Coal seam group with high gas content pressure relief and co-mining method based on gob-side entry retaining of working face of first mining total rock pressure relief

A technology of working face and coal seam group, which is applied in the directions of gas discharge, mining fluid, safety device, etc., can solve the problems of high gas coal seam group mining problems that have not been well solved, cannot reach safety values, and gas drainage is not complete. , to achieve the effect of optimizing the stress field in the entry retaining area, controlling the deformation of the entry retaining, and using a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

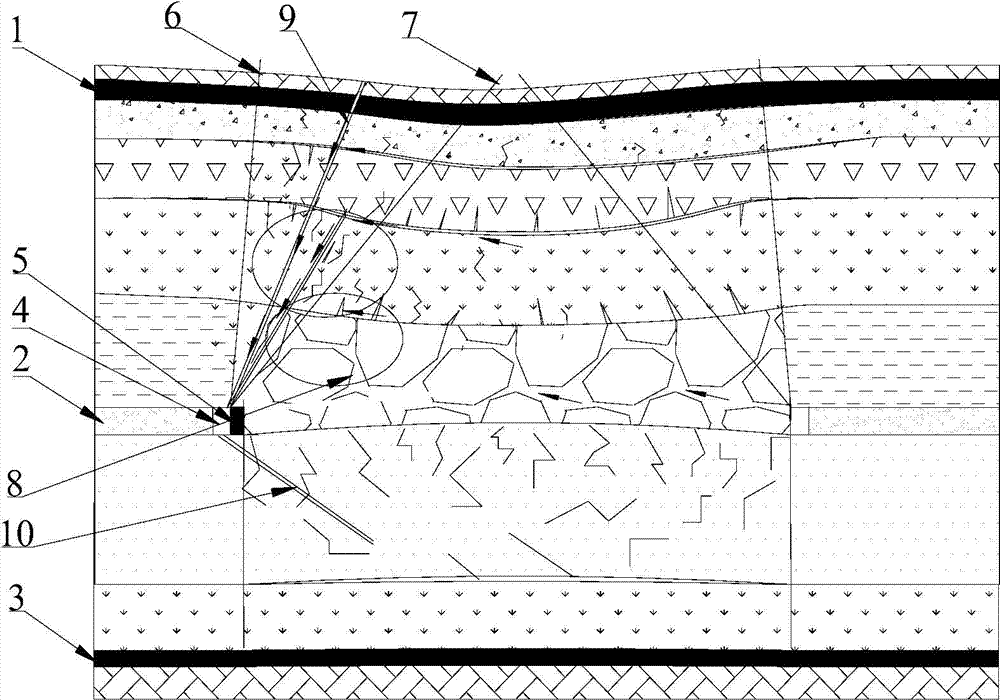

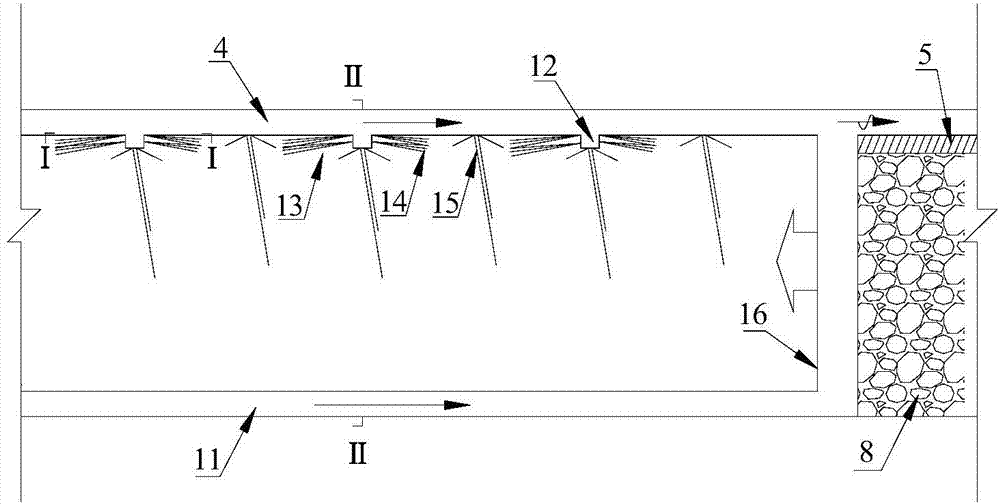

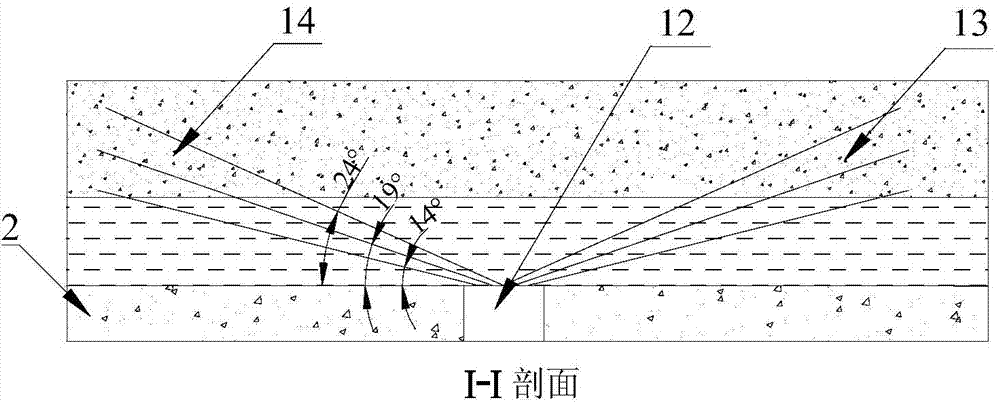

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] A pressure relief co-mining method for high gassy coal seam groups based on gob-side entry retaining in the first-mined whole-rock pressure-relieving working face. The pressure-relieving coal seam is firstly mined to cause the coal and rock layers to move to generate roof pressure-relieving fracture circles and floor pressure-relieving fracture circles. In the gob-side entry retaining, respectively arrange gas drainage boreholes upward to the roof pressure relief fracture circle and downward pressure relief fracture circle gas drainage boreholes on the bottom plate to extract the desorbed free gas; when the first pressure relief coal seam cannot be selected , through the first mining of the whole rock pressure relief working face, the movement and destruction of the coal and rock layers are caused, the overlying high gassy coal seam and the underlying high gassy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com