Method for preventing and controlling water burst of coal mining base board rock stratum on pressure bearing water body

A coal seam floor and floor technology, which is applied in mining equipment, earthwork drilling, shaft equipment, etc., can solve the problems of deep coal seam floor water damage, large frost heave deformation, insufficient strength, etc., so as to save the thawing process, freezing The effect of short cycle and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

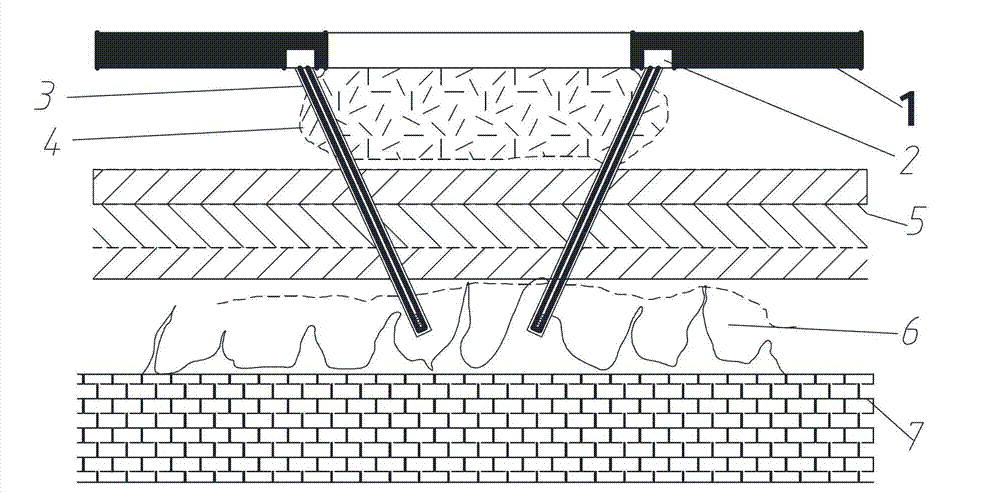

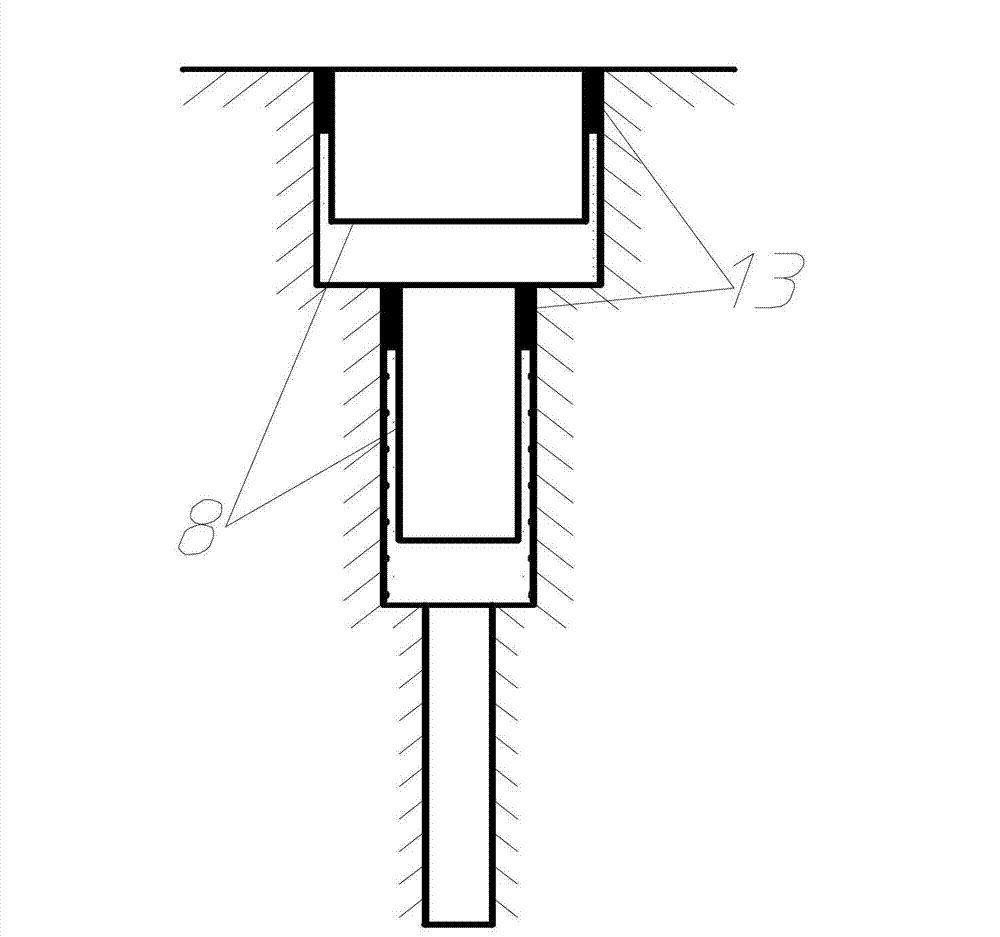

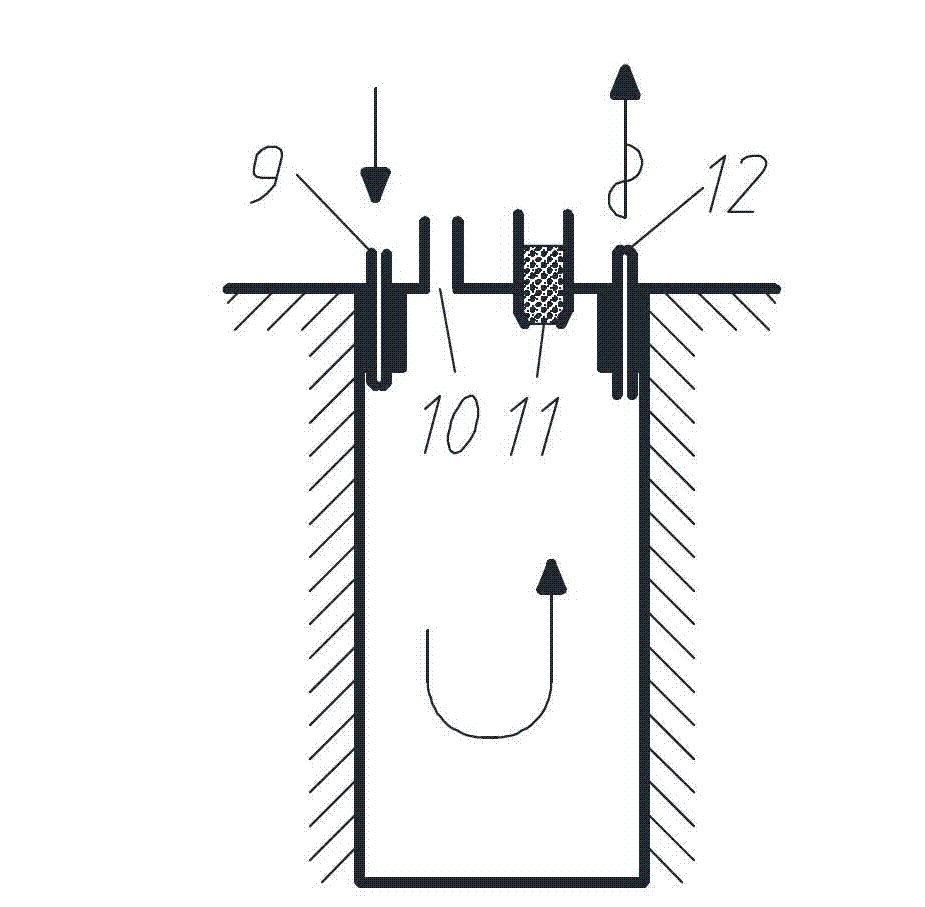

[0042] Attached below Figure 1-3 , taking the water inrush reinforcement of mining floor 1 in the deep coal seam of a mine as an example, the prevention and control method and construction steps of water inrush in the coal mining floor rock layer on the confined water body are explained in detail:

[0043] Preparation stage of construction materials:

[0044] The grouting material selected is No. 425 ordinary Portland cement, clay, fine aggregate mixed with fly ash, fine yellow sand and stone powder. The specific gravity of the clay slurry is 1.15-1.2, and the ratio of the amount of cement to the amount of clay is 0.1-0.15:1, the water-cement ratio is 1:1.

[0045] According to the detection results, develop the drilling site on both sides of the forward transport chute and the return air chute 2, design the location and number of drilling 3 in the drilling site, the diameter of the drilling hole is greater than 75 mm, and the drilling holes are evenly arranged according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling aperture | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com