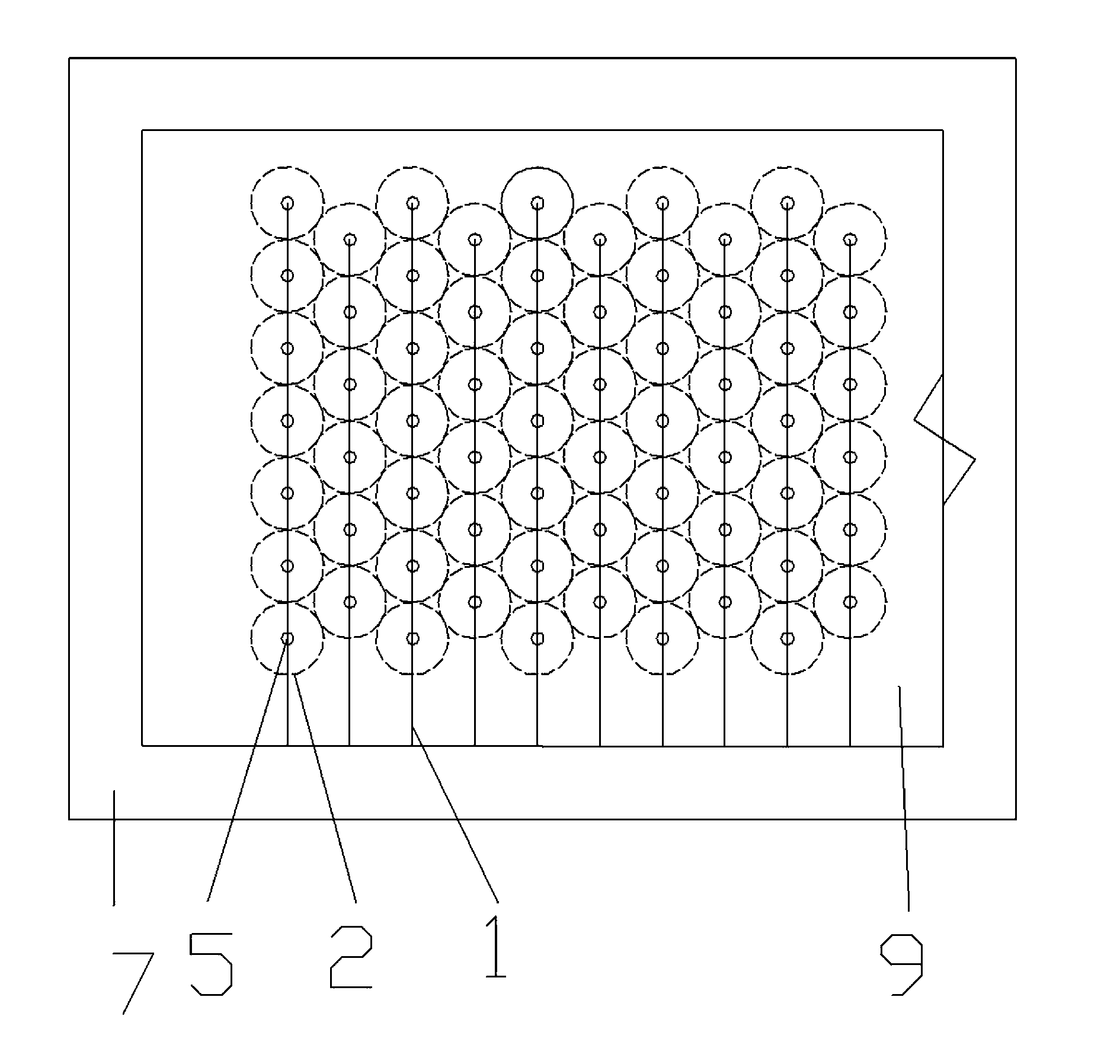

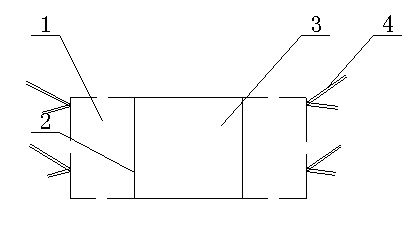

Methods for arranging and supporting wall-expanded gas extraction drill sites

InactiveCN102587962AImprove integrityAvoid loose damageUnderground chambersGas removalEconomic benefitsEngineering

The invention discloses methods for arranging and supporting wall-expanded gas extraction drill sites. A plurality of wedge-shaped walking drill sites are arranged in two walls of a stoping tunnel in a staggering manner; the spans of the walking drill sites are gradually increased along the tunneling direction of the stoping tunnel; 1 to 3 rows of extraction drilled holes are formed in the fractured zone of the local coal layer or the coal layers adjacent to a top plate and a base plate of the inner wall of each walking drill site; a hole protection tube is arranged at the orifice of each extraction drilled hole, and a gas extraction tube connected with each hole protection tube is arranged; and the spans of the drill sites are gradually increased along the tunneling direction of the stoping tunnel and distributed in the two walls of the stoping tunnel in a staggered walking manner. Due to the wedge-shaped structure, an enough working space is supplied to drilling machinery and gas extraction equipment; furthermore, the drill site construction amount is reduced greatly, and the construction difficulty is reduced; due to the staggered walking distribution and the wedge-shaped structure, the span is reduced greatly, and supporting and maintenance are facilitated; and moreover, extraction and tunneling of the stoping tunnel can be performed at the same time, the tunneling efficiency is improved, and relatively high economic benefit is achieved.

Owner:CHINA UNIV OF MINING & TECH

System and method for compliance management of fluids in and about drilling sites

ActiveUS20130291999A1Risk minimizationEliminate riskLiquid transferring devicesSolid materialDrill siteControl system

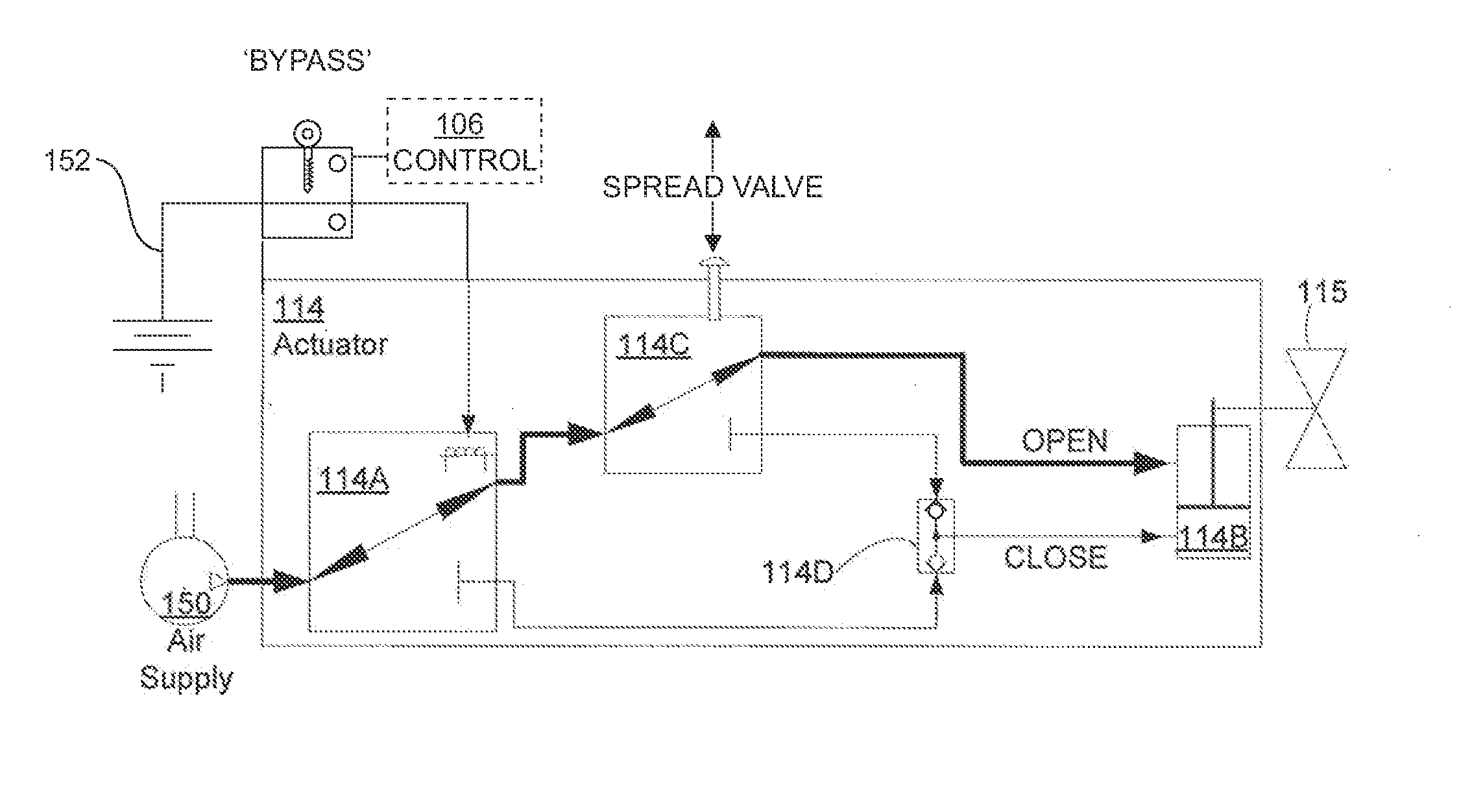

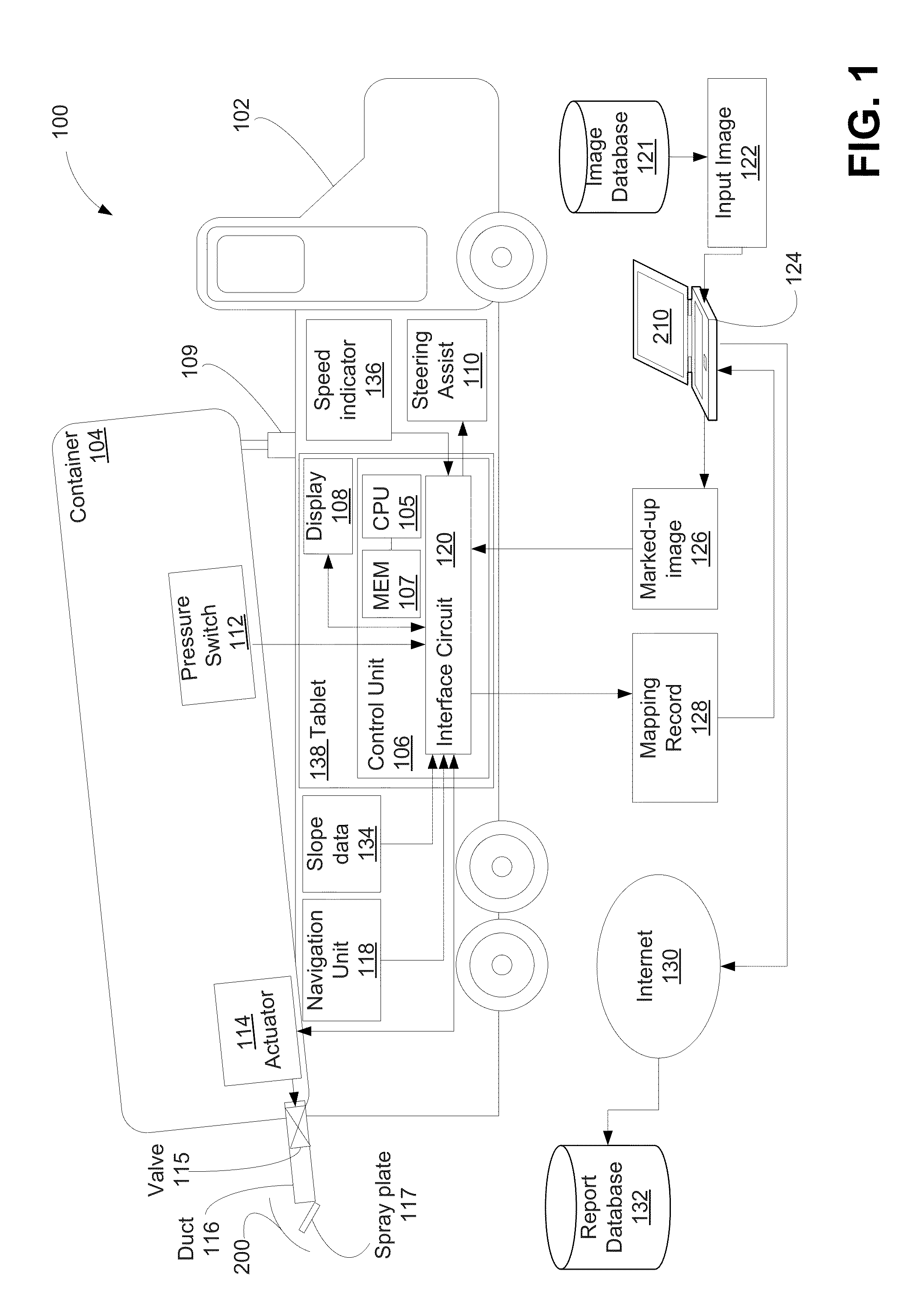

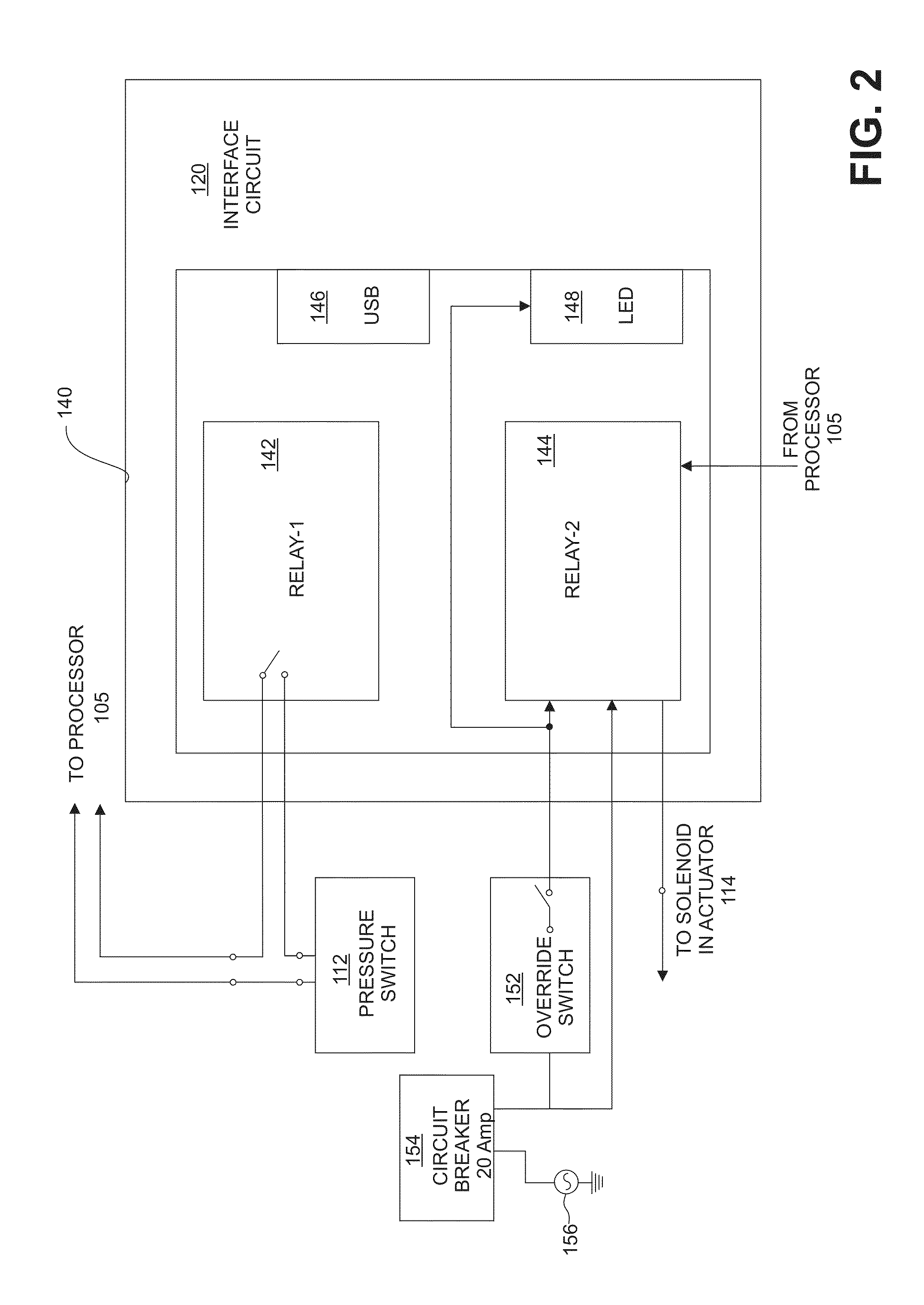

A system and method are provided for automated intake and discharge of fluids to and from specified inclusion zones at a drilling site and related sites. A surface map is annotated with shapes designating at least inclusion zones for managed control of permitted intake and discharge of fluids tt and from permitted zones. For specified water sources, the inclusion zone is a loading zone associated with specified conditions and another inclusion zone is an unloading zone also having specified conditions. A control system in a vehicle uses the annotated map and GPS to assist the operator of the vehicle avoid restricted intake from and discharge to restricted zones and limit volumes and rates based on monitored parameters. Records are maintained to confirm the fluid, fluid location and volumes.

Owner:SUMMIT LIABILITY SOLUTIONS

Method for preventing gas from being accumulated at corners on coal faces

InactiveCN102562088AAvoid accumulationAdjust the shunt flowTunnel/mines ventillationGas removalDrill siteProcess engineering

The invention relates to a method for preventing gas from being accumulated at corners on coal faces. A process tunnel is added on the basis of an original 'U'-shaped mining gateway, and is placed at the top of a coal seam, and is close to the inner side of a return airway and parallel to the return airway and an intake airway, and the intake airway is respectively communicated with the return airway and the process tunnel via working surfaces so as to form two 'U'-shaped ventilating channels; and the process tunnel not only can realize total negative-pressure ventilation, but also realizes local fan ventilation. A drill site is further arranged in the process tunnel, gas is extracted, and water or stopping liquid is injected into the coal seam. The process tunnel is added on the basis of the original 'U'-shaped mining gateway to form the double 'U'-shaped ventilating channels, return air of the original return airway is divided, and accumulation of gas at corners on a return air area is avoided; and the drill site further can be arranged in the process tunnel to extract gas of the coal seam, an adjacent layer and a worked-out section, or the water or stopping liquid is injected into the coal seam, the purposes of dust fall and fire prevention are achieved, and production is not affected.

Owner:SHANXI FENXI MINING GRP +1

Outburst coal seam floor pitch-up through-bed directional hole leading area shield coal roadway driving method

ActiveCN105909254AThe elongation of the hole section is longHigh elongationGas removalTunnelsDrill siteEngineering

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com