Patents

Literature

45results about How to "Avoid insensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

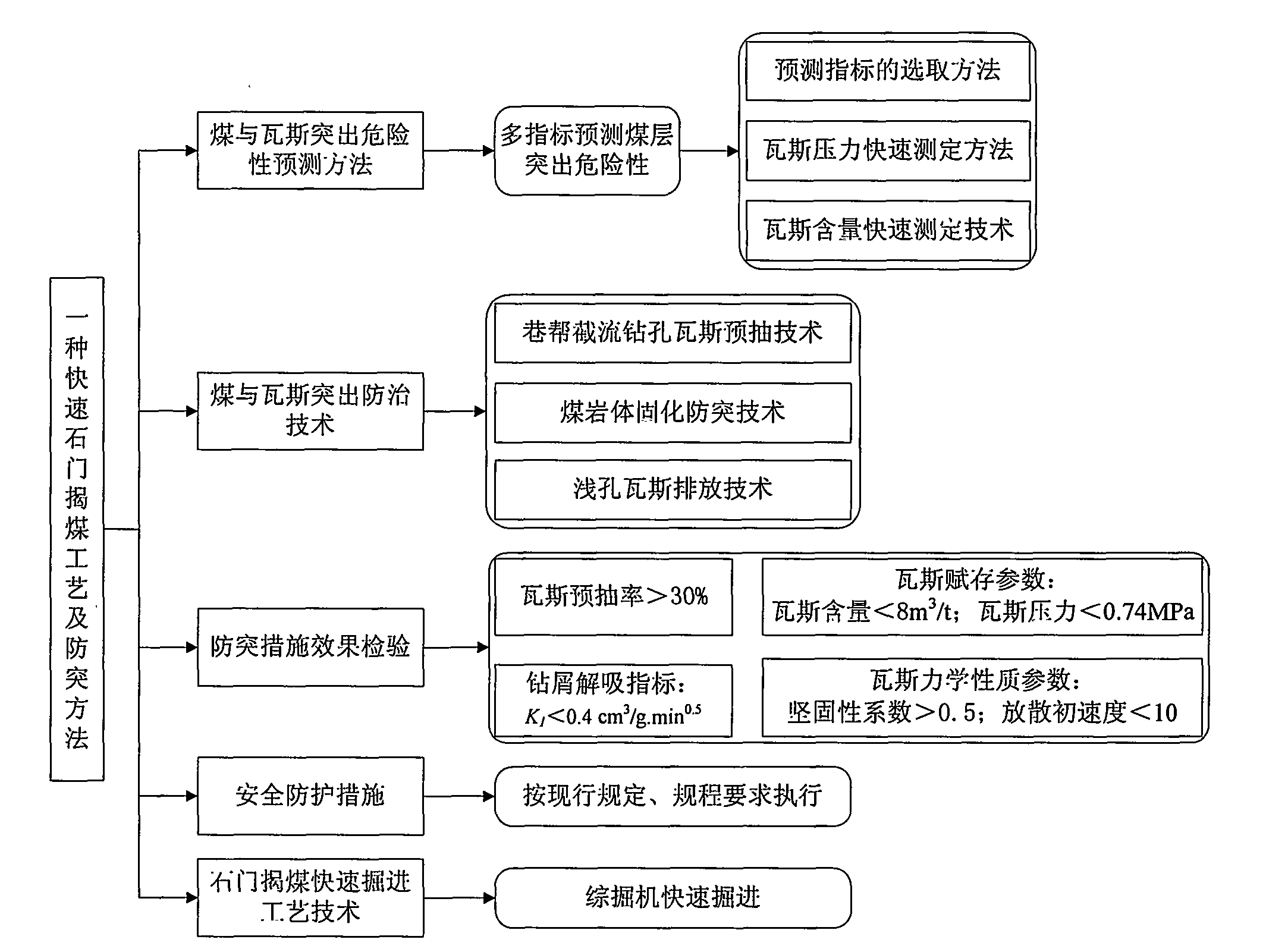

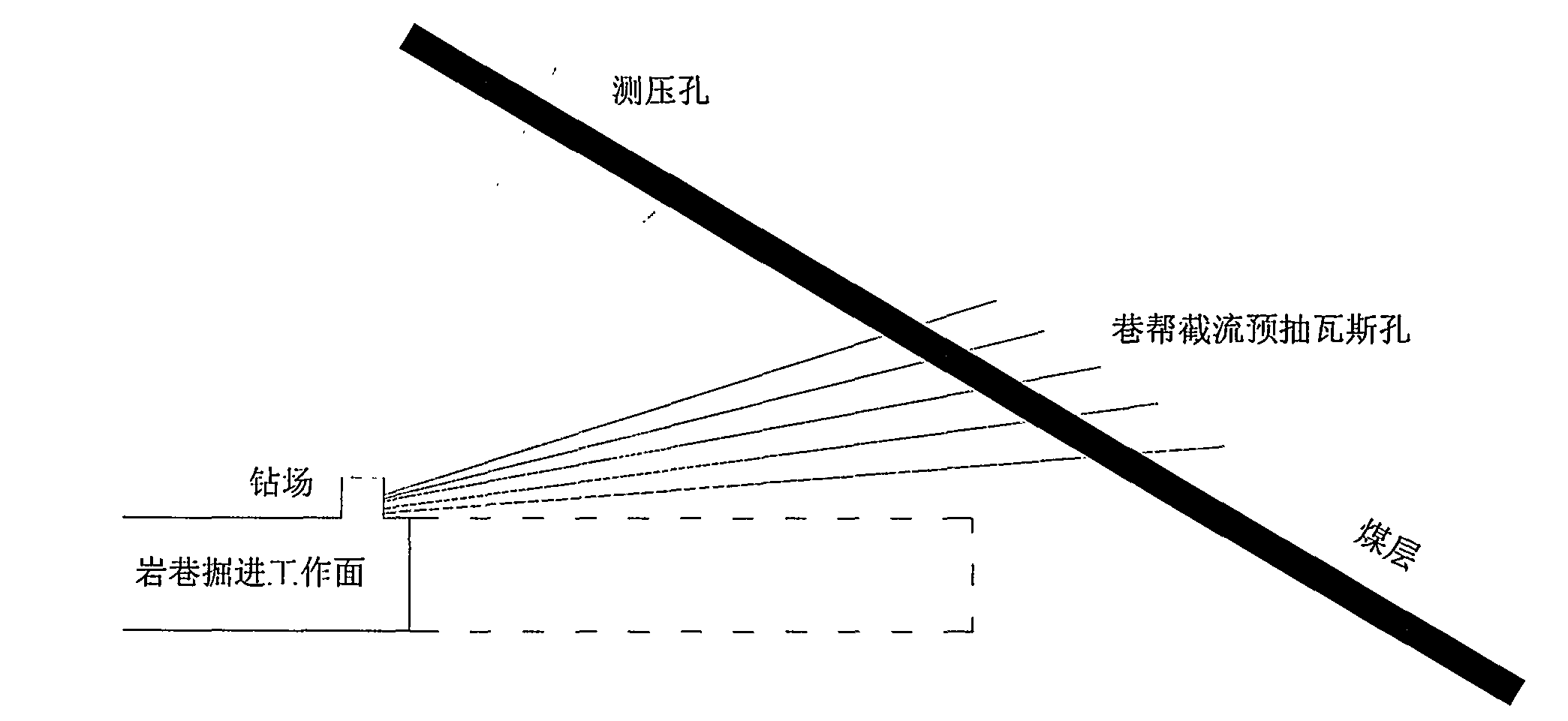

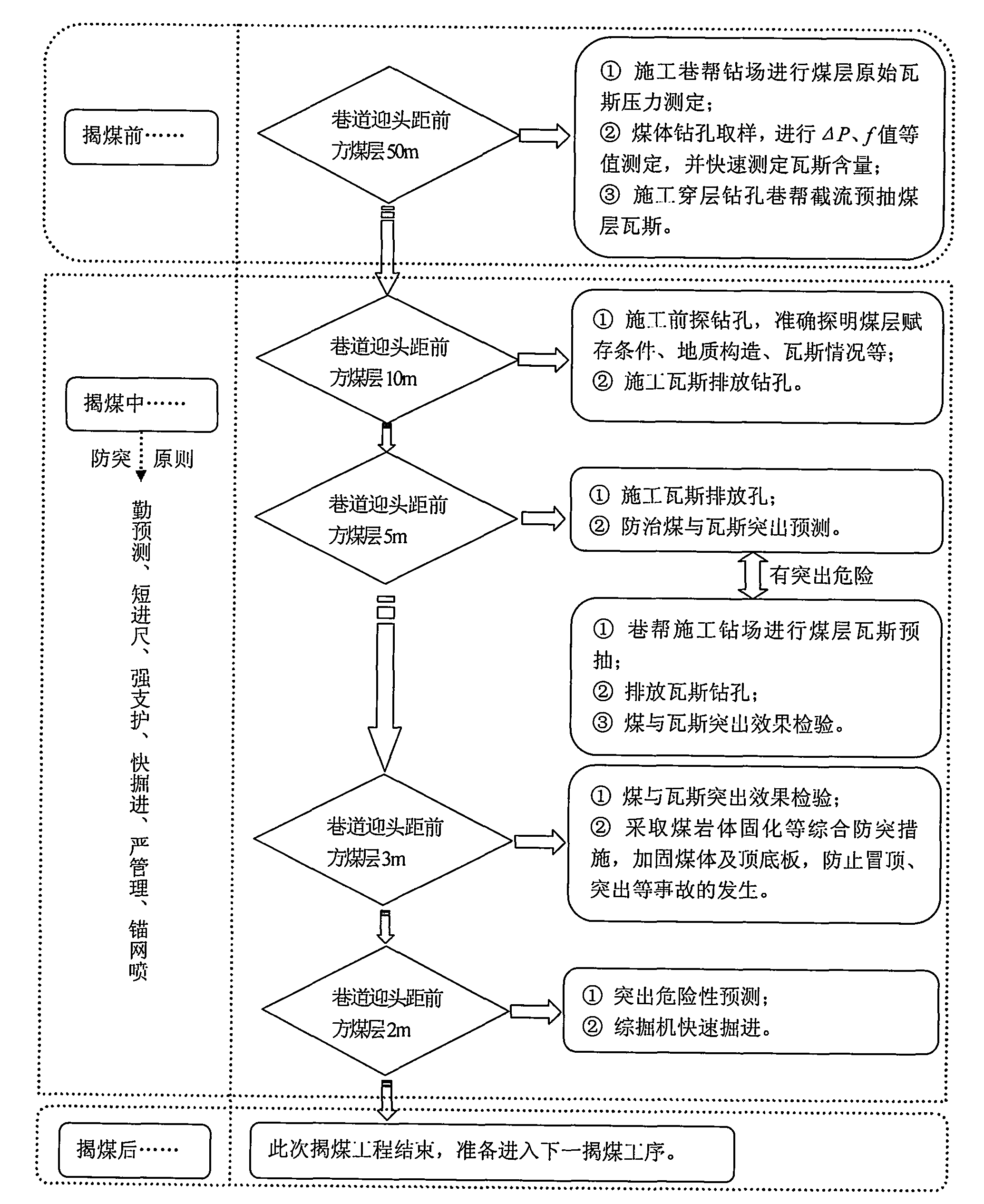

Rapid rock cross-cut coal uncovering process and outburst prevention method

InactiveCN103306677AImprove accuracyShorten the timeUnderground miningSurface miningDrill siteCross cut

The invention relates to a rapid rock cross-cut coal uncovering process and an outburst prevention method. The rapid rock cross-cut coal uncovering process comprises the following steps: performing lane drill site construction advance borehole during rock drivage period, performing penetration drilling to measure the gas pressure of the coal seam and rapidly measuring the gas content, the mechanical property of the coal and other parameters by utilizing extraction drilling and sampling under the conditions that the rock gangway construction is not influenced and the coal seam to be uncovered is subjected to gas interception and extraction in advance, and realizing the outburst danger of the multi-index prediction coal seam; increasing the specific coal and rock mass curing measures in addition to the gas outburst prevention measures with the uncovering related regulations and standard requirements, so that the rock cross-cut is excavated by employing an integrated excavator after the rock cross-cut uncovering working face is subjected to complete outburst removal, and rapid rock cross-cut coal uncovering is realized. The whole set of coal uncovering process and the outburst prevention are used for the experimental coal mine 937m roadways, and 18 layers of coal are uncovered totally, so that the whole construction period is shortened by 1.63 years and is only 1 / 3 of the expected coal uncovering time. The method is easy and convenient to operate, safe in construction, short in overall coal uncovering time and good in outburst prevention effect and has wide practicability.

Owner:GUIZHOU INST OF COAL SCI

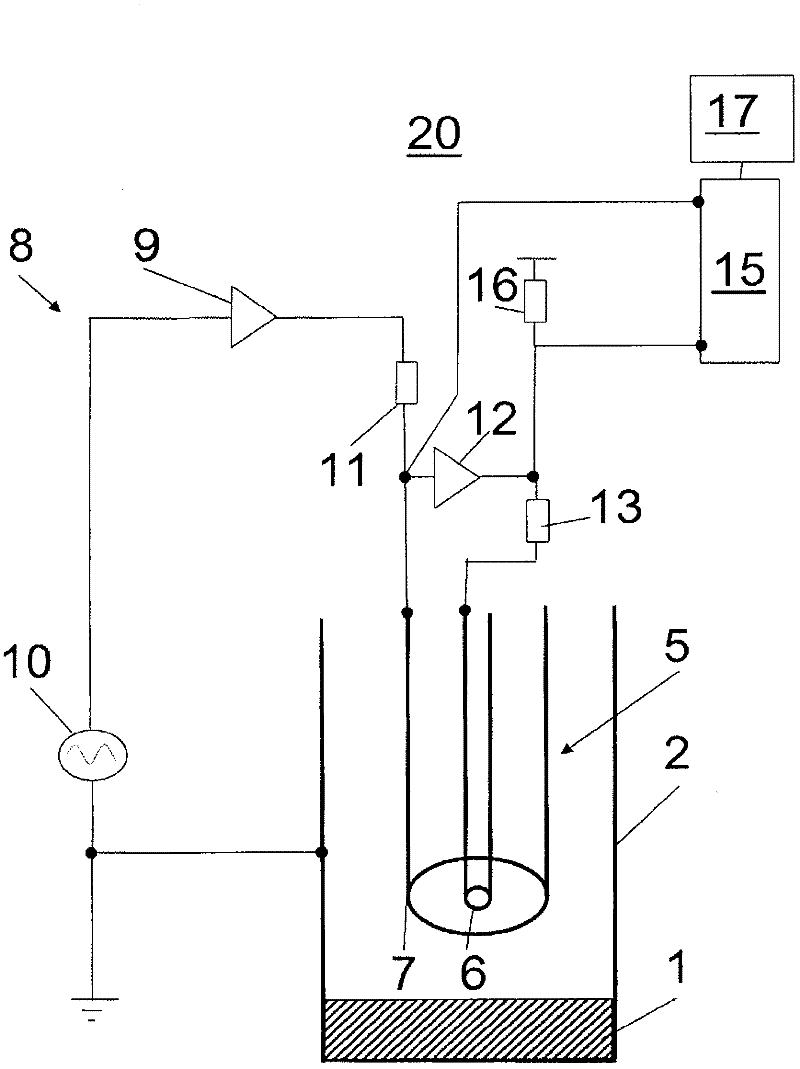

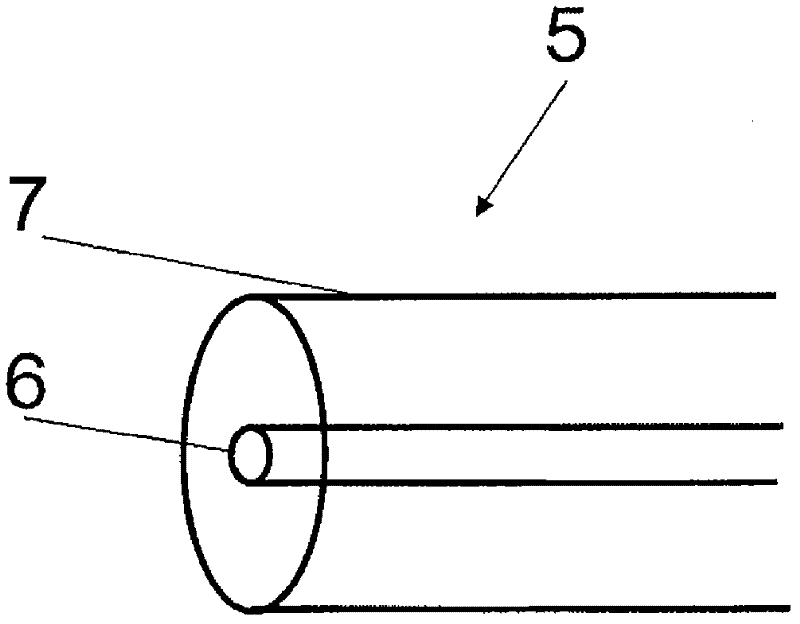

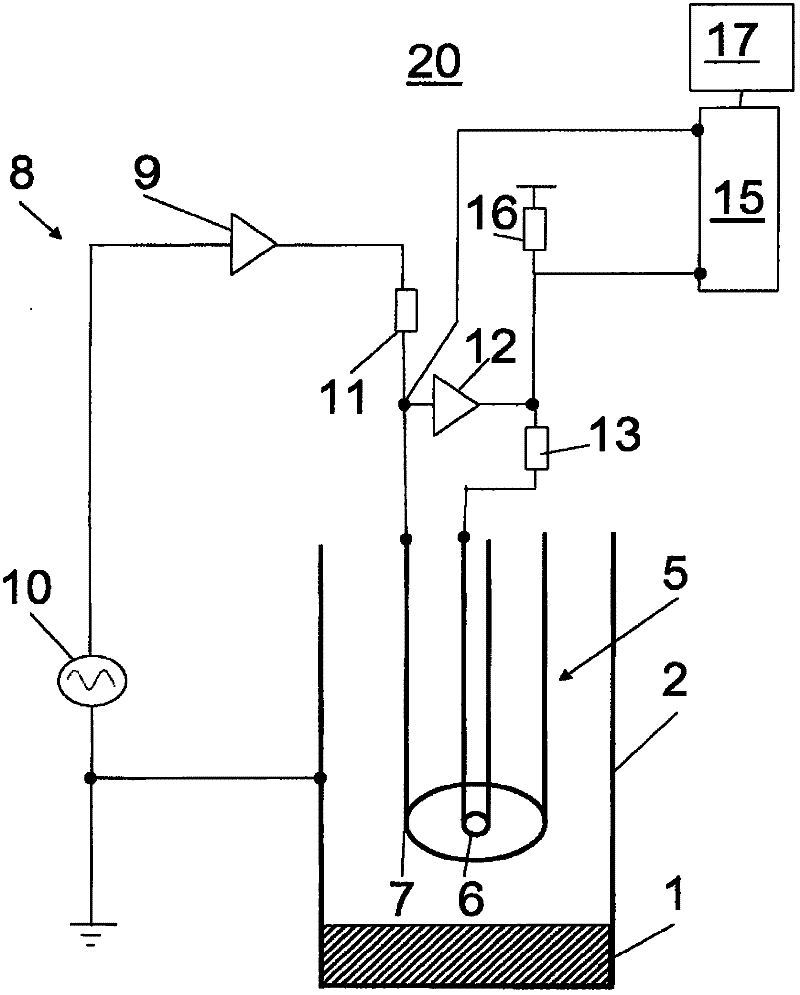

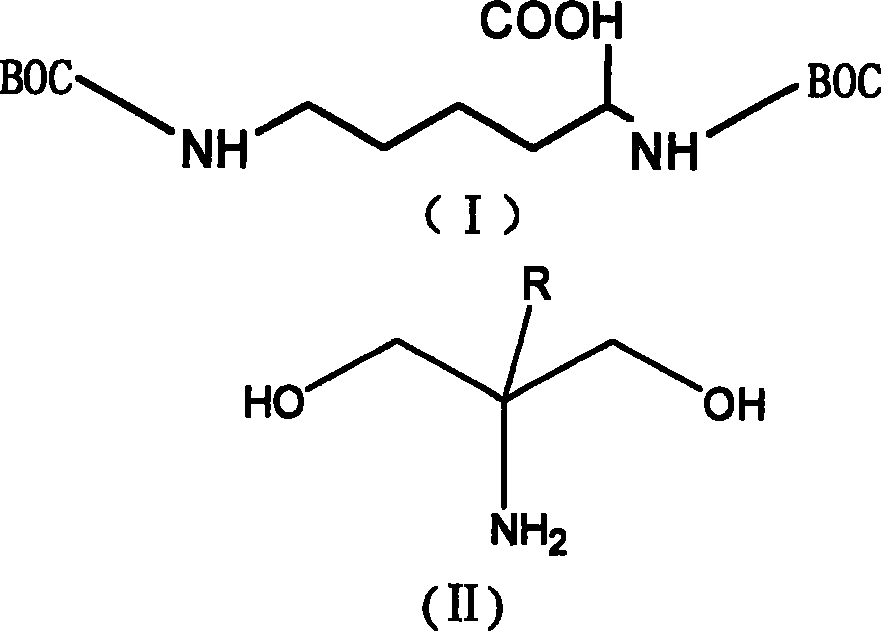

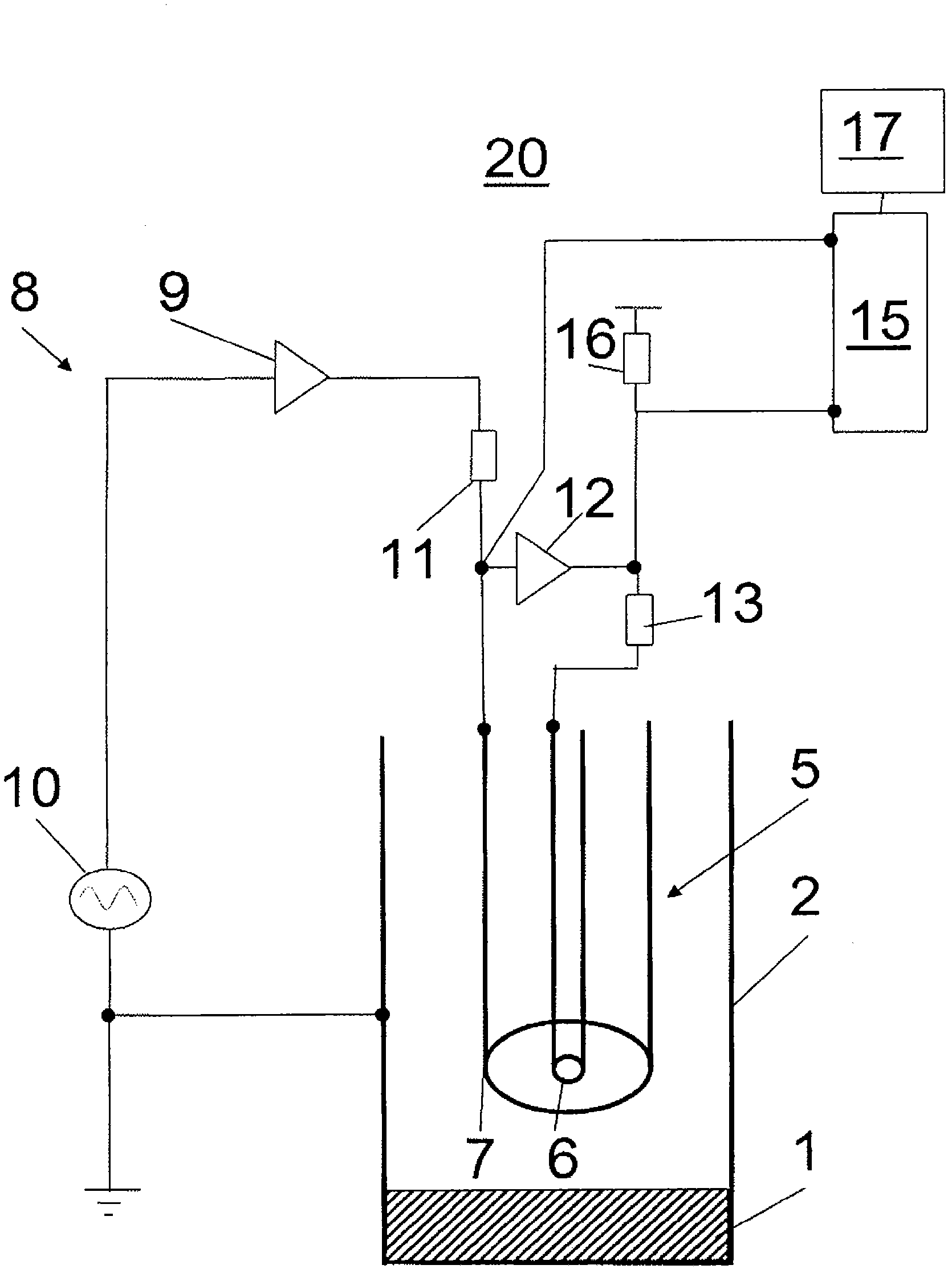

Apparatus for determining and/or monitoring a process variable for a medium

ActiveCN102203570AAvoid insensitivityTesting/calibration apparatusElectronic switchingProcess engineeringProcess variable

The invention relates to an apparatus for determining and / or monitoring at least one process variable for a medium (1), having at least one evaluation unit (15) which monitors and / or signals when a prescribable limit value for the process variable is exceeded and / or undershot by the medium (1), and having at least one memory unit (17) which stores limit values for the process variable which are associated with at least one property of the medium (1), and wherein the evaluation unit (15) takes a statement about the property of the medium (1) as a basis for using the stored limit value which is associated with the property of the medium (1) from the memory unit (17) to determine and / or monitor the process variable.

Owner:EHNDRESS KHAUZER GMBKH KO KG

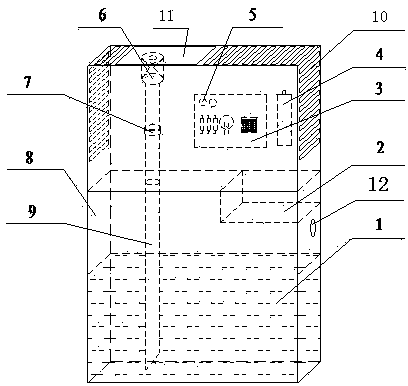

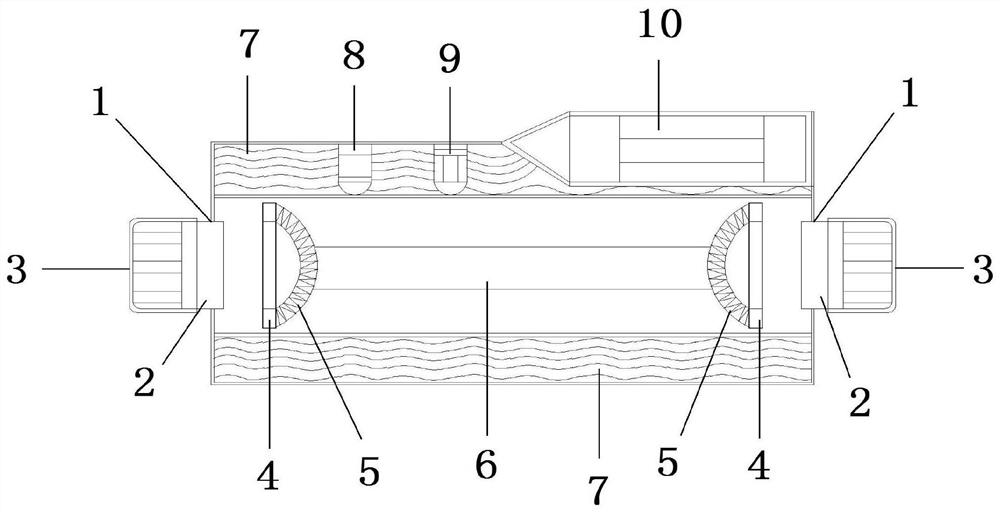

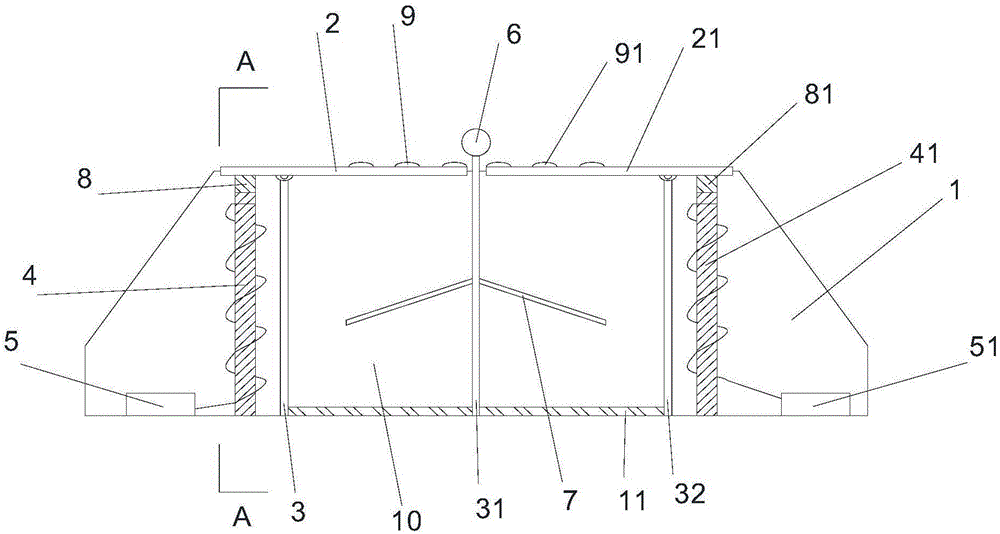

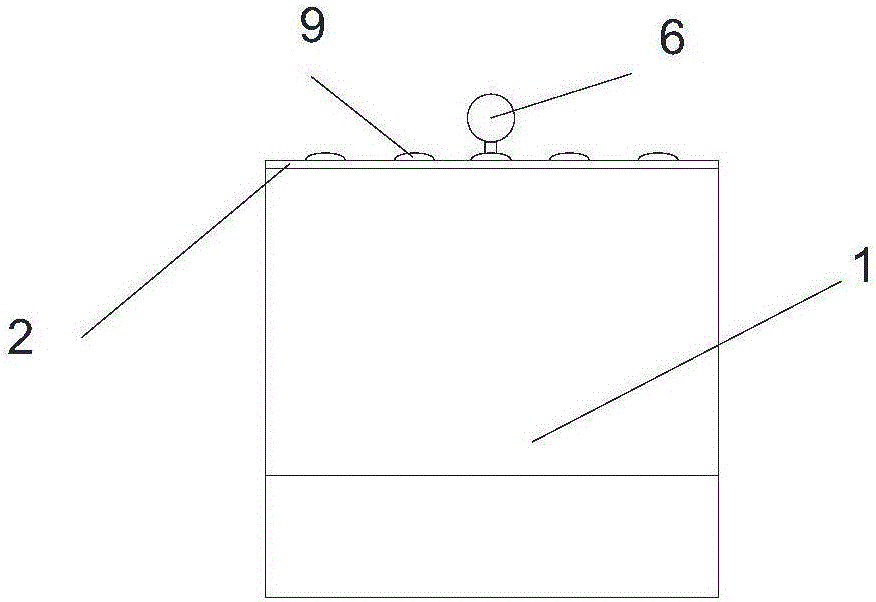

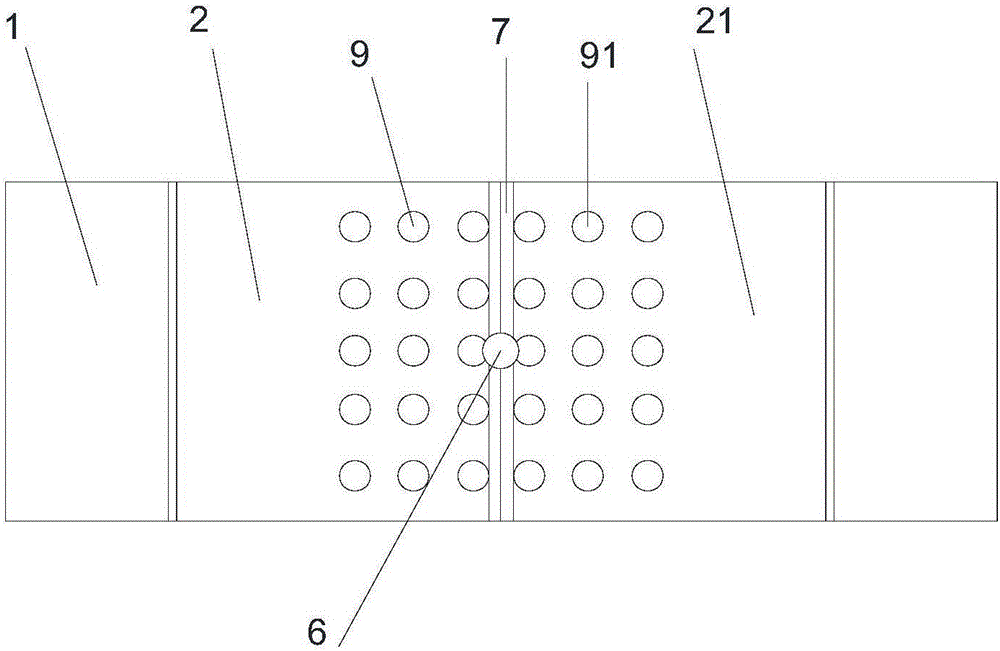

Automatic fire extinguishing device for automobile

The invention relates to an automatic fire extinguishing device for an automobile. The automatic fire extinguishing device comprises fire extinguisher devices mounted in an automobile cabin body at fire-hazardous parts of an engine cabin body, wherein each fire extinguisher device comprises a box body; a closed containing cavity for storing a fire extinguishing agent is formed in the lower part of each box body; a fire extinguishing control device is arranged at the upper part in each closed containing cavity; the fire extinguishing device is arranged in the engine cabin body of the automobile; when fire happens in the engine cabin body of the automobile, a fire detector detects a fire happening signal and sends the signal to a control chip; the control chip is used for switching on a gas generator, so that pressure is generated in a fire extinguishing agent container, and a sealing film on a nozzle is punctured to spray a liquid fire extinguishing agent out of the nozzle through a flow guide pipe for fire extinguishing.

Owner:WUXI EPIC TECH

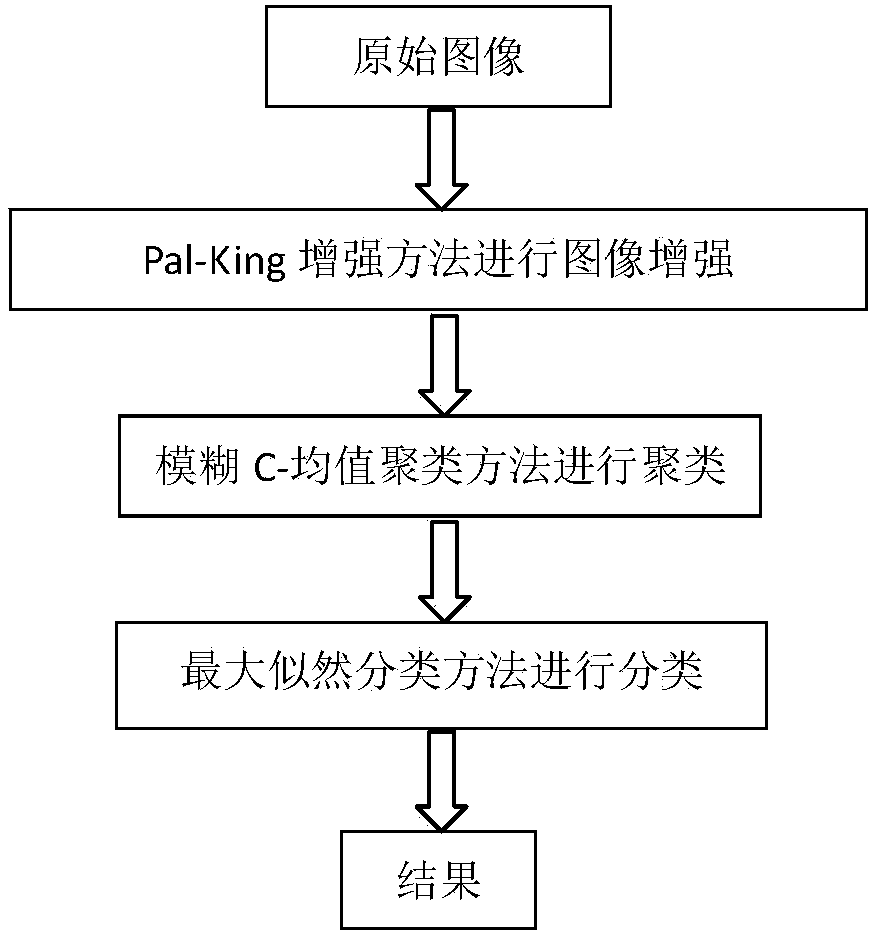

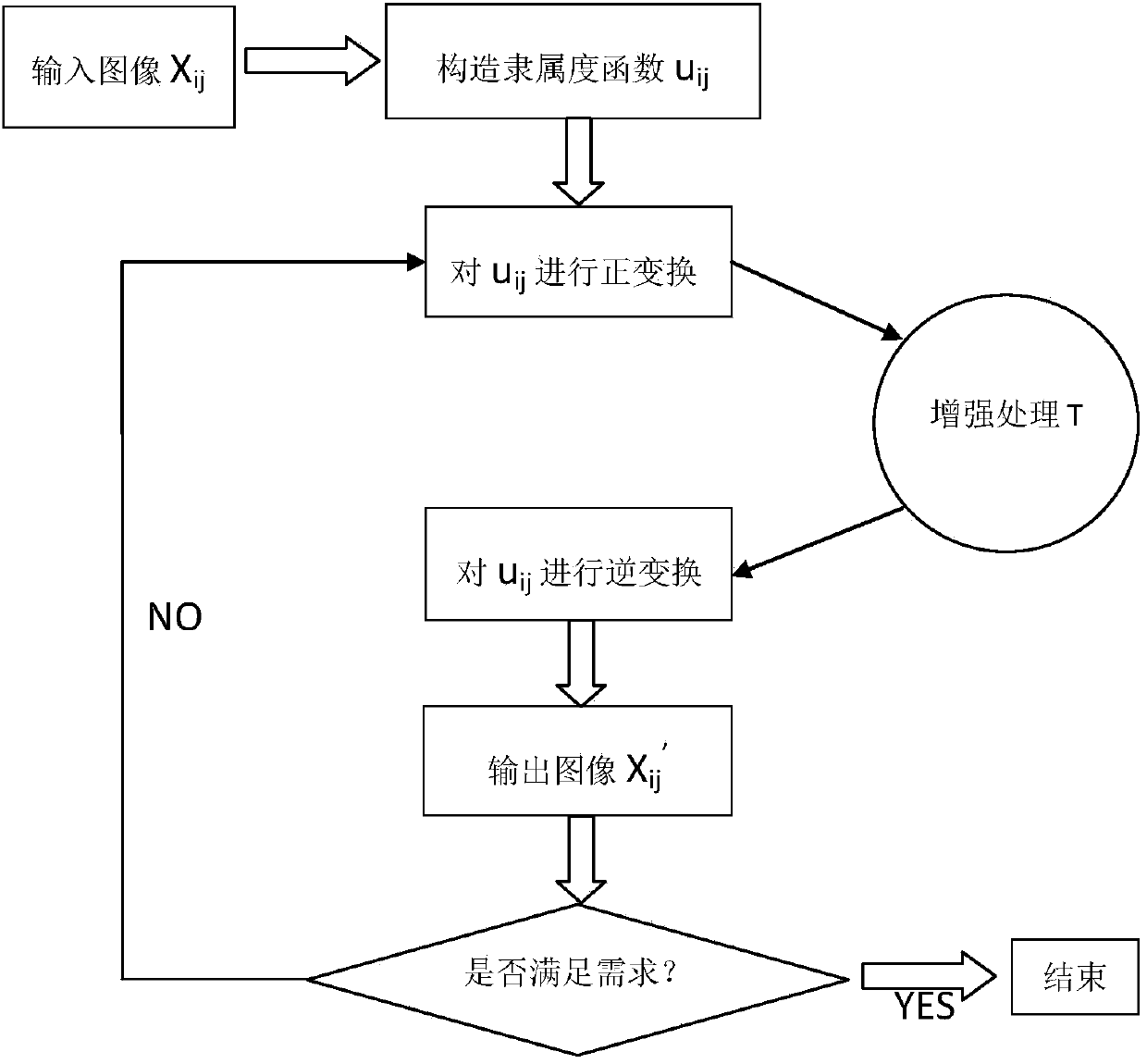

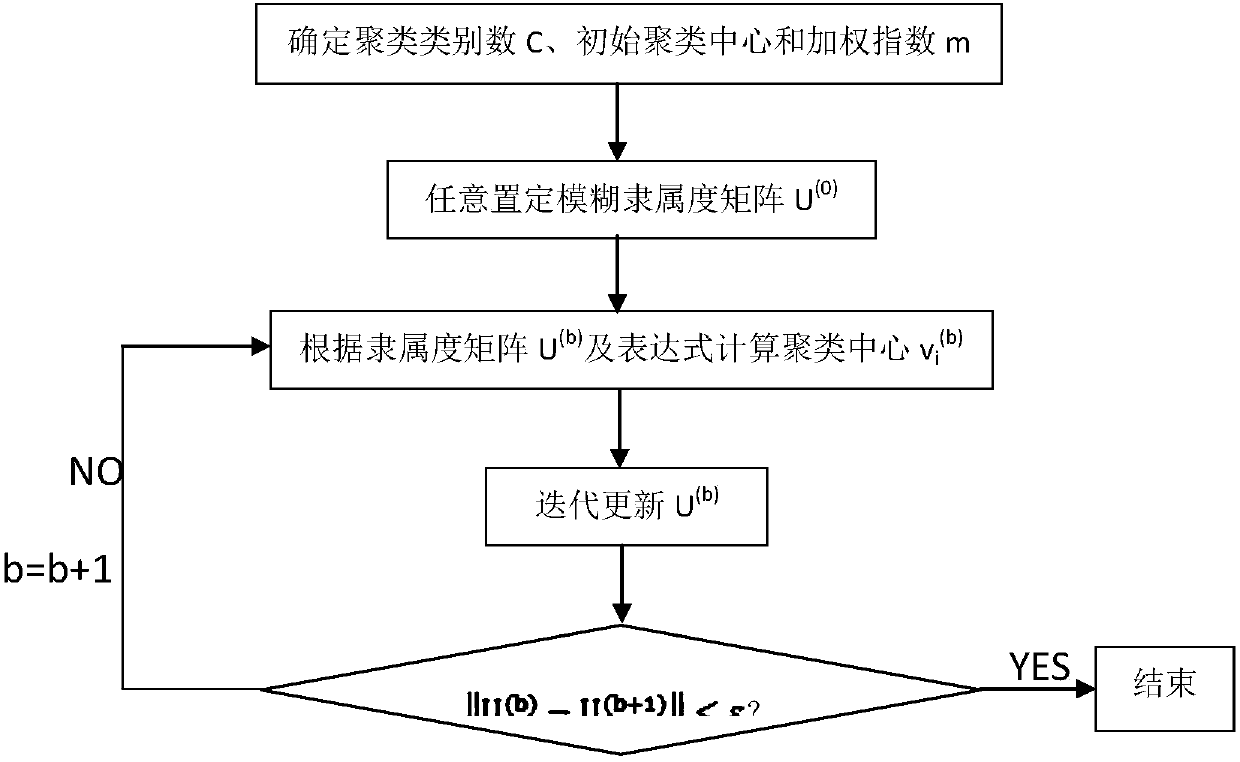

Image enhancement technology and remote image classification method based on fuzzy set theory

InactiveCN108268826AAvoid ambiguityImprove classification performanceImage enhancementImage analysisImaging processingClassification methods

The invention provides an image enhancement technology and remote image classification method based on a fuzzy set theory. The image enhancement technology and remote image classification method basedon the fuzzy set theory are implemented through a set device. The set device comprises a fuzzy set unit and further comprises an image enhancement unit, wherein the image enhancement unit comprises afuzzy feature plane module, and the image enhancement unit further comprises a fuzzy enhancement transformation module. The set device also comprises a remote sensing unit. The image enhancement method based on the fuzzy set theory is applied to image processing, thereby overcoming a defect that the detail part of an image is weaken while the noise is suppressed because the traditional image enhancement technology does not take the fuzziness of the image into consideration but only simply changes the contrast or suppress the noise for the whole image.

Owner:GUANGDONG KINGPOINT DATA SCI & TECH CO LTD

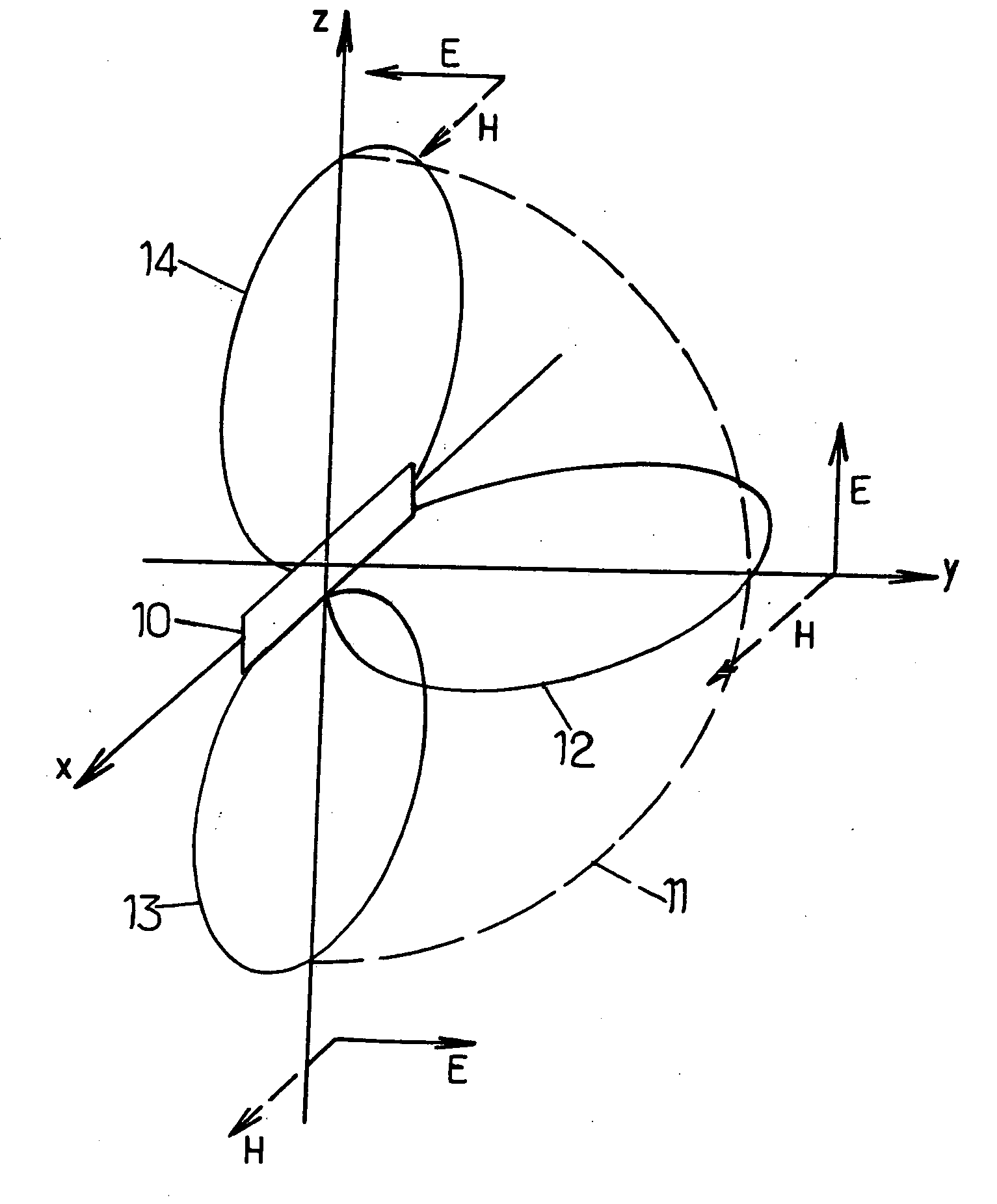

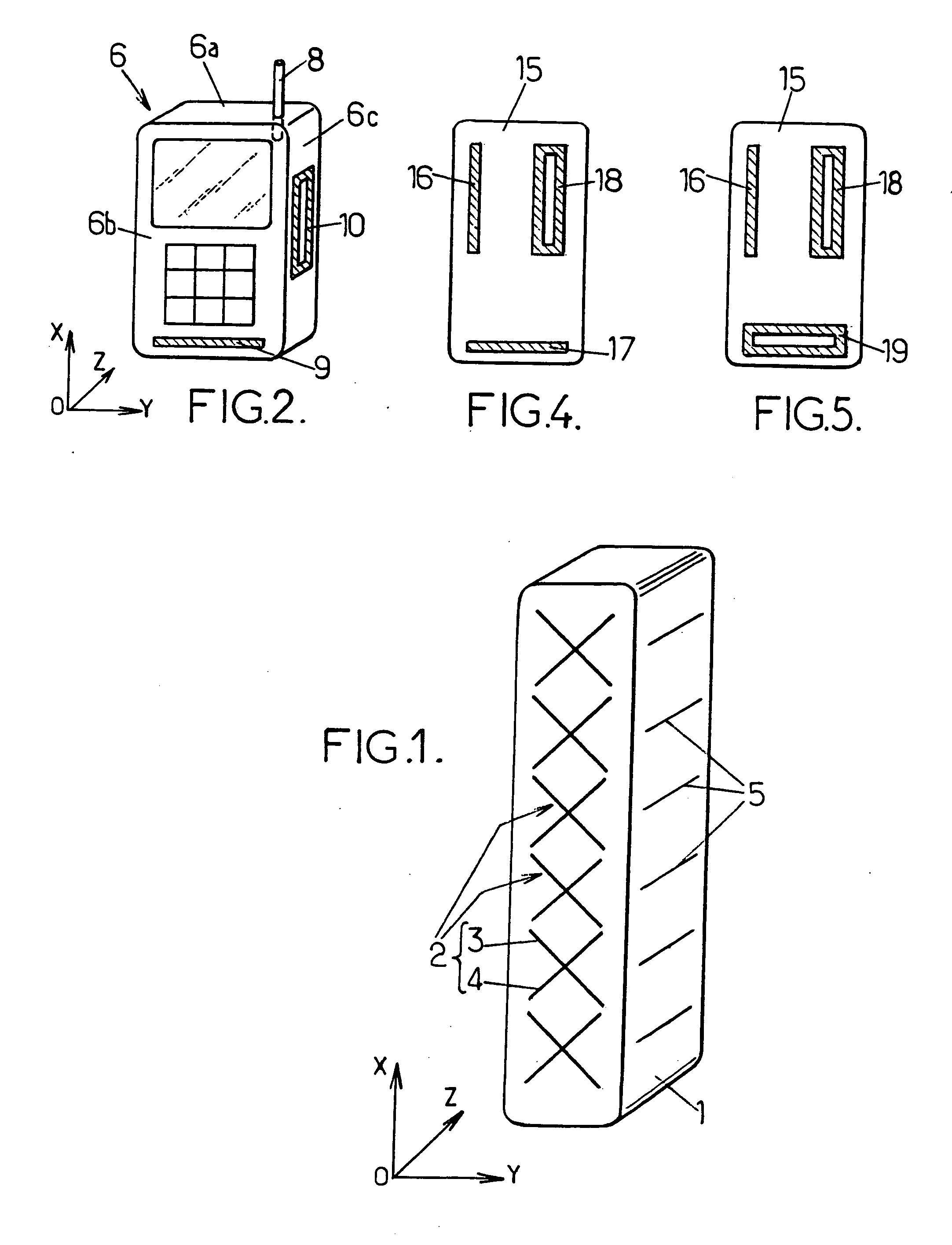

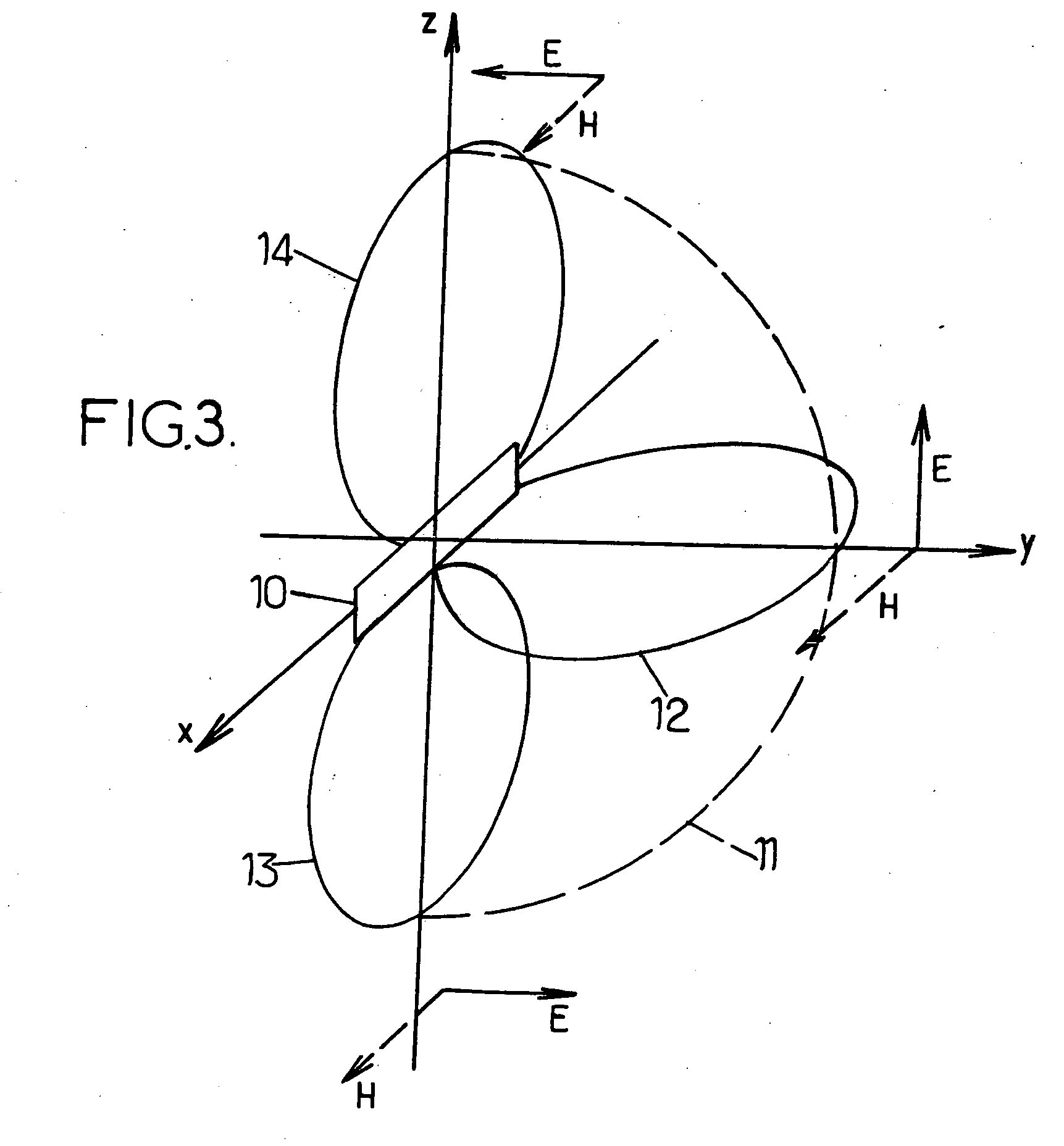

Antenna system for a radiocommunication station, and radiocommunication station having such antenna system

InactiveUS20070069962A1Avoid insensitivityImprove performancePolarisation/directional diversityAntenna supports/mountingsEngineeringAntenna element

The antenna system for a radiocommunication station has a plurality of antenna elements having different polarizations and arranged for coupling with RF electric field components oriented along three mutually perpendicular directions.

Owner:NORTEL NETWORKS LTD +1

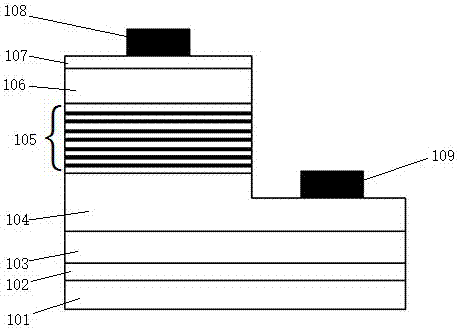

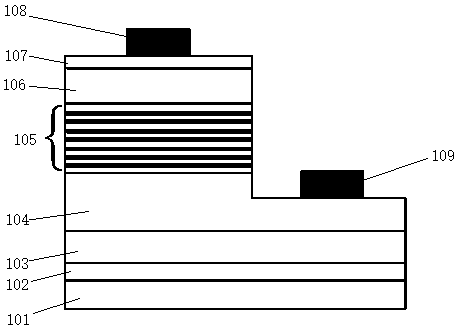

PIN structure ultraviolet photoelectric detector and preparation method thereof

ActiveCN106960885AHigh absorption coefficientEnhanced electric fieldFinal product manufactureSemiconductor devicesPhotovoltaic detectorsResponsivity

The invention discloses a PIN structure ultraviolet photoelectric detector. The PIN structure ultraviolet photoelectric detector comprises a sapphire substrate, an AIN nucleation layer, an Alx1Gal-x1N buffer layer, an n-type Alx2Gal-x2N layer, a non-doped i-type ZnO / TiO2 superlattice absorption layer, a p-type Alx3Gal- x3N layer, and a p-type GaN layer. An n-type ohmic electrode is led out from the n-type Alx2Gal-x2N layer, and a p-type ohmic electrode is led out from the p-type GaN layer. In the non-doped i-type ZnO / TiO2 superlattice absorption layer, the repetition period of the superlattice is in a range from 1 to 10. The invention also discloses the preparation method of the PIN structure ultraviolet photoelectric detector. By using the PIN structure ultraviolet photoelectric detector, the responsivity of the detector to weak ultraviolet signals is improved.

Owner:苏州科帕特信息科技有限公司

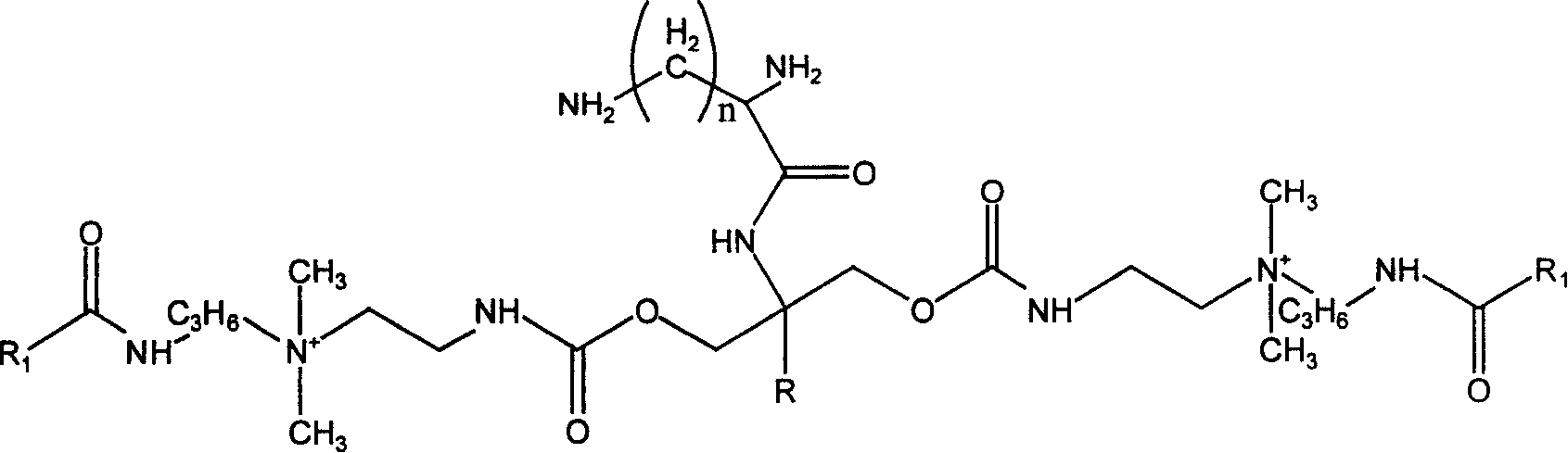

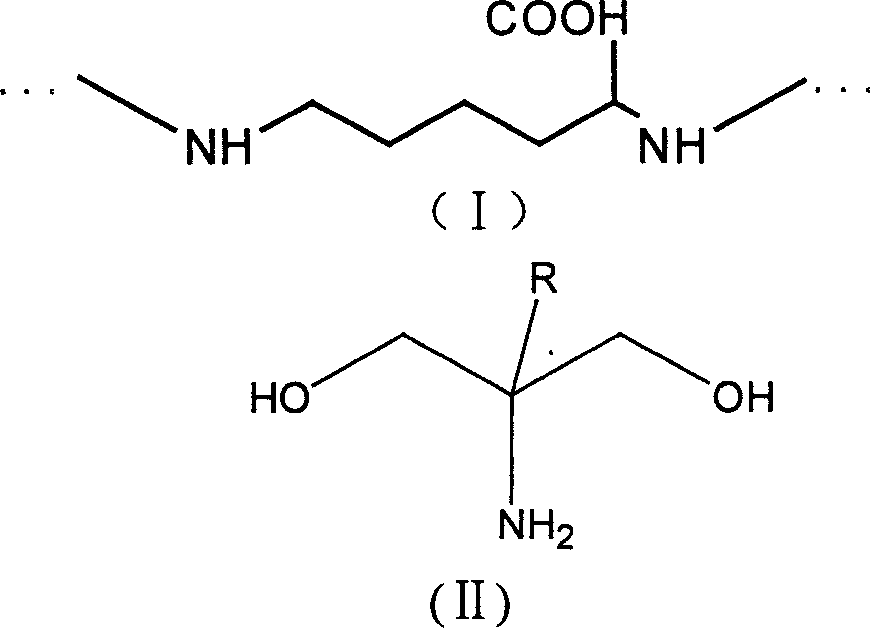

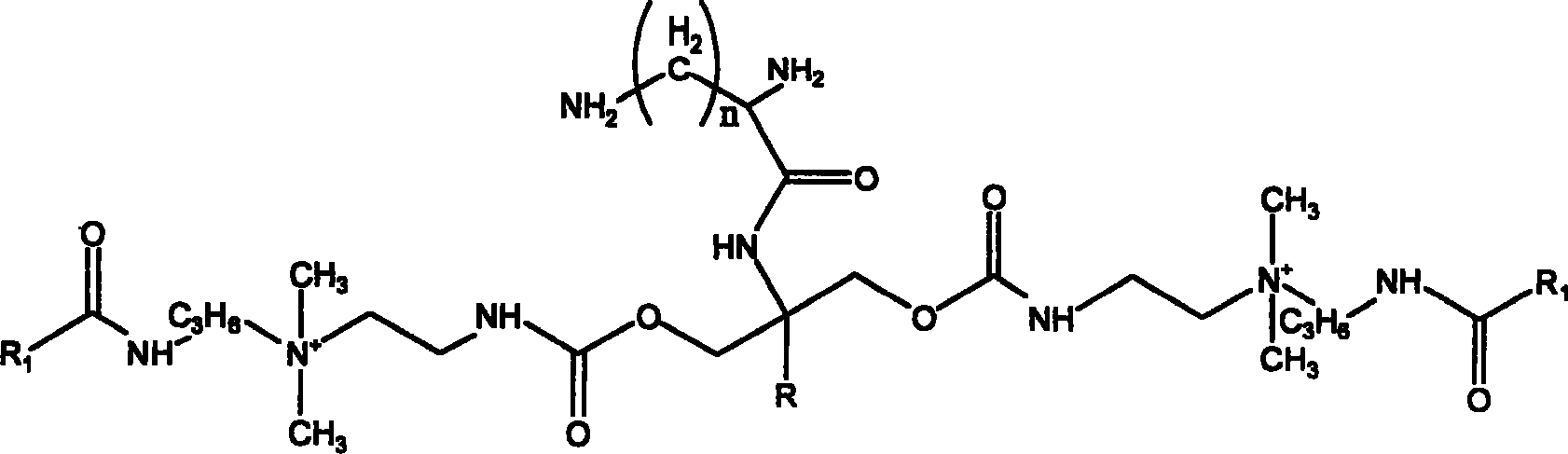

Quaternary bis-ammonium salt diamine fluoride and preparation method thereof

InactiveCN1927829AHigh reactivityImprove the bactericidal effectBiocideCarbamic acid derivatives preparationChemical reactionCompound (substance)

The present invention discloses fluoric double quaternary ammonium salt diamine in the structure as shown and its preparation process. The fluoric double quaternary ammonium salt diamine has two primary amino radicals with excellent reaction activity in its structure, so that it may be introduced into polymer easily to form polymer with excellent effect of killing Gram negative bacteria. The preparation process adopts facile industrial materials and includes serial simple easy-to-control chemical reactions.

Owner:SICHUAN UNIV

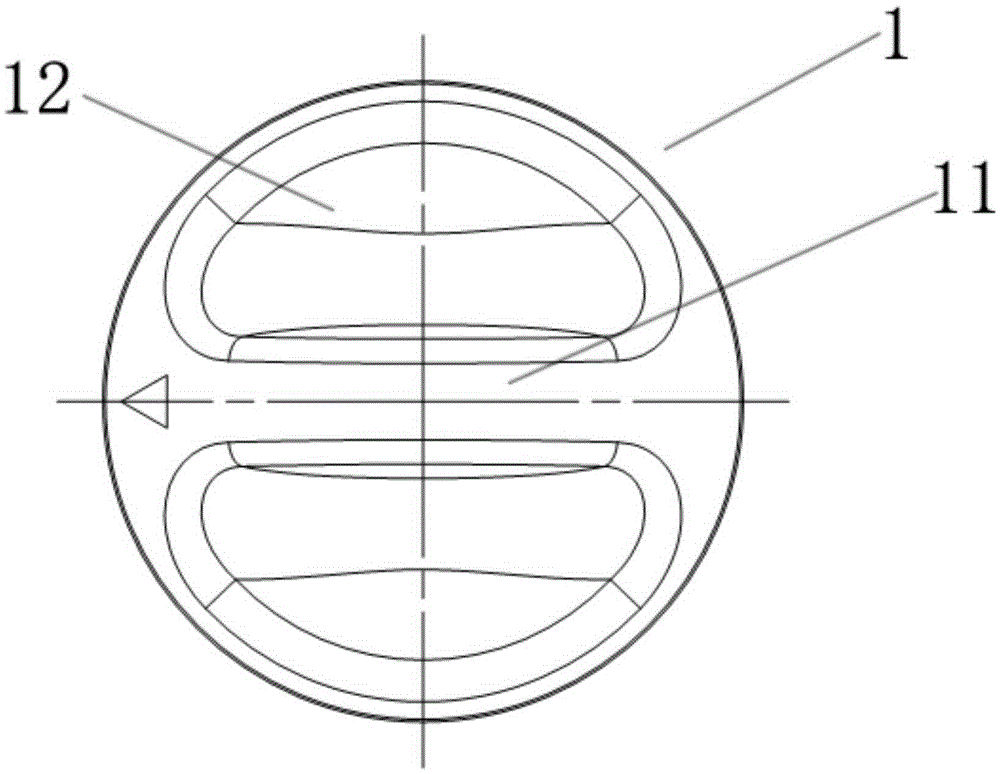

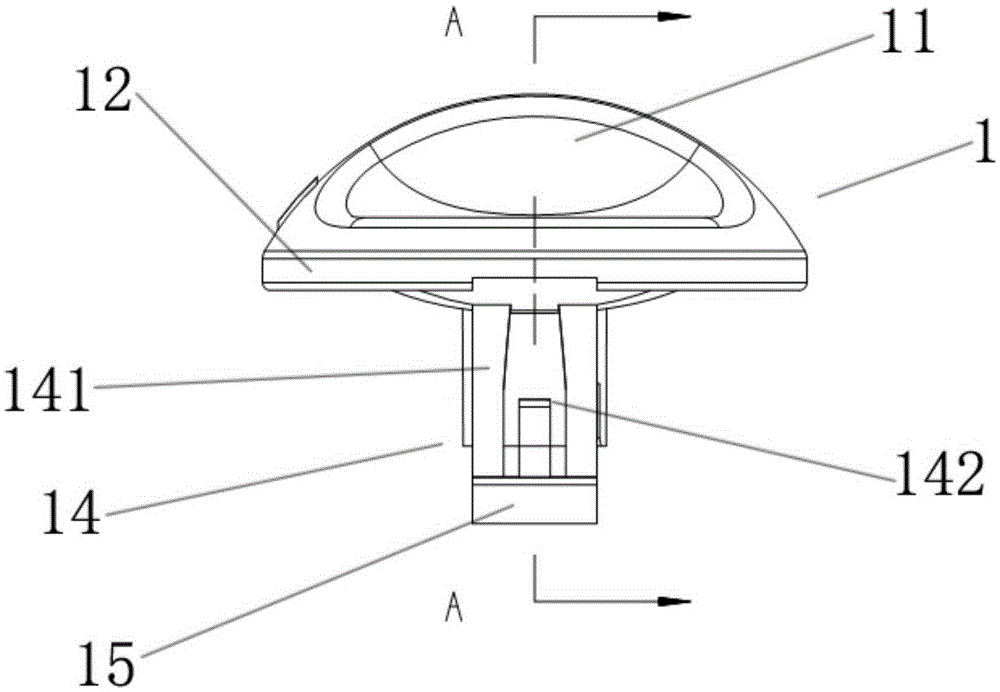

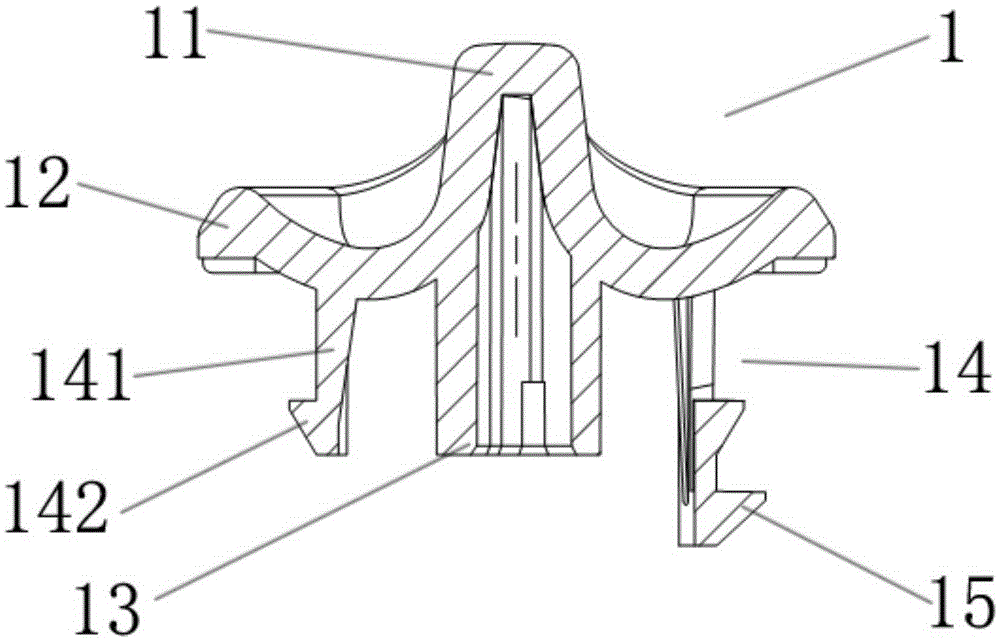

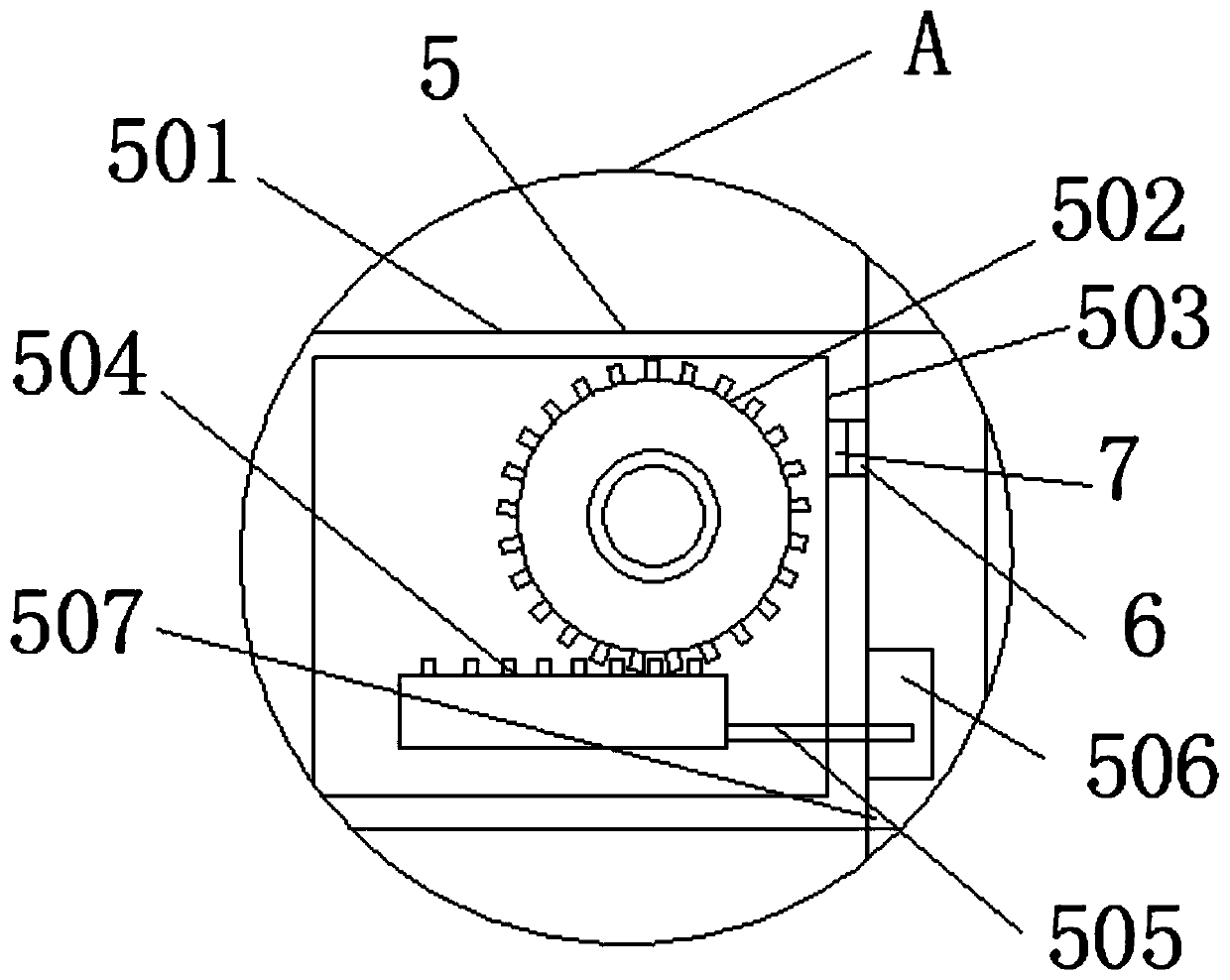

Rotary knob, temperature control panel comprising same and freezer

InactiveCN105276915AImprove reliabilityNot easily taken outDomestic cooling apparatusLighting and heating apparatusTemperature controlUltimate tensile strength

The invention relates to a rotary knob, a temperature control panel comprising the same and a freezer. The rotary knob comprises a handheld part, an assembly joint part and a running fit part, wherein the running fit part is in running fit with a temperature controller in the temperature control panel; the lower end of the assembly joint part is provided with at least two buckle structures which rotate relative to the temperature control panel and are connected with the temperature control panel in a clamped mode. One buckle structure is additionally provided with a limiting clamping jaw which rotates relative to the temperature control panel and is connected with the temperature control panel in a clamped mode. The limiting clamping jaw and a limiting block on the temperature control panel abut against each other and carry out limiting. The rotary knob is provided with at least two buckle structures which ensure effective connection between the rotary knob and the temperature control panel and stress uniformity together, increase the connection reliability of the rotary knob and guarantee that the rotary knob cannot be taken out easily. On one hand, the limiting clamping jaw improves the connection strength between the rotary knob and the temperature control panel, and on the other hand, the limiting clamping jaw and the limiting block on the temperature control panel jointly play a role of limiting and guarantee the rotating angle of the rotary knob.

Owner:HEFEI HUALING CO LTD +1

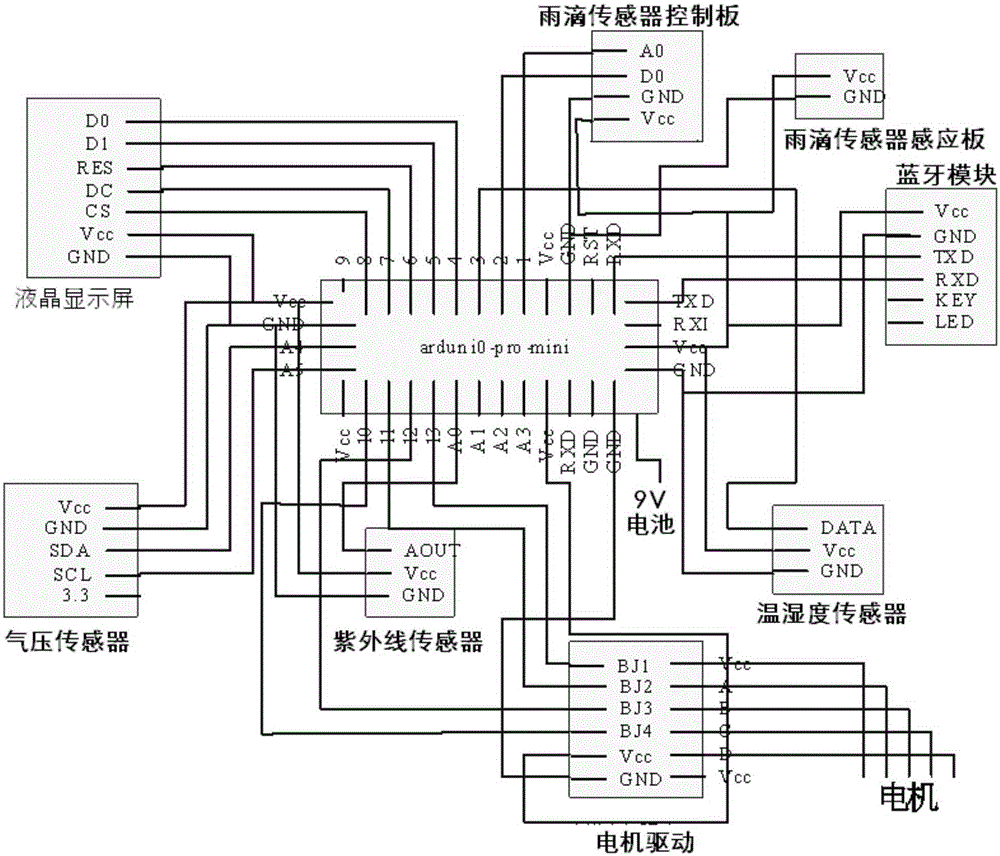

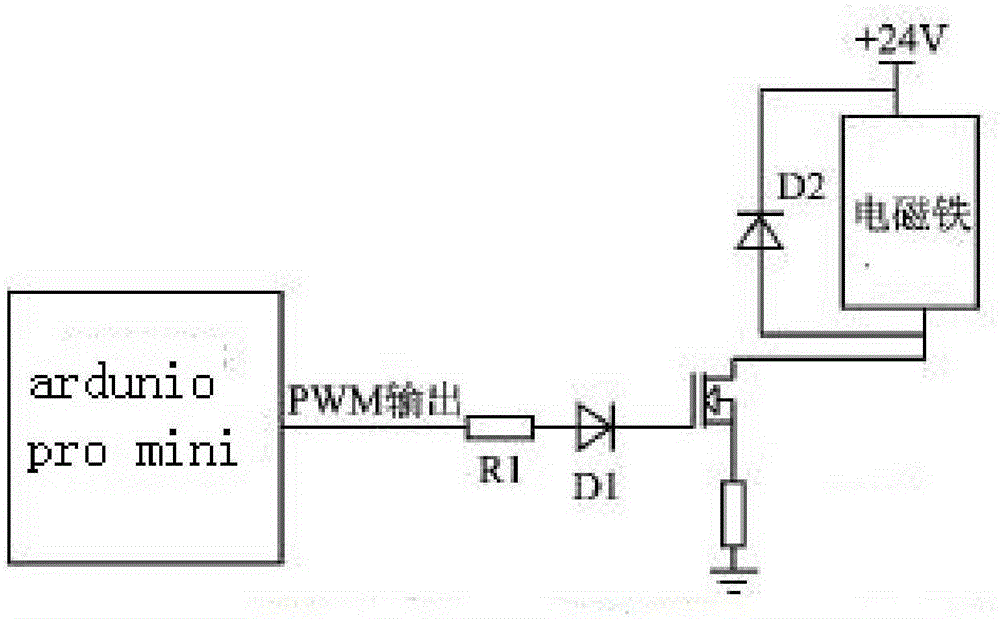

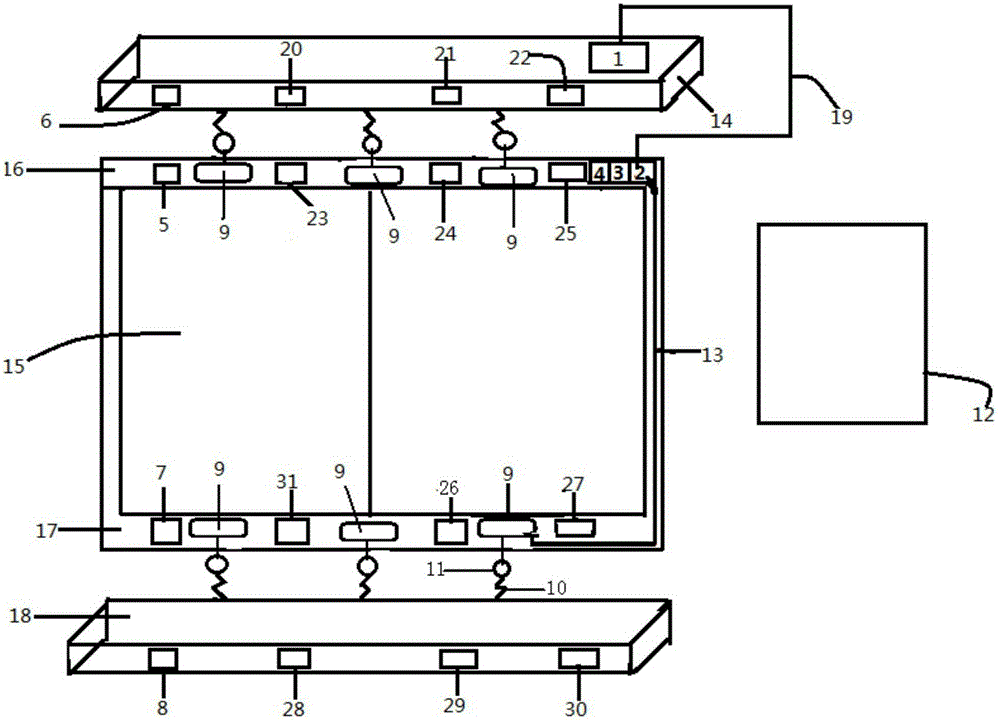

Window capable of predicting weather condition to be automatically opened and closed and work method

InactiveCN105201325AAvoid insensitivityExtended service lifePower-operated mechanismWing suspension devicesEngineeringMultiple function

The invention relates to a window capable of predicting a weather condition to be automatically opened and closed and a work method, and belongs to the technical field of smart household equipment. The window comprises a window outer frame and window sashes, wherein sliding chutes are formed in the window outer frame; the window sashes are embedded in the sliding chutes; grooves are formed in upper sides and lower sides of the window sashes; a controller is arranged in one groove; a battery, a temperature and humidity sensor, an ultraviolet sensor, an air pressure sensor and a raindrop sensor are arranged on the window outer frame and are connected with the controller; motors and wheels are arranged in one groove; the motors are connected with the controller; springs are arranged on the wheels. The window is controlled to be automatically opened and closed by the sensors with multiple functions, the weather condition is detected more accurately, and control of the window is more humanized and more intelligent.

Owner:国网山东阳谷县供电公司

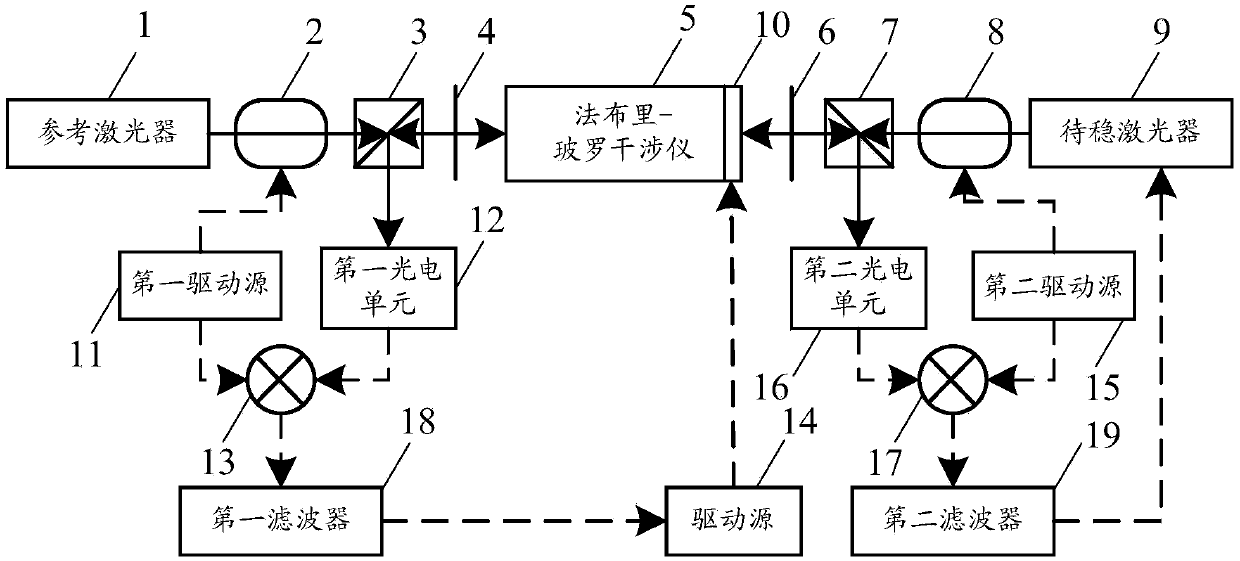

Laser frequency stabilizing system

ActiveCN105375325AAvoid insensitivity to error signalsGuaranteed long-term stabilityLaser detailsOptical pathFabry–Pérot interferometer

The invention discloses a laser frequency stabilizing system and belongs to the laser device field. The system comprises a reference laser device, a first electric light modulator, a first polarization splitting prism, a first half-wave plate, a Fabry-Perot interferometer, a second half-wave plate, a second polarization splitting prism, a second electric light modulator and a to-be-stabilized laser device and further comprises a piezoelectric ceramic, a first driving source outputting a first reference signal to the first electric light modulator, a first photoelectric unit arranged on a reflection light path of the first polarization splitting prism, a first frequency mixer mixing a first oscillation signal with a frequency signal outputted by the first photoelectric unit, a driving source generating a voltage signal according to a signal outputted by the first frequency mixer, a second driving source outputting a second reference signal to the second electric light modulator, a second photoelectric unit arranged a reflection light path of the second polarization splitting prism, and a second frequency mixer mixing a second oscillation signal with a frequency signal outputted by the second photoelectric unit.

Owner:JIANGHAN UNIVERSITY

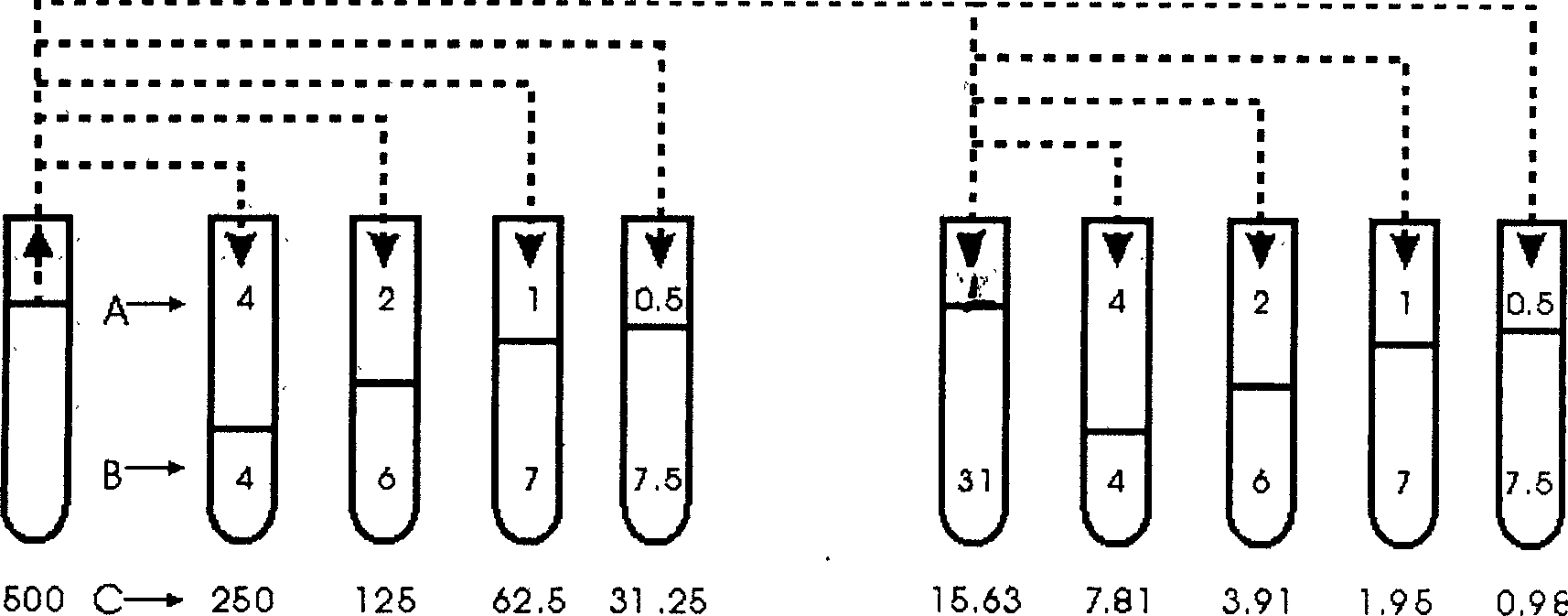

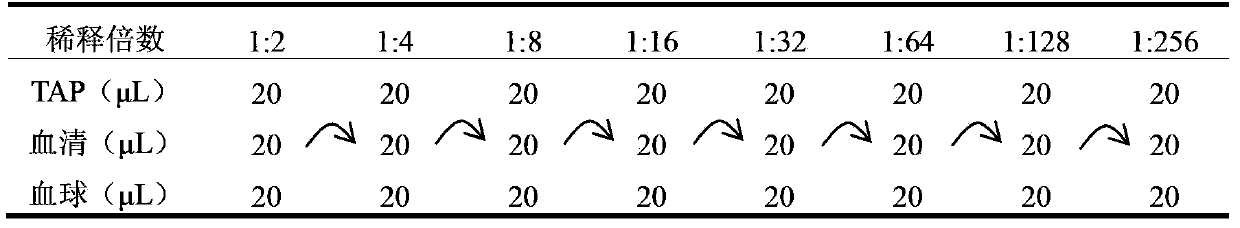

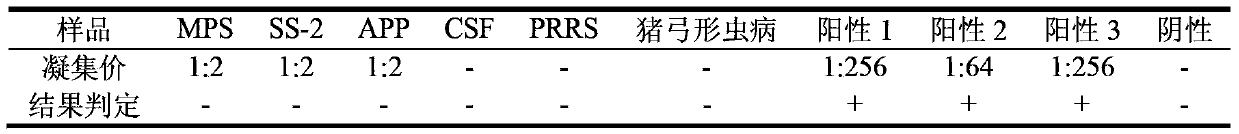

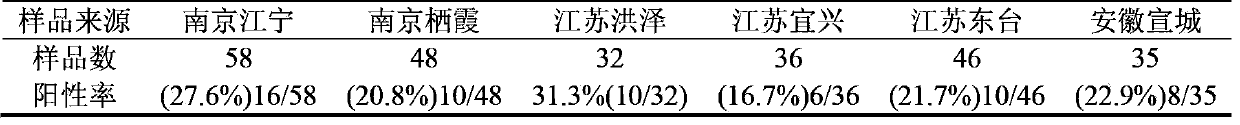

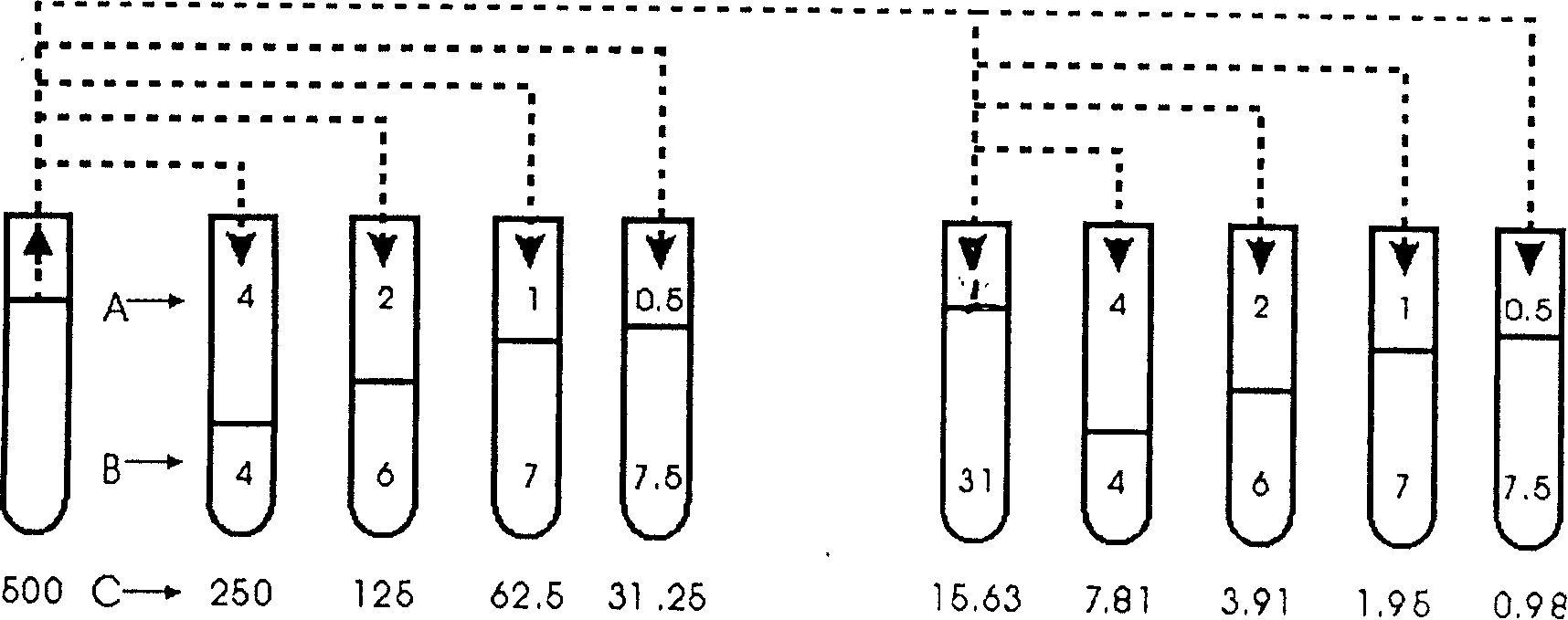

Haemophilus parasuis indirect hamagglutination detection reagent

The invention relates to the field of veterinary detection reagents, and discloses a haemophilus parasuis indirect hamagglutination detection reagent. The haemophilus parasuis indirect hamagglutination detection reagent is prepared by taking multiple serotype haemophilus parasuis whole protein mixtures as antigens, and is capable of rapidly and sensitively detecting serum antibodies of all serotype haemophilus parasuis diseases. The production technology is optimized through balanced mixing of each whole protein antigen, and then sensibilization and double hydroformylation of mutton red cells; and the prepared haemophilus parasuis indirect hamagglutination detection reagent is stable, sensitive, good in specificity, long in storage life, simple in operation, and applicable to a large amount of clinical sample detection on the haemophilus parasuis diseases, immune level detection and epidemiology investigation.

Owner:JIANGSU ACAD OF AGRI SCI

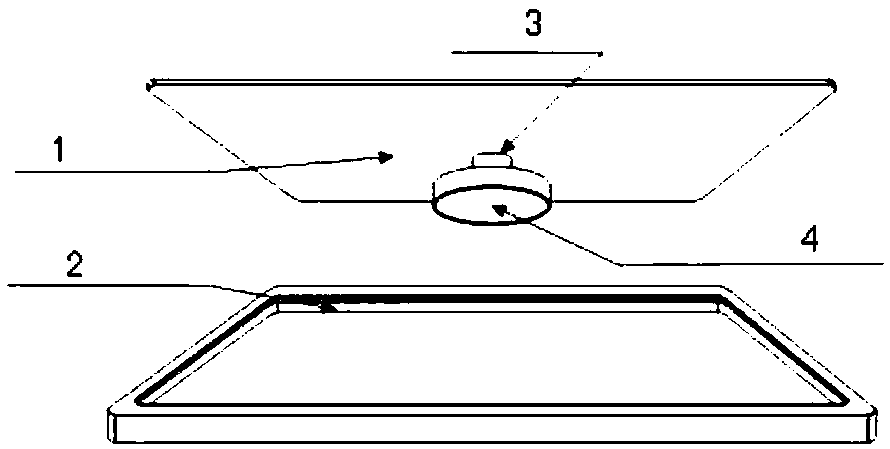

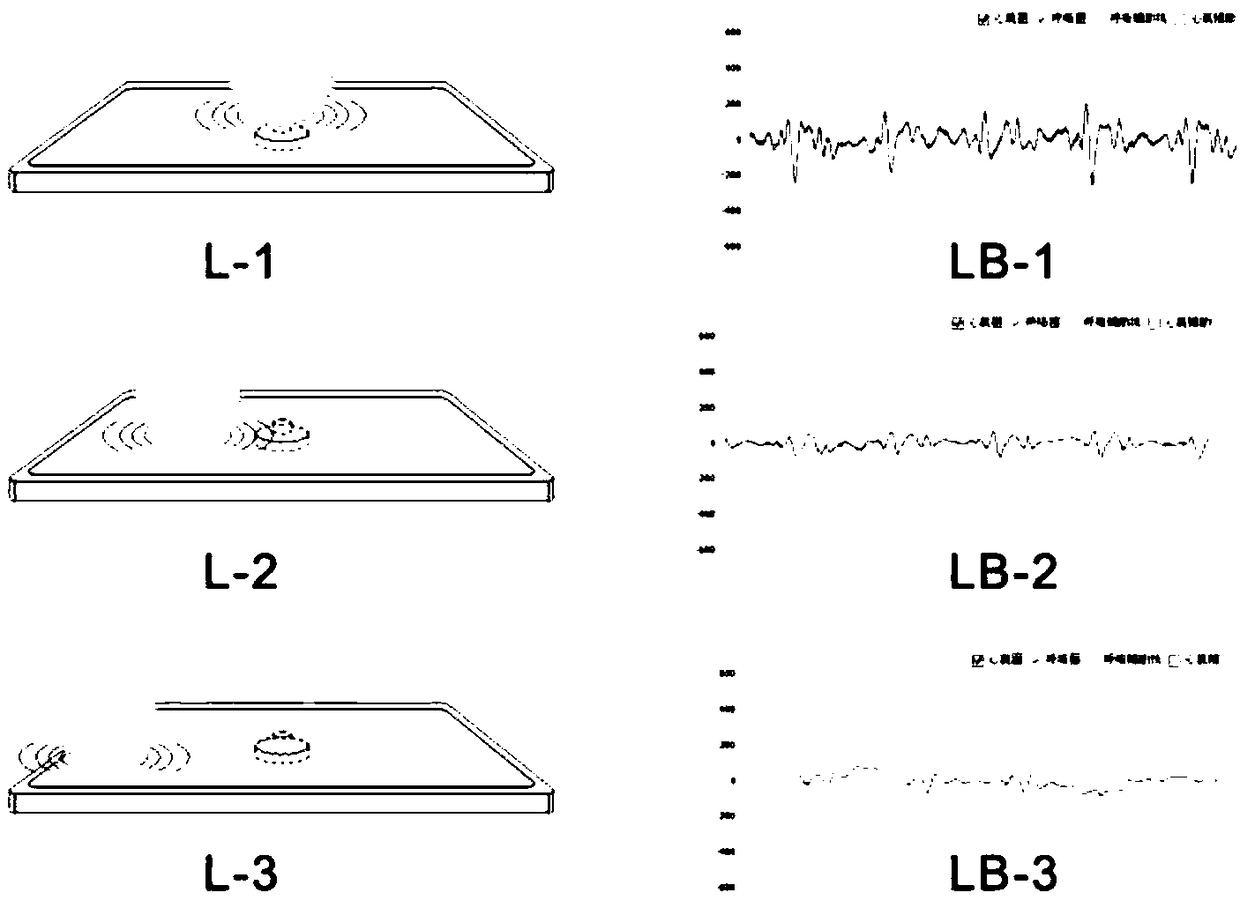

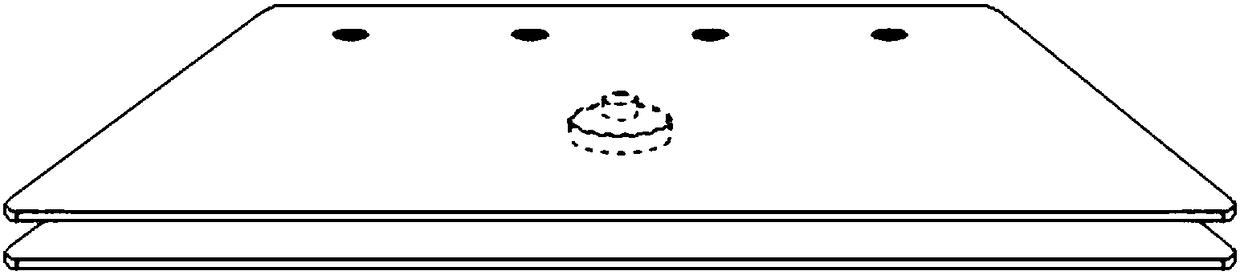

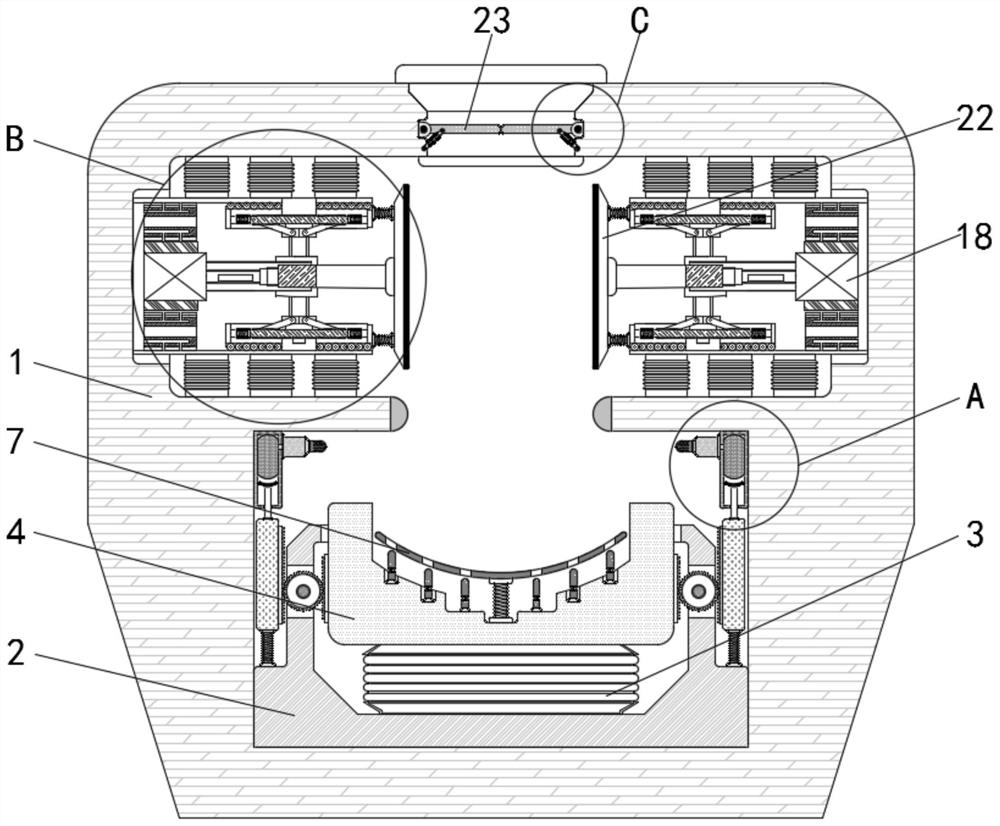

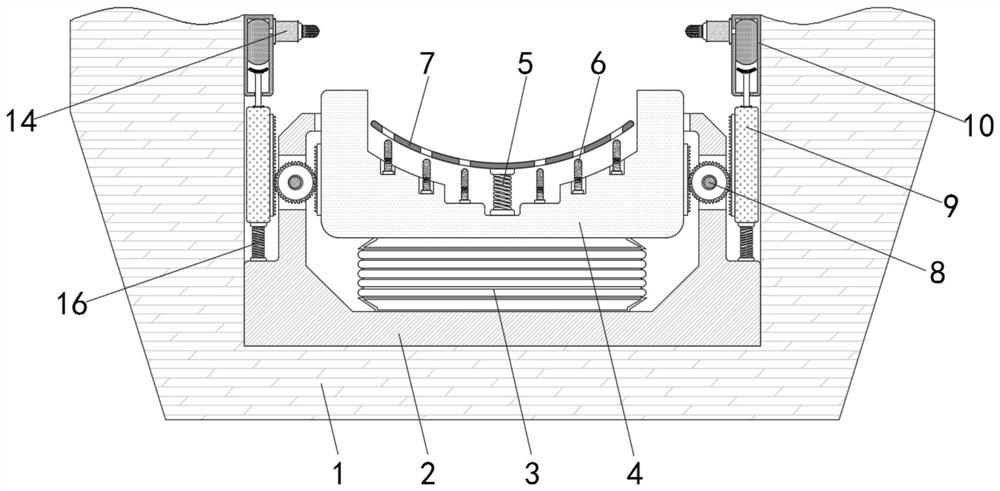

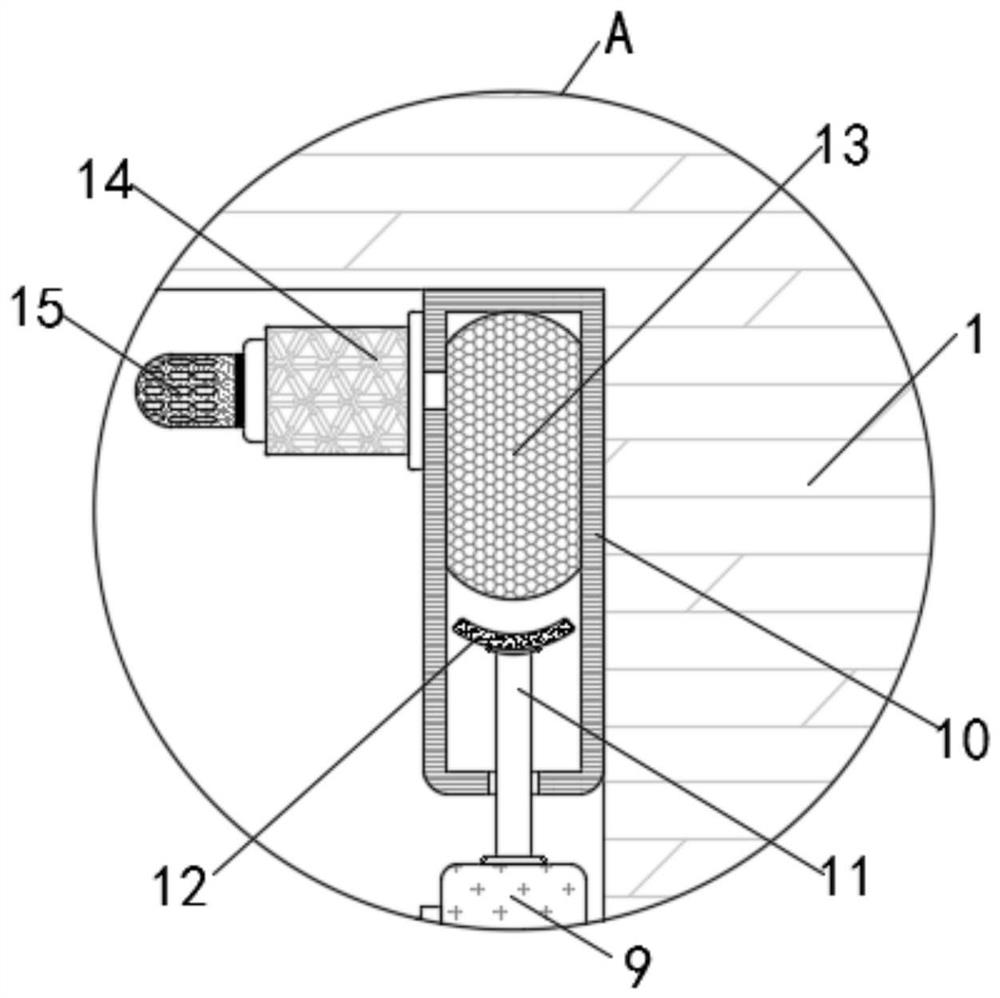

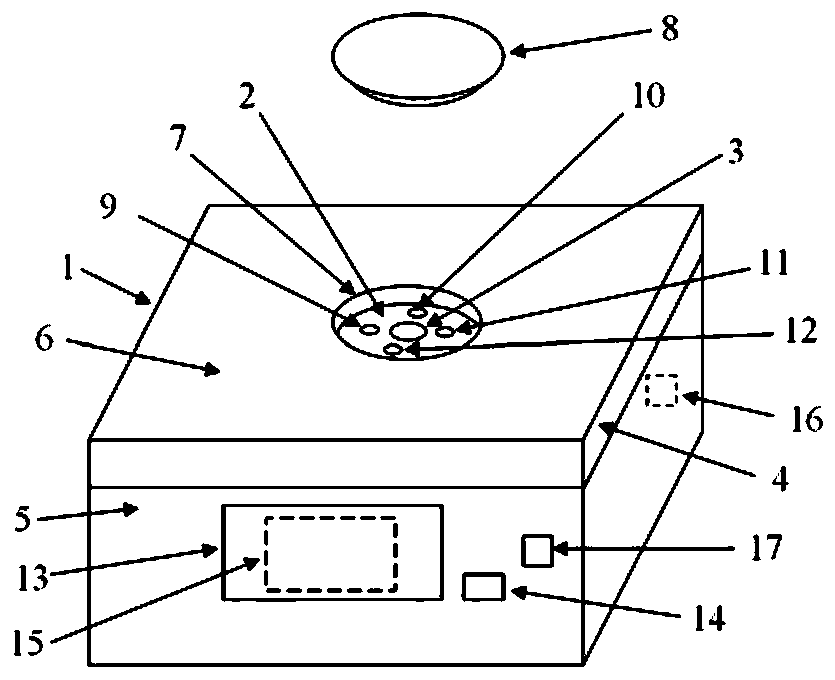

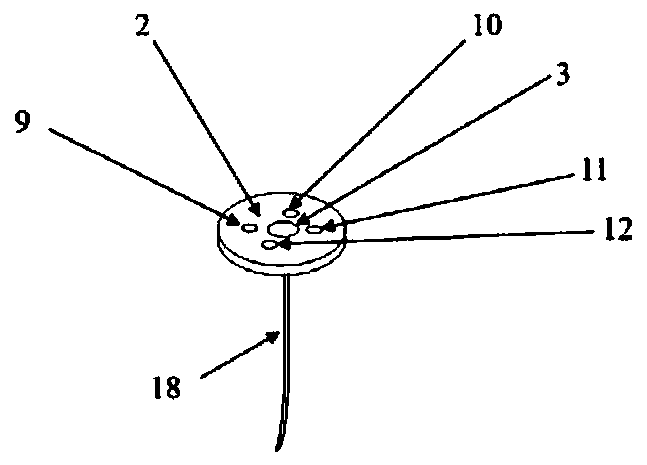

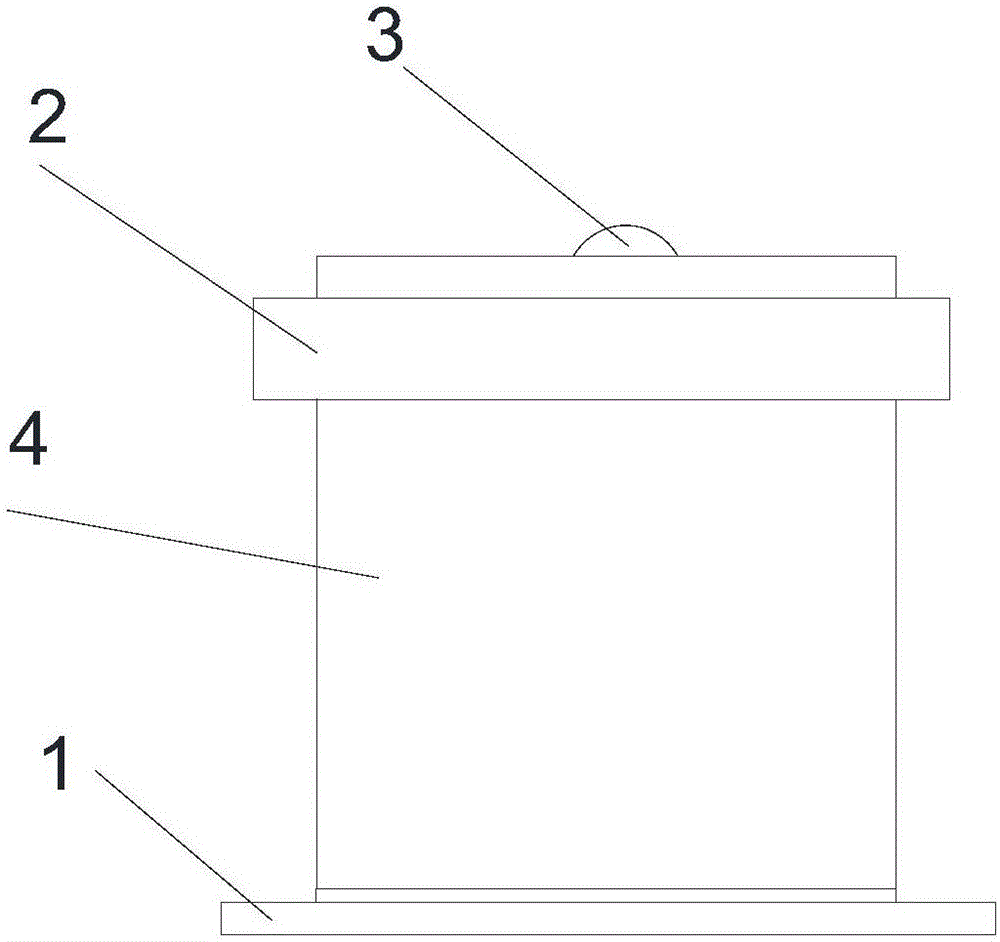

Improved ballistocardiogram signal system

PendingCN108378855AHigh sensitivityAvoid insensitivityDiagnostic recording/measuringSensorsUltrasound attenuationEngineering

The invention provides an improved ballistocardiogram signal system. The system comprises a ballistocardiogram signal acquisition and conduction device and an extremely low-frequency micro-vibration signal sensor, wherein the ballistocardiogram signal acquisition and conduction device comprises a vibration acquisition panel, a conduction sheet, a supporting piece and a bottom plate; except for thecontact part of the supporting piece, the other part of the acquisition panel and the bottom plate maintain suspended; the conduction sheet and the extremely low-frequency micro-vibration signal sensor form one supporting point between the vibration acquisition panel and the bottom plate; and the vibration acquisition panel and the local area of the bottom plate are fastened through the supporting piece, so that during signal acquisition, the vibration acquisition panel and the bottom plate are not loosened or displaced. The sensitivity of the ballistocardiogram signal system is greatly improved, and the conditions of signal distortion, attenuation or unstable operation are avoided.

Owner:DEQING DEYI COMP CO LTD

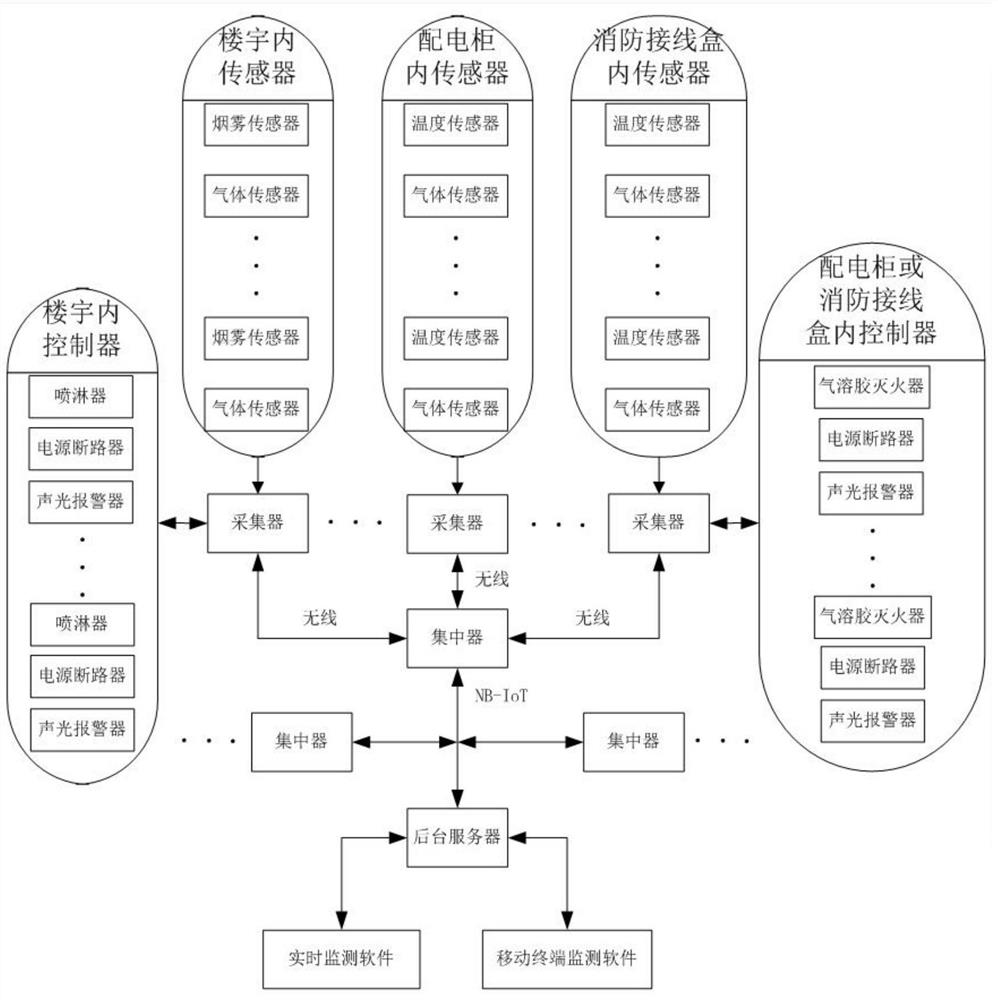

Data model establishing device and method for fire fighting equipment

The invention discloses a data model establishing device and method for fire fighting equipment. The data model establishing device for the fire fighting equipment comprises a collecting module, a control module, a network transmission module, a fire fighting module, an alarm module, and a fire fighting monitoring control system. The collecting module is provided with a plurality of sensors monitoring environment information. The sensors are installed in a building and / or a power distribution cabinet and / or a fire fighting junction box; the control module is provided with a collector, a concentrator and a controller; and the controller is in control connection with an aerosol fire extinguisher, a sprayer and a power circuit breaker which are arranged in the fire fighting module, and the fire fighting monitoring control system is provided with a background server, real-time monitoring software and mobile terminal monitoring software. According to the data model establishing device for the fire fighting equipment, all-around intelligent fire fighting joint control, real-time monitoring, intelligent control and timely alarm of a residential area or an office area are realized, comprehensive monitoring of buildings is realized through coverage of the sensors, electric fire is extinguished at the source through installation of the aerosol fire extinguisher, and personal safety and property safety are protected.

Owner:STATE GRID GANSU ELECTRIC POWER CORP

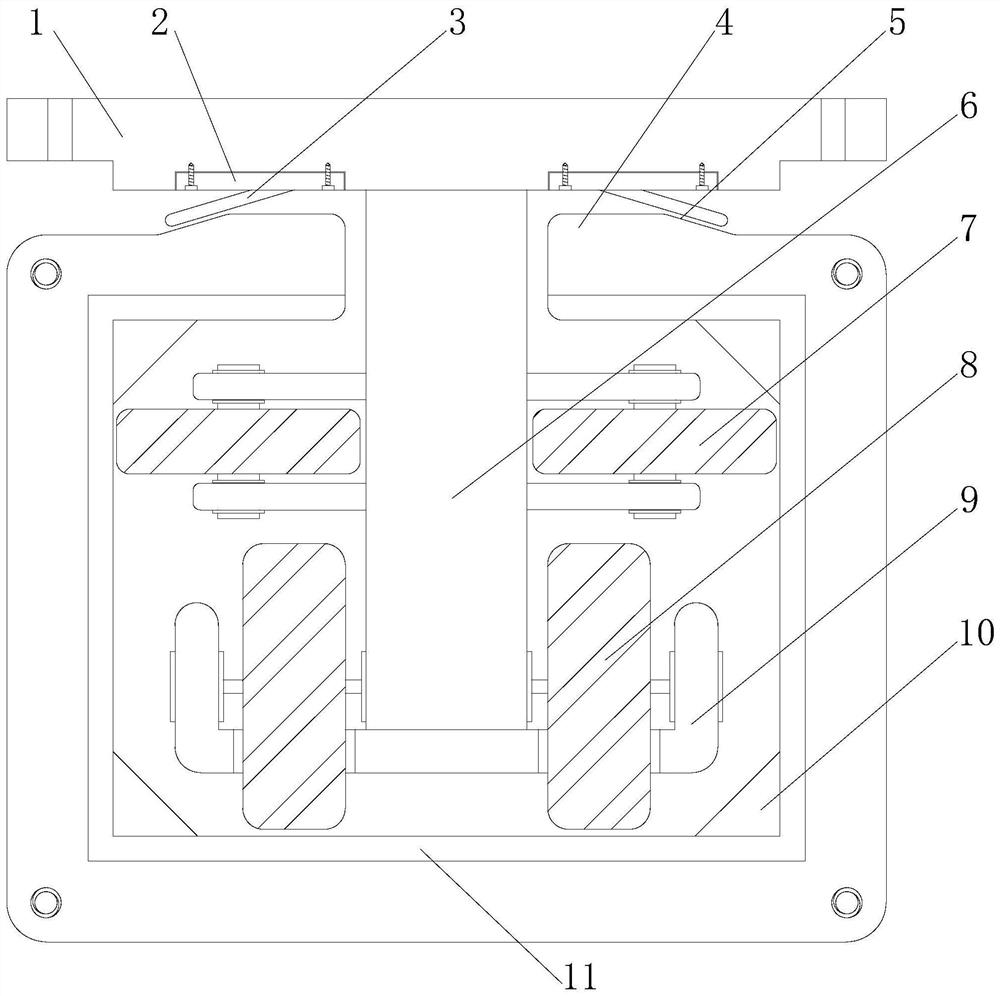

Jack auxiliary device for preventing poor contact for computer memory bank

InactiveCN113422245AEffectively fixedImprove the quality of useCouplings bases/casesCleaning using gasesMemory bankStructural engineering

The invention provides a jack auxiliary device for preventing poor contact for a computer memory bank. The device comprises a main body, a fixed base is fixedly mounted at the bottom of the inner wall of the main body, a mounting air cushion is fixedly mounted at the bottom of the inner side wall of the fixed base, and a movable part is fixedly mounted at the top of the mounting air cushion. And a mounting spring and sensing rods are mounted in the movable part, and the sensing rods are arranged on the left side and the right side of the mounting spring. According to the jack auxiliary device for preventing poor contact of the computer memory bank, an electric signal is triggered when the shaft end where the memory bank is inserted is in contact with an induction sheet on a movable part, so that a driving mechanism generates kinetic energy, and a fixed clamping plate is pushed to be in contact with the memory bank by utilizing a driving connecting rod, the memory bank is effectively fixed, and the device effectively avoids the loosening phenomenon in the use process, facilitates normal use of people, improves the use quality of users, and is easy to operate, convenient to install, rapid, efficient and safe and reliable to use.

Owner:广州奥祥科技有限公司

A kind of pin structure ultraviolet photodetector and preparation method thereof

ActiveCN106960885BHigh absorption coefficientEnhanced electric fieldFinal product manufactureSemiconductor devicesPhotovoltaic detectorsResponsivity

The invention discloses a PIN structure ultraviolet photoelectric detector. The PIN structure ultraviolet photoelectric detector comprises a sapphire substrate, an AIN nucleation layer, an Alx1Gal-x1N buffer layer, an n-type Alx2Gal-x2N layer, a non-doped i-type ZnO / TiO2 superlattice absorption layer, a p-type Alx3Gal- x3N layer, and a p-type GaN layer. An n-type ohmic electrode is led out from the n-type Alx2Gal-x2N layer, and a p-type ohmic electrode is led out from the p-type GaN layer. In the non-doped i-type ZnO / TiO2 superlattice absorption layer, the repetition period of the superlattice is in a range from 1 to 10. The invention also discloses the preparation method of the PIN structure ultraviolet photoelectric detector. By using the PIN structure ultraviolet photoelectric detector, the responsivity of the detector to weak ultraviolet signals is improved.

Owner:苏州科帕特信息科技有限公司

Cockroach catching and killing device

The invention discloses a cockroach catching and killing device and relates to the technical field of animal catching. The cockroach catching and killing device comprises a box, a first rotary door and a second rotary door. The first rotary door and the second rotary door are arranged at the top of the box. A first support part, a second support part, a third support part, a first electromagnet, a first controller, a second controller and a second electromagnet are arranged in the box at intervals. The first support part, the third support part and the box form a catching chamber together in a surrounding mode. The first electromagnet and the second electromagnet are arranged outside the catching chamber and are connected with the first controller and the second controller correspondingly. According to the cockroach catching and killing device, a cockroach is attracted by a homemade bait at the top end of the cockroach catching and killing device, an inductor induces the position of the cockroach, and thus the rotary doors are controlled to be opened or closed through the electromagnets. The second support part is further provided with a power grid plate, so that the cockroach falling into the cockroach catching and killing device is stunned or killed through striking. A glue layer is arranged on the bottom layer of the cockroach catching and killing device to prevent the cockroach from escaping, and cockroaches can be continuously and effectively caught and killed.

Owner:GUANGXI UNIV

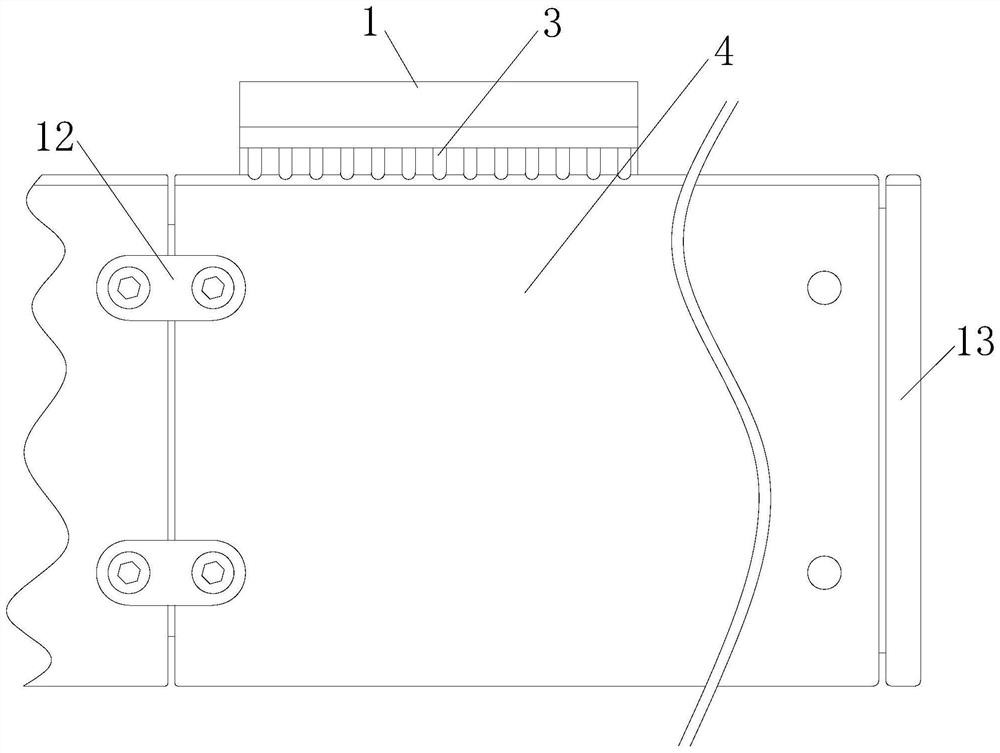

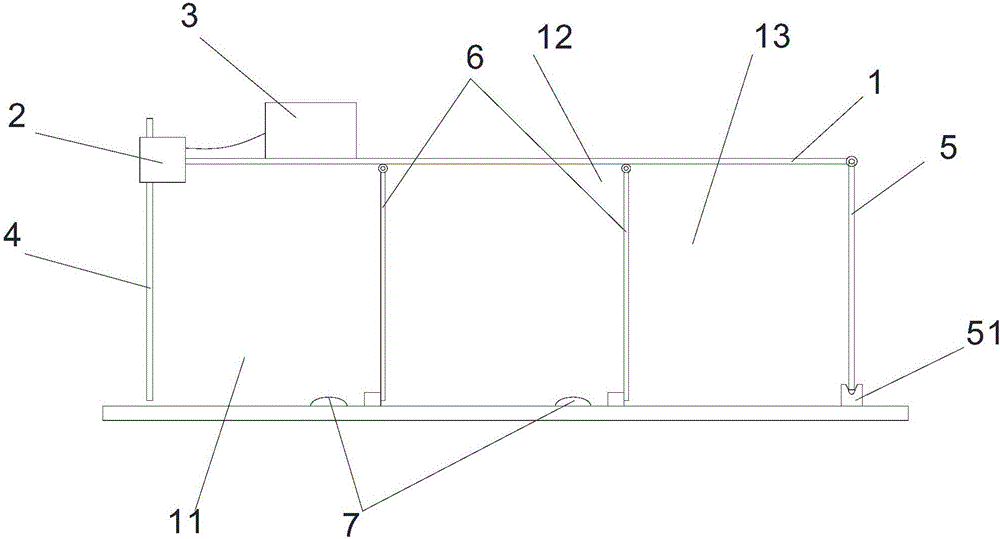

Durable sliding rail convenient to use

PendingCN112998456AUse impactImprove the strength of its own structureCleaning using toolsDrawersBristleControl theory

The invention belongs to the technical field of sliding rails, and particularly relates to a durable sliding rail convenient to use, which comprises a fixed rail, an extension frame is placed in the fixed rail, a mounting frame is fixed at the bottom end of the extension frame through welding, a rotating shaft is arranged on the side surface of the extension frame and the side surface of the mounting frame in a penetrating manner, and the side surface of the rotating shaft is sleeved with a pulley. One side of the pulley penetrates through the side wall of the mounting frame and is in contact with the inner wall of the fixed rail, and an auxiliary roller is erected on the side surface of the extension frame through a bracket; when the sliding rail is used, the auxiliary rolling wheels and the sliding wheels make contact with the inner side surface of the fixed rail, so that the extending frame keeps stable in the fixed rail, the reinforcing ribs improve the structural strength of the fixed rail, and the situation that the fixed rail deforms and influences use of the sliding rail is avoided; bristles of the brush at bottom end of slide rail body contact with the side surface of a chip removal slope, when the sliding rail body slides, chippings on the fixed rail are swept away through bristles of the brush, the situation that the chippings reach the interior of the fixed rail to cause insensitive movement of the sliding rail is avoided, and the service life of the sliding rail is effectively prolonged.

Owner:常州三博金属制品有限公司

Peritoneal dialysis device

PendingCN110393831AAvoid insensitivityFor self-observationPeritoneal dialysisDiseasePeritoneal dialysis catheter

The invention discloses a peritoneal dialysis device, comprising a support position, a detection position, a protective window and control software. The bottom of the detection position is provided with a color sensor, the color sensor at the bottom of the detection position acquires color of waste liquid in a waste liquid container arranged on the support position, the peritoneal dialysis deviceis used to replace a manual color detection of the waste liquid, abnormal color of the waste liquid and continuous gradient of the color are notified to a patient and / or a medical worker through the control software of the peritoneal dialysis device and / or the associated patient-side APP, the peritoneal dialysis device effectively prevents the patient from carelessness, helps the patient get helpat the first time, definitely diagnose and exclude disease, and has a positive clinical significance.

Owner:苏州爱力想电子科技有限公司

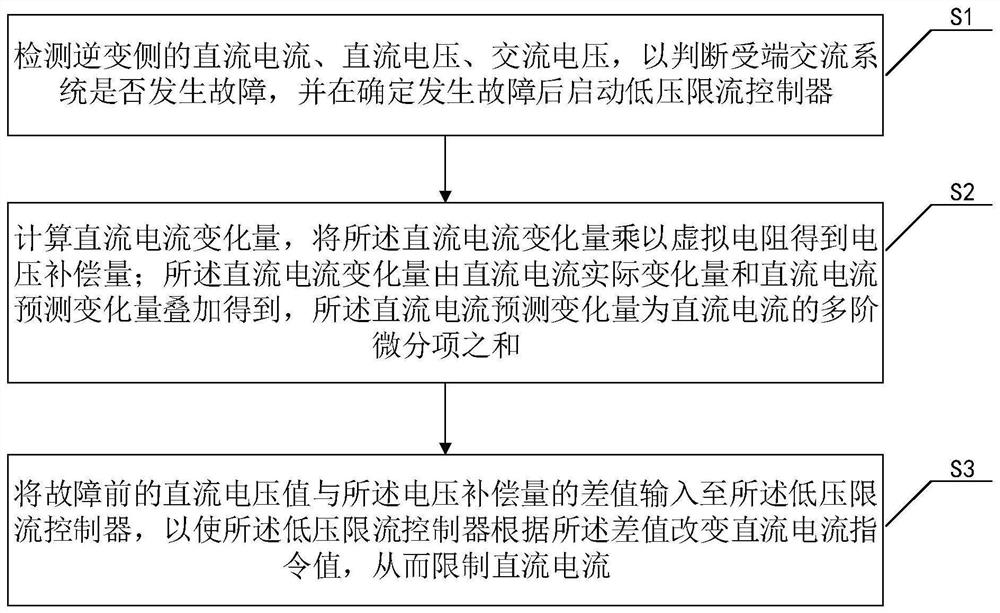

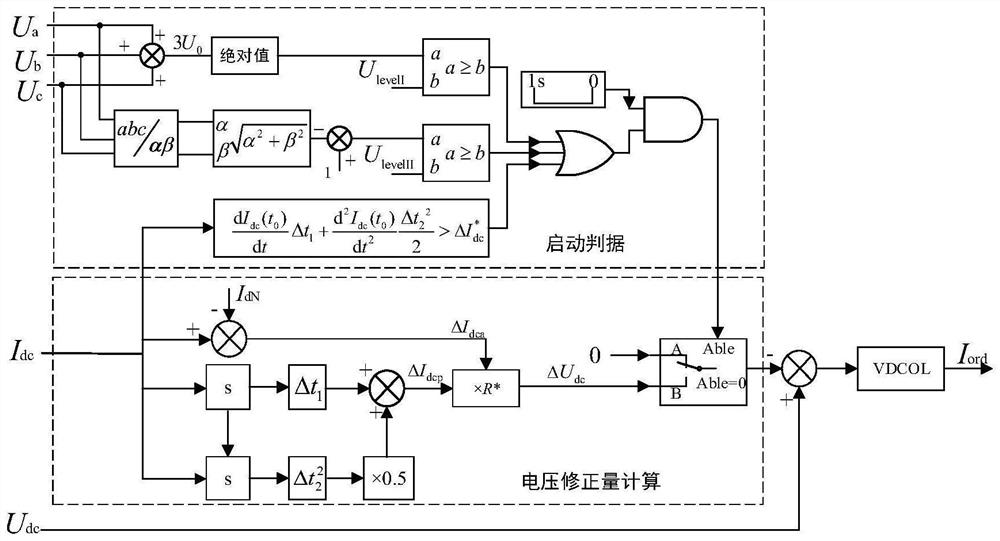

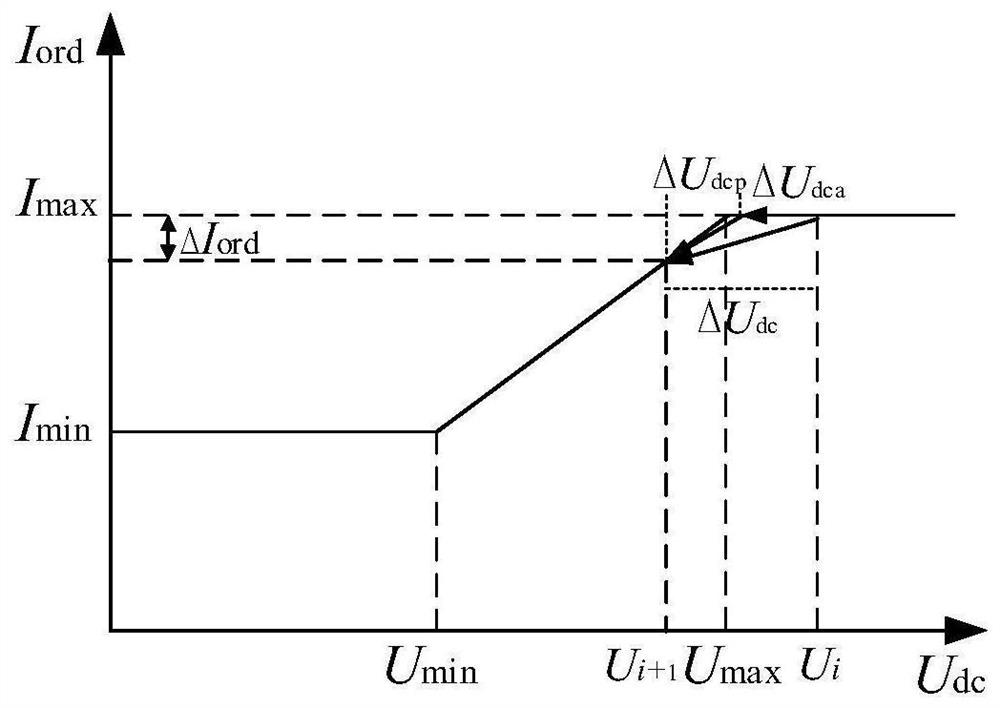

Low-voltage current-limiting control method for suppressing commutation failure

ActiveCN113162102ACushion the shockIncreased sensitivityElectric power transfer ac networkEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceDc current

The invention discloses a low-voltage current-limiting control method for suppressing commutation failure, and belongs to the technical field of high-voltage direct-current transmission. The method comprises the steps: detecting a direct current, a direct-current voltage and an alternating-current voltage of an inverter side, and starting a low-voltage current-limiting controller after determining that a fault occurs; calculating a direct current variable quantity, and multiplying the direct current variable quantity by virtual resistance to obtain a voltage compensation quantity, wherein the direct current variable quantity is obtained by superposing an actual variable quantity and a predicted variable quantity, and the predicted variable quantity is the sum of multi-order differential terms of the direct current; and inputting a difference value between the direct-current voltage value before the fault and the voltage compensation amount to a low-voltage current-limiting controller, so that the low-voltage current-limiting controller changes a direct-current instruction value according to the difference value so as to limit the direct current. According to the invention, after an alternating current fault occurs, direct current can be reduced in advance and commutation conditions can be improved by combining direct current prediction and the virtual resistance, so that commutation failure is inhibited, current impact during an alternating current system fault is reduced, and system recovery after the fault is promoted.

Owner:HUAZHONG UNIV OF SCI & TECH

Electronic mousetrap

The invention discloses an electronic mousetrap, and relates to the technical field of animal catching. The electronic mousetrap includes a box body and a controller arranged on the box body, a movable first gate and a movable second gate are arranged at the two ends, opposite to each other, of the box body, the first gate is arranged on the controller and can move under the control of the controller, and the bottom surface, corresponding to the second gate, of the box body is provided with a switch used for controlling the opening or closing of the second gate; the inner portion of the box body is divided by two sets of one-way doors into three spaces, namely, the first level trap, the second level trap and the third level trap; the bottom of the box body is provided with a first sensor and a second sensor, the first sensor and the second sensor are arranged on the bottom surface of the first level trap and the bottom surface of the second level trap respectively, and both the first sensor and the second sensor are connected with the controller so as to control the opening or closing of the first gate. The electronic mousetrap can be used for catching mice continuously.

Owner:GUANGXI UNIV

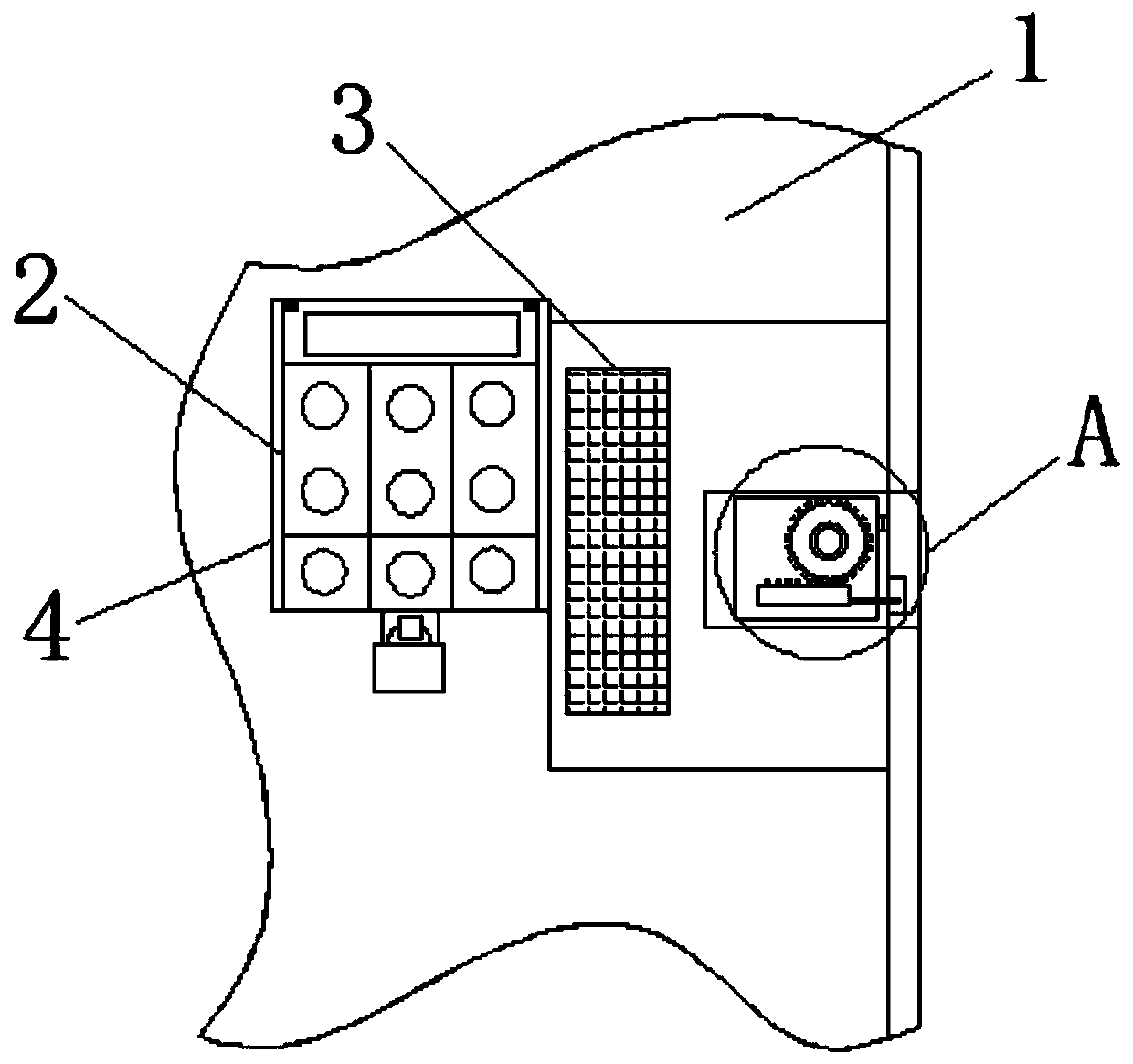

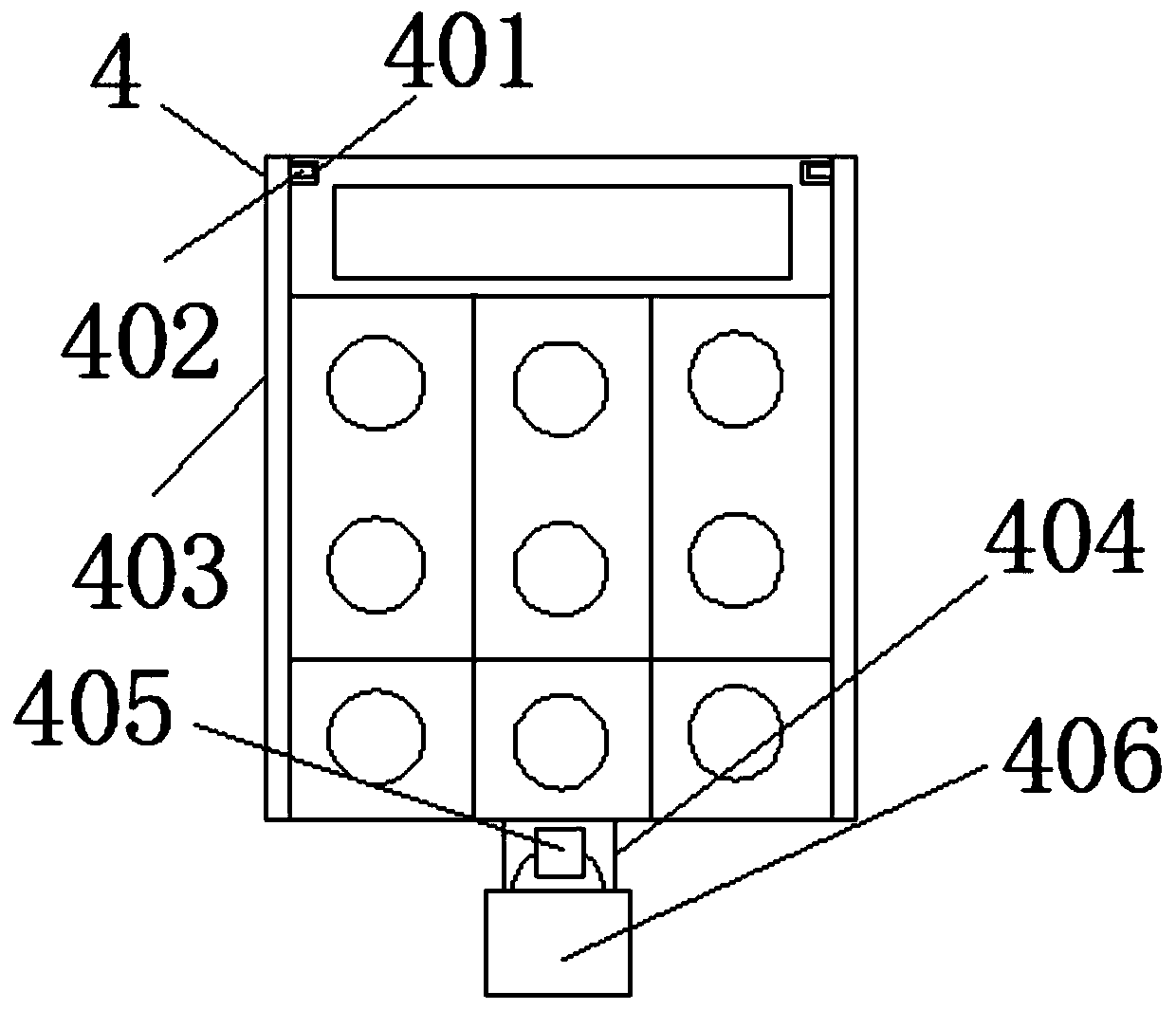

Lock opening and closing remote signaling device for electric meter box

InactiveCN110630116AProtection securityPrevent malicious openingNon-mechanical controlsElectric permutation locksProtection mechanismElectrical and Electronics engineering

The invention discloses a lock opening and closing remote signaling device for an electric meter box. The device comprises the electric meter box, wherein the outer wall of the electric meter box is fixedly connected with a coded lock, the inner side of the electric meter box is connected with a PCB, and the outer side of the coded lock is provided with a protection mechanism. According to the lock opening and closing remote signaling device for the electric meter box, the electric meter box is provided with an box opening and closing detection module, and the number and the time of opening and closing of the electric meter box are recorded in real time; meanwhile, the situation of damaging the electric meter box through abnormal means is alarmed through a magnetic field detection module,and the box opening detection module arranged in the electric meter box detects the opening and closing state of the electric meter box through detecting the state of a door contact arranged in the electric meter box; and when the state of the door contact changed from opening to closing or the box opening detection module judges that a metering box door is opened, a trigger signal is sent to a MCU, and then the MCU can record the corresponding time of box opening and closing on an upper computer through an encoding program according to the received signal and notify a worker through a messagemode.

Owner:FUSHUN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

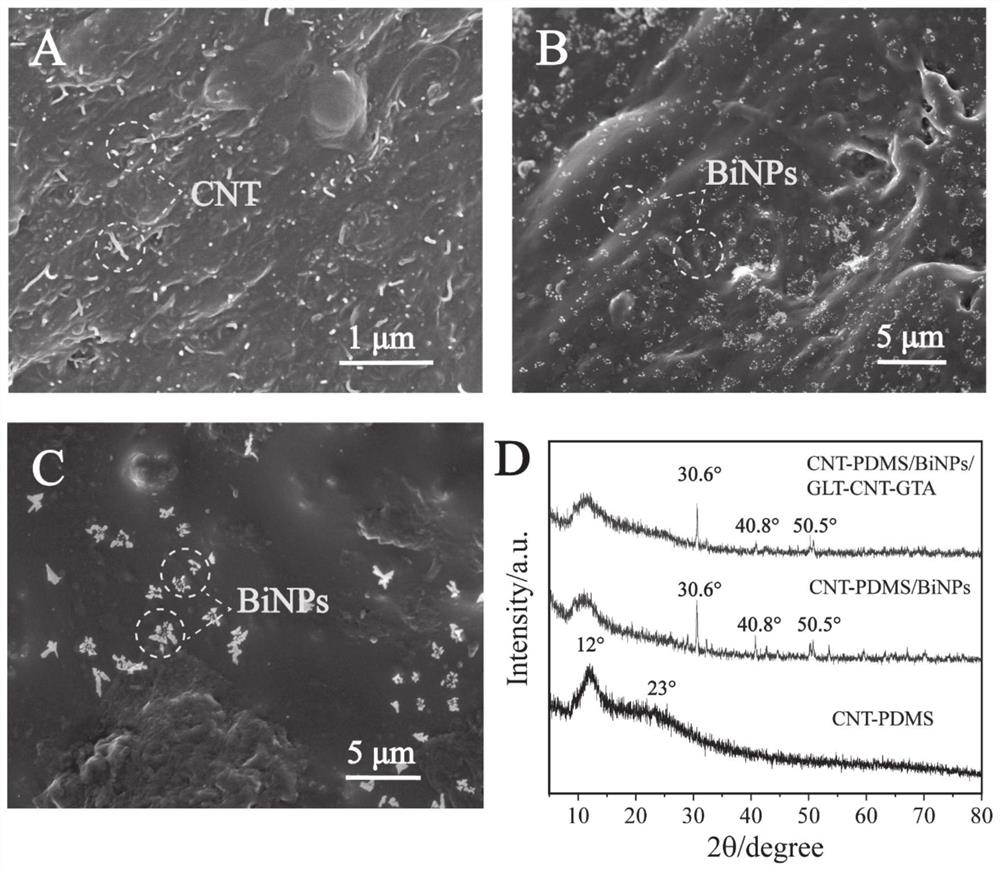

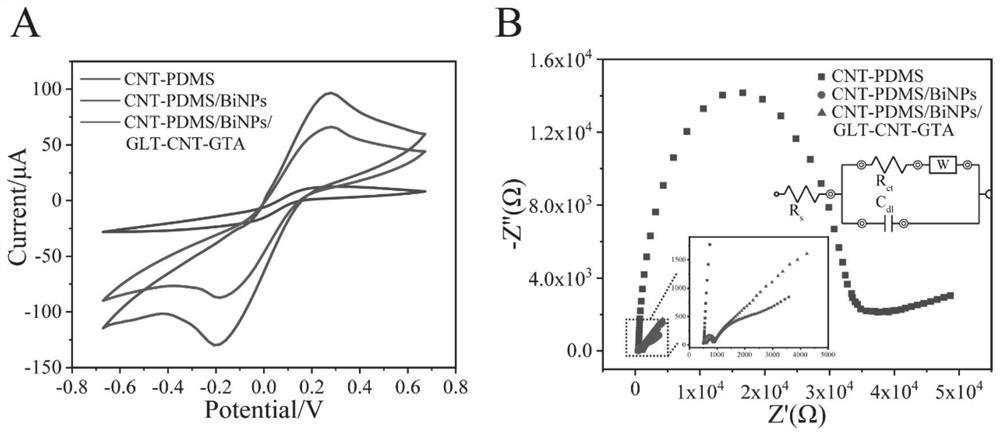

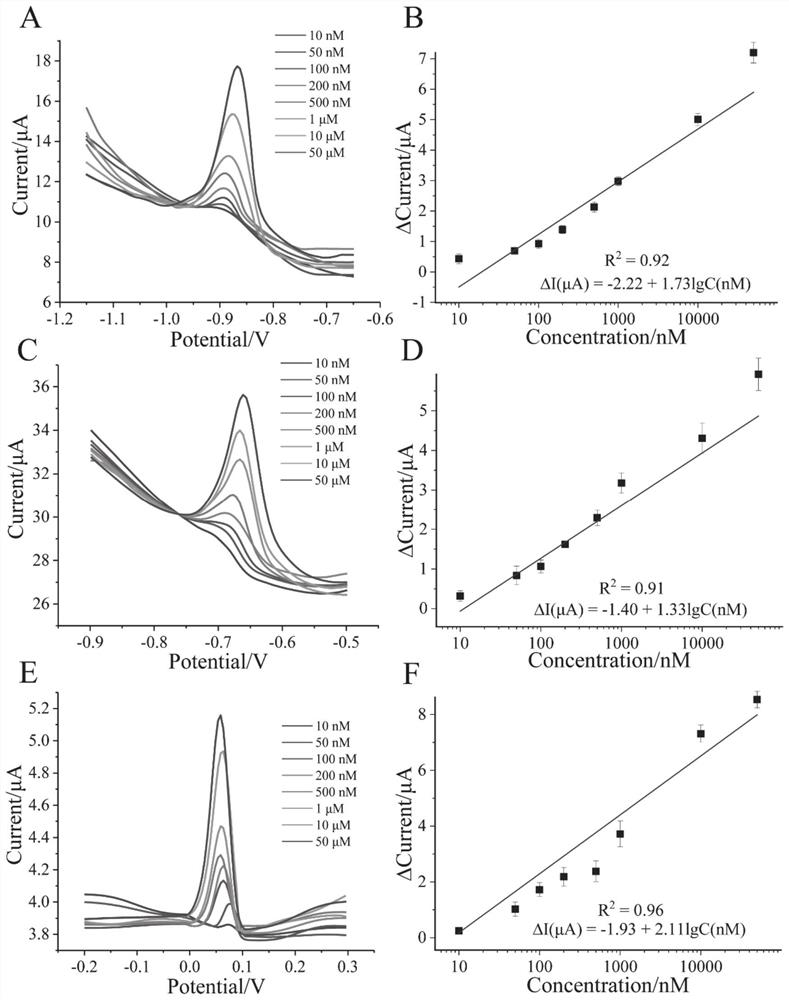

Flexible electrode array and preparation method and application thereof

ActiveCN113533458ALarge specific surface areaFast transferGeneral water supply conservationMaterial electrochemical variablesEngineeringHydrogel film

The invention belongs to the technical field of microfluidic setting, and particularly relates to a flexible electrode array and a preparation method and application thereof, the flexible electrode array comprises a CNT-PDMS substrate, and the surface of a substrate electrode is provided with a bismuth film and a hydrogel film. The electrode array is integrated in a micro-fluidic chip, and Cd < 2 + >, Pb < 2 + > and Hg < 2 + > in human serum can be detected at the same time. Due to the advantages of simple structure, simplicity in operation, practicability, reliability and low cost, the microfluid device has a potential application prospect in detection of human serum.

Owner:QILU UNIV OF TECH

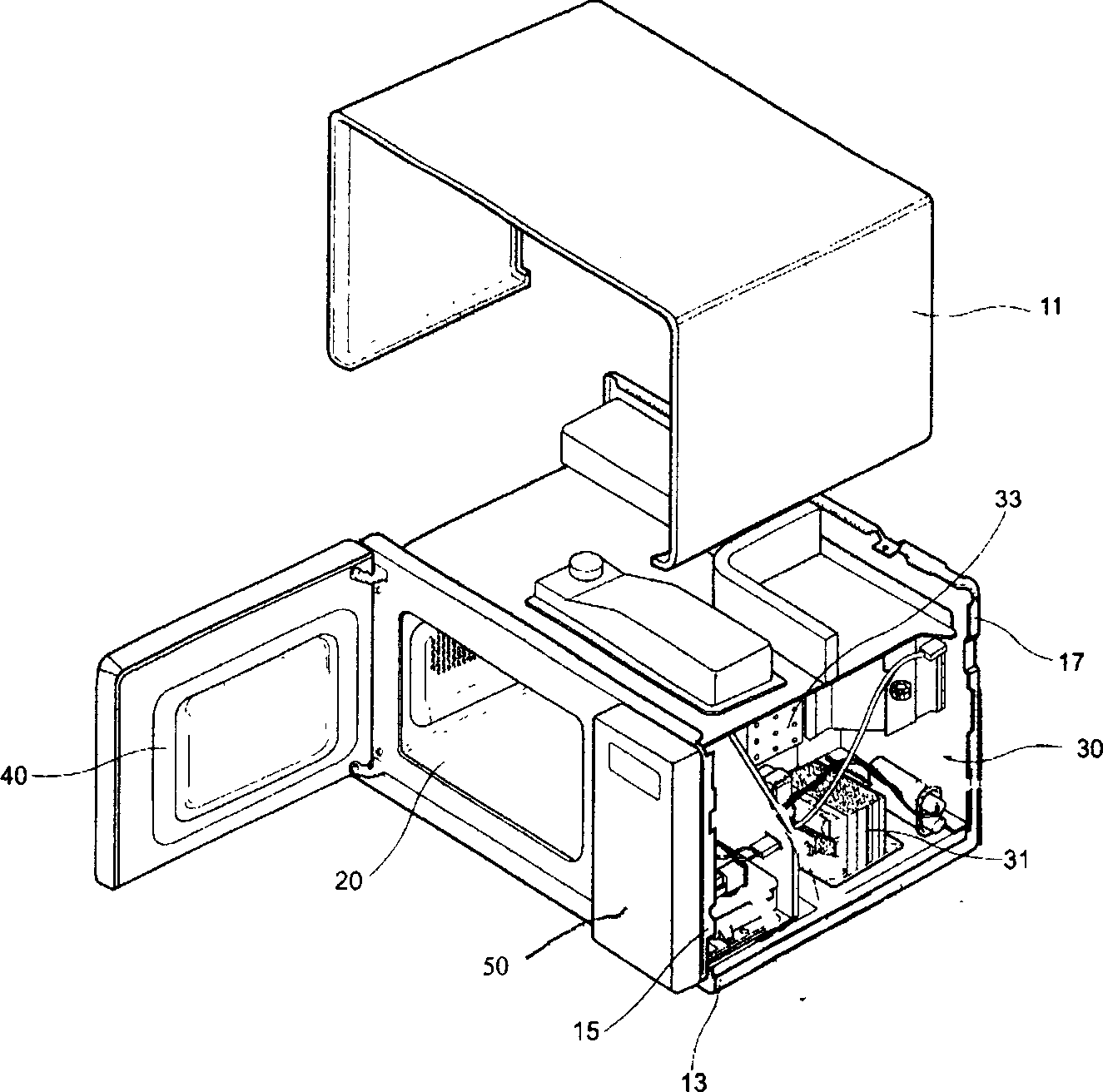

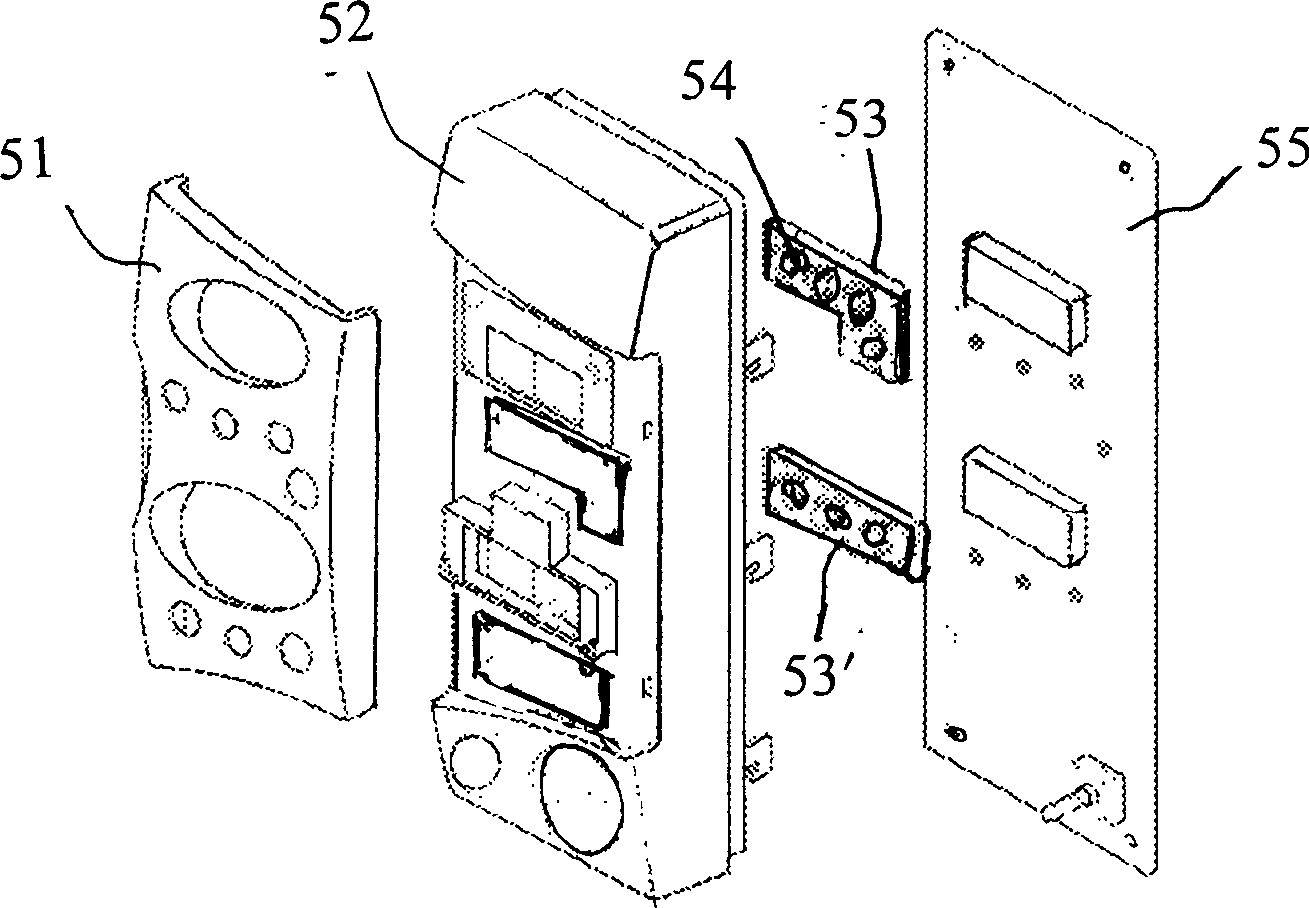

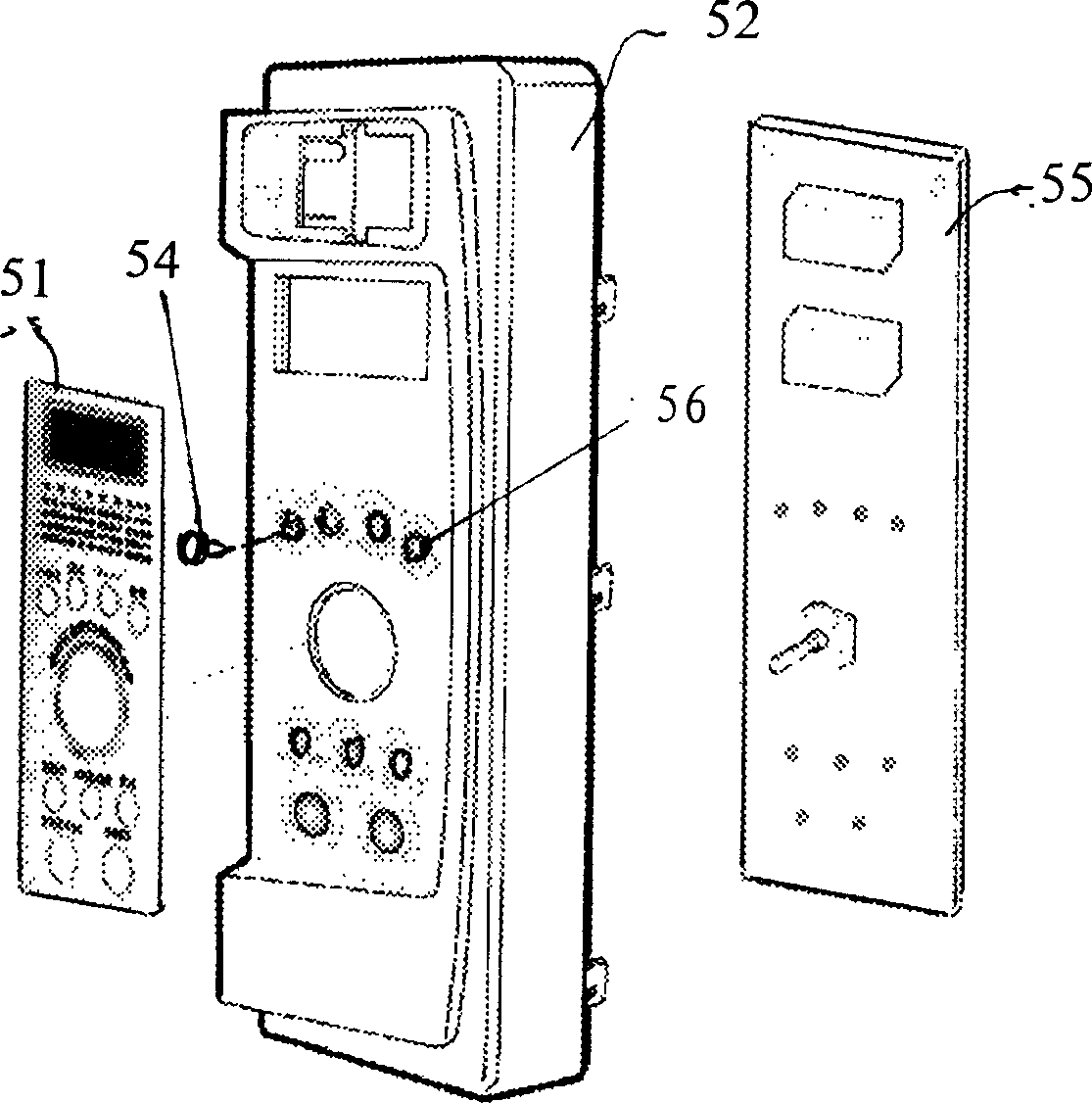

Microwave oven control part mounting structure

InactiveCN1766421AShorten the development cycleReduce manufacturing costsDomestic stoves or rangesLighting and heating apparatusMicrowave ovenEngineering

The invention discloses a microwave oven control part assemblage structure, which comprises the following parts: control board, control front panel, control button and control circuit board, wherein the integral injection molding of control board and control button forms assemblage hole with the control button on the assemblage hole; the control front panel is composed of plastic film with adhesive agent on one side and printed function, which reduces the development period and saves the making cost. The invention avoids the error of mating each part and the phenomenon of insensitive control button.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Quaternary bis-ammonium salt diamine fluoride and preparation method thereof

InactiveCN100376550CHigh reactivityImprove the bactericidal effectBiocideCarbamic acid derivatives preparationChemical reactionCompound (substance)

The present invention discloses fluoric double quaternary ammonium salt diamine in the structure as shown and its preparation process. The fluoric double quaternary ammonium salt diamine has two primary amino radicals with excellent reaction activity in its structure, so that it may be introduced into polymer easily to form polymer with excellent effect of killing Gram negative bacteria. The preparation process adopts facile industrial materials and includes serial simple easy-to-control chemical reactions.

Owner:SICHUAN UNIV

Apparatus for determining and/or monitoring a process variable for a medium

ActiveCN102203570BAvoid insensitivityTesting/calibration apparatusElectronic switchingEngineeringLimit value

An apparatus for determining and / or monitoring at least one process variable of a medium. The apparatus includes: at least one evaluation unit, which monitors and / or signals an exceeding and / or subceeding of a predeterminable limit value of the process variable by the medium; and at least one memory unit, in which limit values of the process variable associated with at least one property of the medium are stored; and wherein the evaluation unit, based on information concerning the property of the medium, applies from the memory unit, for determining and / or monitoring the process variable, a stored limit value associated with the property of the medium.

Owner:EHNDRESS KHAUZER GMBKH KO KG

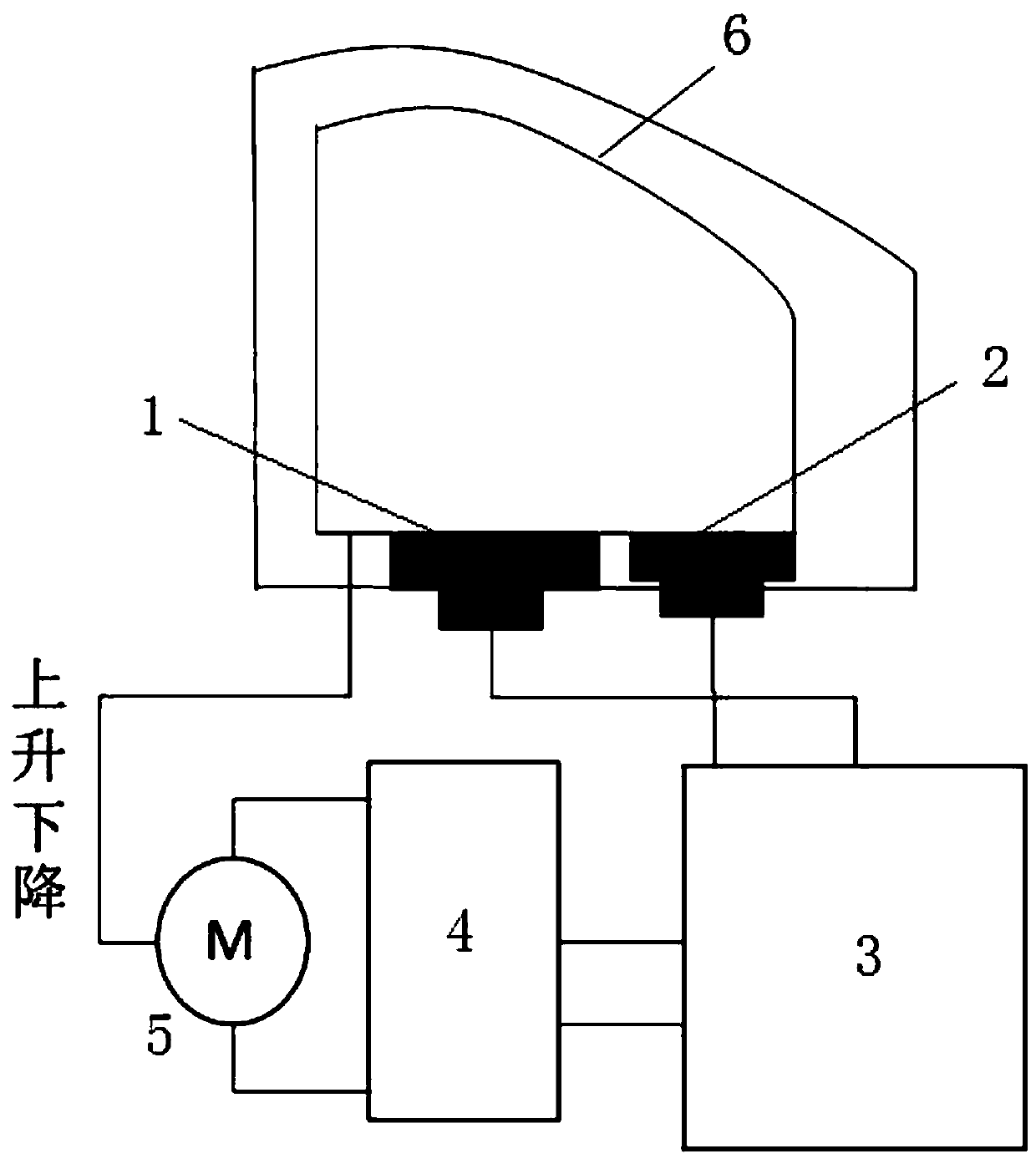

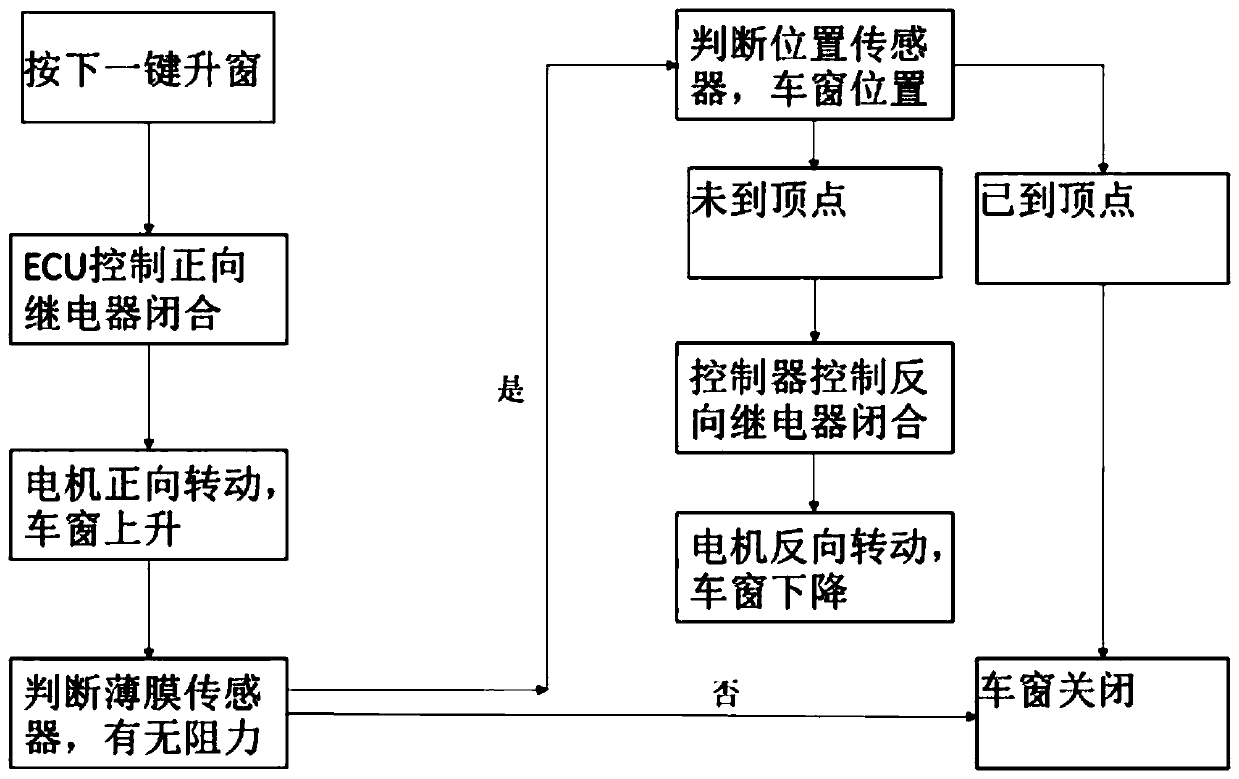

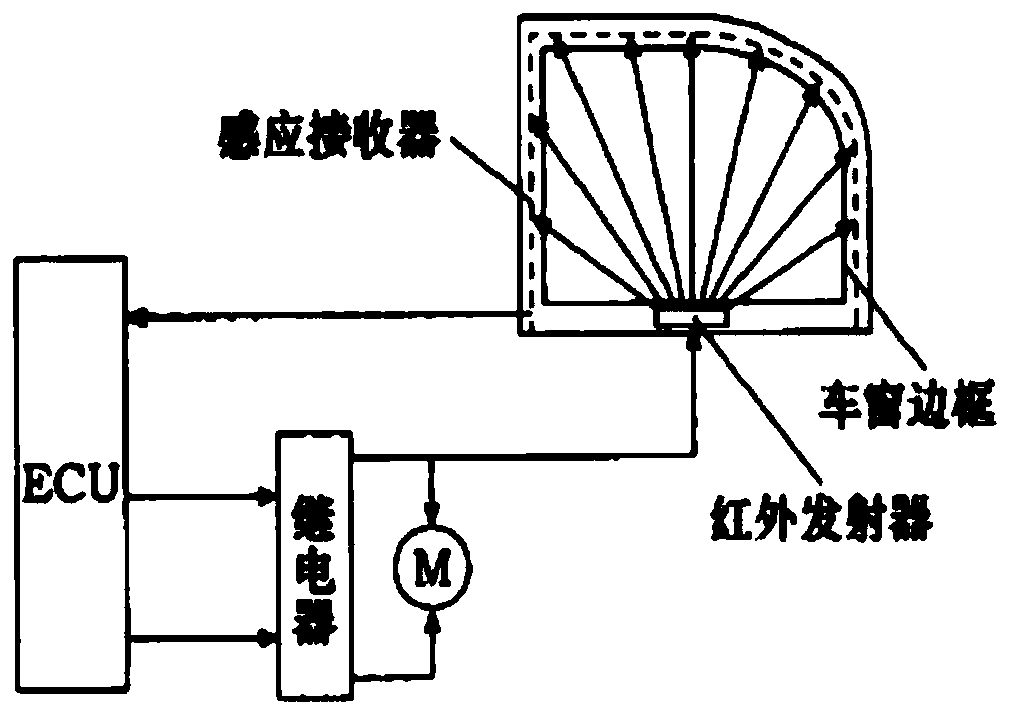

Anti-pinching system for vehicle window and control method of anti-pinching system

The invention relates to an anti-pinching system for a vehicle window. The anti-pinching system for the vehicle window comprises a thin film sensor, an upper-lower layer thin film, a position sensor,a controller, a relay and a two-way driving motor, wherein the upper-lower layer thin film is arranged at the upper end of the glass of the vehicle window; both the thin film sensor and the position sensor are mounted at the lower end of the glass of the vehicle window; the thin film sensor judges whether the external force which prevents the glass of the vehicle window from rising exists or not through the upper-lower layer thin film; output ends of the thin film sensor and the position sensor are respectively connected with an input end of the controller through lines; the controller monitors the states of the thin film sensor and the position sensor in real time; an output end of the controller is connected with an input end of the relay; an output end of the relay is connected with aninput end of the two-way driving motor through a line; an output end of the two-way driving motor is connected with the glass of the vehicle window and drives the glass of the vehicle window to perform ascending or descending motion; according to the anti-pinching system for the vehicle window, unnecessary glass pinching accidents can be reduced; in addition, the defects that the conventional anti-pinching technology is insensitive and the application range is not wide are overcome.

Owner:MAGNA STEYR AUTOMOTIVE TECHNOLOGY (SHANGHAI) LTD

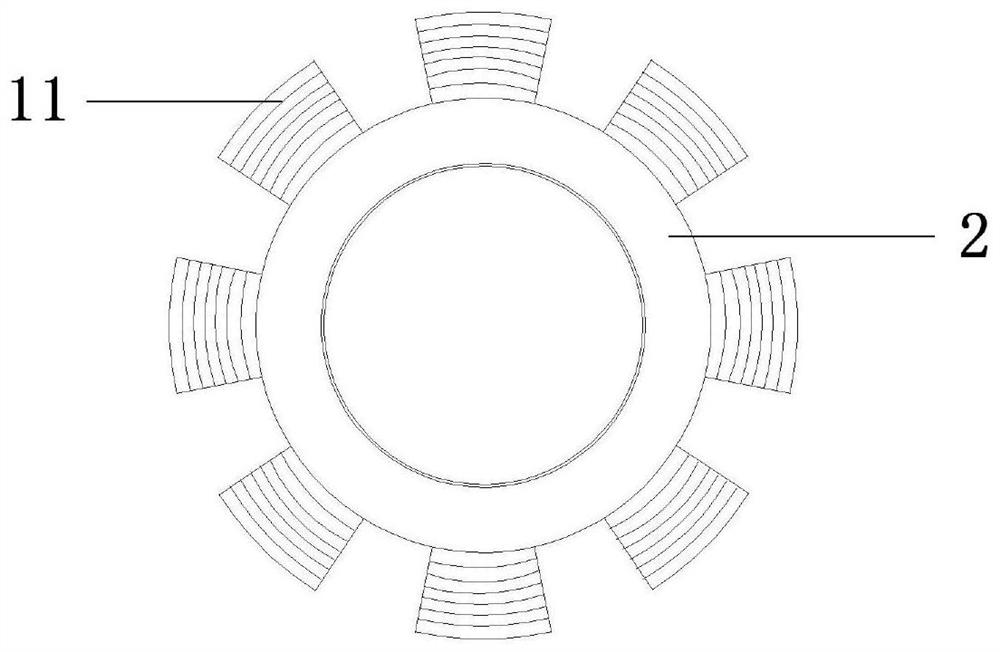

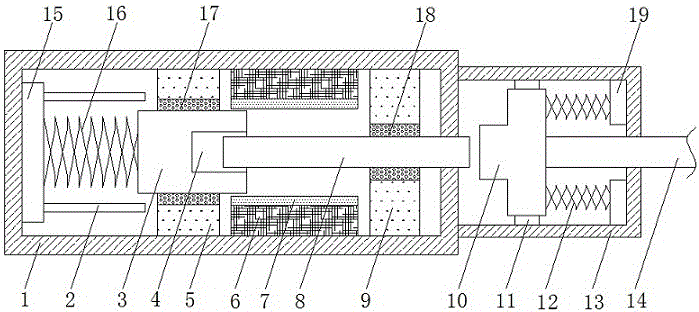

Fuel shut-off electromagnet for diesel engine

InactiveCN106368864AAvoid insensitivityGuaranteed flexibilityMachines/enginesLiquid fuel feedersDiesel enginePlain bearing

The invention discloses a fuel shut-off electromagnet for a diesel engine. The fuel shut-off electromagnet for the diesel engine comprises a shell. The shell is cylindrical. The inner wall of one end of the shell is fixedly connected with a fixing seat. One side face of the fixing seat is fixedly connected with a rest spring and two limiting plates. The reset spring is located between the two limiting plates. The interior of the shell is fixedly connected with a circular-ring-shaped front cover and a circular-ring-shaped rear cover. A first sliding bearing is fixedly connected to the middle of the front cover. A second sliding bearing is fixedly connected to the middle of the rear cover. By the adoption of the fuel shut-off electromagnet for the diesel engine, the phenomena that a fuel shut-off electromagnet is insensitive and stuck are avoided effectively, the safety performance is high, the flexibility is good, the stability of the fuel shut-off electromagnet is guaranteed, flexible movement of a magnetic iron core and a push rod is guaranteed, the occurrence of the failure is avoided effectively, the stability is better, and the service life of the diesel engine is guaranteed effectively.

Owner:JIANGYIN CITY TIANRUN MACHINERY

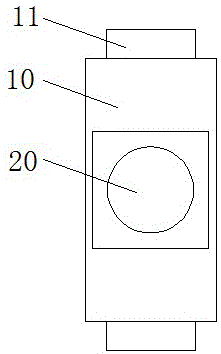

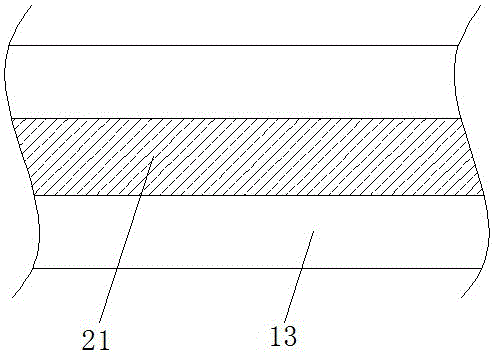

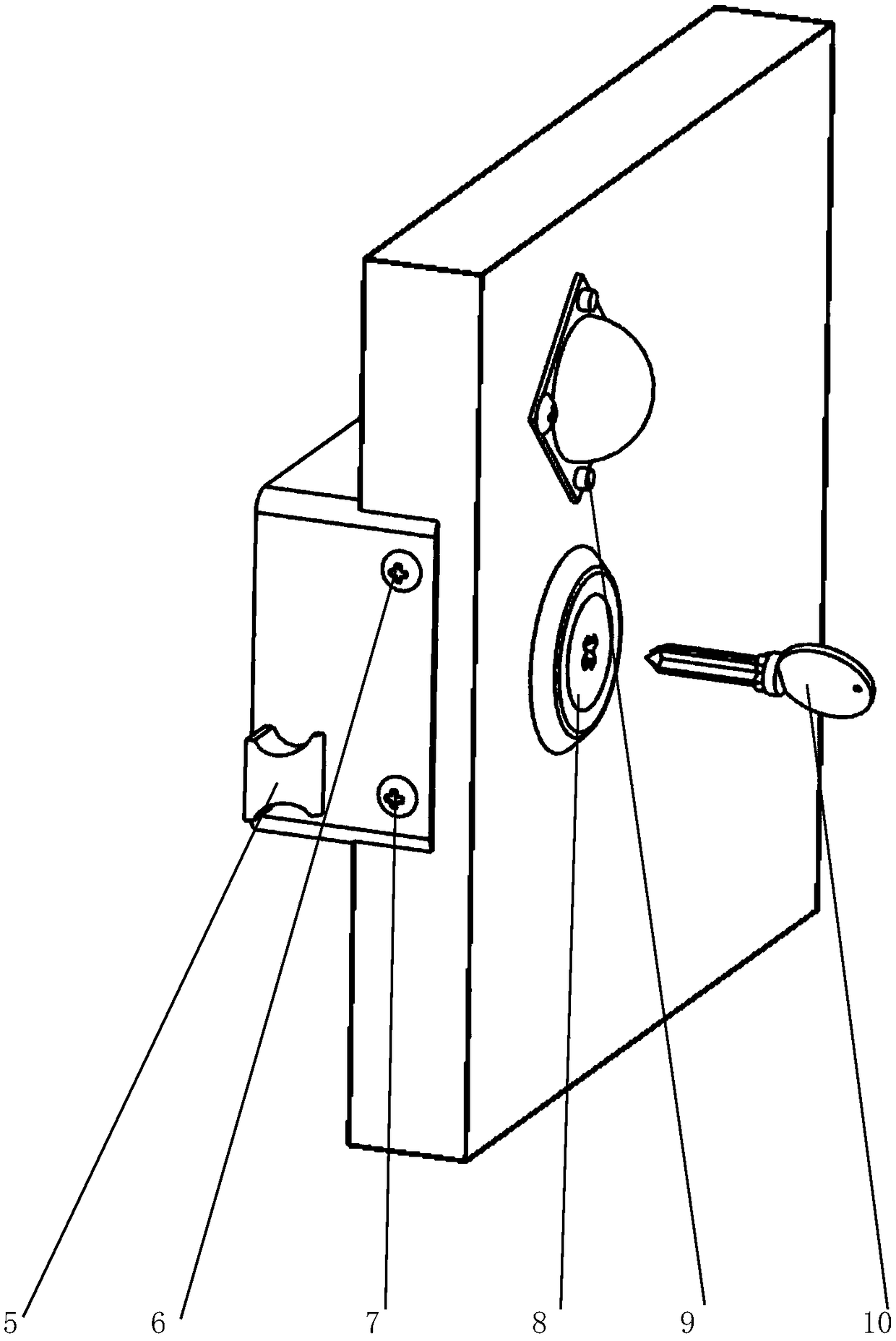

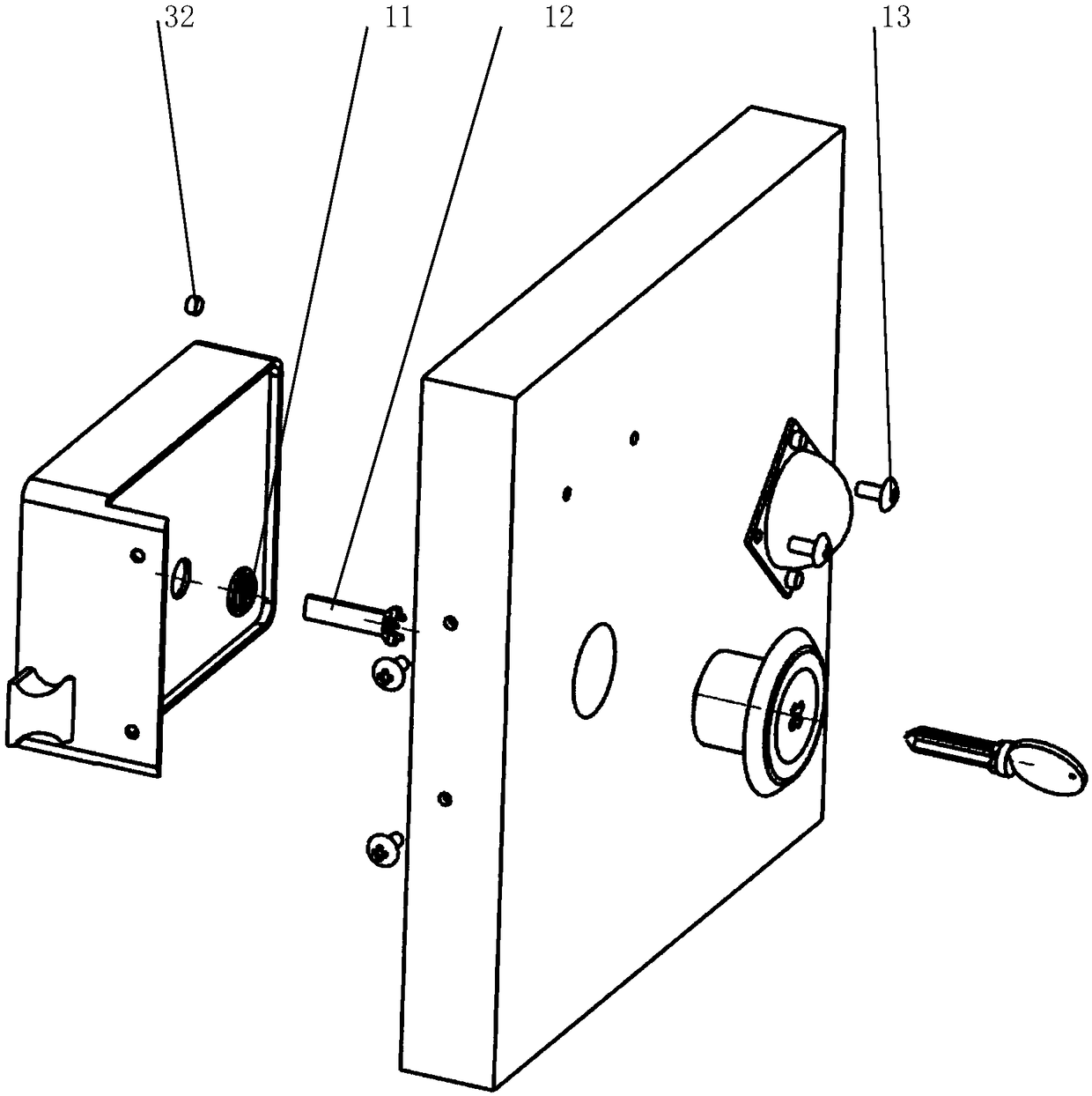

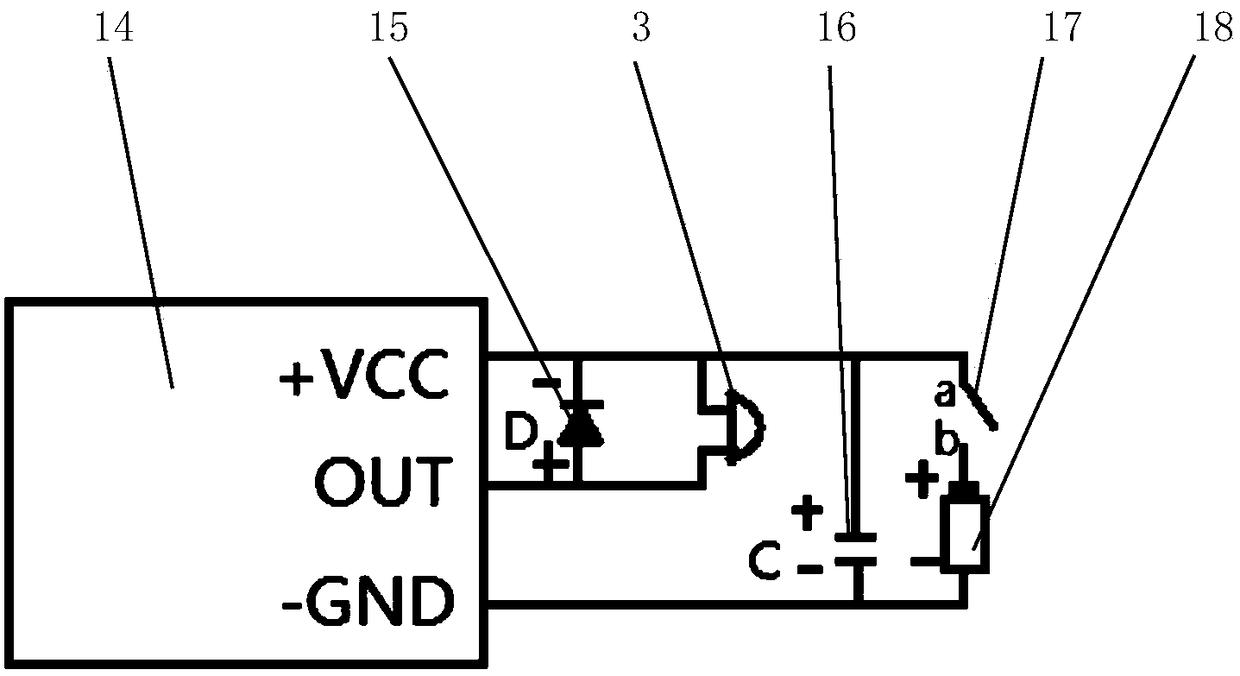

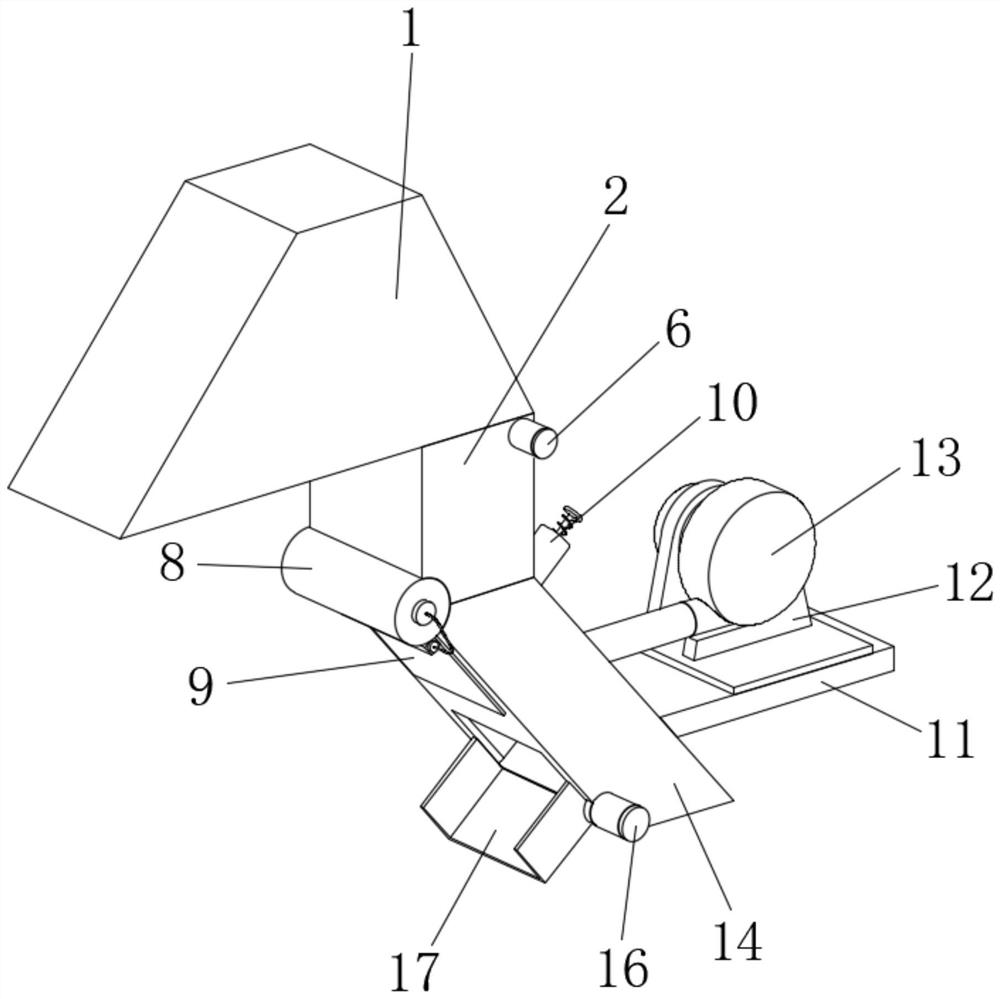

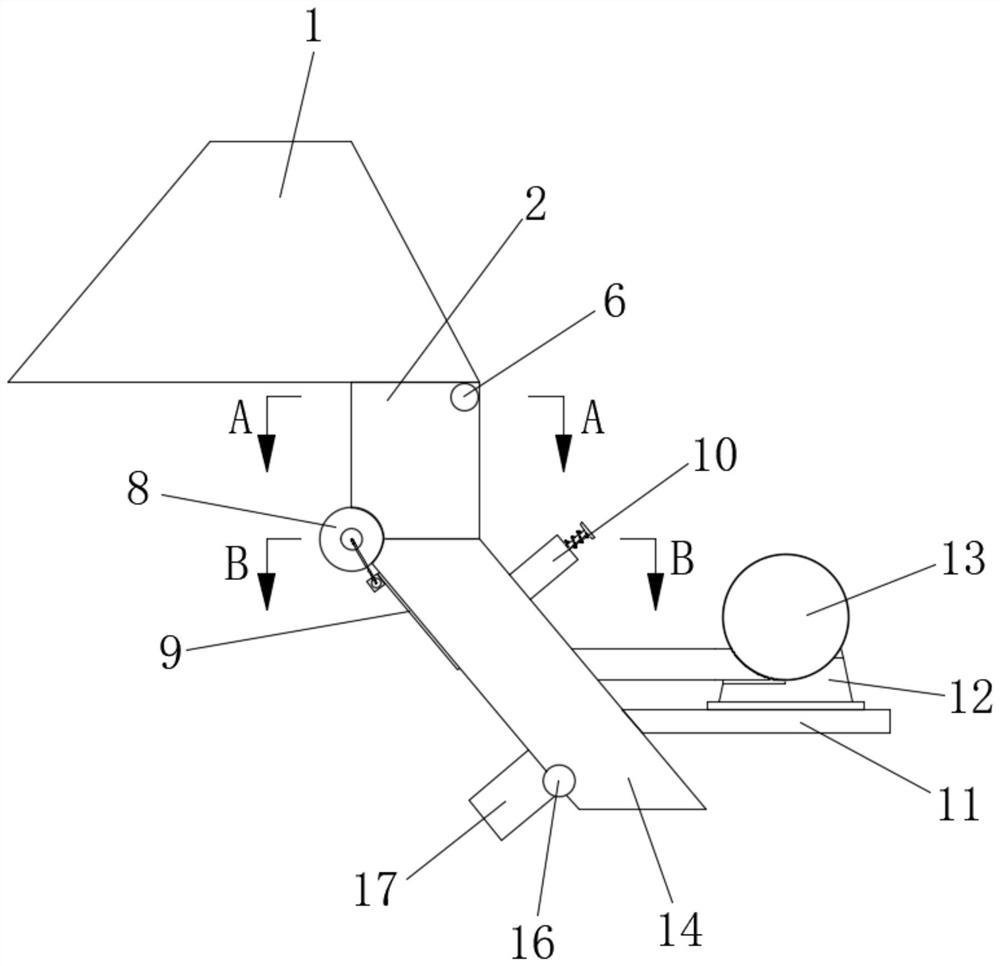

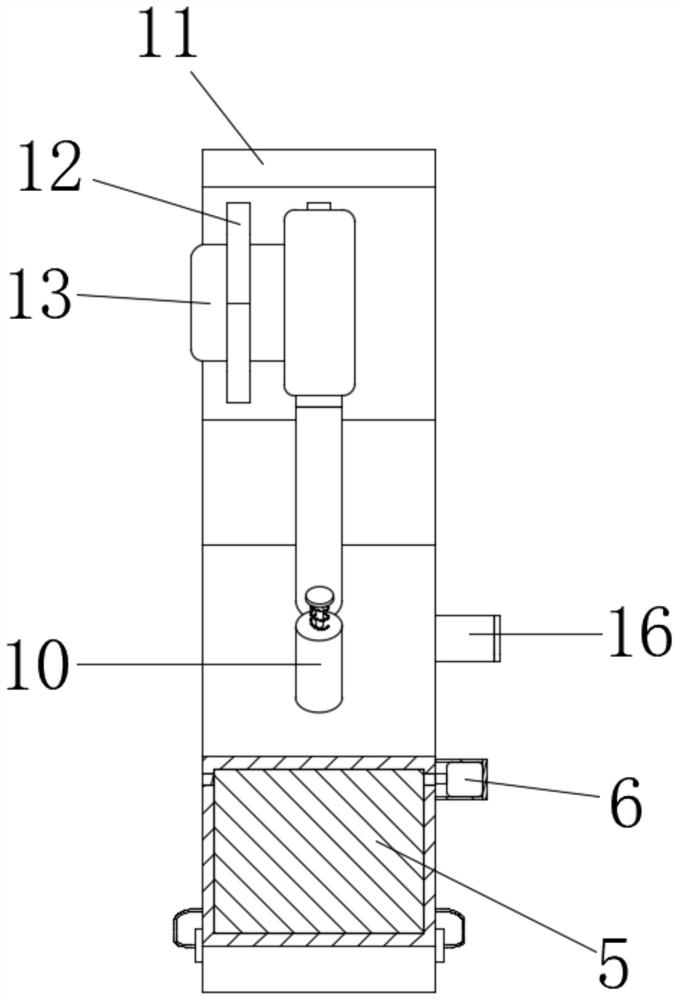

Door lock device with alarming function and illuminating function

InactiveCN108643716ASmall sizeSafe and stable jobElectric circuit arrangementsLighting elementsTime delaysComputer module

The invention provides a door lock device with an alarming function and an illuminating function. The door lock device comprises a door lock, a buzzing device, a mechanical triggering switch device and an illuminating system; the mechanical triggering switch device is installed in a groove of a metal sheet in the door lock, and is connected with a power supply device and buzzers to form a closed loop; when a key is inserted into a lock cylinder to be in contact with a key contact point of the mechanical triggering switch device, a circuit is closed and a time delay module VCC in the power supply device is started, if the key is not pulled out within the set time of the time delay module VCC, the buzzers are started, and then the alarming function is completed; the illuminating system comprises an infrared sensing module, a photosensitive control part in the infrared sensing module determines whether the illuminating system works or not according to whether the light is dim or not, andthe infrared sensing module controls an LED to be lighted when sensing that a human body is located nearby the door lock within a certain range. The door lock device is simple and reasonable in structure, relatively low in cost, safe and reliable, and has good convenience, practicability and economic benefits.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Waste gas treatment device for iron-containing steel scrap smelting

InactiveCN113522521AImprove stabilityAvoid damageMagnetic separationWaste heat treatmentInductorMechanical engineering

The invention relates to the technical field of steel scrap smelting, and discloses a waste gas treatment device for iron-containing steel scrap smelting. The device comprises a collecting hopper, wherein a straight flue channel is fixedly mounted at the bottom of the collecting hopper and close to one side, a partition plate is fixedly mounted at the position of one side of the top of the straight flue channel and located in the collecting hopper, and an inductor is fixedly installed at the position, close to the bottom, of one side of the inner wall of the collecting hopper, the top of the inner cavity of the straight flue channel is movably sleeved with a rotating partition plate. According to the invention, a partition plate is fixedly installed at the position, located in a collecting hopper, of one side of the top of a straight flue channel so as to divide the inner cavity of the collecting hopper into two parts by the partition plate, the tops of the two parts communicate with each other, and when a furnace mouth bin door is opened, internal high-temperature airflow flows into the collecting hopper and cannot be in direct contact with an inductor under the blocking effect of the partition plate, so that the problems that high-temperature gas in the furnace directly makes contact with the inductor, the temperature of the high-temperature gas is too high, the high-temperature gas is opened too early or closed too completely, and induction is not sensitive are solved.

Owner:韩倩

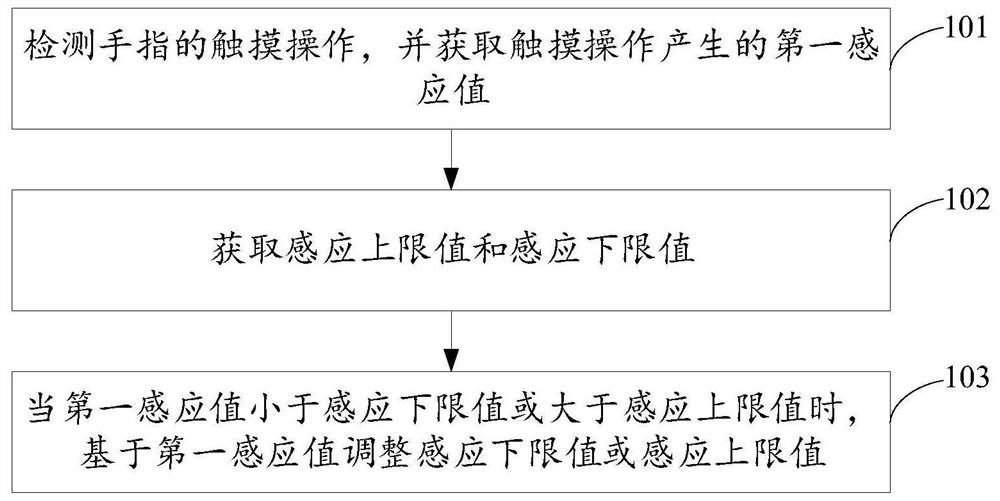

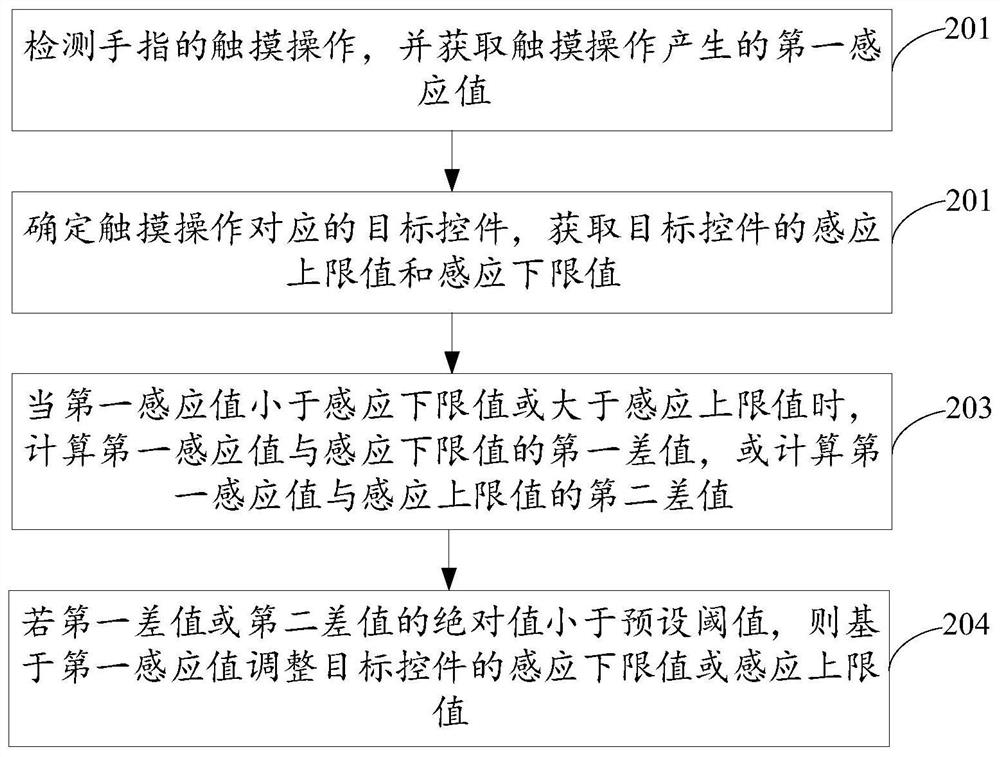

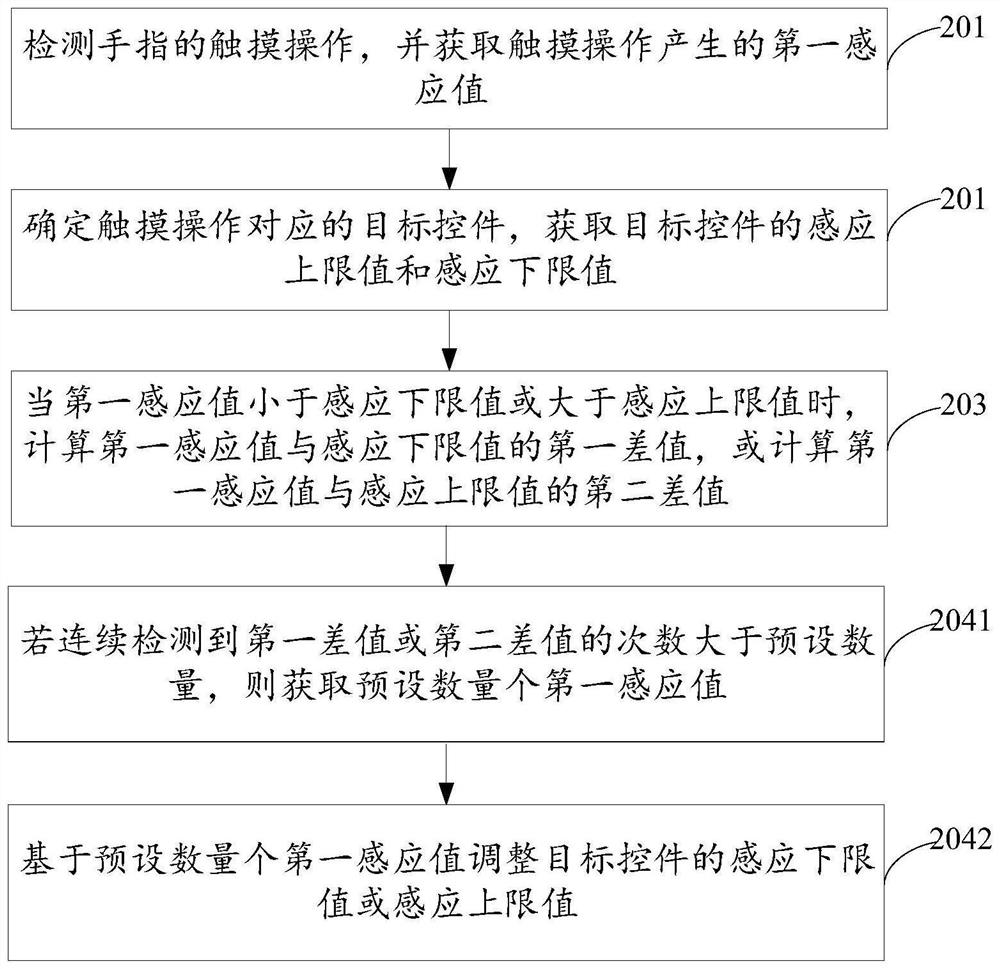

Touch sensitivity adjusting method and device, storage medium and electronic equipment

PendingCN113849080AHigh sensitivityAvoid insensitivityInput/output processes for data processingEngineeringReal-time computing

The invention discloses a touch sensitivity adjusting method and device, a storage medium and electronic equipment, and the method comprises the steps: detecting a touch operation of a finger, and obtaining a first induction value generated by the touch operation; acquiring an induction upper limit value and an induction lower limit value; and when the first sensing value is less than the sensing lower limit value or greater than the sensing upper limit value, adjusting the sensing lower limit value or the sensing upper limit value based on the first sensing value. The first induction value generated by the touch operation is detected, and the induction upper limit value or the induction lower limit value is adjusted by using the first induction value, so that the touch sensitivity can be adaptively adjusted according to the use environment in the use process.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com