Rapid rock cross-cut coal uncovering process and outburst prevention method

A fast technology for uncovering coal in Shimen, applied in earthwork drilling, gas discharge, safety devices, etc., can solve problems such as coal and gas outburst accidents, long waiting time, etc., to improve accuracy, shorten time, and ensure accuracy and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

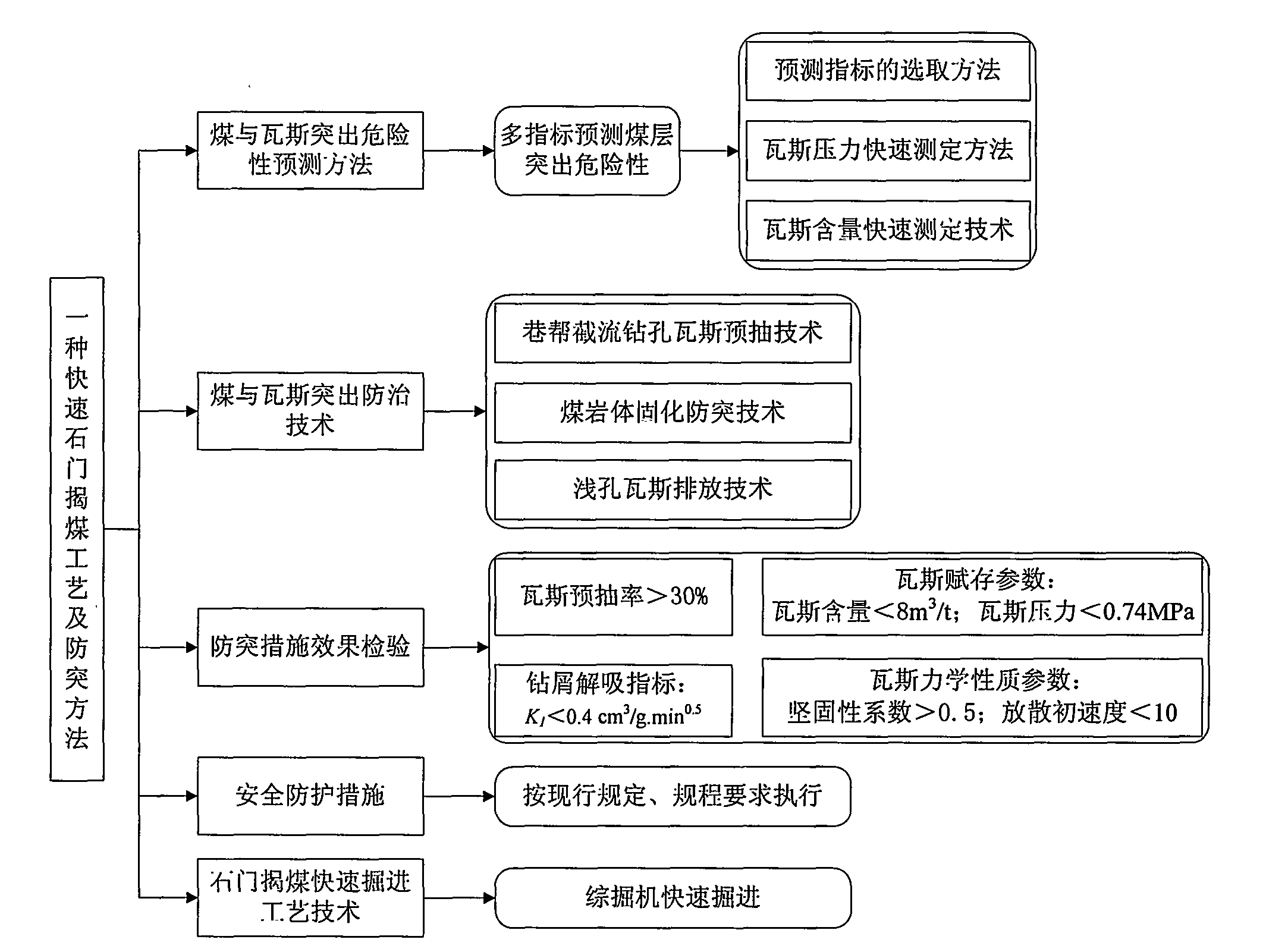

Method used

Image

Examples

Embodiment 1

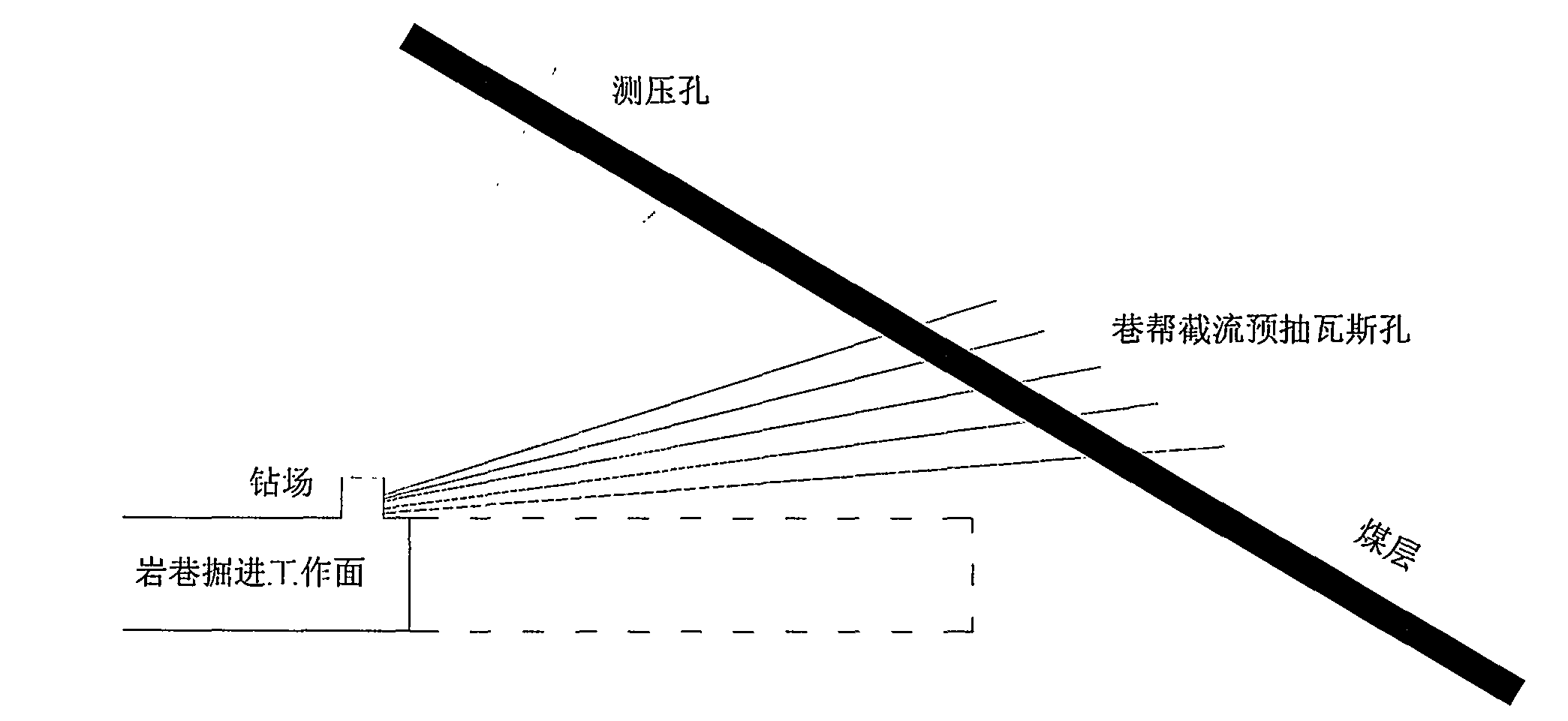

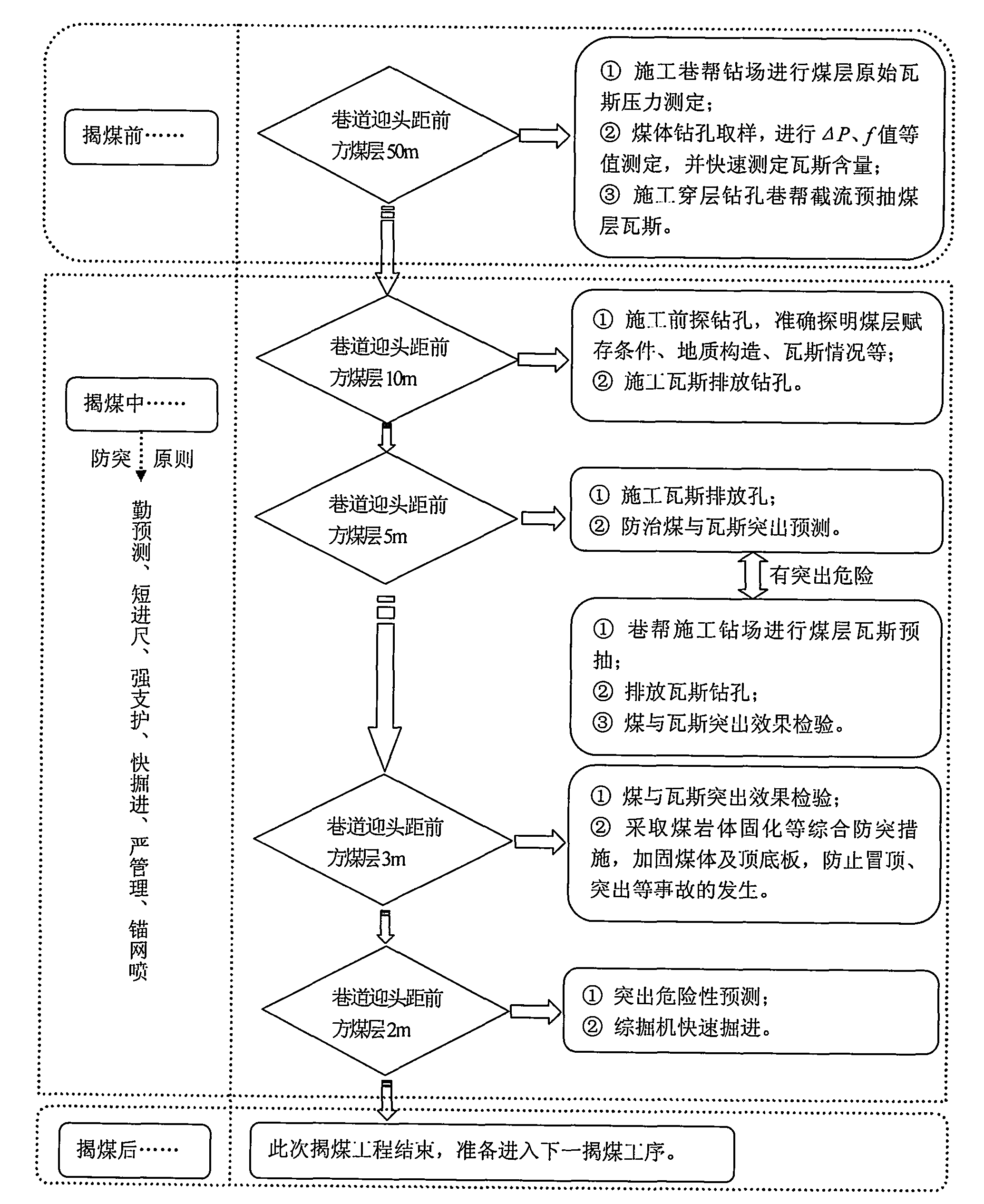

[0069] Step 1: Combining the gas occurrence in the coal seam to be uncovered in the test mine and the coal seam occurrence conditions, start two construction drilling sites at an appropriate position (50-100m) away from the coal seam, and then design the gas pre-extraction drilling parameters;

[0070] Step 2: According to the layout principle of the pre-drainage borehole, calculate the extraction time, extraction volume and gas extraction rate, including the targeted measurement of the gas flow rate in the borehole and the characteristic parameters of gas emission, and further calculate the gas permeability of the coal seam Then, according to the degree of difficulty of coal seam gas drainage, the extraction time and the influence radius of borehole extraction are determined, so as to provide a basis for the arrangement of pressure relief and discharge holes in the future if the outburst elimination effect is not good;

[0071] Step 3: According to the above steps, calculate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com