Method for judging fluid type of reservoir through acoustic porosity-neutron porosity differential

A neutron porosity and fluid type technology, which is applied in earthwork drilling, suspension and porous material analysis, wellbore/well components, etc., can solve problems such as low identification rate and difficulty in natural gas development and production, and achieve improved Distinguish coincidence rate, ease of operation, and effect of improving guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention discloses a method for discriminating reservoir fluid types based on the difference between acoustic porosity and neutron porosity, which is characterized in that the steps include:

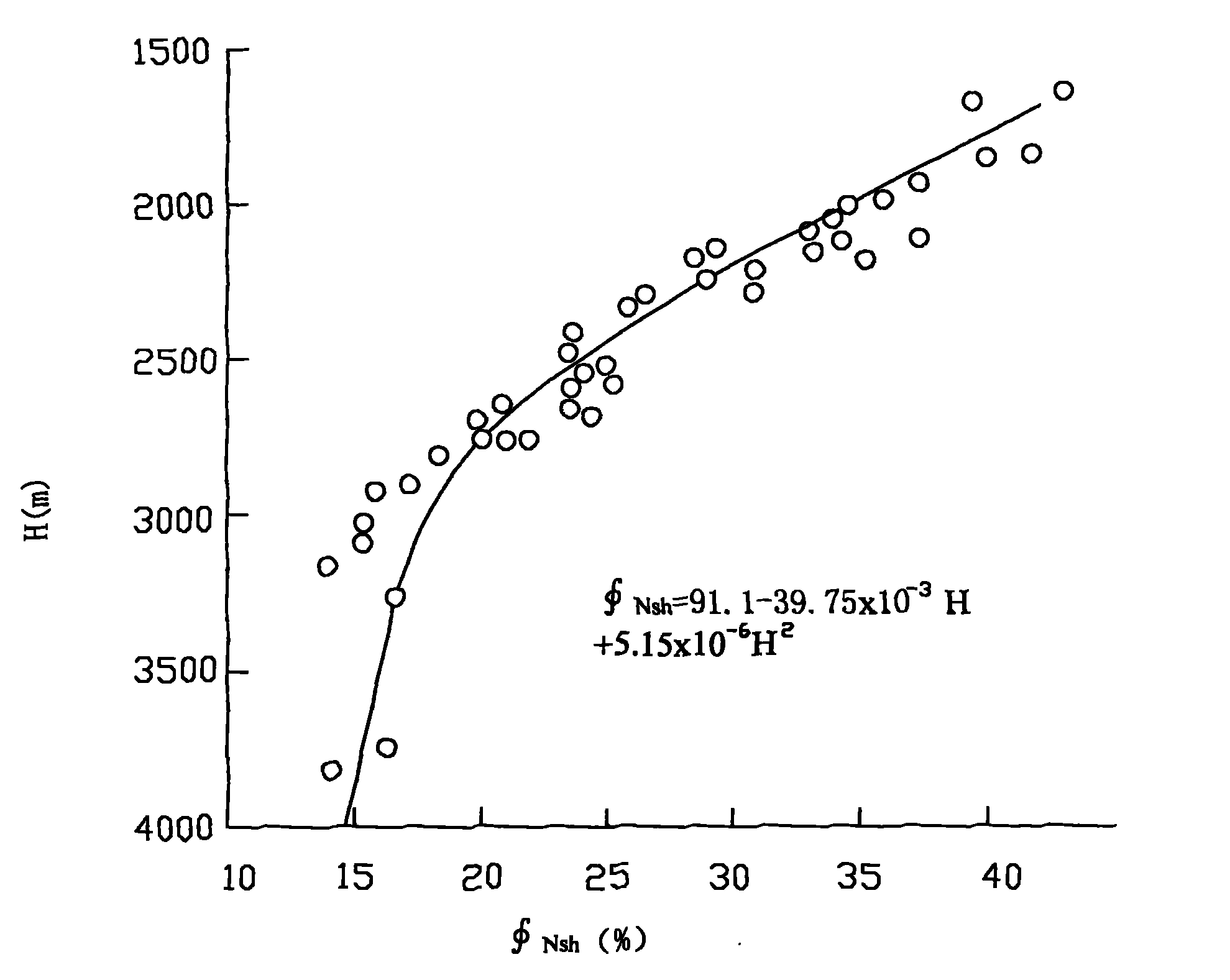

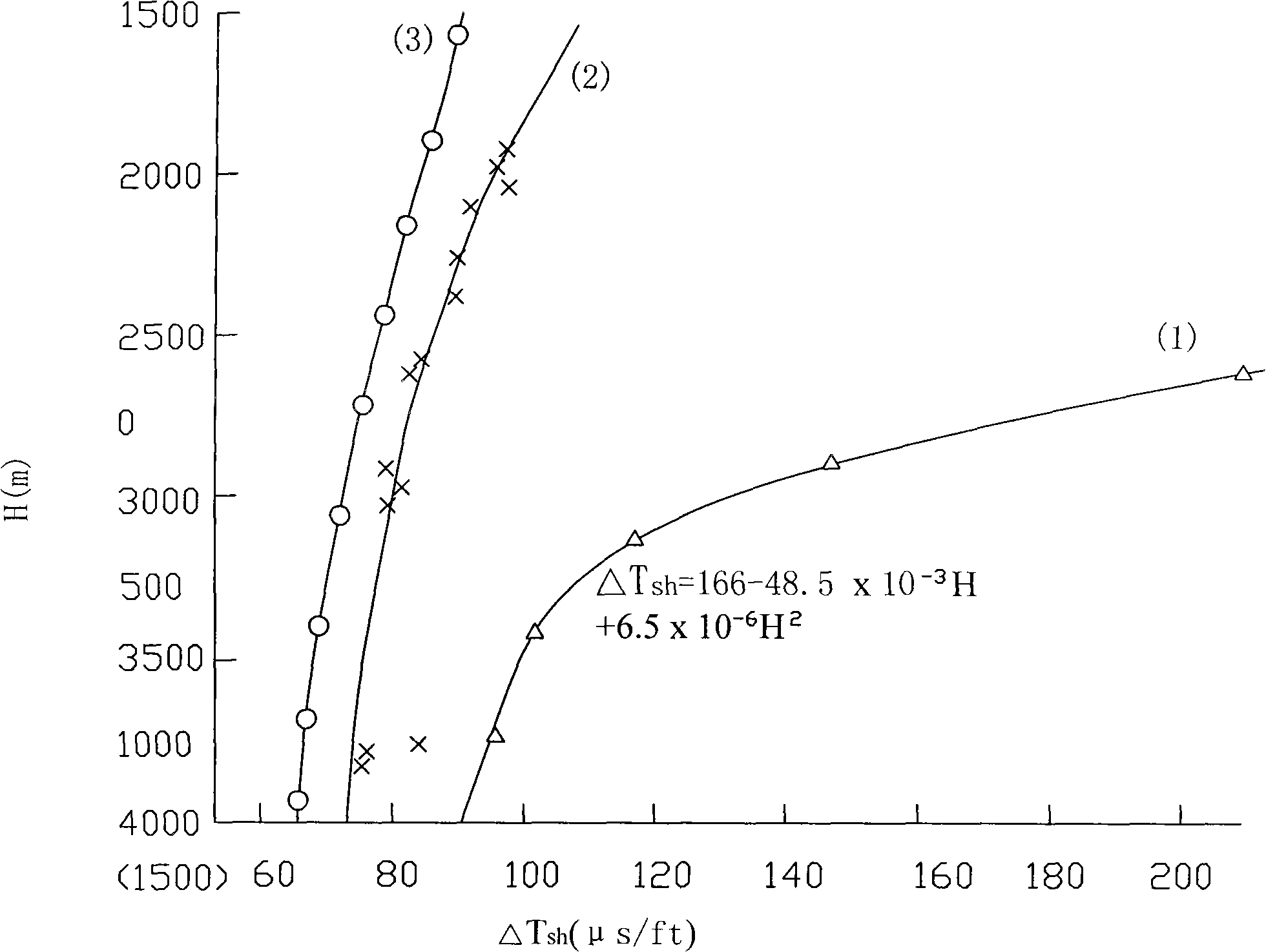

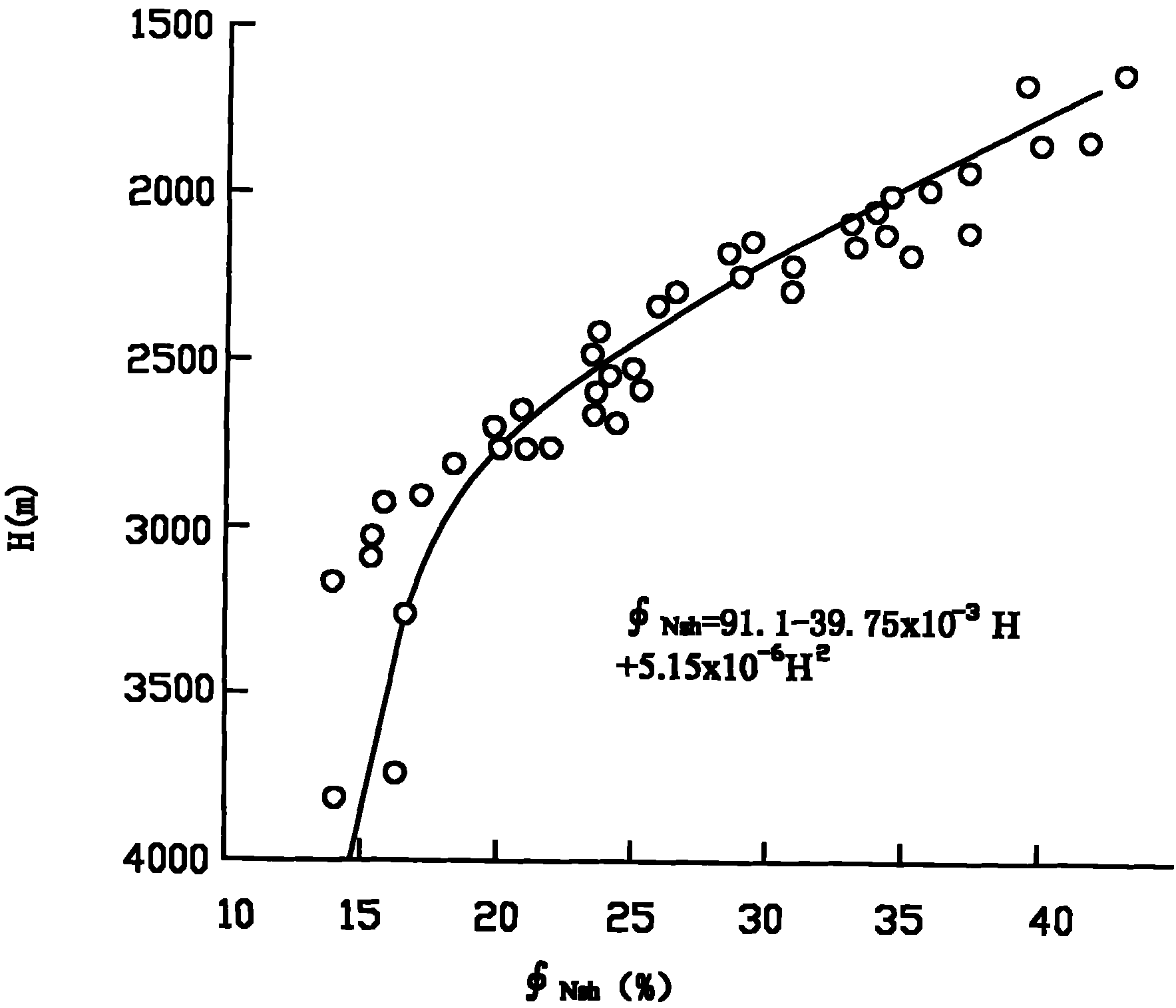

[0036] 1) Accurately calculate reservoir shale content, rock composition, acoustic porosity and neutron porosity through calibration logging of core data and environmental correction of logging data;

[0037] Logging data indirectly reflects the storage and seepage conditions and oil and gas conditions of rock layers by measuring the physical parameters of underground rocks, and the actual geological data such as cores must be calibrated to correctly interpret and evaluate reservoirs.

[0038] The described core calibration logging mainly includes two aspects: on the one hand, calibration logging processing parameters through core analysis data, such as core X-ray diffraction analysis data calibration parameters for calculating shale content, rock electricity analysis data to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com