Flexible electrode array and preparation method and application thereof

A flexible electrode and array technology, applied in the field of flexible electrode array and its preparation, can solve the problems of poor repeatability, stability, sensitivity and anti-interference, inability to detect multiple heavy metal ions at the same time, increase production costs, etc., to improve sensitivity , Improve the electrochemical performance and promote the effect of transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In one embodiment of the present disclosure, a method for preparing a flexible electrode array includes: including: using chronoamperometry to deposit a bismuth film on the surface of a CNT-PDMS substrate, and then dropping the prepared GLT-CNT-GTA onto the deposited On the CNT-PDMS electrode with bismuth film.

[0034] Further, the preparation method of the CNT-PDMS includes: uniformly dispersing the CNT and PDMS by a dry mixing method, and then performing vacuum treatment; adding PDMS and a curing agent to the CNT-PDMS in a weight ratio of 7-13:0.5-2 In the composite material, mixing and stirring; the cavity mold is prepared by 3D printing technology, and then the mold is fixed on the glass, and the CNT-PDMS composite material is filled into the cavity of the mold.

[0035] Further, the process of depositing bismuth film includes:

[0036] The CNT-PDMS flexible electrode was transferred to the mixed solution of bismuth nitrate and hydrochloric acid, and the CNT-PDMS / ...

Embodiment 1

[0048] A microfluidic electrochemical sensor, the specific preparation method is as follows:

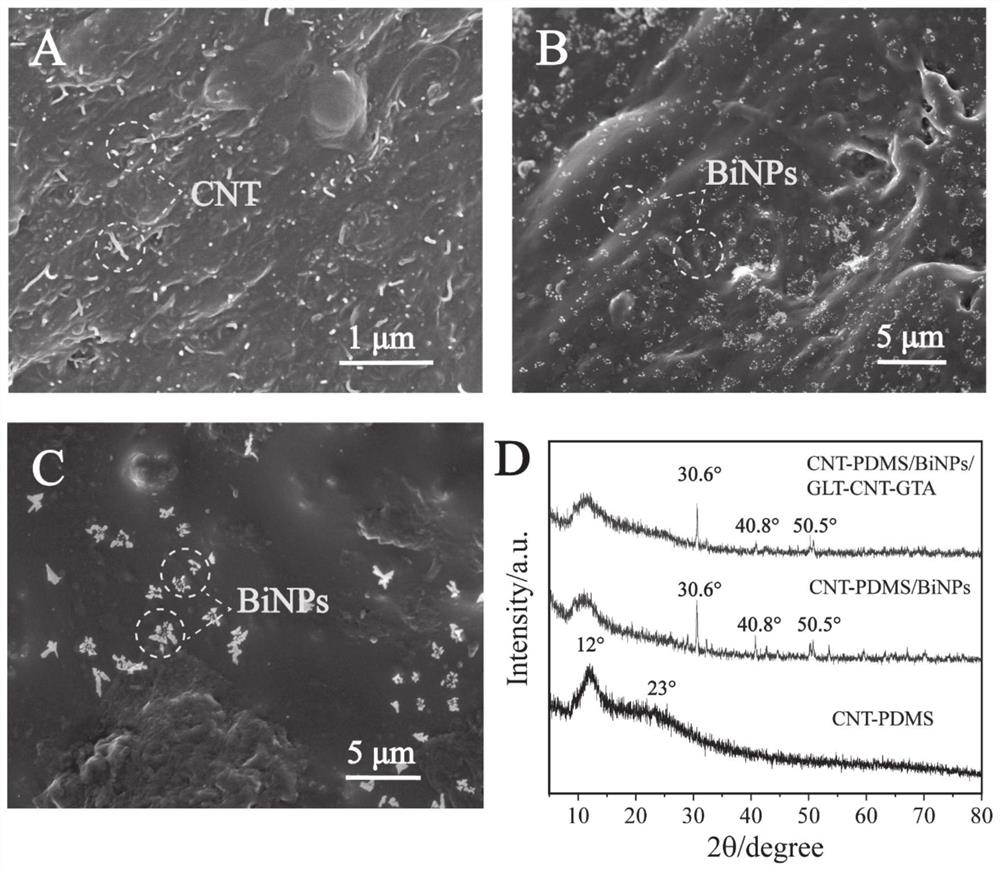

[0049] Firstly, 10 wt.% CNT and PDMS were dispersed by dry mixing at a speed of 150 r / min for 24 hours. The CNT-PDMS composite was vacuum-treated in a vacuum pressure chamber (>40Pa) for 30 min. Subsequently, PDMS and curing agent were added to the CNT-PDMS composite material at a weight ratio of 10:1, and mixed and stirred for 2 min to prepare for use. In order to obtain CNT-PDMS electrodes with the same radius of 1.5 mm and the same thickness of 500 μm, 3D printing was used to manufacture cavity molds. Fix the mold to the glass, and then fill the above-mentioned CNT-PDMS composite into the cavity of the mold. Before the CNT-PDMS is cured, carbon fibers are inserted as wires, which will be used to connect the electrochemical workstation during the measurement. Finally, use an oven to cure the mixed CNT-PDMS composite at 70 °C for 1 hour to obtain a CNT-PDMS electrode; transfer th...

experiment example 1

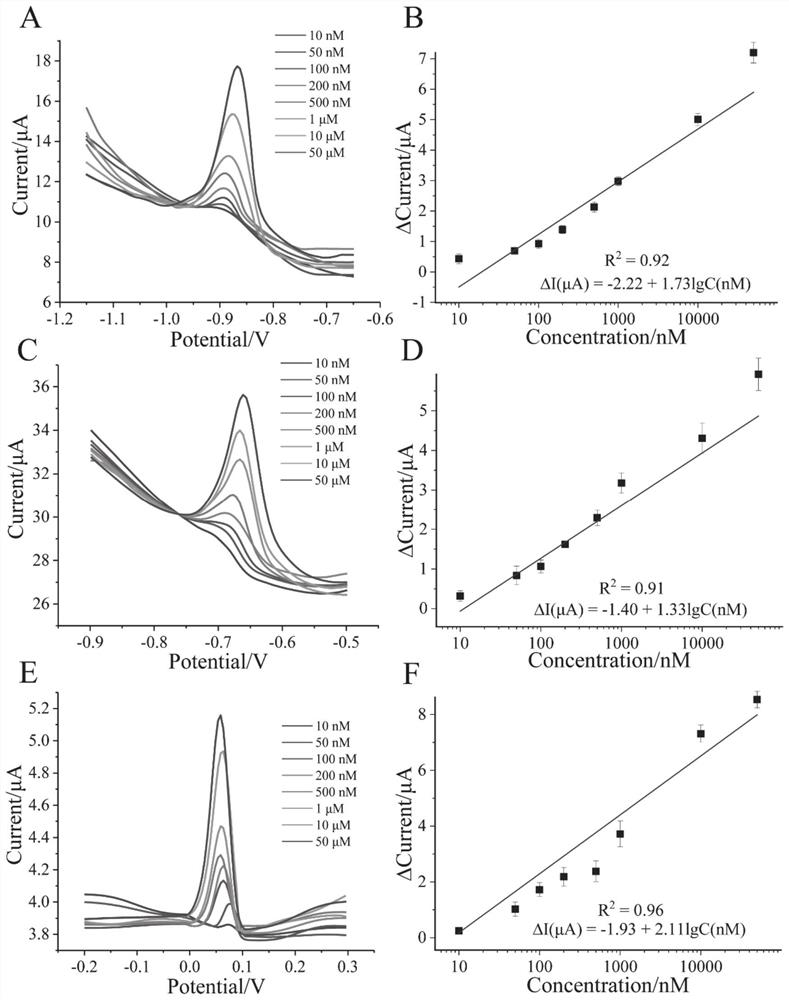

[0053] Based on embodiment 1, the electrochemical behavior test is carried out, and the specific measurement conditions are as follows:

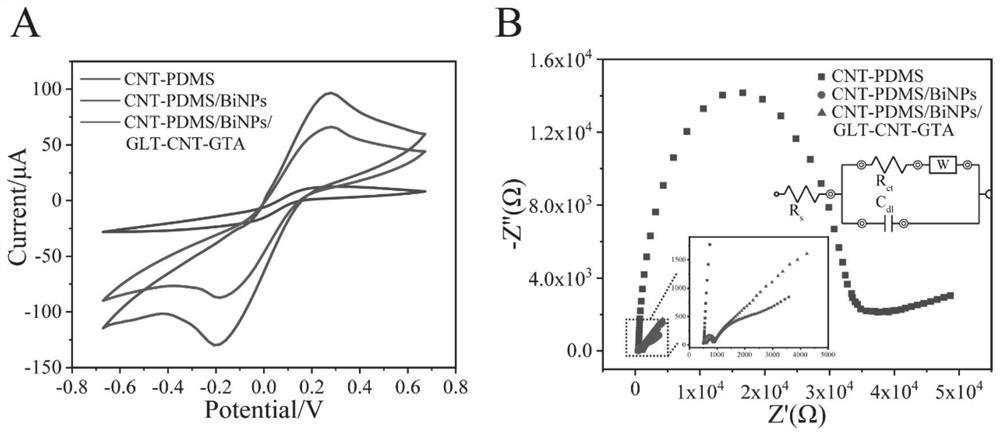

[0054] To evaluate the electrochemical performance of the CNT-PDMS / BiNPs / GLT-CNT-GTA electrode, the [Fe(CN) 6 ] 3- The electrochemical response was compared with CNT-PDMS electrode and CNT-PDMS / BiNPs electrode in 0.1M KCl.

[0055] In the presence of 5mM [Fe(CN) 6 ] 3- and 0.1M KCl solution to characterize the CNT-PDMS / BiNPs / GLT-CNT-GTA electrode. CV measurements were performed at a scan rate of 50 mV / s over a potential range of -0.65V-0.65V. EIS testing is performed at a frequency of 1Hz-100kHz at open circuit voltage. DPV measurements were made with an amplitude of 25mV, a pulse of 50ms, an interval of 500ms, and a quiet time of 5s.

[0056] Analysis of test results:

[0057] CV and EIS were also used to study the electron transfer capabilities of CNT-PDMS electrodes, CNT-PDMS / BiNPs electrodes and CNT-PDMS / BiNPs / GLT-CNT-GTA electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com