Microwave oven control part mounting structure

An installation structure and microwave oven technology, applied in the field of microwave ovens, can solve the problems of increasing the development cycle and cost, and prone to errors, so as to avoid errors, reduce manufacturing costs, and reduce the development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

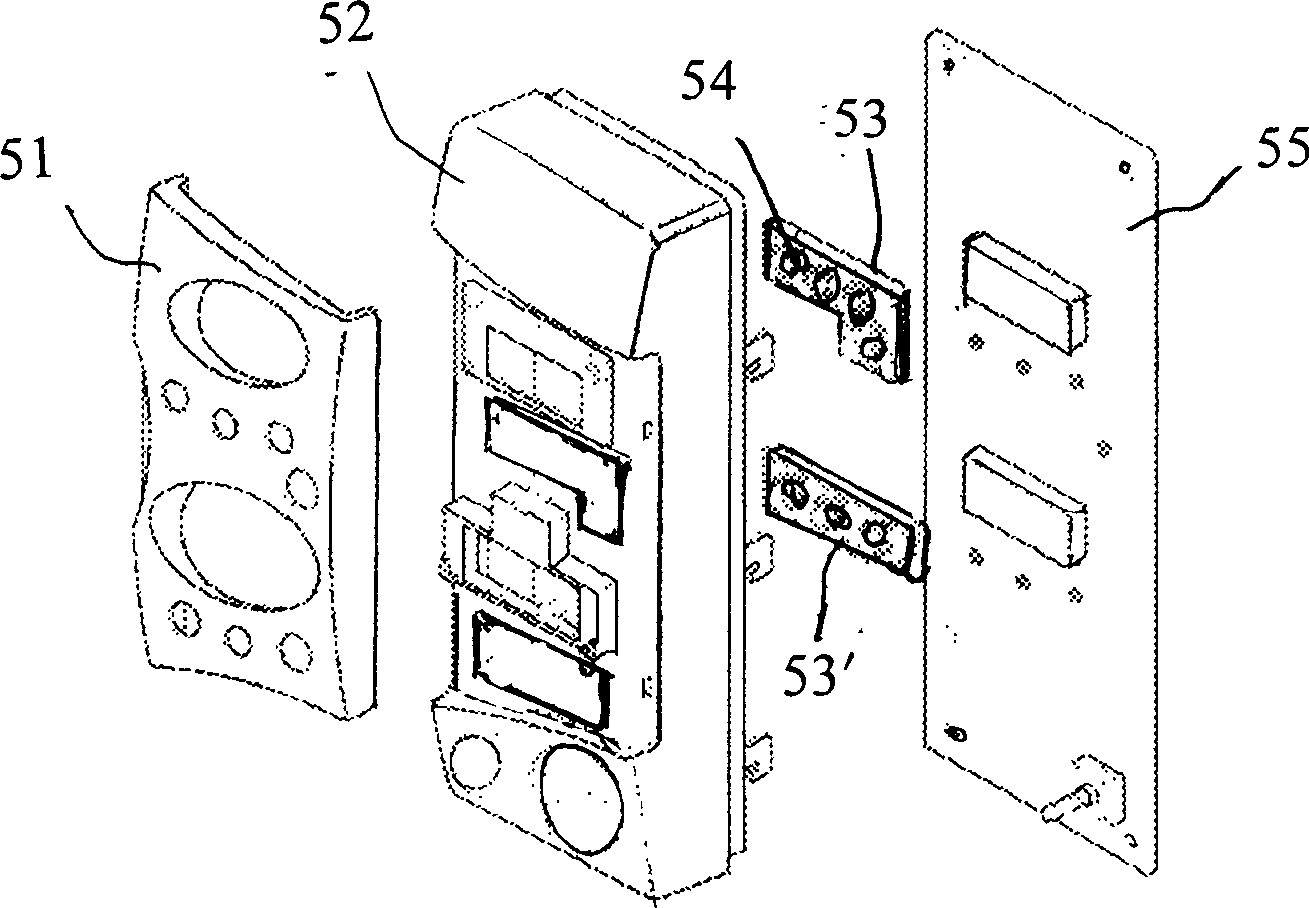

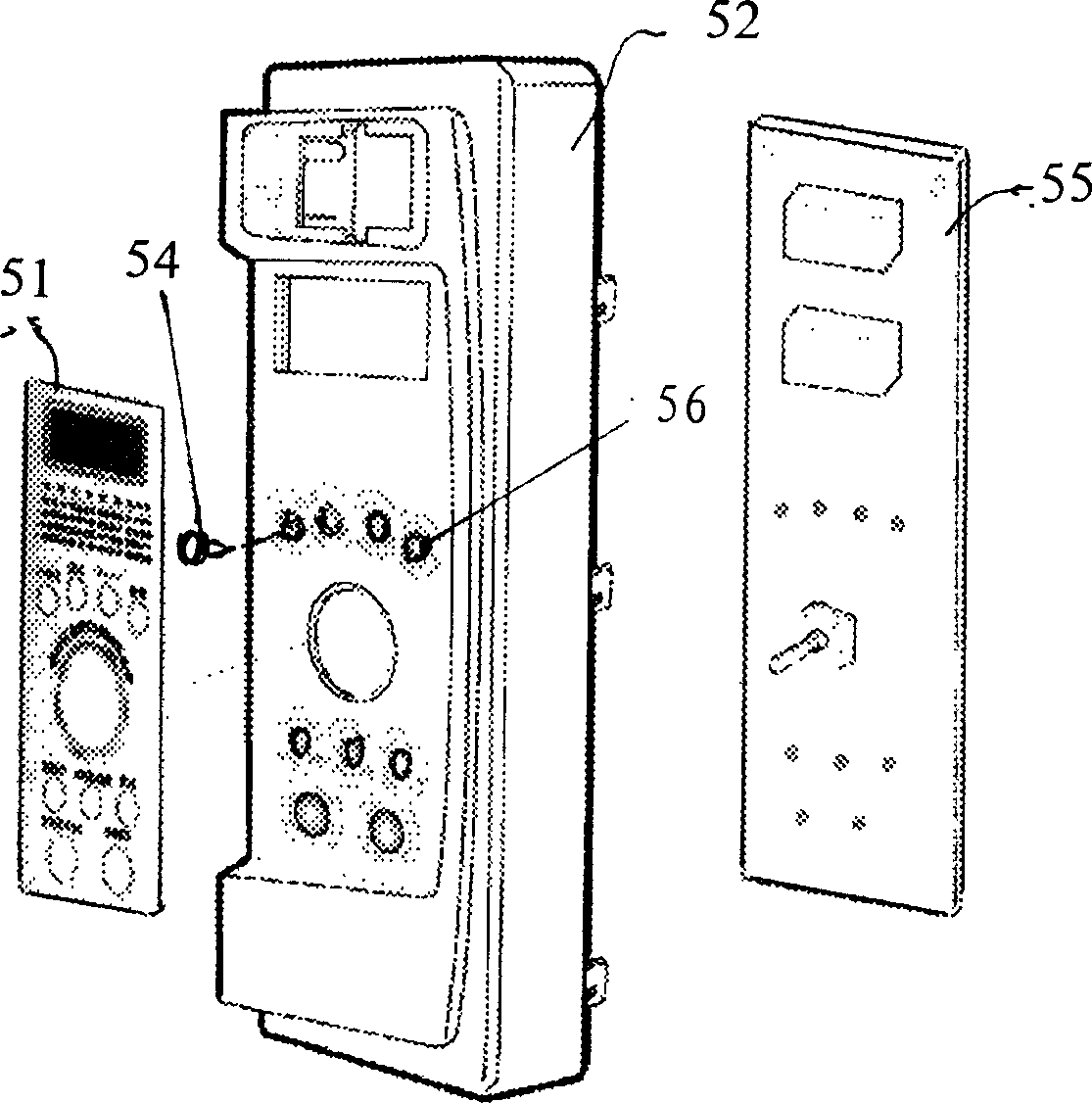

[0027] image 3 It is an exploded view of the structure of the control part of the microwave oven of the present invention.

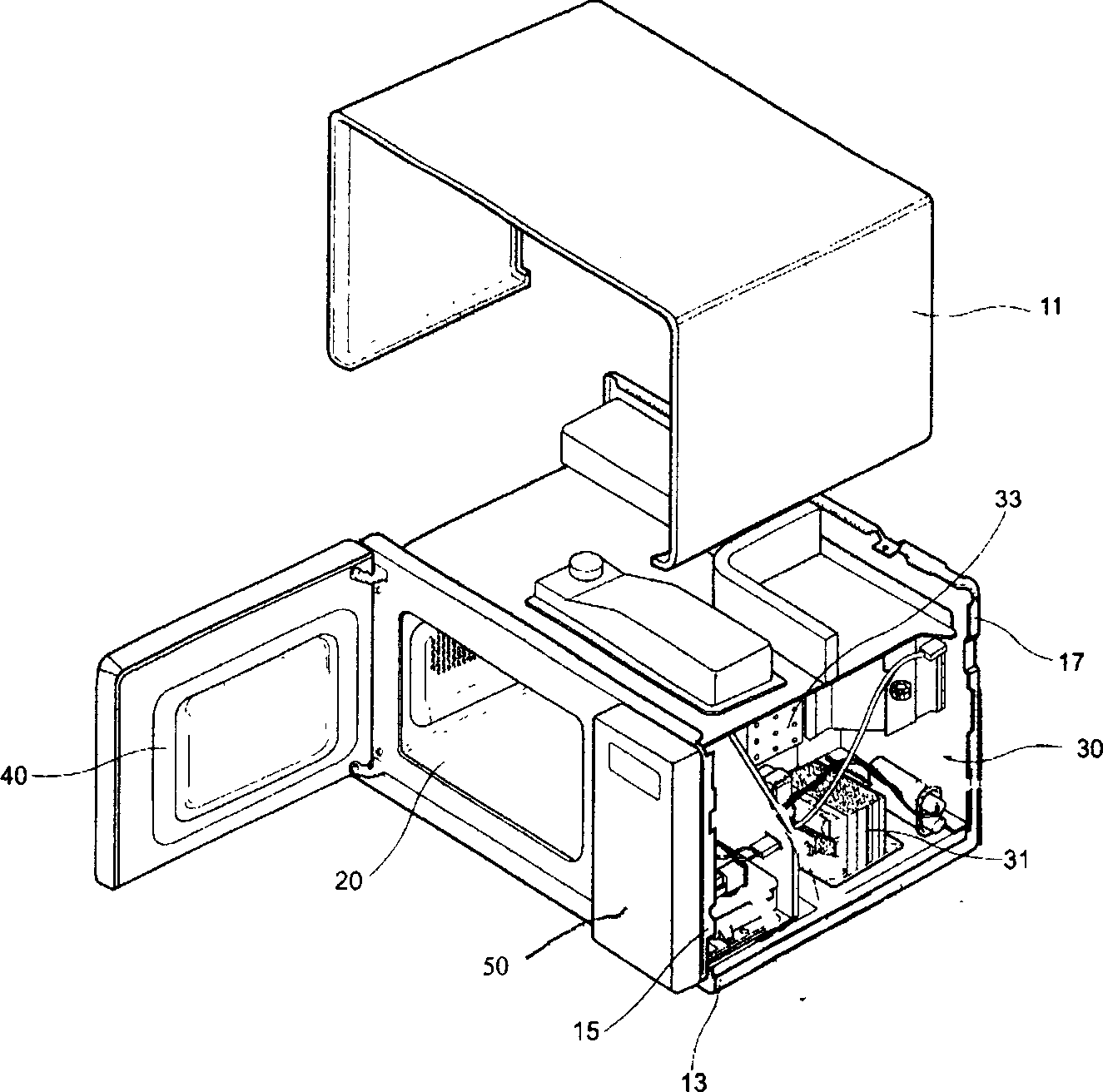

[0028] The microwave oven includes an outer casing forming an appearance, a cavity for placing food, and a storage room for controlling various electronic components for controlling the cavity. A door for selectively opening and closing the inner space of the oven cavity is provided at the front of the oven cavity, and the front end of the electric storage room is a control unit 50 .

[0029] Such as image 3 As shown, the control unit 50 includes a control panel 52 integrally injection-molded with the control button panel, a control front panel 51, a control button 54, and a control circuit board 55. The control pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com