Patents

Literature

58results about How to "Avoid pulping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

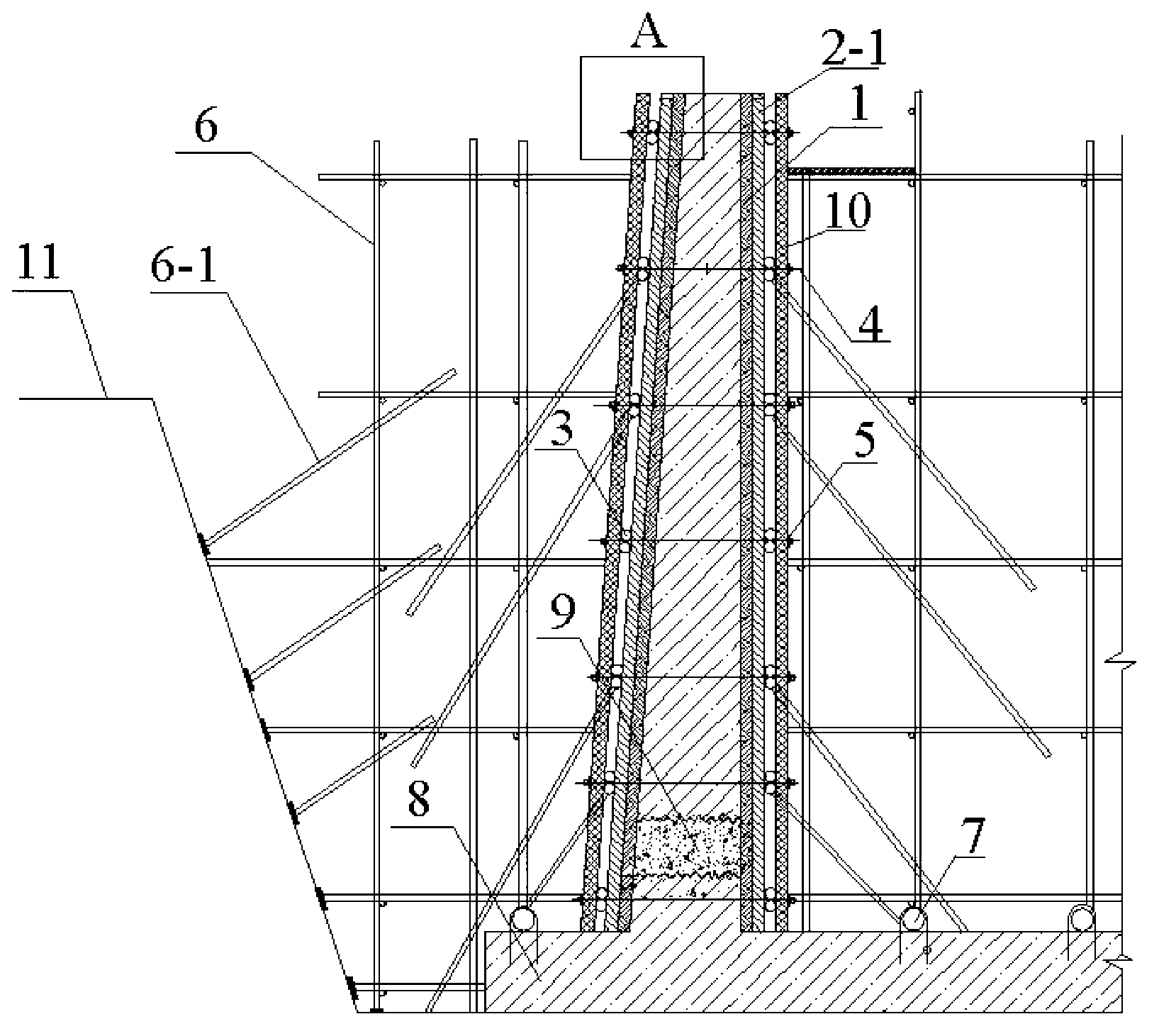

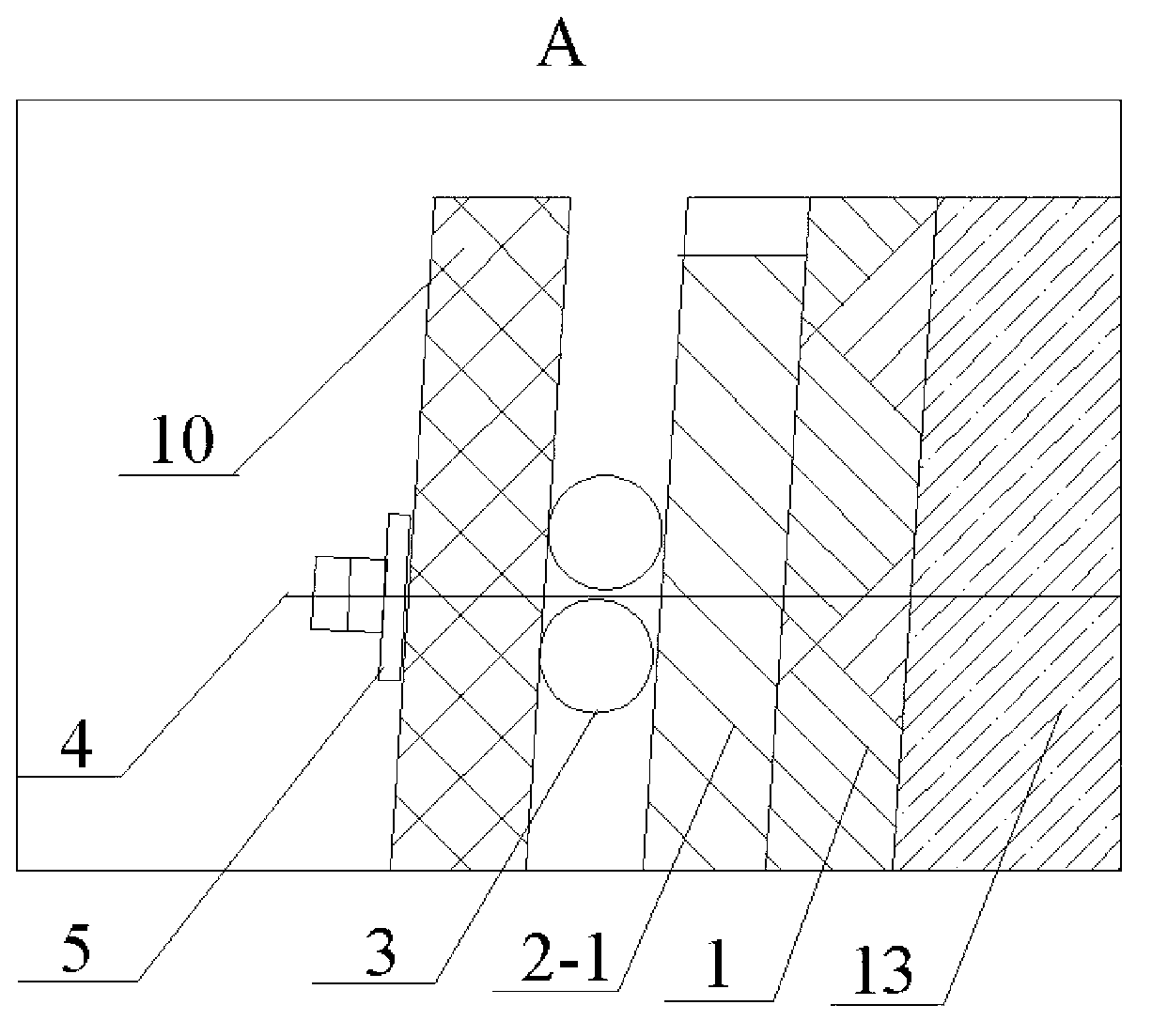

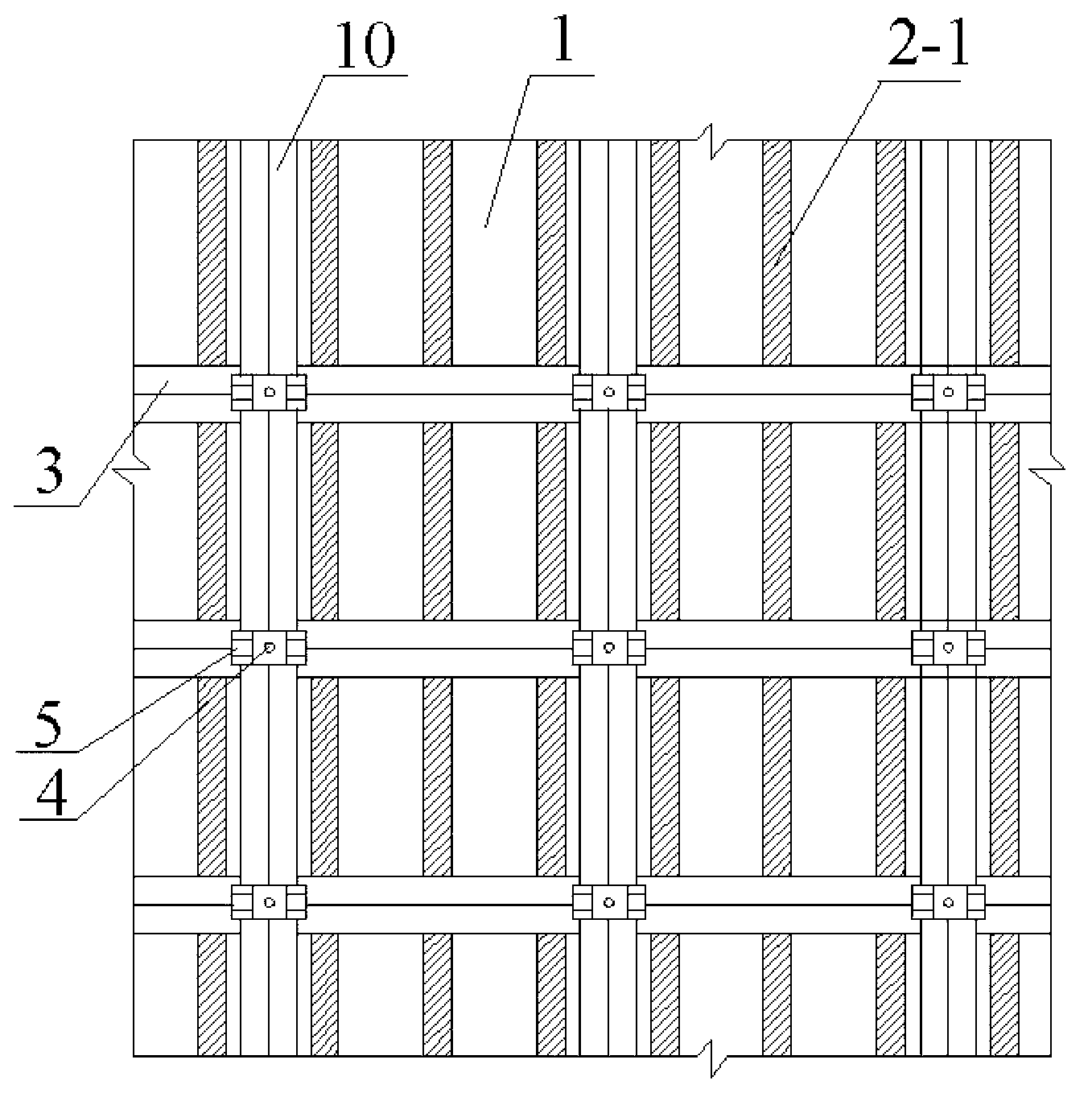

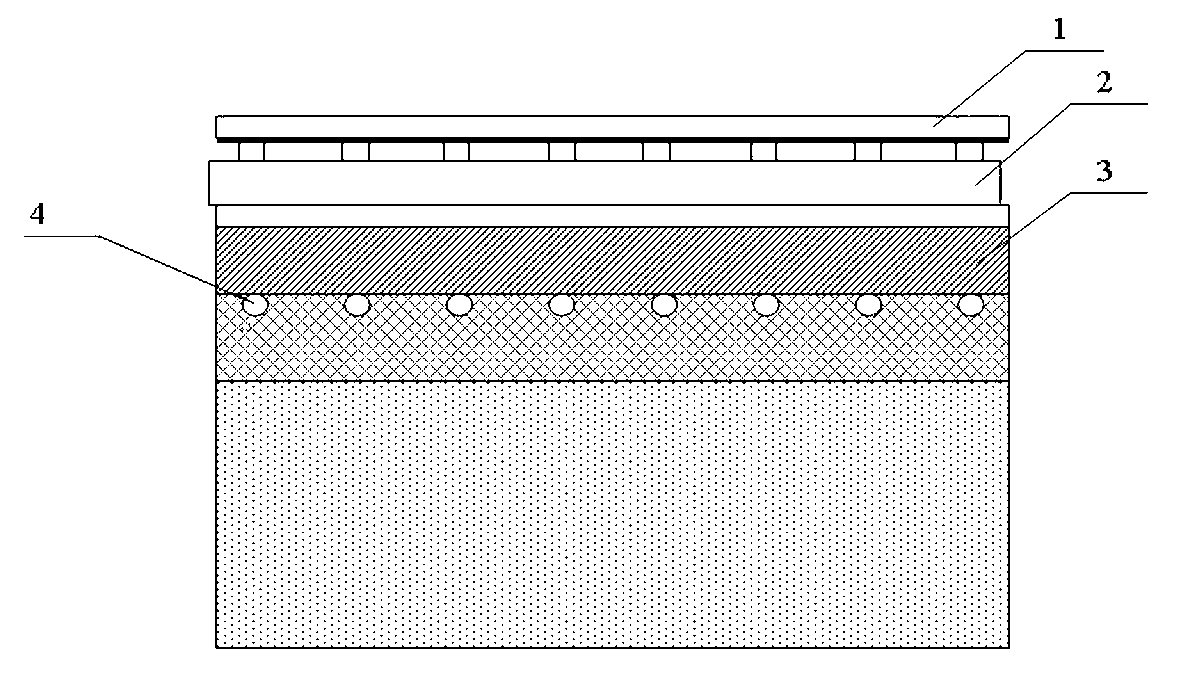

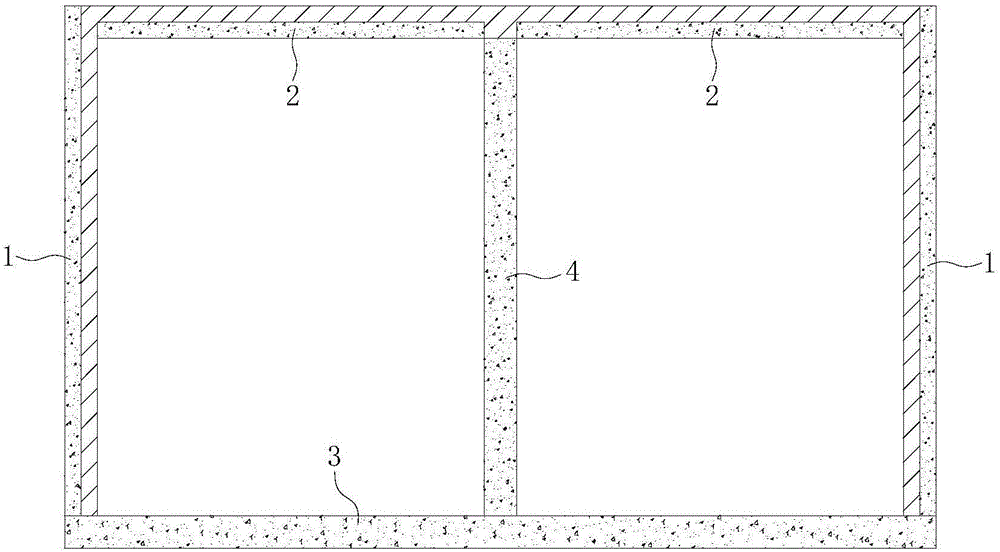

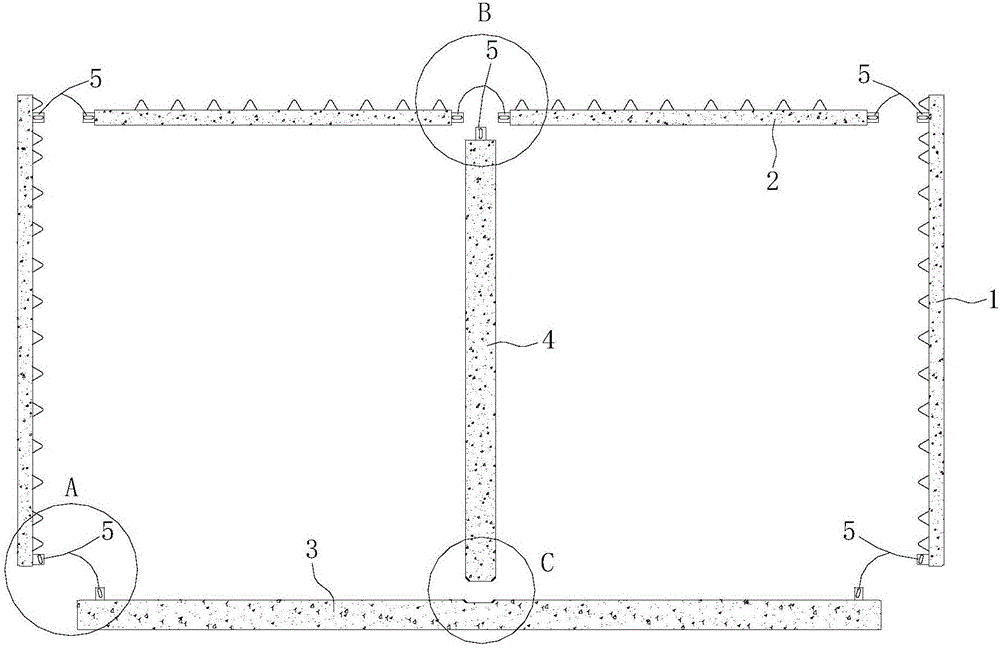

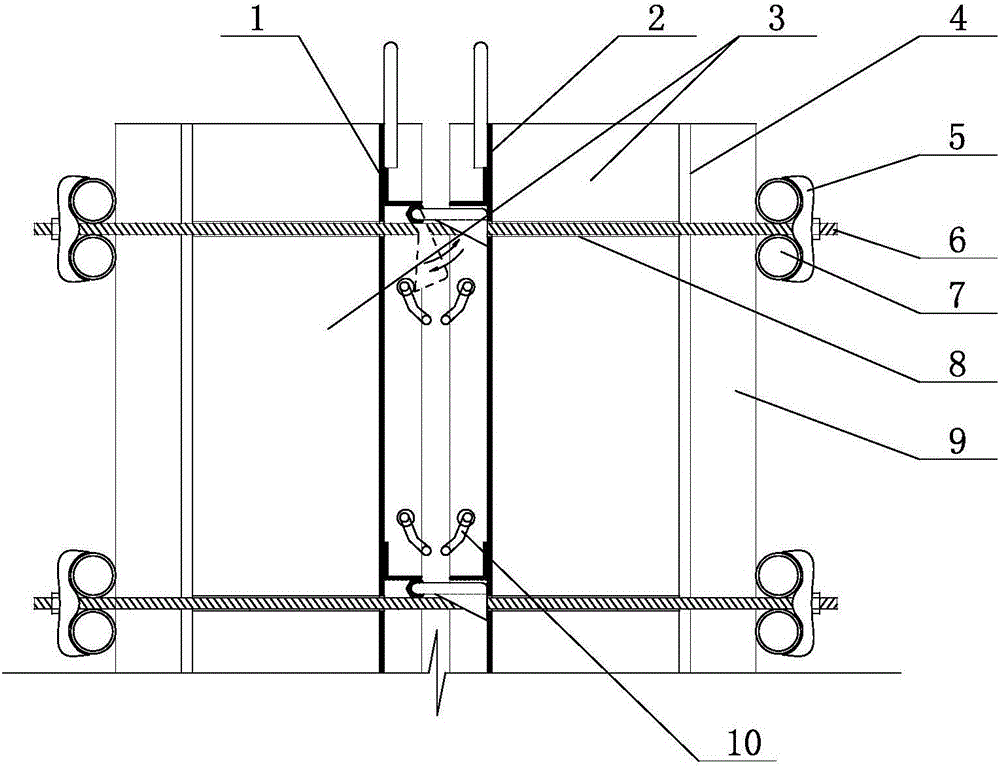

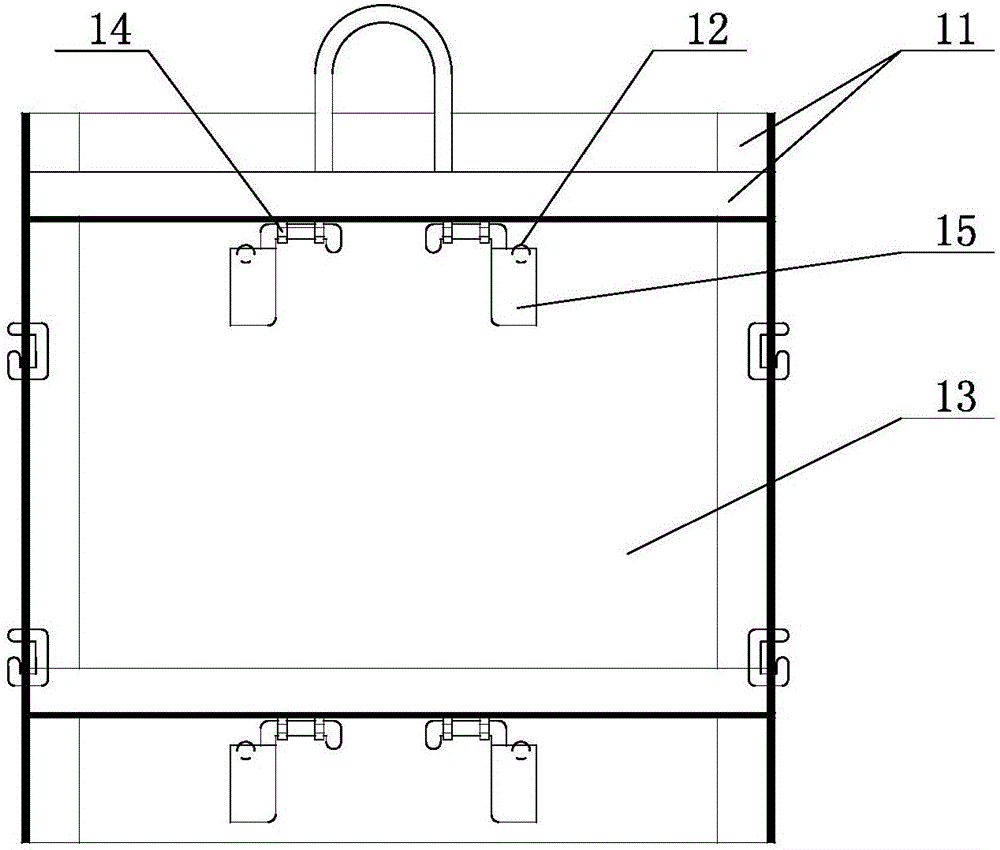

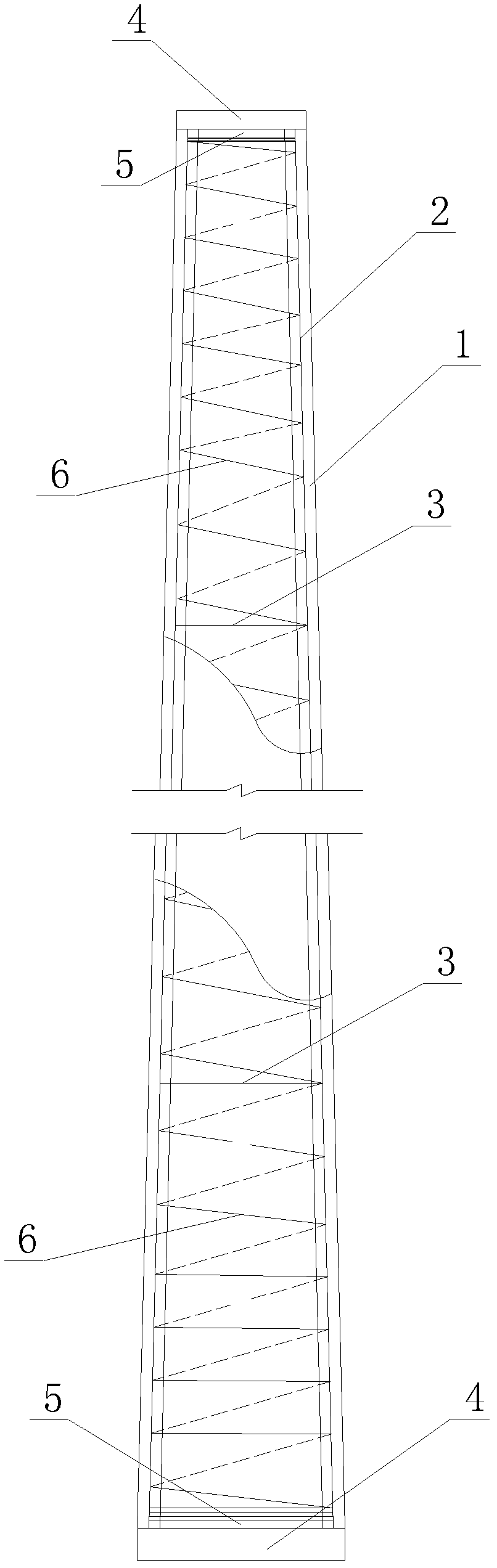

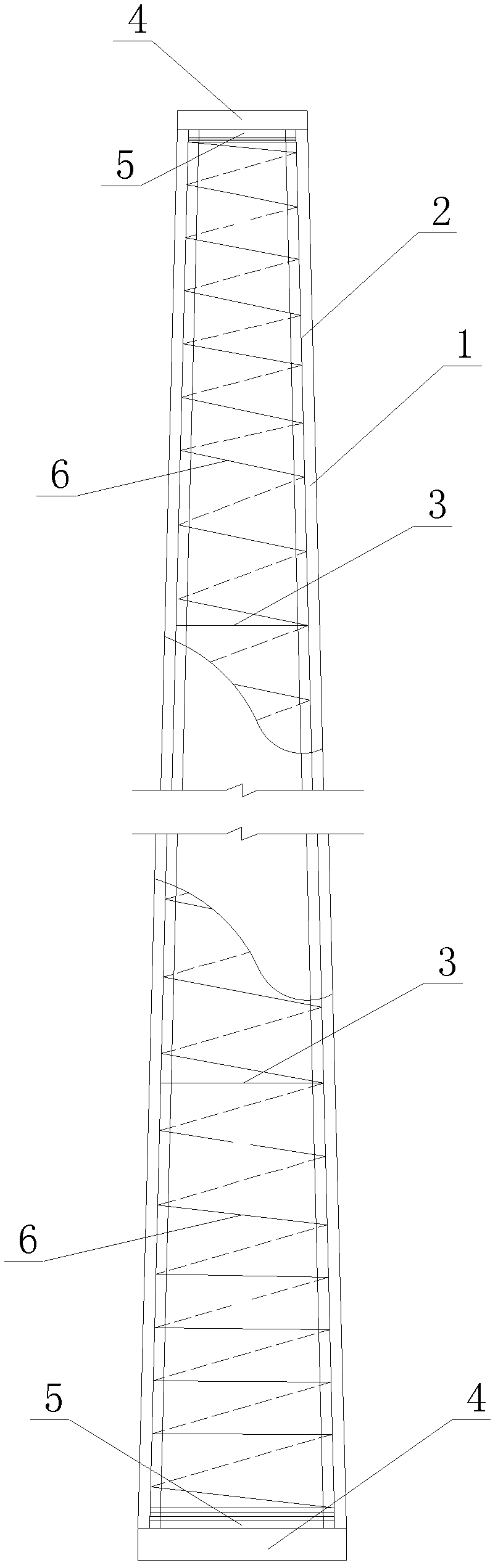

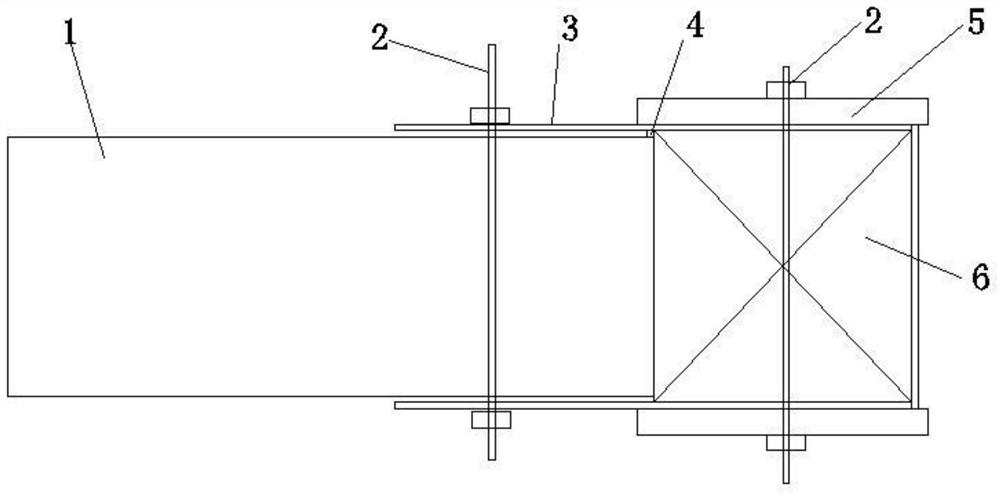

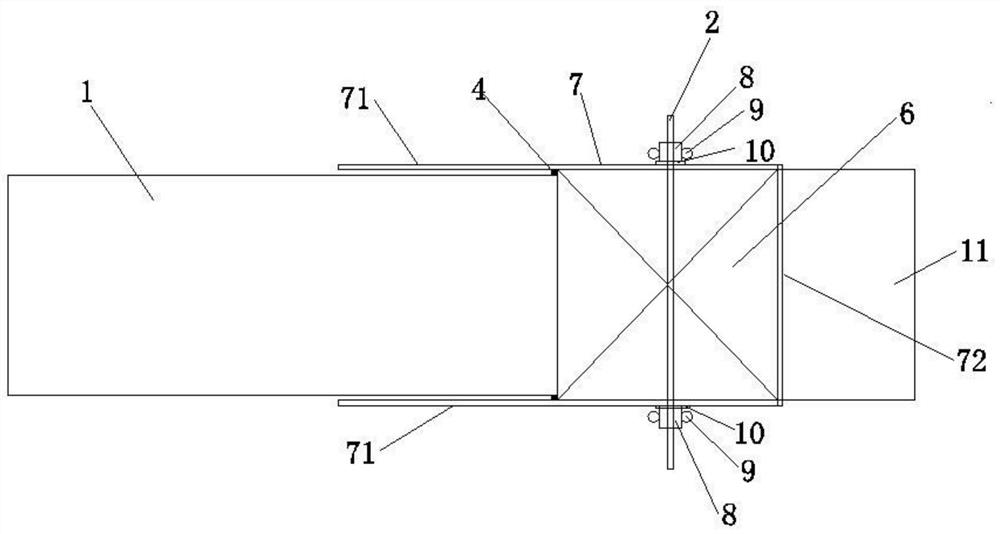

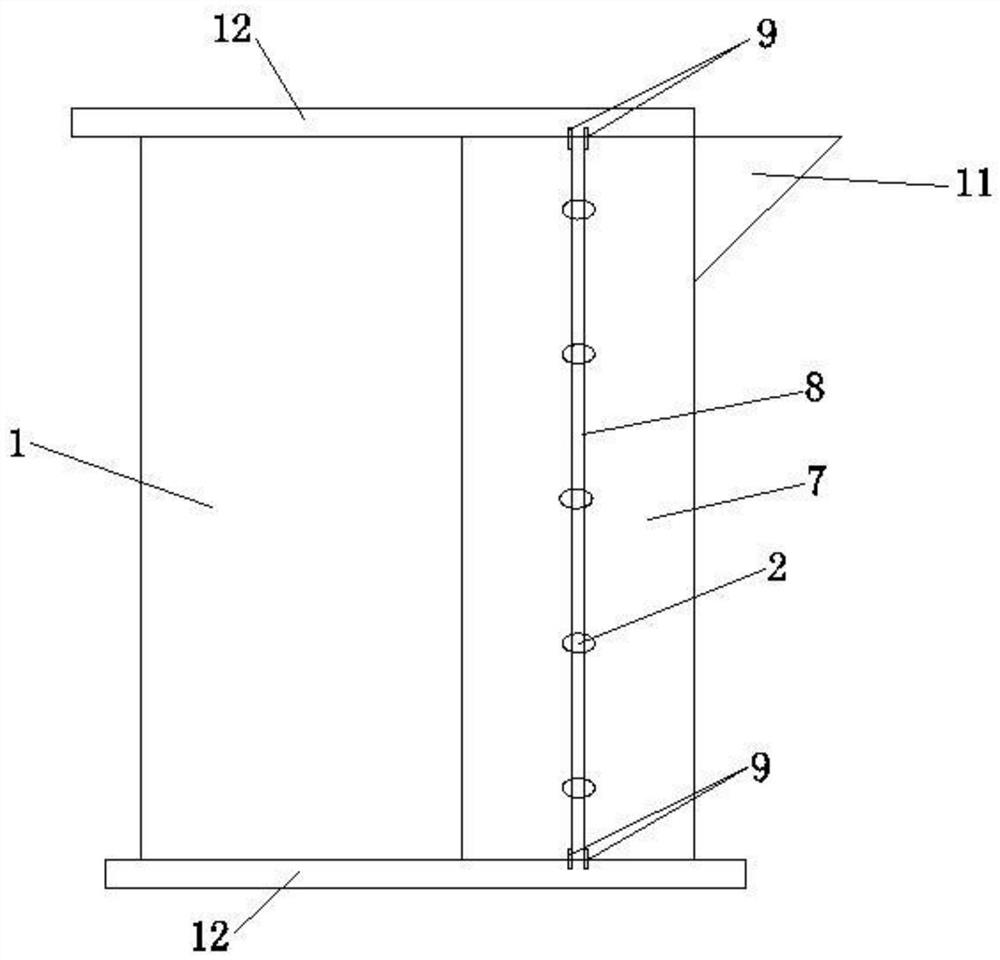

Construction method for one-time formation of concrete pool wall

ActiveCN103321421AGood structural integrityEnsure integrity and compactnessBuilding material handlingBulk storage containerWater leakageSupport system

The invention discloses a construction method for one-time formation of a concrete pool wall. The method includes the steps of erection of a pool wall reinforced frame, mounting of pool wall forms, mounting of a support system, and casting of the concrete pool wall. The method has the advantages that the problems of large pool wall height and large form side pressure are solved by the use of the solid side forms and a reinforcing support system; the pool wall forms are erected to the top once, and the appearance quality of the pool wall is easily guaranteed; pool concrete is cast once, structure integrity is good, and the potential water leakage problem of the pool wall caused by reservation of multiple horizontal construction joints; construction process is greatly quickened, construction period is shortened, labor cost and materials cost are saved, and engineering cost is lowered; the method is especially applicable to construction of concrete pool walls 9m in height and 300mm-1100mm in thickness.

Owner:河北省第二建筑工程有限公司

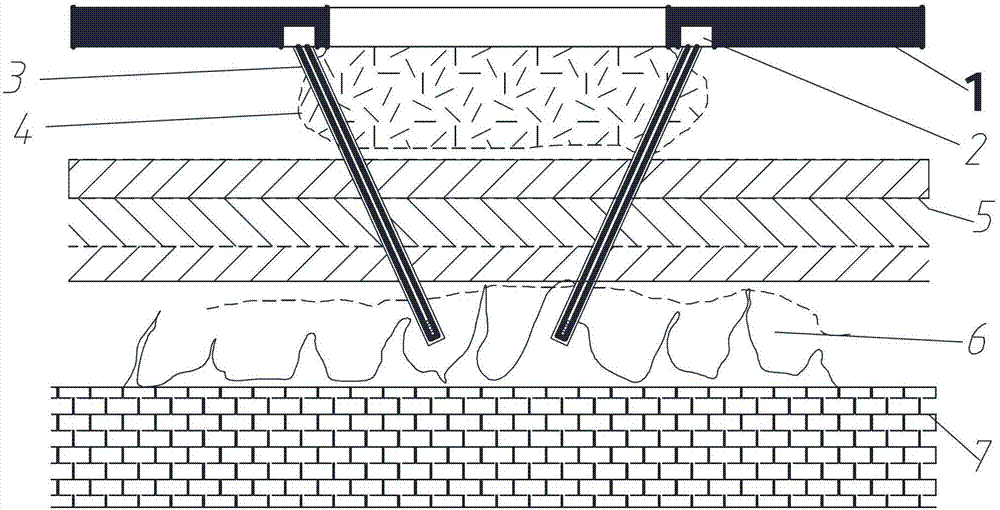

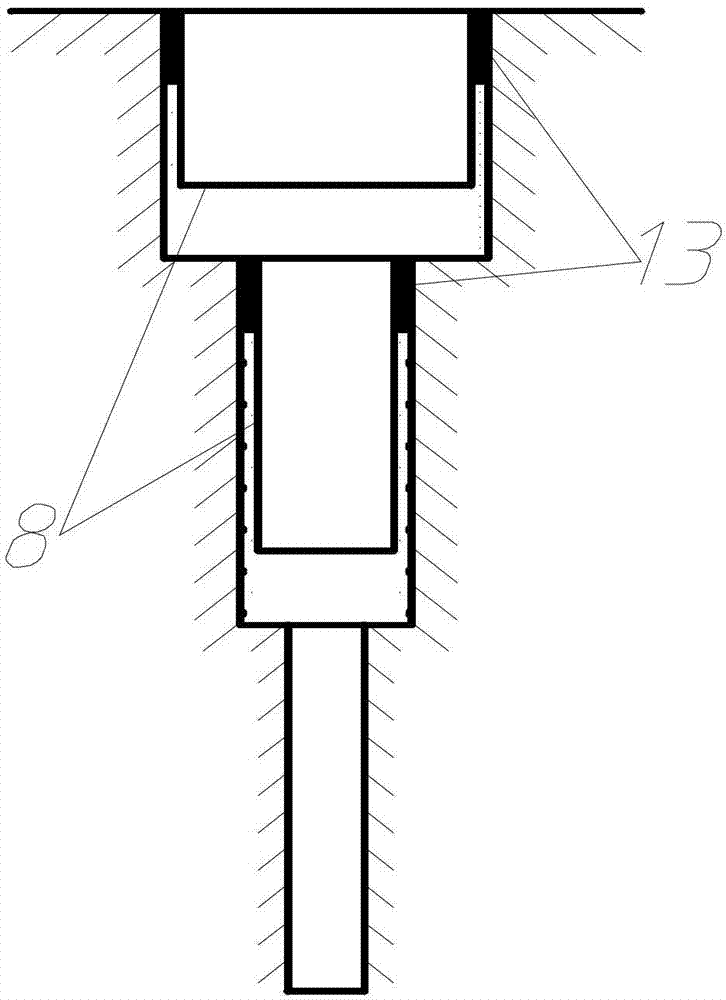

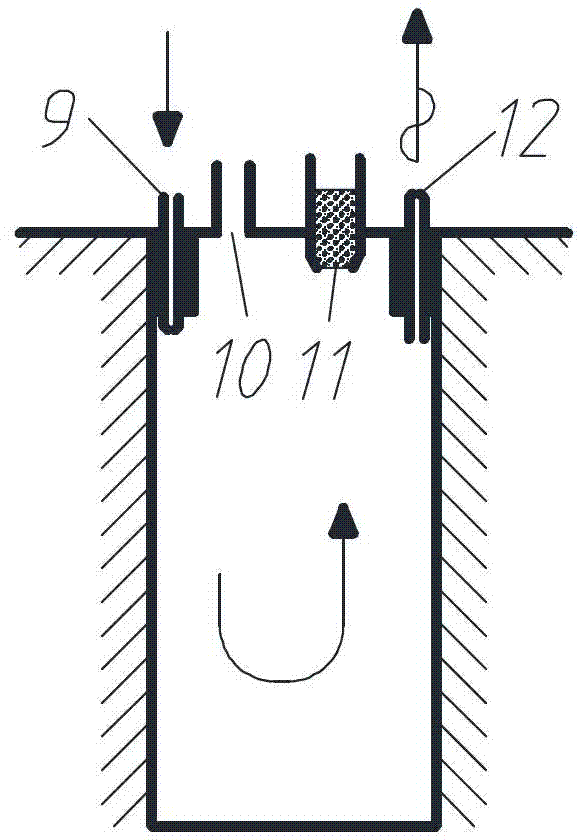

High polymer grouting method for lifting ballastless track of high speed railway

ActiveCN103215863AAchieve liftingGuaranteed smoothnessRailway track constructionSocial benefitsEngineering

The invention relates to a high polymer grouting method for lifting a ballastless track of a high speed railway. The method comprises the following steps that (1) grouting holes are drilled; (2) geotextile bags are manufactured, and in addition, the geotextile bags and grouting pipes are bound; (3) the geotextile bags are tied up; (4) the geotextile bags are placed; (5) the grouting is carried out in the geotextile bags; (6) the track is lifted; (7) the grouting is filled; and (8) the lifting quantity is monitored: a laser gradienter is used for monitoring the vertical lifting height in real time, and the grouting stops when the lifting requirement is reached. The method has the advantages of high speed, little damage, light weight, high tenacity, economy, endurance and the like, the lifting of the ballastless track of the high speed railway can be fast realized, and a novel, advanced, efficient, economic and practical method is provided for the subgrade settlement repair of a high-speed rail. The method is successfully applied to multiple ballastless track lifting projects, and huge economic and social benefits and wide development and application prospects are realized.

Owner:南方工程检测修复技术研究院

Method for controlling water-rich fractured rock mass comprehensive grouting under effective sealing batholite shortage condition

ActiveCN104453943AEffective transformationAvoid pulpingUnderground chambersSealing/packingSocial benefitsWater source

The invention discloses a method for controlling water-rich fractured rock mass comprehensive grouting under the effective sealing batholite shortage condition. The method includes the steps of comprehensively detecting a hazard-formation water source and a water guide channel, designing a sealing batholite refitting scheme and a grouting treatment scheme, refitting sealing batholite, controlling the grouting process and the safety, conducting draining, pressure relieving, drilling and blocking, comprehensively detecting the grouting effect, compensating a weak zone for slip casting and the like. After construction is conducted through the method, by refitting the sealing batholite, the problems that due to the shortage of the effective sealing batholite, sap loss and grout leakage occur in the grouting process and the grouting effect is not good are solved, the grouting efficiency is improved, and good social benefits and economic benefits are created.

Owner:SHANDONG UNIV OF SCI & TECH

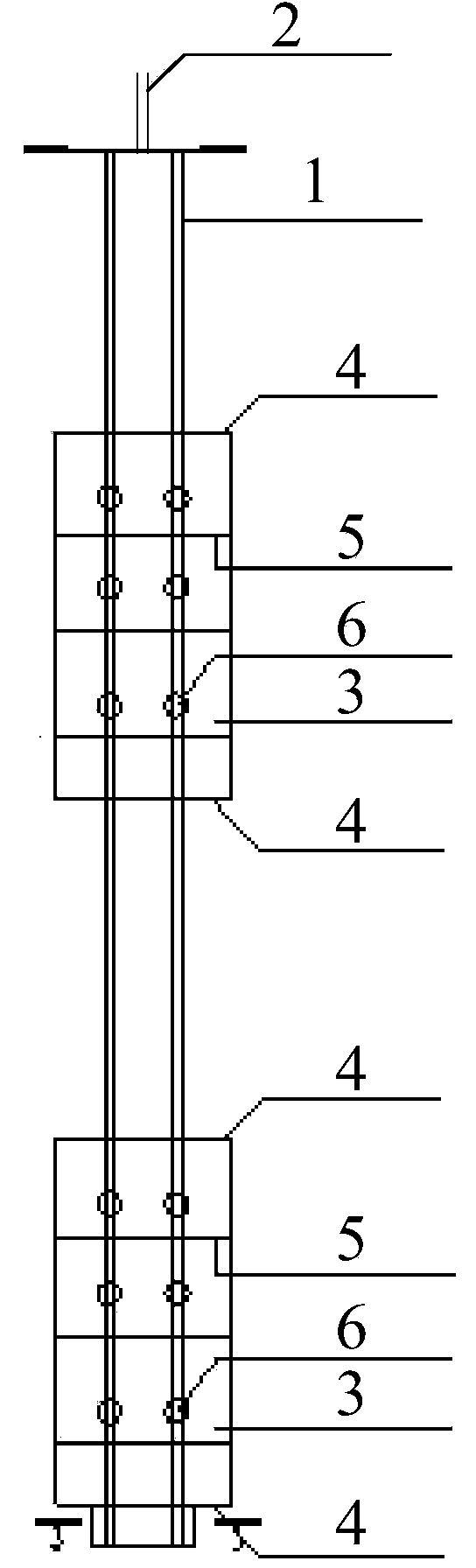

Cement casting die for manufacturing of electric wire pole

InactiveCN108908687AImprove stabilitySave the step of fixing and tightening the boltsMouldsRebarMaterials science

The invention discloses a cement casting die for manufacturing of an electric wire pole. The cement casting die comprises a die body, longitudinal reinforcing ribs and a plurality of reinforcing seats, wherein the multiple reinforcing seats are arranged on the die body; an upper die is arranged in each reinforcing seat; a lower die is arranged in each reinforcing seat and is symmetric to the corresponding upper die; buffer layers are respectively arranged in each upper die and each lower die; each reinforcing seat consists of an upper part and a lower part; an upper turnover fixed block is arranged at the left side of the upper half part of each reinforcing seat, and is rotationally connected with a lower turnover fixed block through a second rotary shaft. The cement casting die has the advantages that in the use process, each upper die is opened, a reinforcement cage of the electric wire pole is put into each lower die, a proper amount of concrete is cast, then each upper die is closed, a convex block at the lower side of the right end of each upper die is inserted into a groove, and the die can be stabilized; a locking press handle is pressed down, and a clamp block is clamped with a locking block, so that the die can be directly and effectively tightened, the step of fixing and tightening the bolt in the traditional bolt is not required, and the production time is shortened.

Owner:无为县红宇通信器材有限责任公司

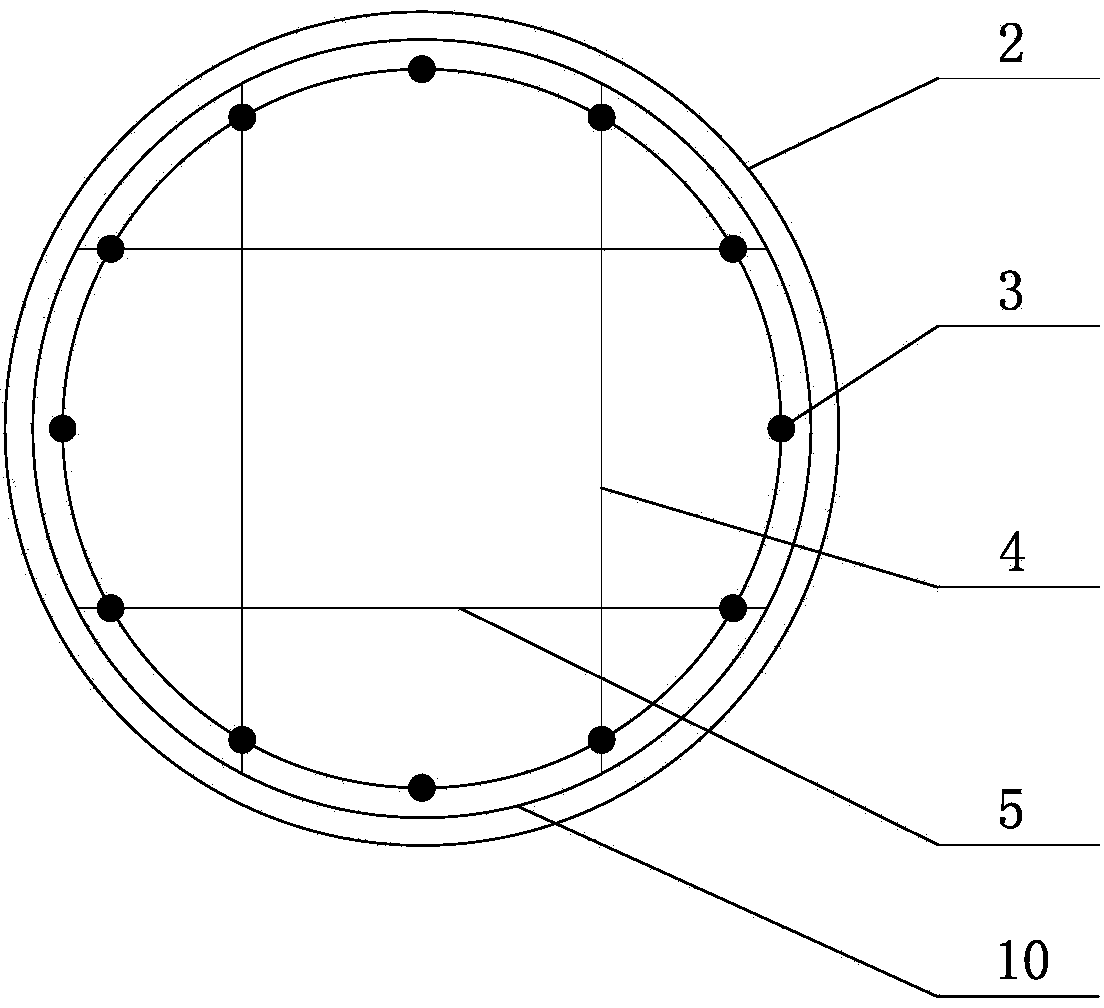

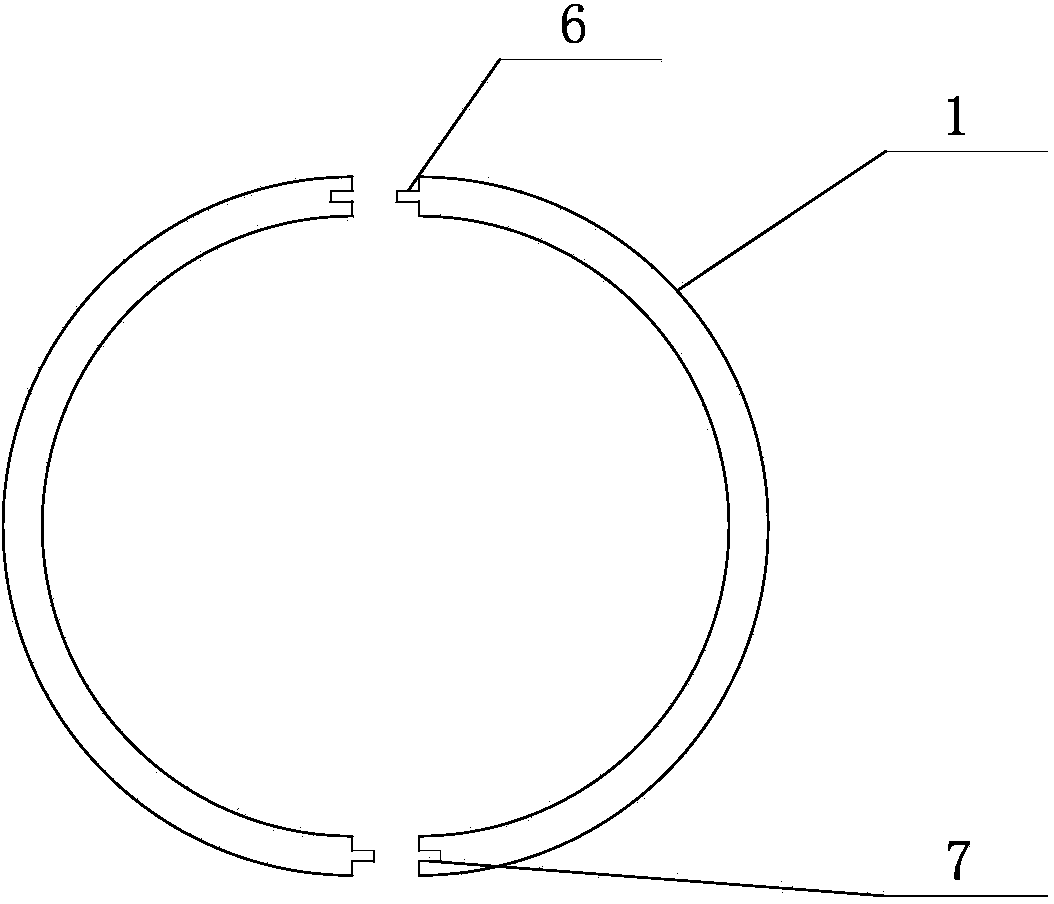

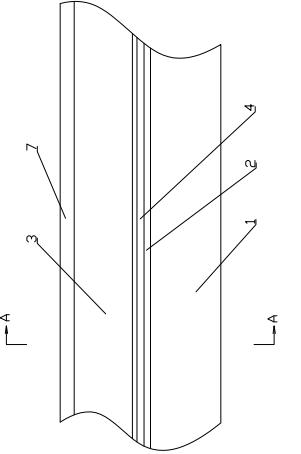

Fastening type cylindrical timber formwork concrete casting construction method

ActiveCN103643795AHigh strengthImprove toughnessForms/shuttering/falseworksBuilding material handlingUltimate tensile strengthToughness

The invention belongs to the technical field of construction and particularly relates to a fastening type cylindrical timber formwork concrete casting construction method. The method comprises the following steps: (1) binding a pillar main bar; (2) positioning; (3) manufacturing a template; (4) mounting the template; (5) cutting the template at the crossed part of a beam column; (6) reinforcing the template; (7) integrally fixing a template system; (8) performing concrete casting; (9) stripping of the formwork. According to the invention, the timber formwork is light in weight; as birch and poplar are adopted as the raw materials, the strength is high and the toughness is good; a template of 3 m in height is generally 40-45 Kg, so that two persons can work together to complete the mounting; compared with the traditional steel form construction, 70% construction period is shortened; as the shaped cylindrical template is adopted and the connector of the template adopts a unique convex through groove design, the abutted seams are closely combined, paste void and leakage are prevented, and concrete demoulding is quick and attractive; the difficult problem that the steel form can not be cut at will is solved, arbitrary cutting can be realized according to actual size, and accordingly, the construction difficulty is lowered for the construction side.

Owner:SHANDONG WANXIN CONSTR

Method for grouting and sealing plate-type ballastless track

InactiveCN102051844AAvoid pulpingImprove quality and efficiencyRailway track constructionEngineeringGrout

The invention discloses a method for grouting and sealing a plate-type ballastless track. The method comprises the following steps: 1) cleaning the top surface of a base plate; 2) laying a rubber hose which is laid along the length direction of a track plate on the top surface of the base plate with the width larger than that of the track plate part; and 3) laying an industrial felt and a permeable cloth. The method has the advantages that the sewing body of the industrial felt and the permeable cloth is pressed on the top surface of the base plate and the lateral surface of the track plate by unequal angle steel, while the elastic deformable rubber hose is arranged between the sewing body of the industrial felt and the permeable cloth and the top surface of the base plate, grouted mortar is sealed on the premise of ensuring the permeability, the phenomenon of grout off is prevented, and the grouting quality and the construction efficiency can be effectively improved.

Owner:中铁十七局集团第三工程有限公司

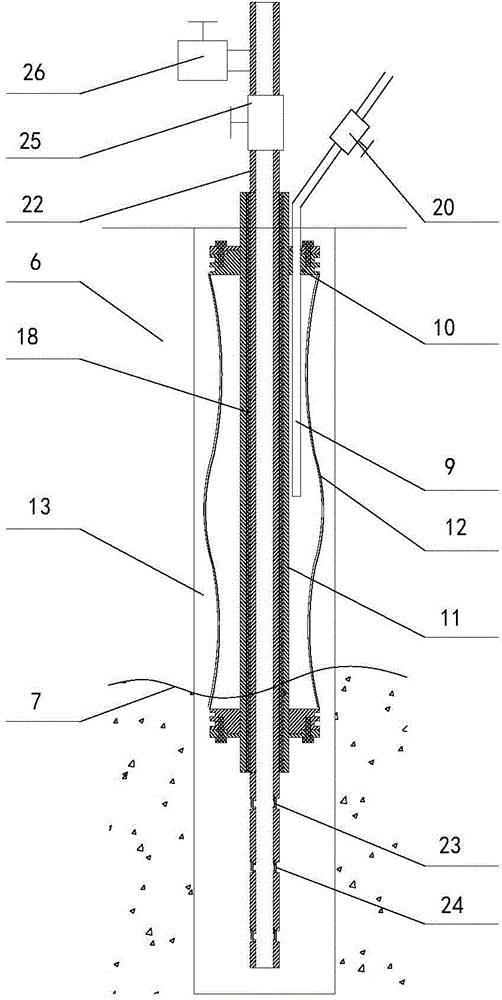

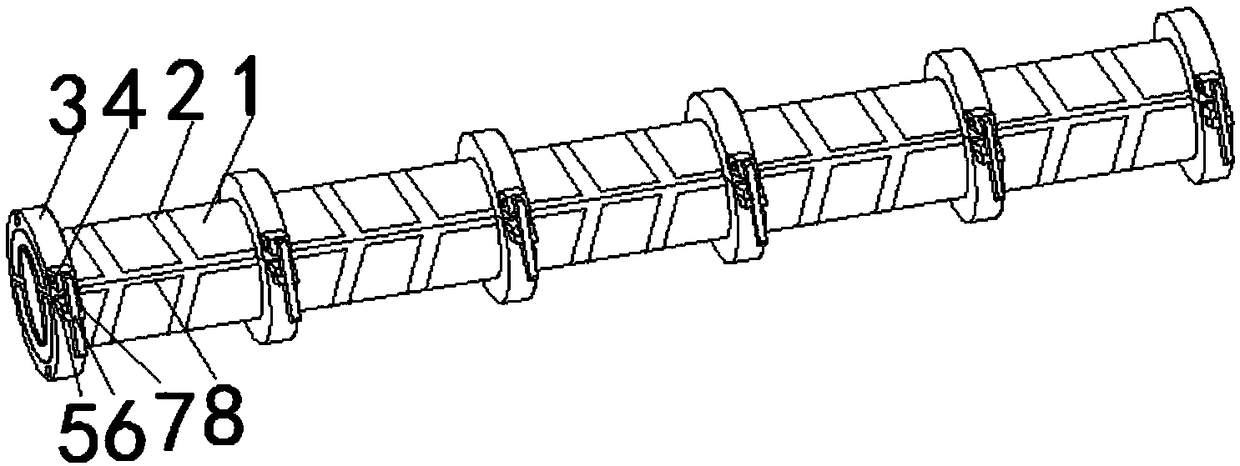

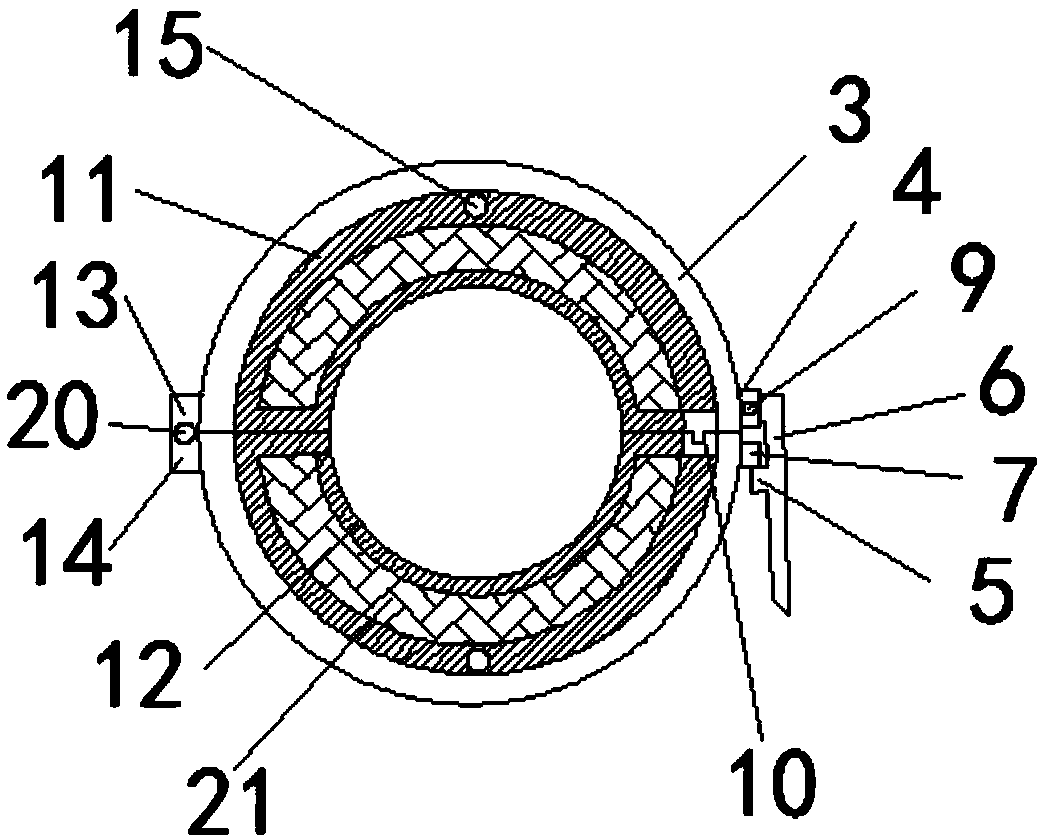

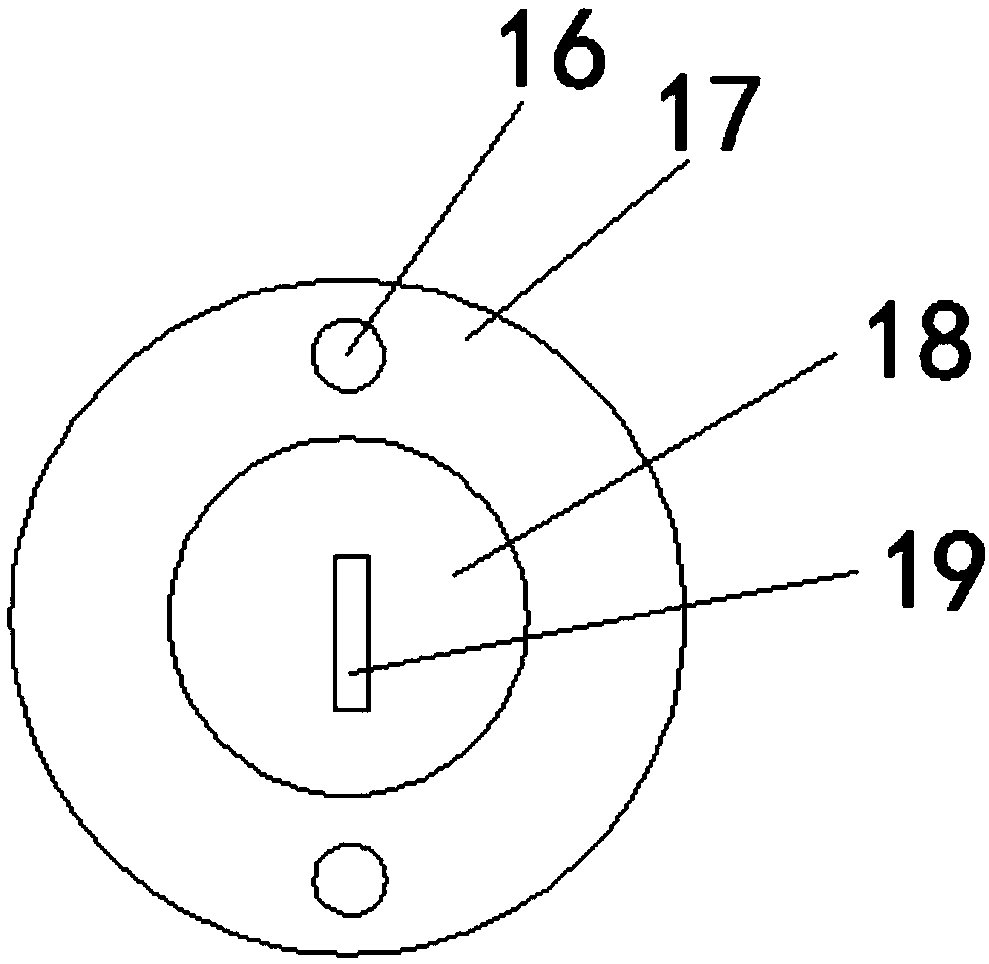

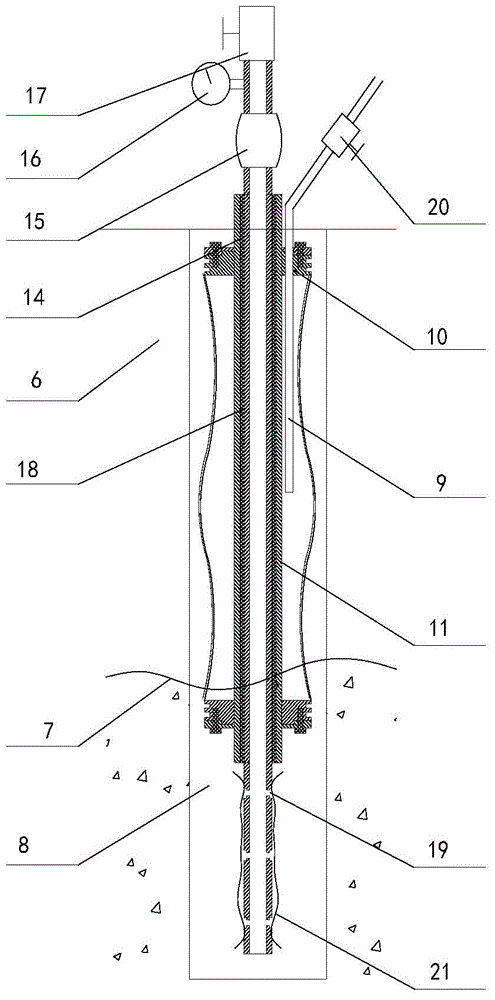

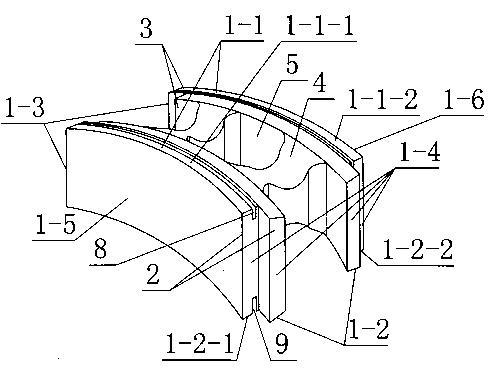

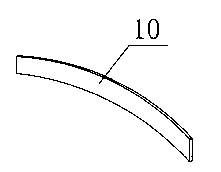

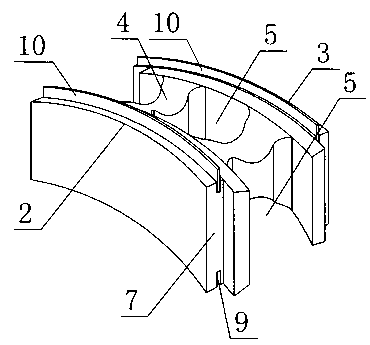

Construction method of slip-casting variable-cross section steel pipe pile and expansion and extrusion device of slip-casting variable-cross section steel pipe pile

The invention provides a construction method of a slip-casting variable-cross section steel pipe pile and an expansion and extrusion device of the slip-casting variable-cross section steel pipe pile. According to the construction method of the slip-casting variable-cross section steel pipe pile and the expansion and the extrusion device of the slip-casting variable-cross section steel pipe pile, provided by the invention, hole forming is firstly carried out by utilizing a drilling machine, slurry in a drill hole can be replaced by utilizing cement slurry after the hole forming is completed, a steel pipe pile which is provided with the expansion and extrusion device is then put in the drill hole, high-pressure cement slurry is pressed into the steel pipe pile or the expansion and extrusion device after the cement slurry in the drill hole is solidified, the expansion and extrusion device is used for expanding to extrude and strengthen a surrounding soil body under the action of the high-pressure cement slurry, a cement slurry body expansion and extrusion head is finally formed around the steel pipe pile, thus the occlusion action between the steel pipe pile and the surrounding soil body is greatly increased, a slurry leakage phenomenon which is easily caused in a post-grouting technology is avoided, and the operation reliability of the expansion and extrusion device is increased.

Owner:上海市建工设计研究总院有限公司

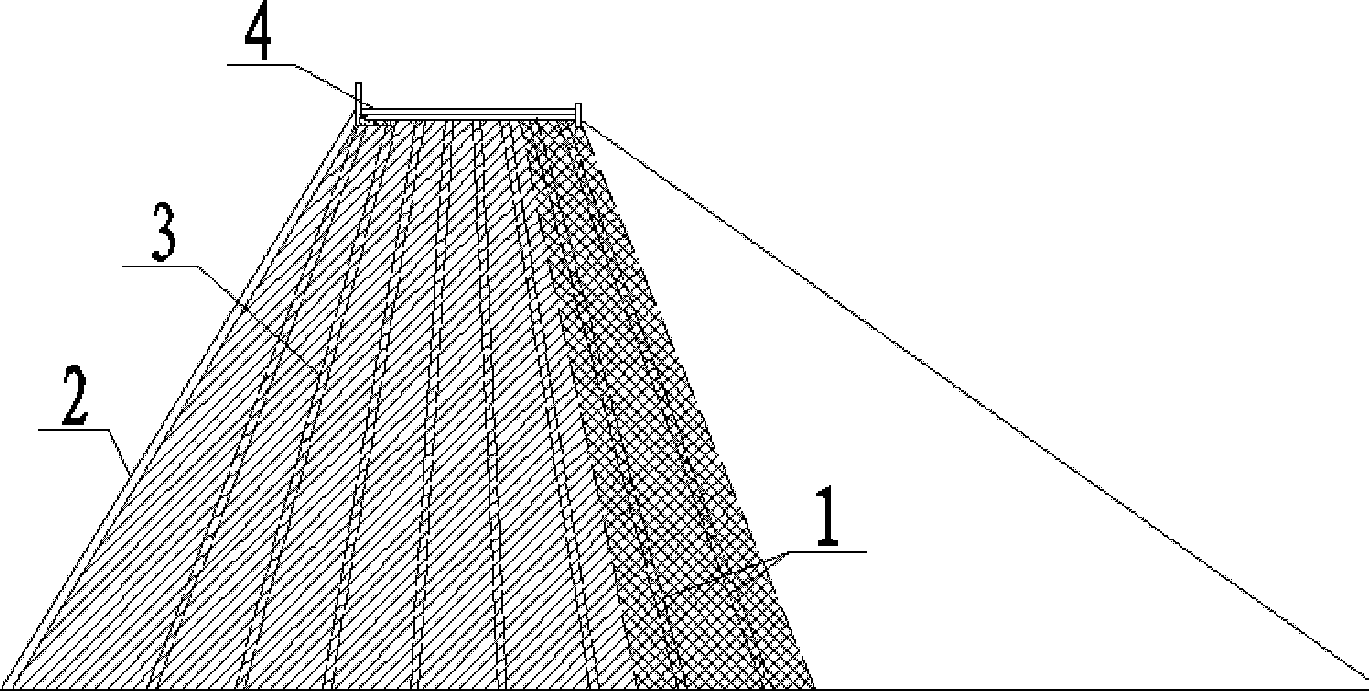

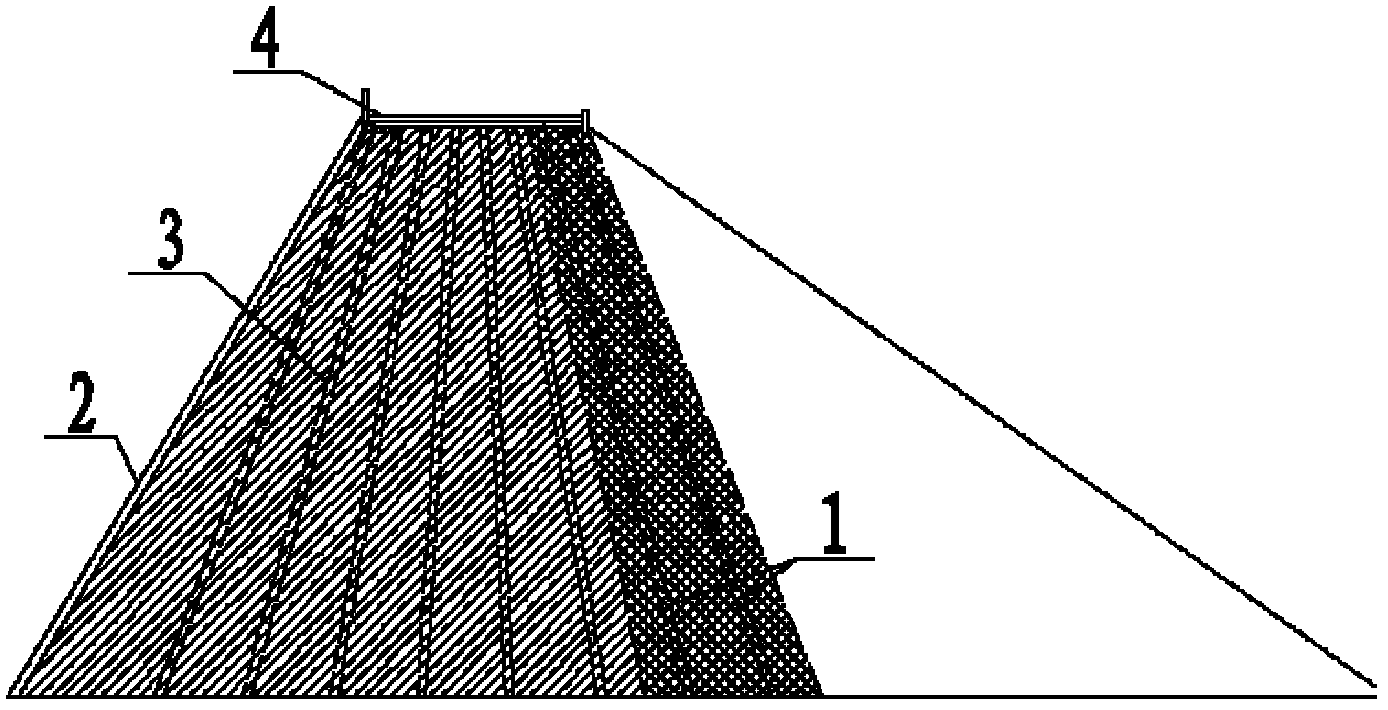

Rock-fill dam deformation control technology

InactiveCN102493403APotableControllableFoundation engineeringEarth-fill damsSlurryDeformation control

The invention belongs to the technical field of hydraulic and hydro-power engineering, and discloses a rock-fill dam deformation control technology which can be applied to diseased rock-fill dams or rockfill deformation control in the hydraulic and hydro-power engineering. The rock-fill dam deformation control technology comprises the following steps of: 1, preparing a pasty stable grouting liquid and cement mortar; 2, drilling holes in the dam body of the rock-fill dam, wherein the holes comprise stable grouting liquid grouting holes for sealing, and filling grouting holes; and 3, grouting: injecting the pasty stable grouting liquid into two rows of holes around a filling grouting area to make the pasty stable grouting liquid and a concrete panel on the upstream side of the rock-fill dam form an enclosed area, injecting the cement mortar into holes in the grouting area in an orifice filling mode after the pasty stable grouting liquid has been injected for 14 days, and controlling the rock-fill dam deformation after the grouting area has been grouted for 28 days. By the rock-fill dam deformation control technology, the deformation resistance of the rock-fill dam can be improved, the deformation of the dam body can be controlled, the grouting quality can be guaranteed, and the rock-fill dam deformation control technology has the advantages of short construction period, high work efficiency and the like.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Convenient grouting sleeve device suitable for backwall grouting and use method

ActiveCN108166993AChange the method of applicationEasy to handleUnderground chambersTunnel liningEngineeringFront loading

The invention relates to a convenient grouting sleeve device suitable for backwall grouting and a use method thereof. The grouting sleeve device can be divided into a front-loading grouting pipe set,a stop grouting expansion rubber sleeve and direct set, an intermediate connecting device and a grout inlet pipeline. The front-loading grouting pipe set includes an ordinary steel tube with an internal thread at one end and four small-bore grout sealing tubes welded at the periphery and provided with overhanging ports of 45-degree inclined angle on the outer wall; a four-way device of the grout inlet pipeline is a stainless steel four-way device with valves at each of end ports, and three end ports are a grout A end port, a grout B end port and a pressure relief end port; and a tube head cover is a round pipe plug device with an external thread at one end, and a grouting hole can be plugged after the tube head cover is screwed. Compared with existing devices, the convenient grouting sleeve device suitable for the backwall grouting successfully realizes the convenient handling of end sockets, the recycle of the device and the rapid restoration of the wall surface, greatly improves thework efficiency, reduces the cost expenditure, and can be widely used in backwall grouting construction.

Owner:SHANDONG UNIV

Cemented filling close to back processing technology for goaf at barren rock filling background

The invention provides a cemented filling close to back processing technology for a goaf at the barren rock filling background and belongs to the technical field of mining engineering. The cemented filling close to back processing technology for the goaf at the barren rock filling background is characterized in that iron tailings and cementation powder are used as filling slurry, and the filling slurry is delivered to underground through an existing filling tube; liquid sodium aluminate accelerator which is, by mass, 7% of the cementation powder are added into a stirring bucket which is arranged on the plane of the goaf, the slurry is delivered to an overflowing pool which is built on the front edge of the goaf through a tube, the slurry takes advantages of the situation when plug flow is formed and slides into the goaf, the slurry entering the goaf loses liquidity in a short time and coagulates, and therefore bottom pavement is achieved; low-cement-sand ratio slurry is used for filling the close to back, and filling is finished, wherein the cement-sand ratio of the low-cement-sand ratio slurry is 1:10-1:12. The cemented filling close to back processing technology for the goaf at the barren rock filling background achieves rapid coagulation of the slurry, reduces the flow resistance of the tubes, the phenomenon that the slurry flows out under the condition that no sealing wall is arranged is avoided, the filling close to back effect is good, strength is high, and technology implementation cost is low.

Owner:SHANDONG UNIV OF TECH

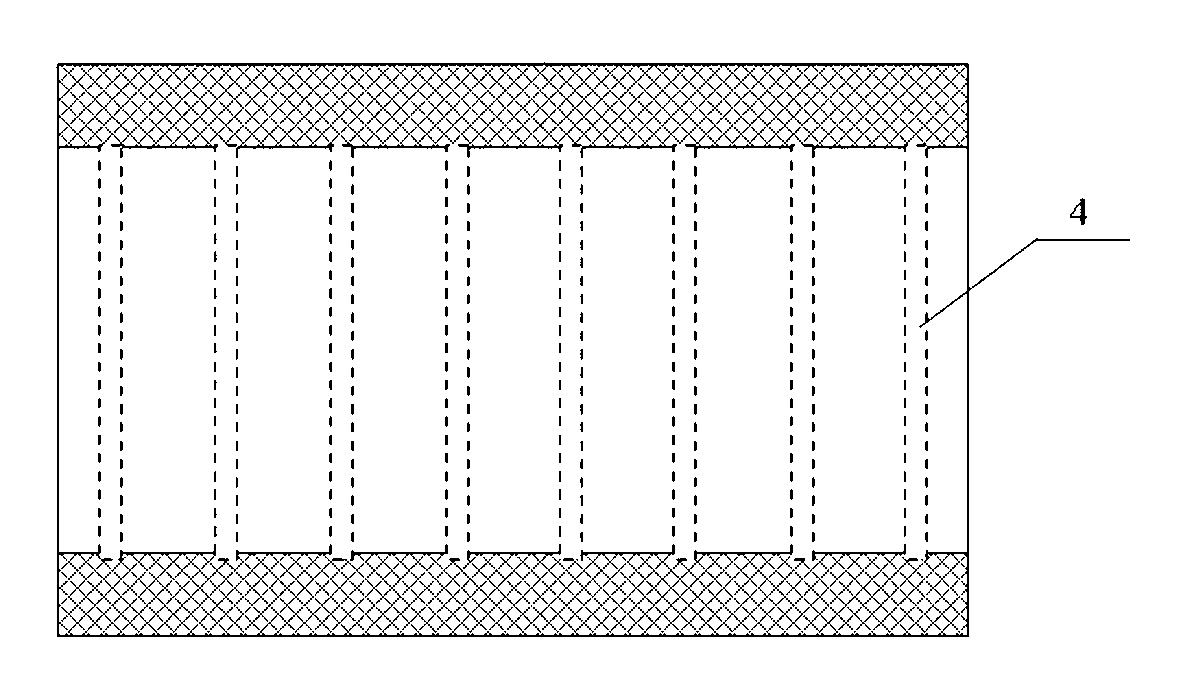

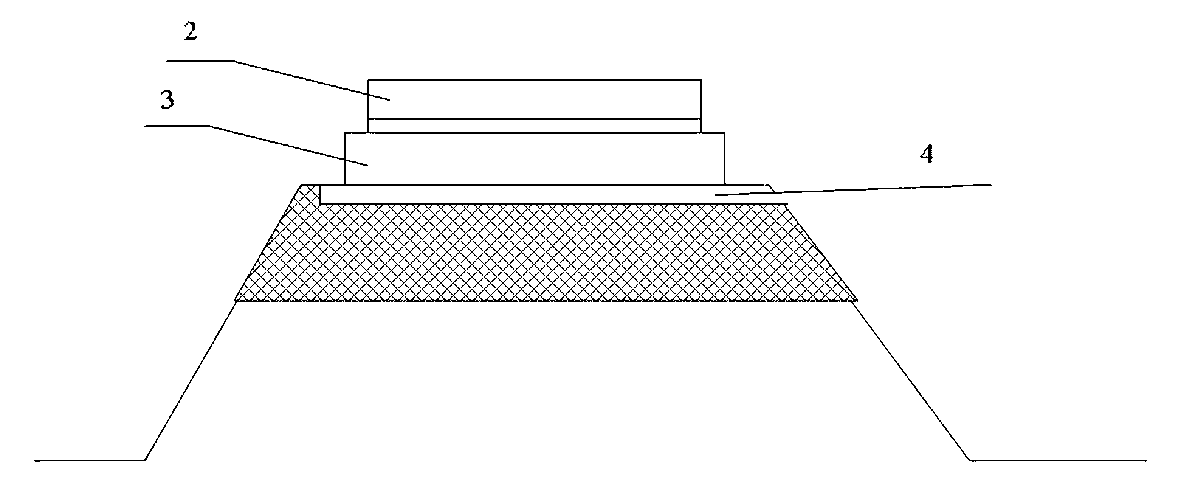

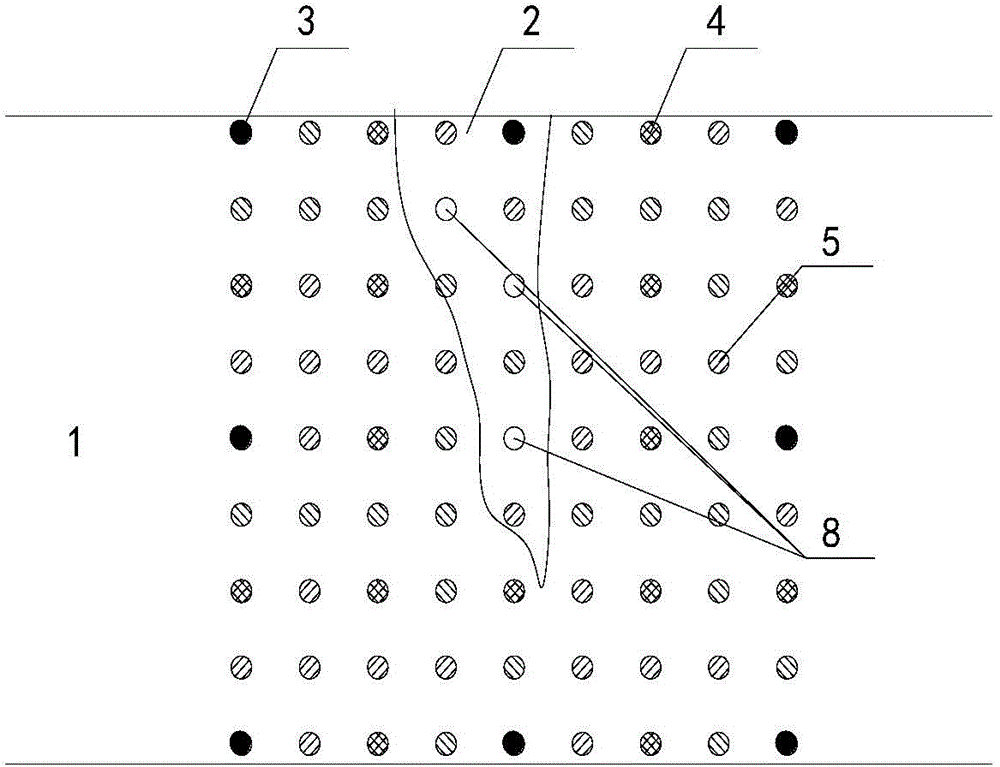

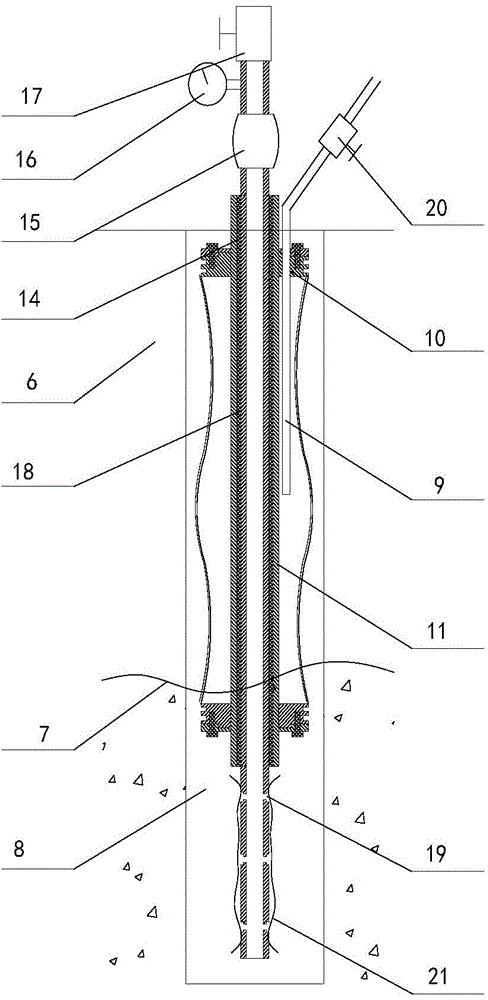

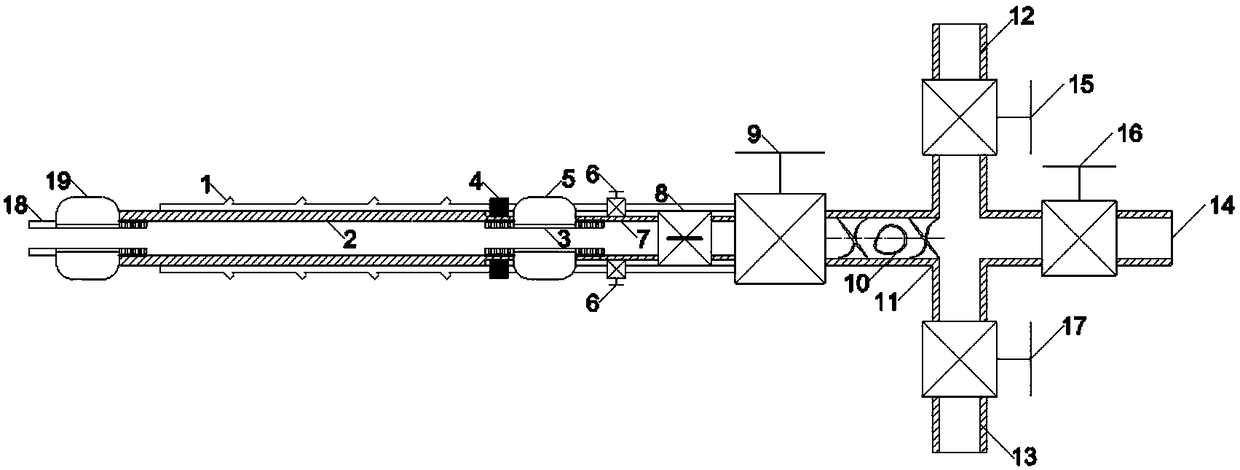

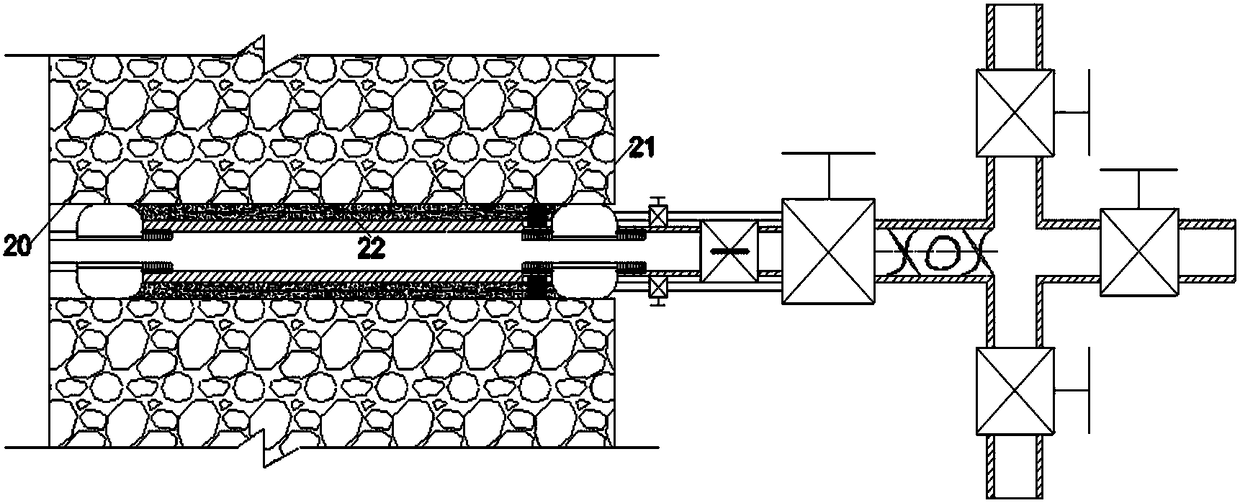

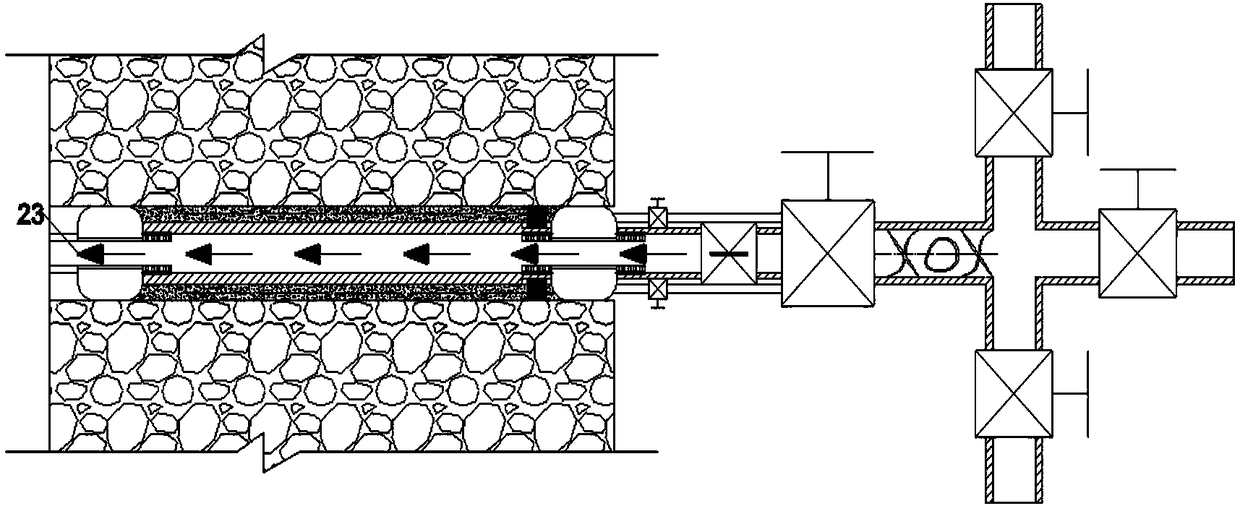

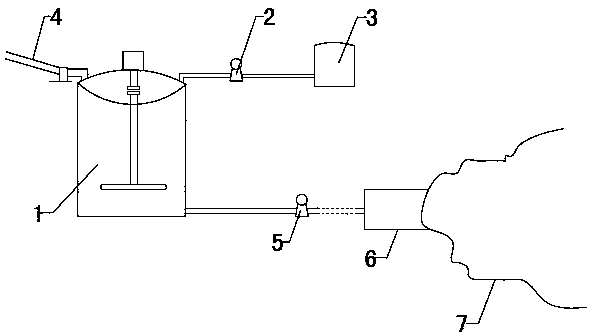

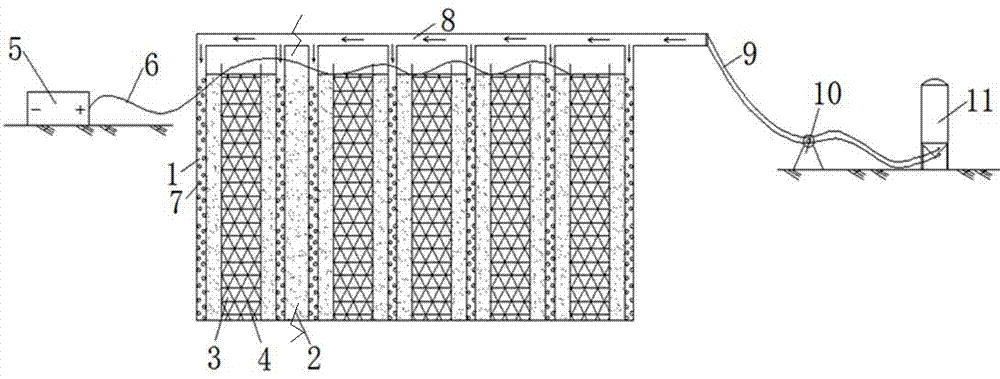

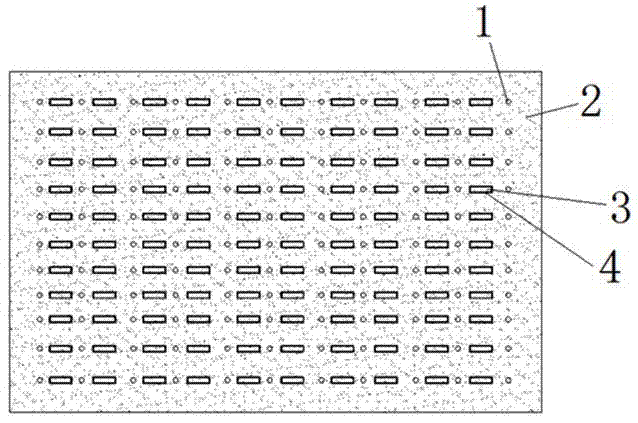

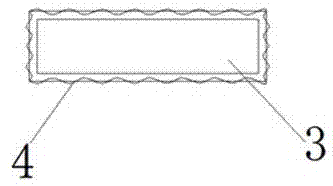

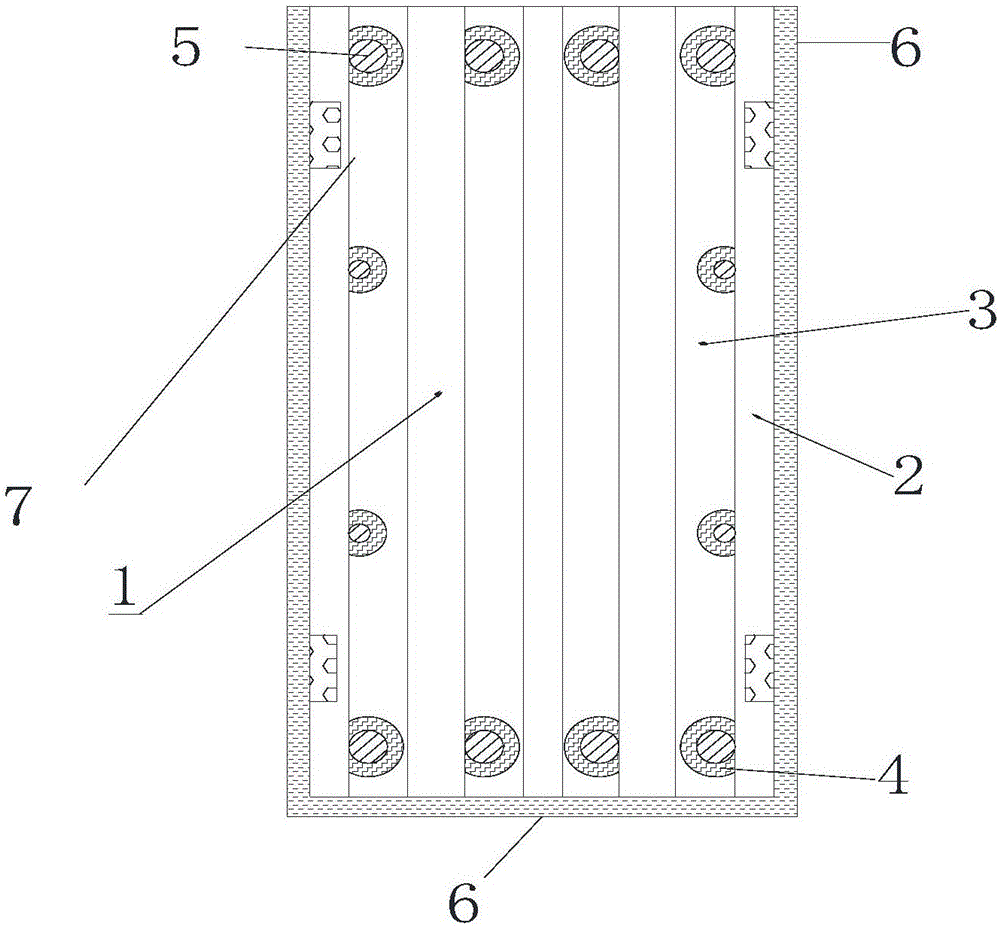

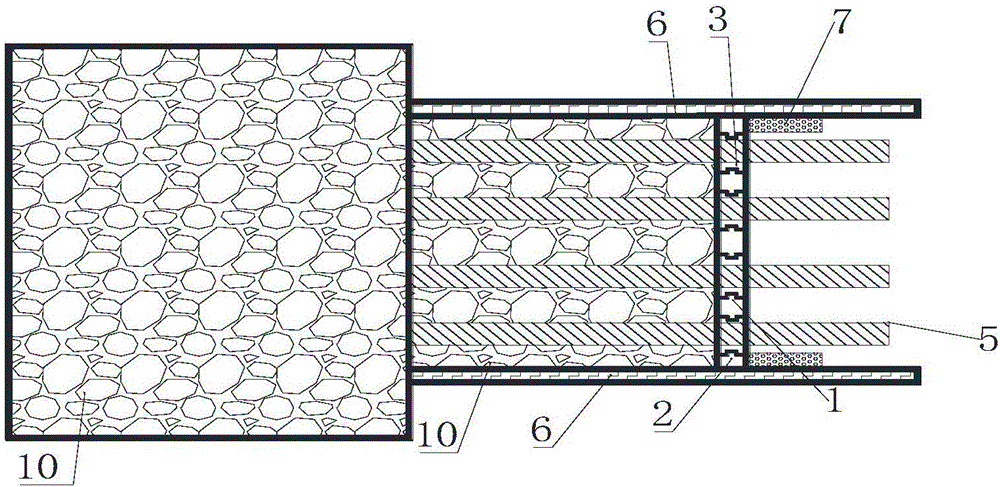

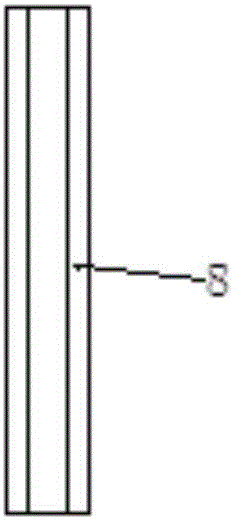

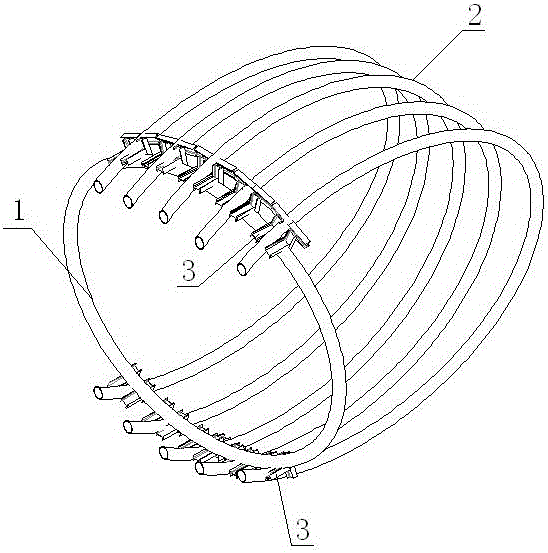

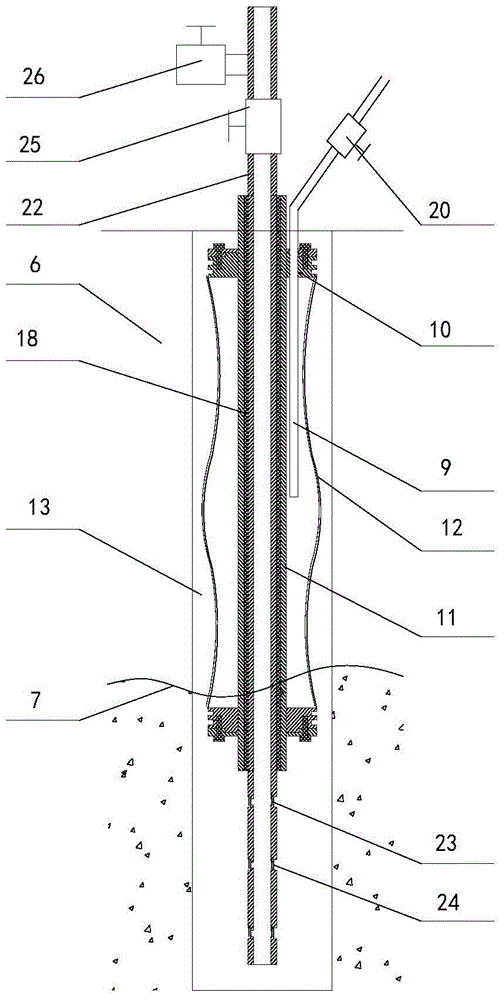

Sludge curing device and method combining vacuum grouting and resistance heating

PendingCN107882013AShorten the consolidation timeHigh strengthSoil preservationElectricityCarrying capacity

The invention discloses a sludge curing device combining vacuum grouting and resistance heating. The sludge curing device comprises a plurality of grouting pipes, water draining plates, a horizontal water draining pipe, resistance wires, a horizontal grout conveying guide pipe, a grout conveying hose, a grout conveying pump and a curing agent grout storage tank. A plurality of grout outlets are formed in each grouting pipe. The multiple grouting pipes communicate with the horizontal grout conveying guide pipe. One water draining plate is arranged between every two adjacent grouting pipes. Themultiple water draining plates communicate with the horizontal water draining pipe. The horizontal water draining pipe communicates with an external water draining pipe. The resistance wires are woundon the water draining plates and electrically connected with a power source arranged in an external power source control box. The horizontal grout conveying guide pipe sequentially communicates withthe grout conveying pump and the curing agent grout storage tank through the grout conveying hose. The invention also discloses a sludge curing method adopting the sludge curing device. The sludge curing method is suitable for shoal sludge for reclaiming land from the sea by building dykes, a shallow soft soil foundation or a deep soft soil foundation, improves the curing degree of the sludge, shortens the curing time and enables the cured sludge to have certain bearing capacity.

Owner:广东赣鸿建设有限公司

Sleeve valve pipe grouting method after boulder blasting treatment

InactiveCN110685716AGood grouting qualityImprove reinforcement effectUnderground chambersTunnel liningSleeve valveStructural engineering

The invention discloses a sleeve valve pipe grouting method after boulder blasting treatment. The method comprises the steps of hole distribution and drilling, closing mud replacement, sleeve valve pipe mounting, sleeve shell material replacement and grouting construction; holes are drilled at intervals for grouting; the hole drilling and grouting operations are performed in sequence; grouting sections are arranged in multiple areas for grouting; the mud mixing, the mud runout, the pipe clamping and the pipe blockage can be effectively prevented in the grouting process; and gaps of the grouting sections are determined according to the scene time conditions, so that the parallel operation is facilitated, and the grouting progress is accelerated.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Construction method for plugging construction joint of frame beam

The invention discloses a construction method for plugging a construction joint of a frame beam. The construction method comprises the following steps: mounting a u-shaped frame beam formwork at the construction joint; mounting positioning baffle blocks at upper and lower parts of the inner sides of the front ends of two vertical plates of the frame beam formwork respectively; mounting a plurality of longitudinal through beam steel bars inside the frame beam formwork; through occlusion of grooves for plugging steel frameworks and lug bosses for connecting steel frameworks and end steel frameworks, forming a combined framework, wherein the combined framework and the frame beam formwork are equal in height; adjusting the combined framework so as to tightly press the combined framework against the positioning baffle blocks. A frame beam concrete structure built with the construction method is compact inside and smooth outside, and slag inclusion, a pitted surface and grout runout of concrete are avoided; meanwhile, the jointing quality of concrete poured in the first time and concrete poured in the second time is good, the steel frameworks are overturned for many times and are conveniently mounted and dismounted, and the construction method has the characteristics of environment friendliness, energy conservation, economy and practicality.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

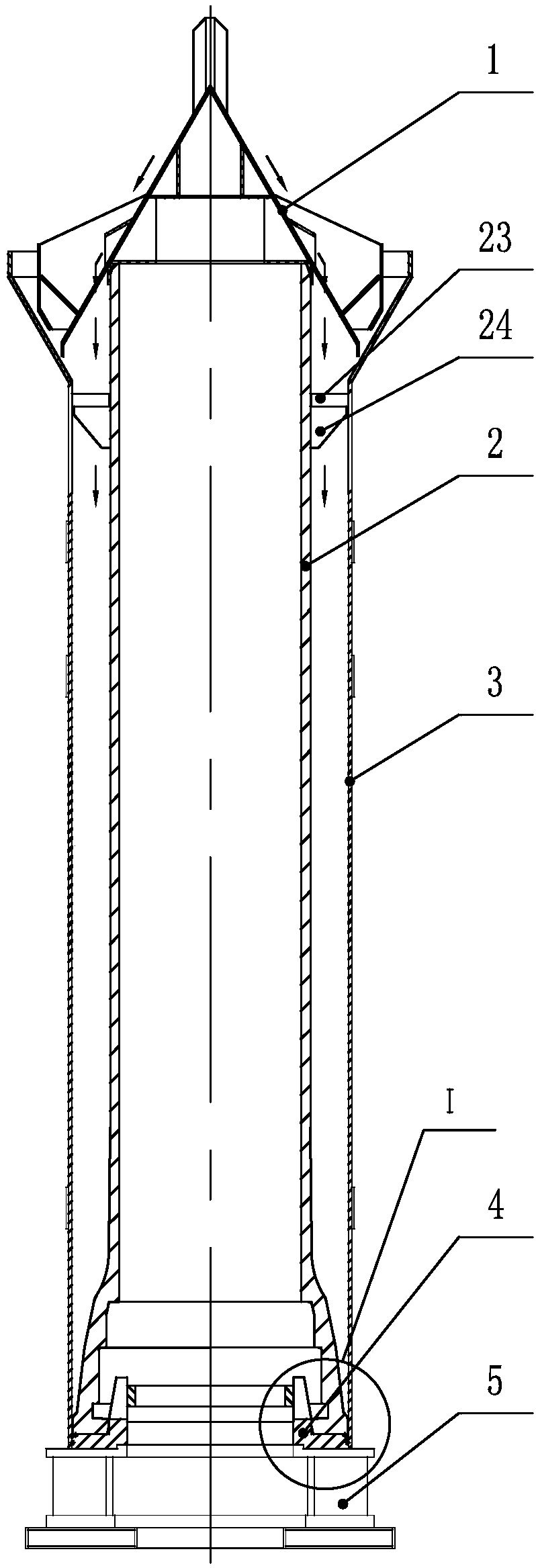

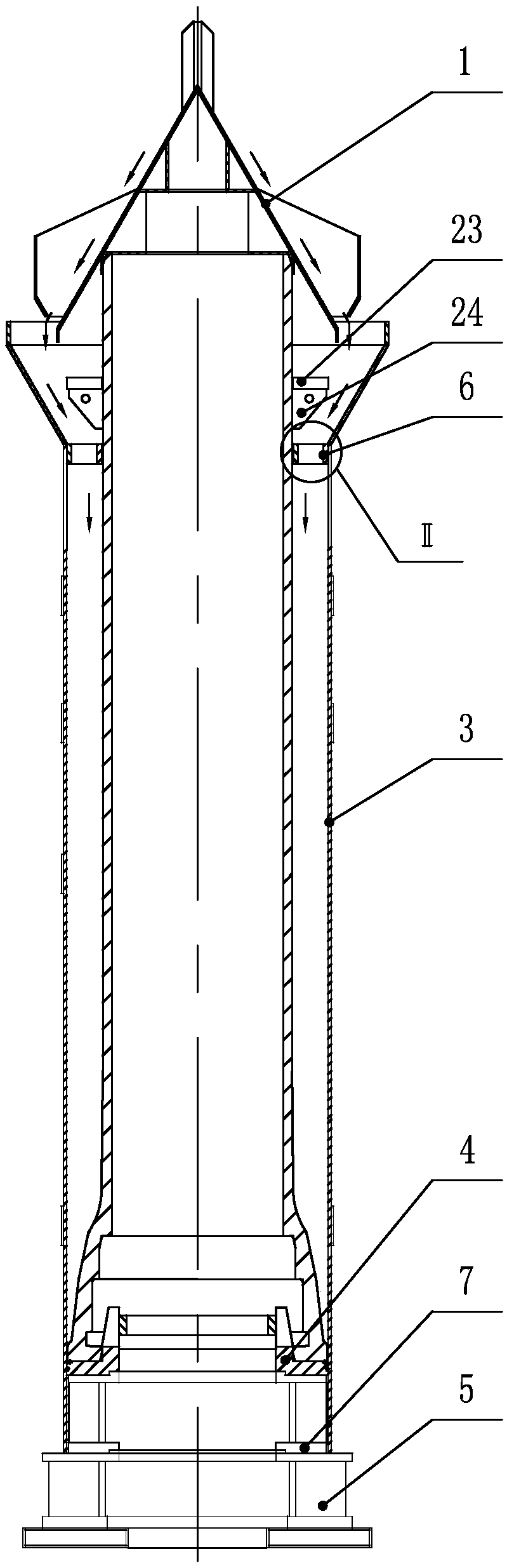

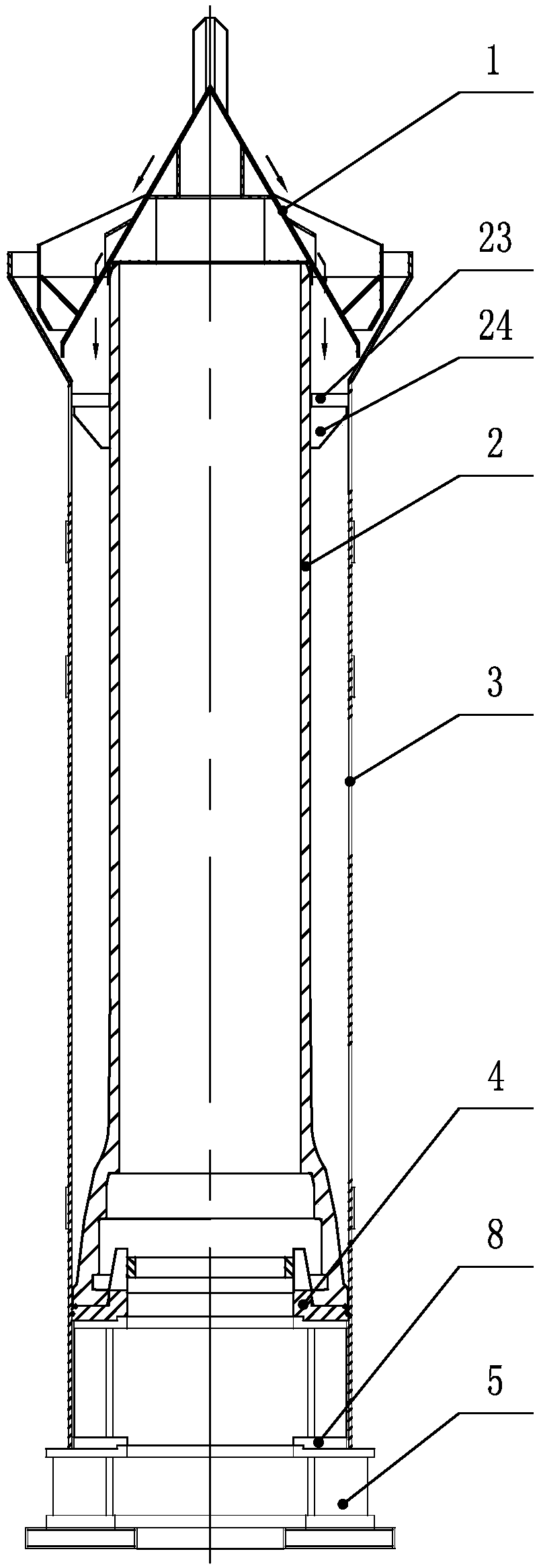

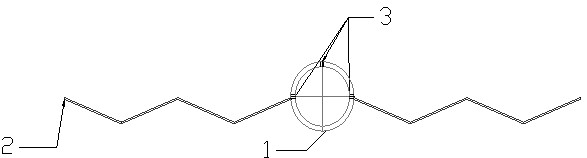

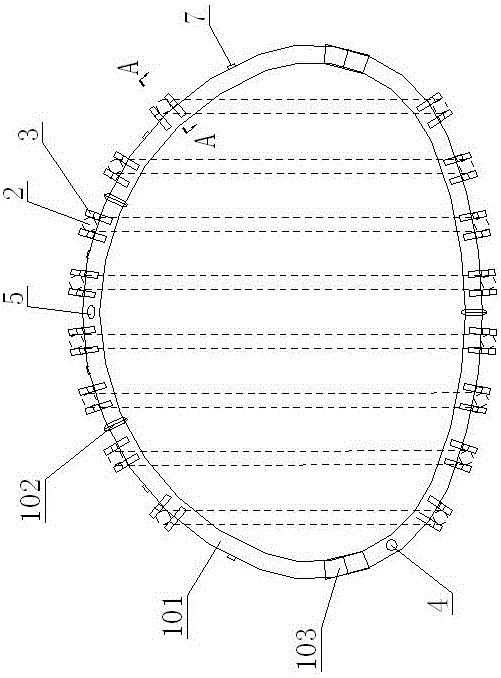

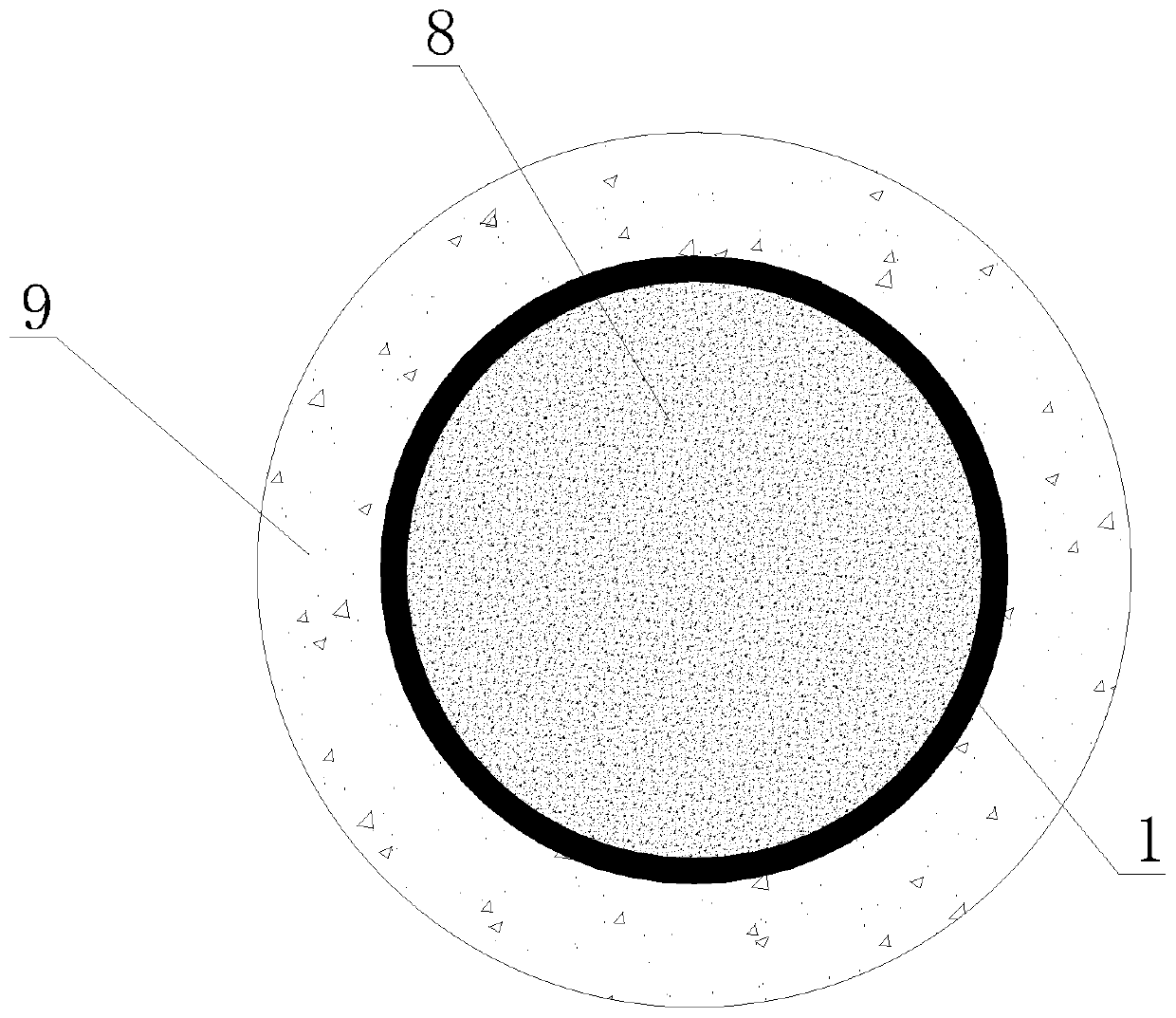

Pouring tool for a nodular cast iron jacking pipe and working method thereof

ActiveCN108638317AGuaranteed concentricityUniform feedingSurface layering apparatusEngineeringDuctile iron

The invention discloses a pouring tool for a nodular cast iron jacking pipe and a working method thereof. The pouring tool comprises a trepanning blanking cone, a flexible external die, a movable bottom die and a fixed bottom die sequentially arranged from top to bottom, wherein the lower part of the fixed bottom die is fixed with the ground; the upper part of the fixed bottom die is fixedly connected with the movable bottom die; the flexible external die is mounted on the outer side of the upper part of the fixed bottom die; the lower part of the movable bottom die is fixedly connected with the fixed bottom die; and the nodular cast iron jacking pipe is mounted at the upper part of the movable bottom die and is composed of a nodular cast iron jacking pipe inserting opening, a nodular castiron jacking pipe bellmouth, a pushing flange, a flange rib plate and a pipe body. The pouring tool is convenient to assemble and facilitates reduction of labor intensity; through overlapped matchingof support rings, manufacture of outer wrapped concrete of the nodular cast iron jacking pipes with different lengths is realized and pouring of the flange with a long slotted hole or without a longslotted hole can be realized.

Owner:XINXING DUCTILE IRON PIPES CO LTD

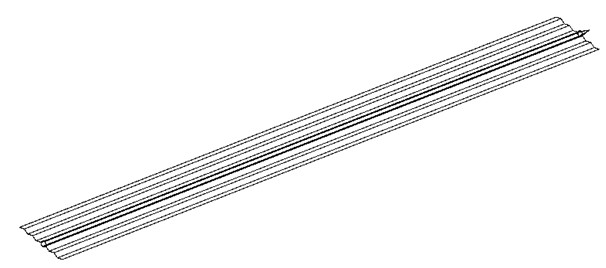

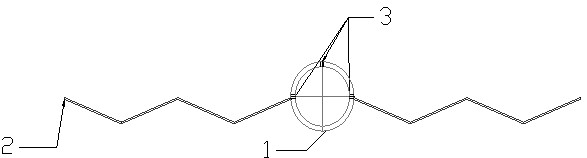

Wing plate type advanced small pipe used for advance support of soft broken surrounding rock tunnel

ActiveCN102619537ALarge diffusion radiusImprove the strength of surrounding rockUnderground chambersTunnel liningRock tunnelSlurry flow

The invention discloses a wing plate advanced small pipe used for advance support of a soft broken surrounding rock tunnel, which comprises small pipes with grouting holes, and both sides of each small pipe are provided with wing plates. The small pipes are pressed into the front broken surrounding rocks at certain inclination angle through a jack or a drill, and the small pipes are buckled together to form a curtain structure during pressing. Slurry is injected into the small pipes, the slurry flows into slots in the wing plates through holes on the pipe walls and is injected into the front surrounding rock cracks along the slots, so that the broken rock bodies are connected into a whole, and the stability of the surrounding rocks is maintained. The wing plate advanced small pipe has easiness in maintenance, high slurry utilization rate and high load bearing, the advance support of loose broken surrounding rocks is truly realized, and the collapse rate of surrounding rocks of a tunnel is greatly reduced. The wing plate advanced small pipe can be machined outside the site and then transported to the site, so that time and labor are saved. Meanwhile, the plate insertion method and the ordinary advanced small pipe are combined to form the wing plate advanced small pipe, so that sufficient supporting counter force can be implemented to the surrounding rocks.

Owner:SHANDONG UNIV

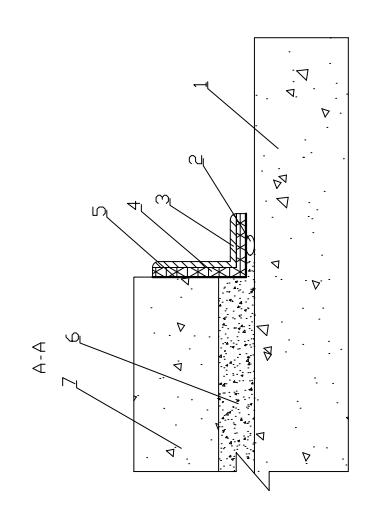

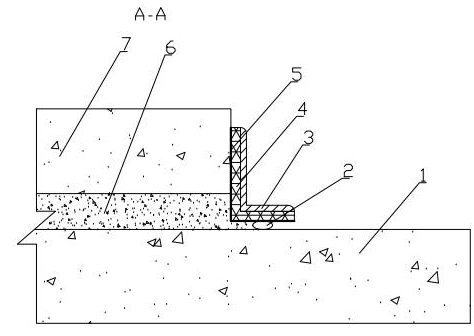

Construction method for prefabricating pipe galleries

ActiveCN106759478AHigh speedImprove securityArtificial islandsUnderwater structuresStructural waterArchitectural engineering

The invention discloses a construction method for prefabricating pipe galleries. The method comprises the following steps: (1) carrying out construction for prefabricating parts by prefabricating an outer side wall, a top plate and a bottom plate, and arranging connection parts at the upper end and the lower end of the outer side wall, the left end and the right end of the top plate and the left end and the right end of the bottom plate respectively; (2) assembling the prefabricated parts by firstly hoisting the bottom plate, then hoisting the outer side wall, then mutually fixing the connection part at the lower end of the outer side wall with the corresponding connection part on the bottom plate, then mounting a die frame device, finally hoisting the top plate and mutually fixing the connection part at the upper end of the outer side wall with the corresponding connection part on the top plate; and (3) pouring in site and forming by pouring concrete on the inner surface of the outer side wall and the outer surface of the top plate. Through the construction method for prefabricating the pipe galleries, the pipe galleries are constructed by a manner with combination of prefabrication and in-site pouring; the method is simple to operate, rapid in speed and high in safety coefficient; the overall speed is far higher than that of the overall prefabrication and hoisting method; the good structural water prevention effect is achieved; the problem of water prevention is effectively solved.

Owner:CHINA COAL NO 3 CONSTR GRP

Prevention and control method of water inrush in coal mining floor stratum on confined water body

InactiveCN103291325BSolve the problem of low pulp intakeSolve the problem of water inrushUnderground chambersTunnel liningDrill siteEngineering

The invention relates to a method for preventing and controlling water burst of a coal mining base board rock stratum, in particular to a method for preventing and controlling water burst of a coal mining base board rack stratum on a pressure bearing water body. The method comprises the following steps that firstly, a coalface is detected; secondly, drill sites are exploited at the two sides of a lead conveying smooth groove and the two sides of a air returning smooth groove respectively so as to perform drilling according to a detected result in the first step; thirdly, slurry filling casing pipes are arranged at drilling openings of lower three belts of the coal layer base board, and a freezing casing pipe is arranged at the bottommost layer section; fourthly, after drilling is finished, slurry is filled into drill holes, the slurry is sequentially filled, starting from the bottom end and going upwards layer by layer, before the slurry is filled into the bottommost layer and in the slurry filling process, liquid nitrogen is used for performing quick-freezing treatment. According to the method for preventing and controlling water burst of the coal mining base board rack stratum on the pressure bearing water body, the principle that the procedures of detection, slurry filling, freezing and digging are sequentially performed is utilized, slurry filling and freezing are respectively performed on the lower three belts sequentially from bottom to top layer by layer, and therefore water disasters in the excavating process of a deep coal layer base board of a complex geological structure can be effectively prevented from happening.

Owner:SHANDONG UNIV OF SCI & TECH

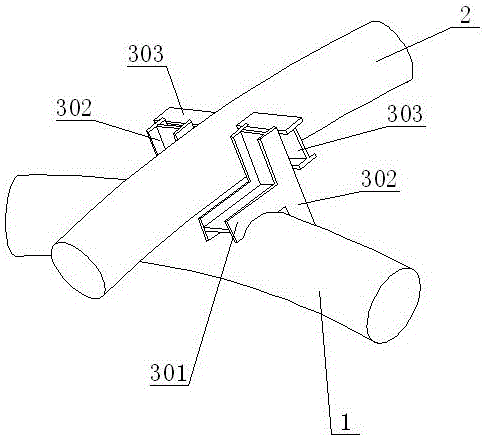

Steel pipe and concrete combined bracket used for roadway junction

ActiveCN106593486AReasonable structural designImprove bearing capacityUnderground chambersTunnel liningButt jointSteel tube

The invention relates to a steel pipe and concrete combined bracket used for a roadway junction. The steel pipe and concrete combined bracket comprises a bracket body which is provided with erecting racks connected with the bracket body through butt joint devices. The steel pipe and concrete combined bracket is reasonable in design, high in bearing capacity, easy to construct, low in subsequent repair rate, high in cost performance and capable of being applied to the deep soft rock roadway junction.

Owner:SHANDONG JIANZHU UNIV

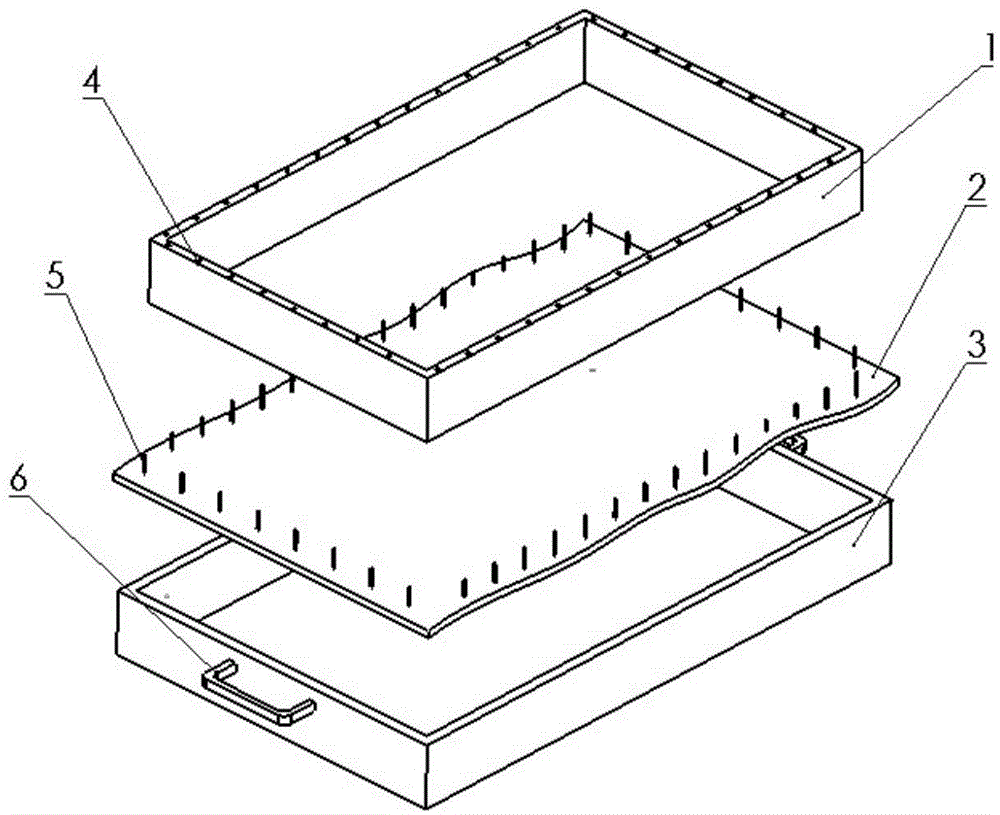

Foam cement pouring die

InactiveCN104441212ALess investmentSimple structureMould separation apparatusMouldsEngineeringCushion

The invention provides a foam cement pouring die. The foam cement pouring die comprises an inner frame, a cloth cushion and an outer frame, wherein both the inner frame and the outer frame are rectangular, the outer wall of the inner frame is matched with the inner wall of the outer frame, the cloth cushion is made of artificial leather, a heat-resistant coating is arranged on the upper end face of the cloth cushion, the cloth cushion is flat laid in the outer frame and is arranged on the borders of the outer frame partially, the inner frame is arranged on the heat-resistant coating, a plurality of pin holes are formed in the borders of the inner frame, a plurality of pins which are matched with the pin holes are evenly arranged on the edges of the upper end face of the cloth cushion, each pin hole corresponds to one pin, and two handles are symmetrically arranged at the two ends of the outer frame. The foam cement pouring die has the outstanding advantages that the design structure is simple, the pins are pressed in the pin holes before foam cement is poured, so that the cloth cushion is fixed and is tightly combined with the bottom surface of the inner frame, using is convenient, and investment of the die is greatly reduced.

Owner:TIANJIN TAIJIN TECH DEV CO LTD

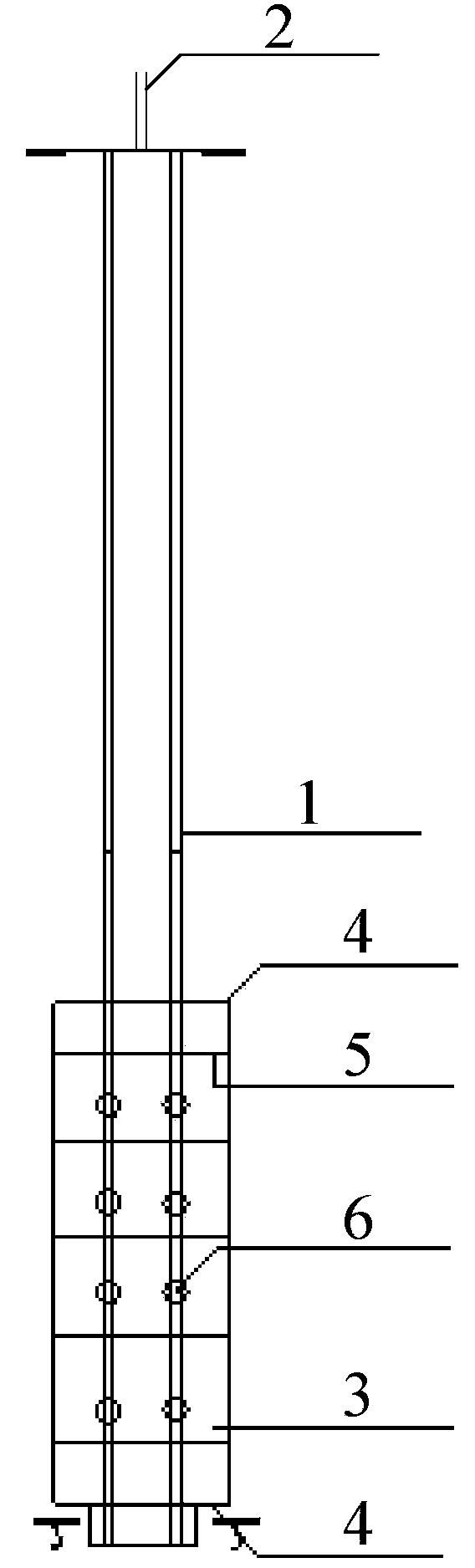

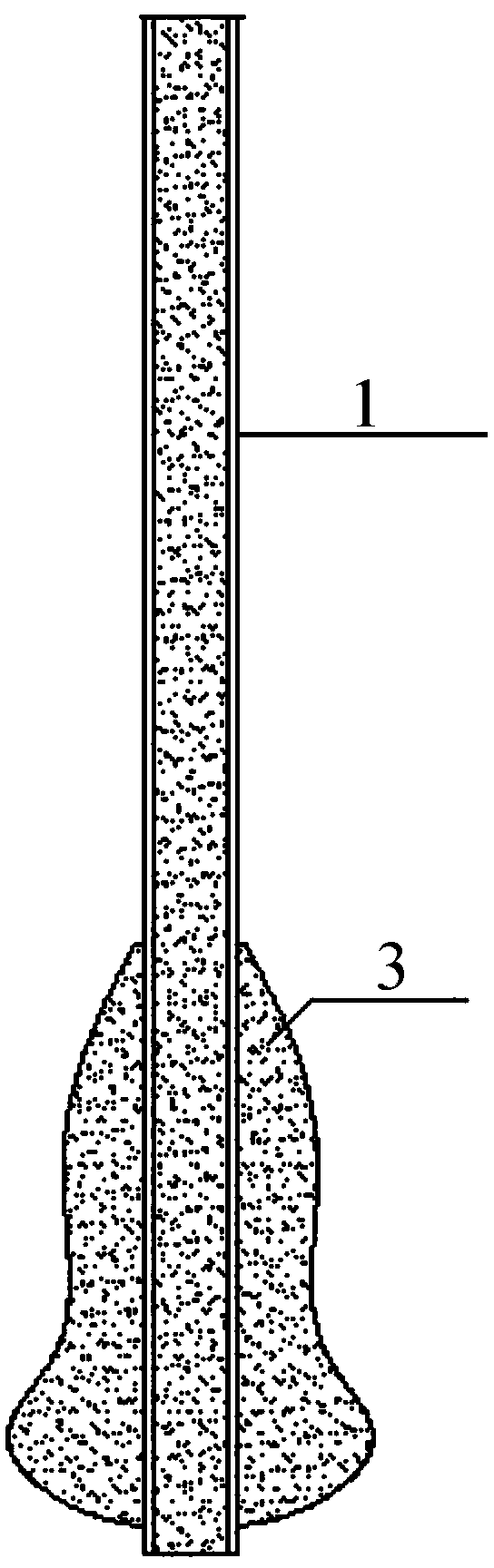

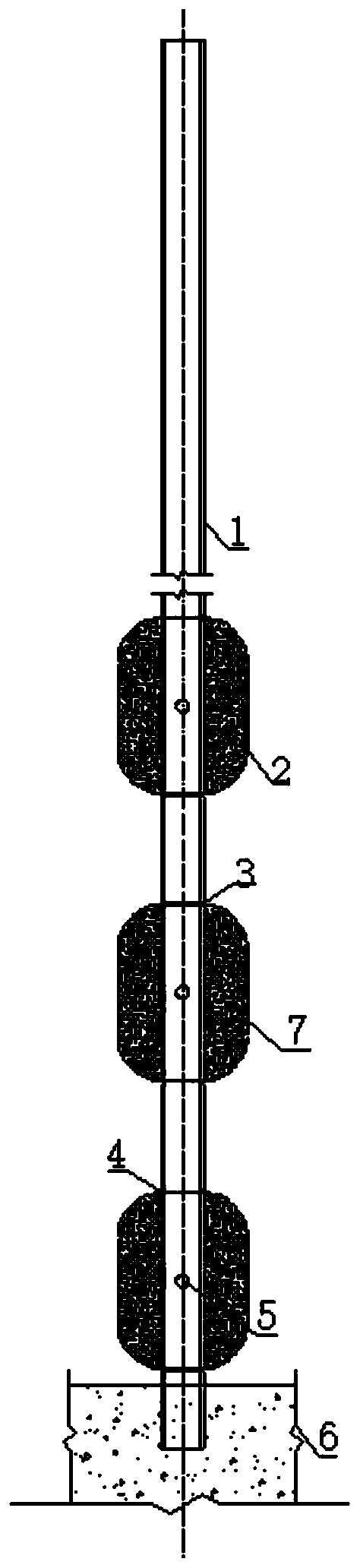

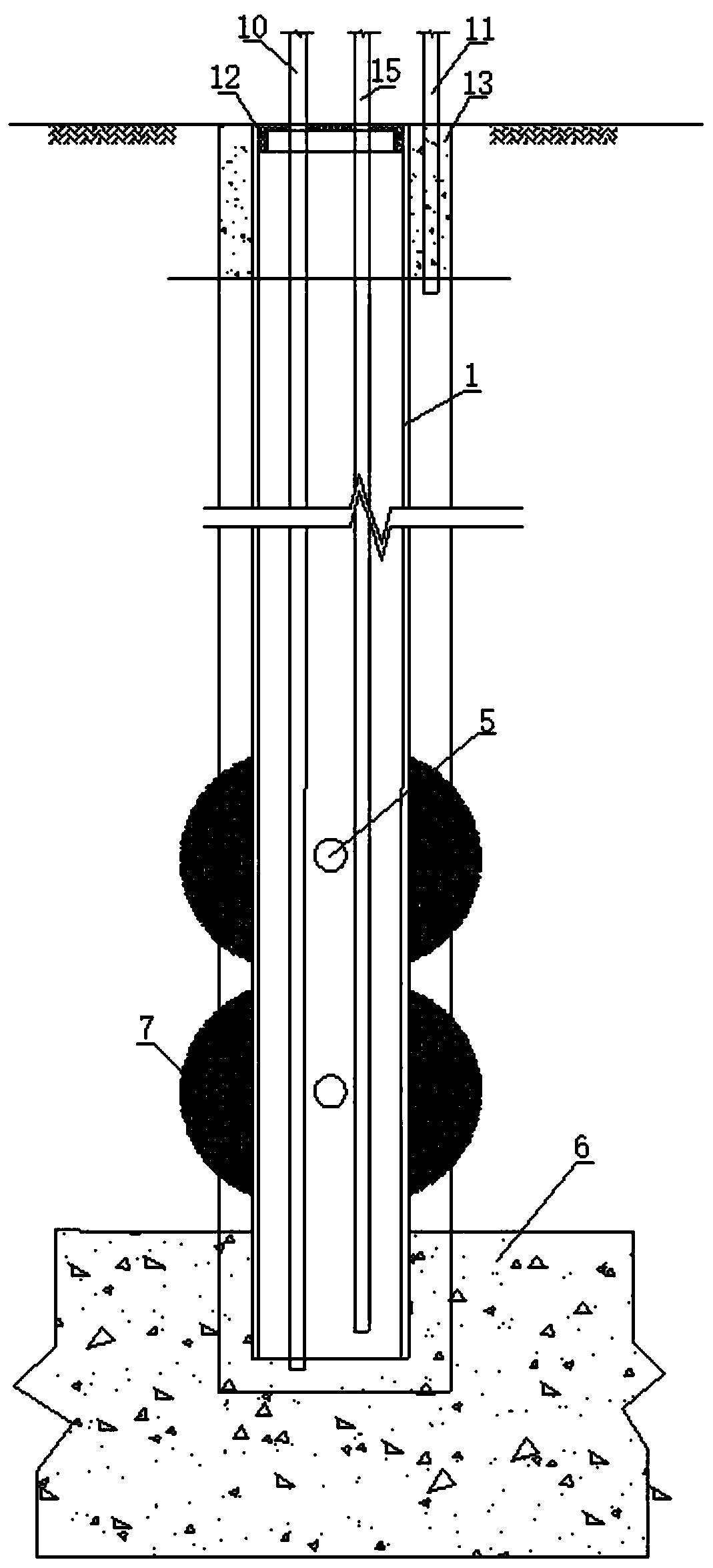

Steel tube miniature pile and construction method thereof

The invention provides a steel tube miniature pile. The steel tube miniature pile comprises a steel tube, an inner slurry layer located inside the steel tube and an outer slurry layer located outsidethe steel tube, and the steel tube comprises an ordinary steel tube segment, an anchoring segment and a fixed end which are connected successively from top to bottom; the anchoring segment is providedwith a grouting hole and a clamping throat for assembling a rubber film, the rubber film sleeves the outer wall of the grouting hole and is used for sealing the grouting hole, and the rubber film isfilled with cement slurry to form an convex structure; and the fixed end is arranged at the lowermost end of the steel tube and used for embedding into a stratum. The invention further provides a specific construction method of the steel tube miniature pile. According to the construction method of the steel tube miniature pile, the situation that grouting slurry in the steel tube does not flow outcan be guaranteed, the problem of slurry runout at the bottom of the pile is solved, the grouting amount is controllable, and the grouting cost is lowered; and meanwhile, friction resistance of the side wall of a pile body can be increased, and the overall compression resistant, anti-pull and axial load resistant capacity of the steel tube miniature pile is improved.

Owner:CENT SOUTH UNIV

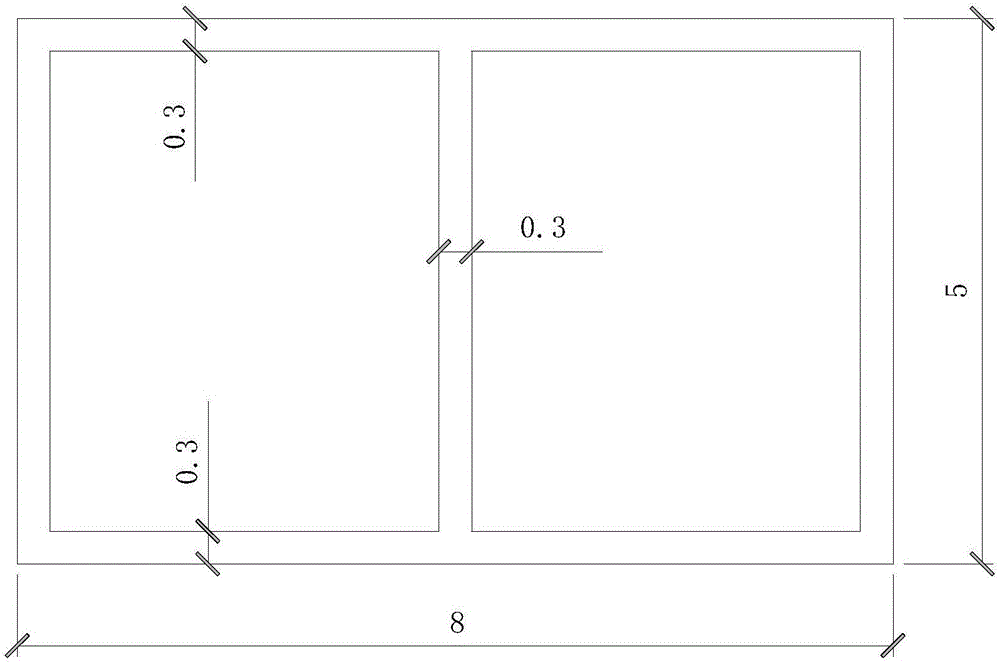

Building deformation joint concrete double-wall synchronous pouring construction method

InactiveCN106320542AShorten the intervalSpeed upForms/shuttering/falseworksBuilding material handlingDouble wallRebar

The invention is mainly applied to the technical field of building construction and particularly relates to a building deformation joint concrete double-wall synchronous pouring construction method. The method mainly comprises the following steps that firstly, a deformation joint main steel formwork and a deformation joint auxiliary steel formwork are manufactured; secondly, the deformation joint auxiliary steel formwork is hoisted and installed; thirdly, the deformation joint main steel formwork is hoisted and installed; fourthly, the deformation joint main steel formwork and the deformation joint auxiliary steel formwork are corrected and installed; fifthly, full-thread split bolts penetrate in sequence along the deformation joint main steel formwork and the deformation joint auxiliary steel formwork; sixthly, on the sides, to be poured, of deformation joint double walls, PVC bolt casing pipes are arranged on the full-thread split bolts in a sleeving mode; seventhly, deformation joint double-wall steel bars are bound; eighthly, the deformation joint main steel formwork and the deformation joint auxiliary steel formwork are fastened; ninthly, the double walls are poured; tenthly, the deformation joint main steel formwork and the deformation joint auxiliary steel formwork are demounted. The building deformation joint concrete double-wall synchronous pouring construction method is easy and convenient to implement and efficient; materials are saved, multiple times of using can be achieved through one-time processing, and formworks and resources are saved; the quality is high, the steel formworks are used for replacing original wood formworks, extruded joint mortar is avoided, and environment protection is promoted.

Owner:SHANDONG GOLDENCITY CONSTR

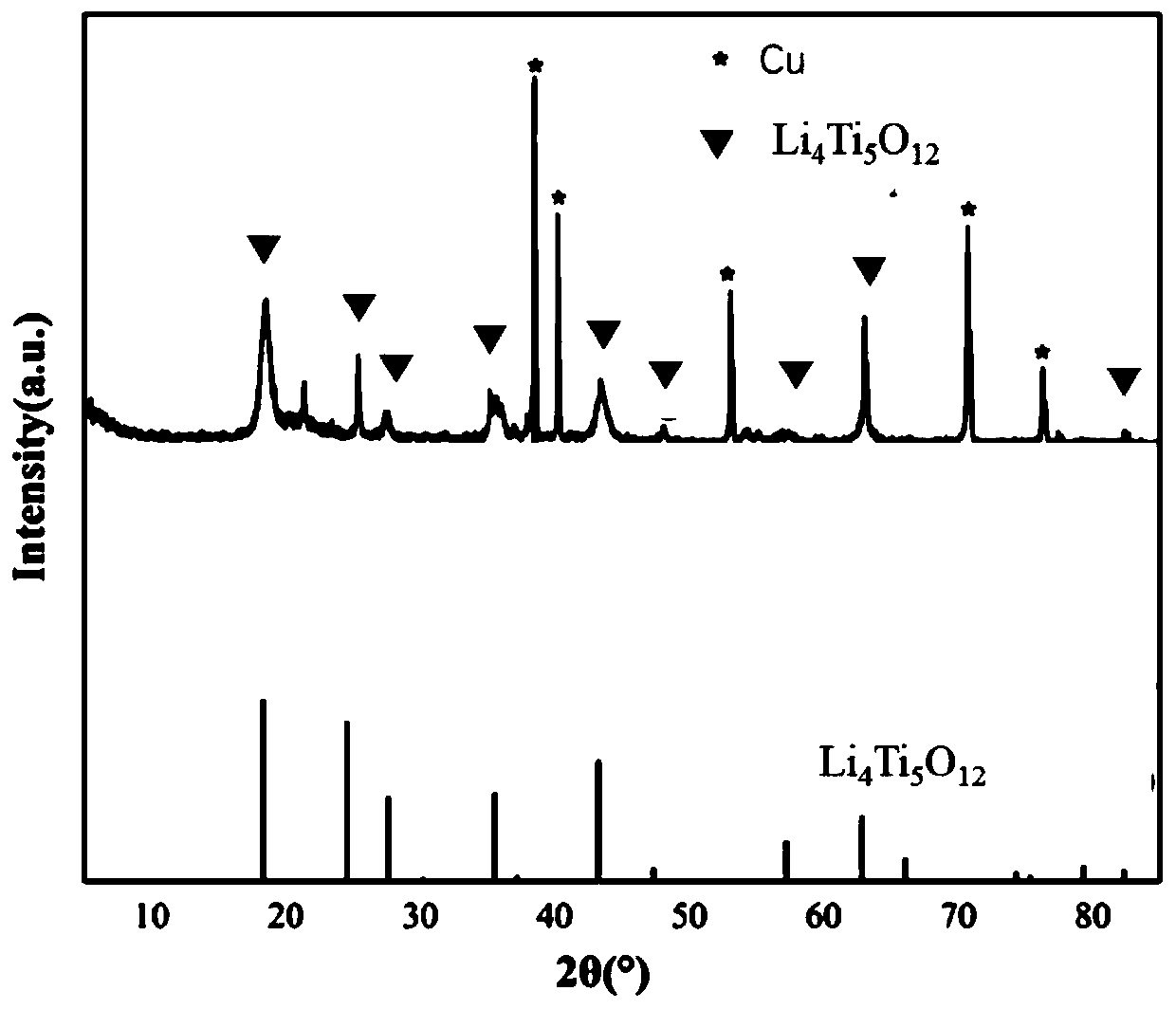

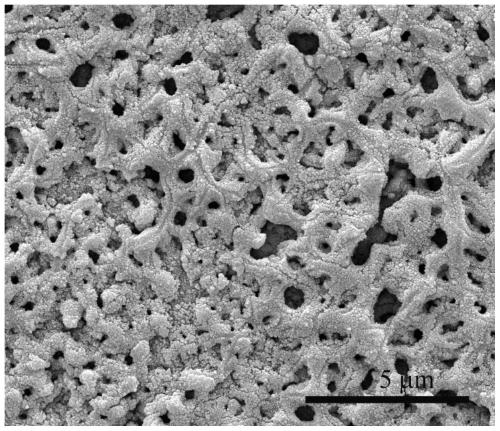

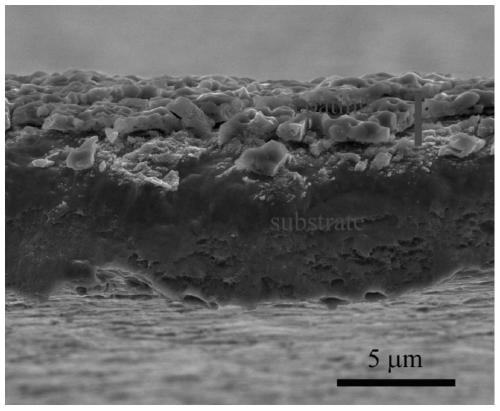

Method for preparing three-dimensional porous carbon-doped lithium titanate coating on surface of copper foil

ActiveCN111370676APromote infiltrationReduce manufacturing costSecondary cellsNegative electrodesElectrolytic agentPorous carbon

The invention discloses a method for preparing a three-dimensional porous carbon-doped lithium titanate coating on the surface of a copper foil, and belongs to the field of lithium ion battery negative electrode preparation. The method comprises the following steps: 1) dispersing a titanium source and lithium hydroxide in deionized water to obtain a mixed solution A; 2) dispersing a macromolecularcarbon source into absolute ethyl alcohol to obtain a mixed solution B; 3) mixing the mixed solution B and the mixed solution A to obtain a mixed solution C; 4) putting the mixed solution C into a stainless steel tank body; taking a copper foil as an anode and a stainless steel tank body as a cathode, supplying power by adopting a liquid-phase plasma oxidation power supply, and oxidizing for 3-8minutes under the conditions that the pulse voltage is 700V-900V and the frequency is 60Hz-1000Hz, thereby forming the three-dimensional porous carbon-doped lithium titanate composite coating on the surface of the copper foil. The carbon-doped lithium titanate coating obtained by the invention has a three-dimensional porous structure, is beneficial to infiltration of electrolyte of the lithium ionbattery, and can reduce the resistance of diffusion and mass transfer.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

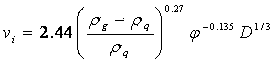

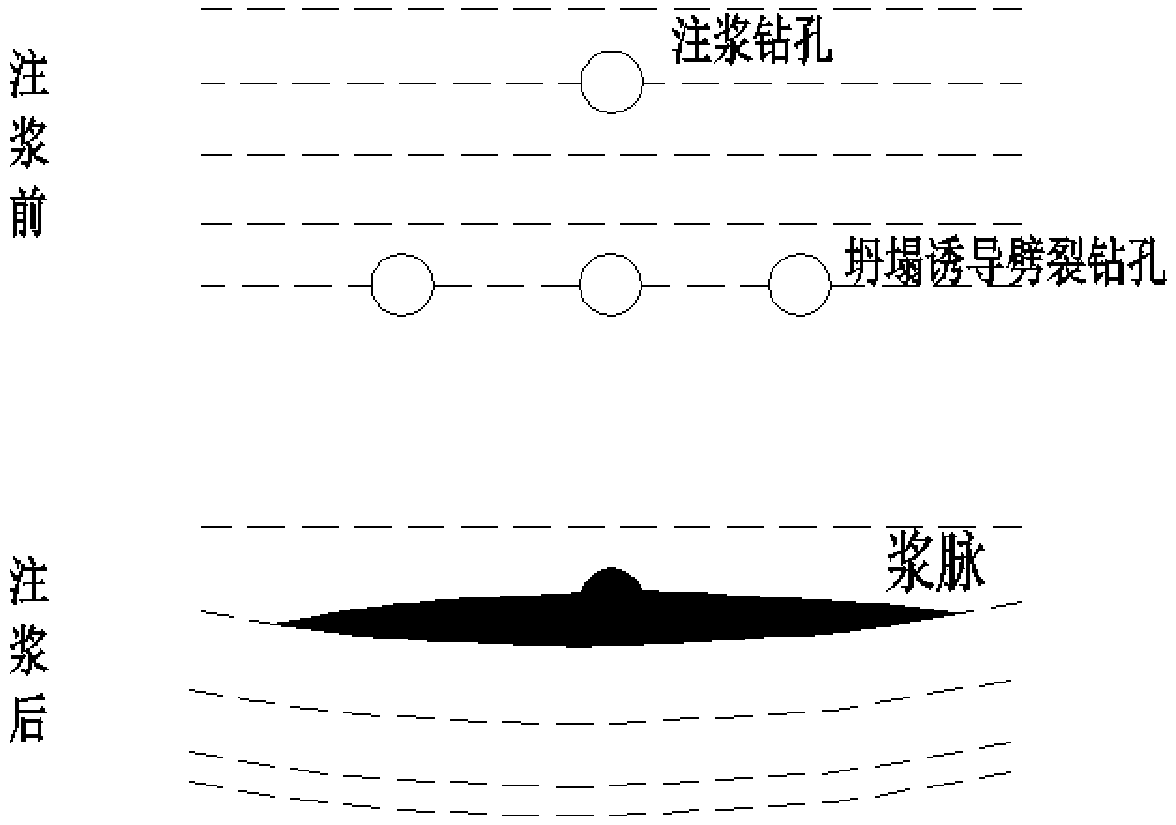

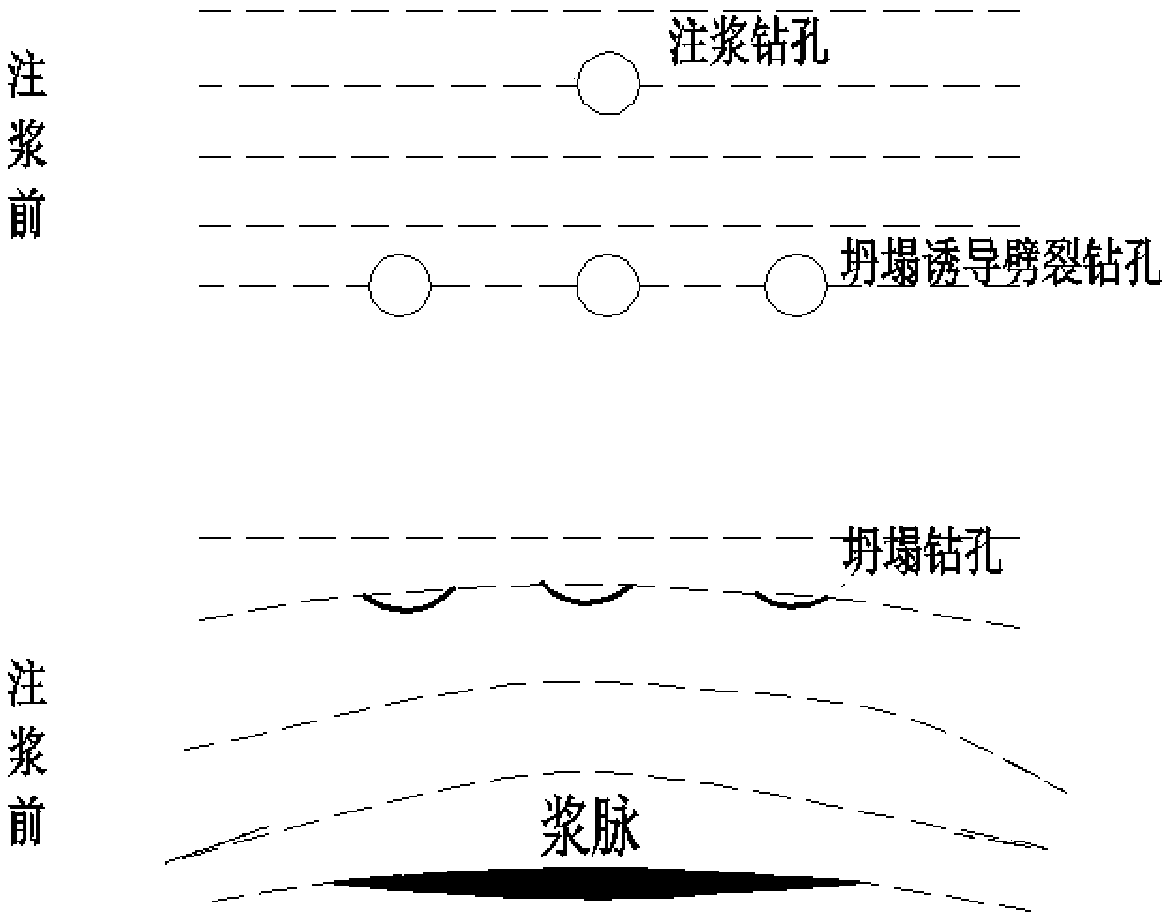

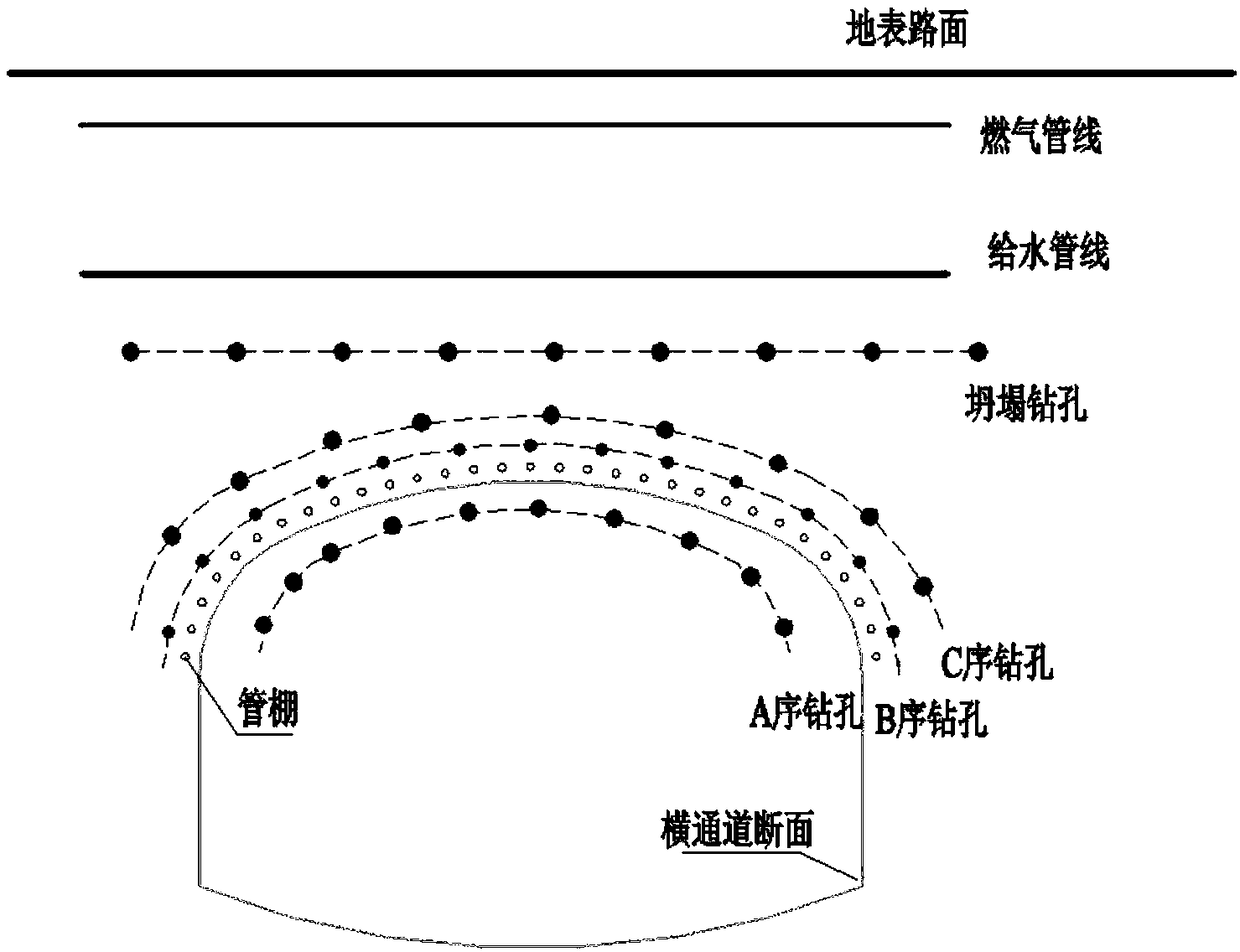

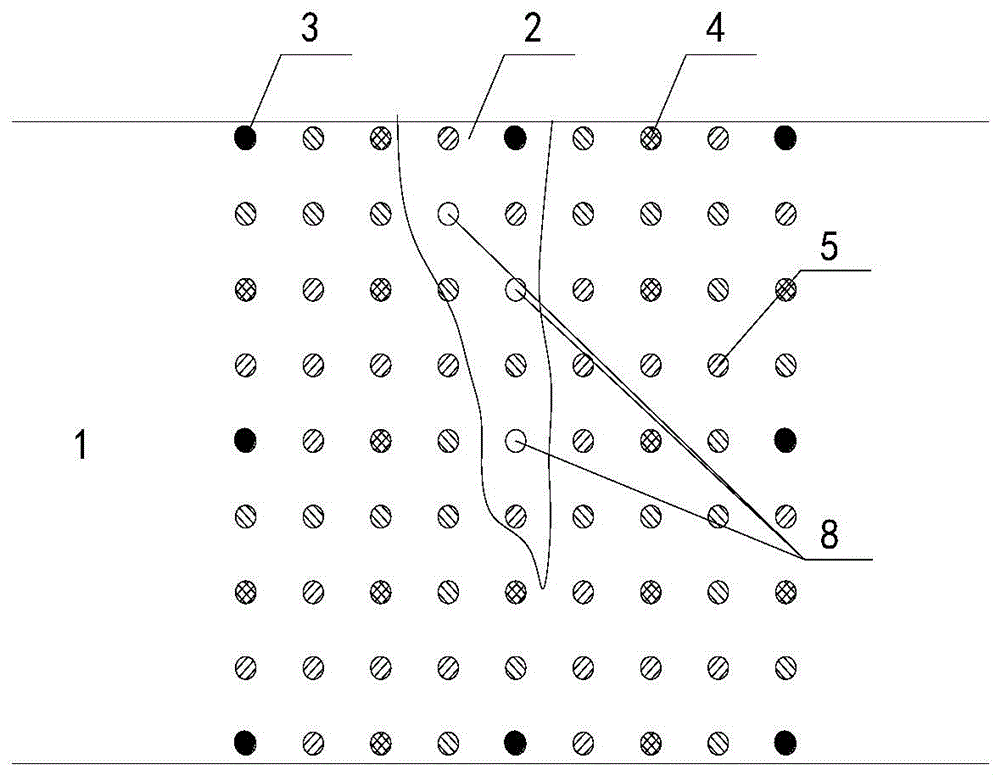

Sand-layer grouting ground surface uplifting control method based on drilling collapse and induced splitting

The invention provides a ground surface uplifting control method based on induced splitting and collapsing drilled holes. Aiming at advanced pre-grouting reinforcement of a transverse channel passingthrough a sand layer in subway engineering, the purposes of controlling the slurry direction and lowering ground surface uplift are achieved by distributing collapsing-induced-splitting drilled holesand the collapsing drilled holes. Through the induced-splitting drilled holes, the formation stress of a target reinforcement area is lowered, the slurry direction is controlled, and slurry runout ofthe ground surface is prevented; through the collapsing drilled holes, a formation uplift buffering area is created, and ground surface uplift is lowered; and the induced-splitting drilled holes and the collapsing drilled holes are matched with a pipe shed, thus the grouting effect can be ensured, and meanwhile, ground surface uplift can be effectively controlled.

Owner:SHANDONG UNIV OF SCI & TECH +3

Comprehensive grouting control method for water-rich broken rock mass under the condition of lack of effective slab

ActiveCN104453943BEffective transformationAvoid pulpingUnderground chambersSealing/packingSocial benefitsWater source

The invention discloses a method for controlling water-rich fractured rock mass comprehensive grouting under the effective sealing batholite shortage condition. The method includes the steps of comprehensively detecting a hazard-formation water source and a water guide channel, designing a sealing batholite refitting scheme and a grouting treatment scheme, refitting sealing batholite, controlling the grouting process and the safety, conducting draining, pressure relieving, drilling and blocking, comprehensively detecting the grouting effect, compensating a weak zone for slip casting and the like. After construction is conducted through the method, by refitting the sealing batholite, the problems that due to the shortage of the effective sealing batholite, sap loss and grout leakage occur in the grouting process and the grouting effect is not good are solved, the grouting efficiency is improved, and good social benefits and economic benefits are created.

Owner:SHANDONG UNIV OF SCI & TECH

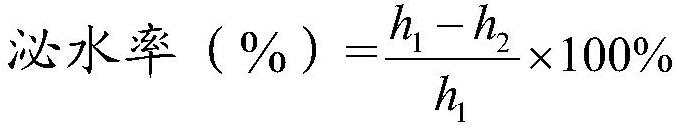

Water-dispersion-resistant grouting material for reinforcing water-rich stratum of subway tunnel and preparation method of water-dispersion-resistant grouting material

PendingCN114213081AImprove the immunityHigh viscosityUnderground chambersTunnel liningCelluloseSoil science

The invention discloses an anti-water-dispersion grouting material for reinforcing a water-rich stratum of a subway tunnel and a preparation method thereof. The grouting material comprises the following components in parts by mass: 250-280 parts of water, 290-320 parts of cement, 390-420 parts of medium-fine sand, 3-7 parts of hydroxyethyl cellulose ether and 20-50 parts of aluminum sulfate. The grouting material is good in fluidity, low in bleeding rate, excellent in water dispersion resistance and high in stability; the grouting agent is used for grouting a water-rich stratum of a subway tunnel, and can be quickly and fully injected and squeezed into cracks or gaps of the stratum; the concrete can be prevented from being dispersed by underground water in a water-rich stratum and can be quickly condensed to form a consolidated body; and the reinforcing effect on the water-rich stratum of the subway tunnel is good.

Owner:中国水利水电第七工程局成都水电建设工程有限公司 +1

Shrinkage compensating type high-performance mortar for grooving method closure grouting

The invention provides shrinkage compensating type high-performance mortar for grooving method closure grouting. The shrinkage compensating type high-performance mortar is characterized by being formed by compounding polymer gelatine powder, silica powder, a superfine micro-powder expanding agent, a high-performance water reducing agent, aggregate and a binding material through the processes of powder drying, dispersion machine pre-dispersion, fiber pre-mixing and vacuum sealing; the mortar is prepared from, by mass, 1.5-3% of polymer gelatine powder, 0.8-1.2% of silica powder, 1.25-2.5% of superfine micro-powder expanding agent, 0.10-0.14% of high-performance water reducing agent, 69-75% of aggregate and 12.5% of binding material (containing cement). The mortar has the advantages of good micro-expansibility, water retaining performance, waterproofness, easy binding and the like, and is suitable for grooving method chemical grouting construction on cracks and expansion joints, the surface of a dug dovetail-shaped groove is effectively closed, grout leakage and runout can be avoided, and grouting quality is improved.

Owner:WATER CONSERVANCY & HYDROPOWER SCI RES INST OF LIAONING PROVINCE

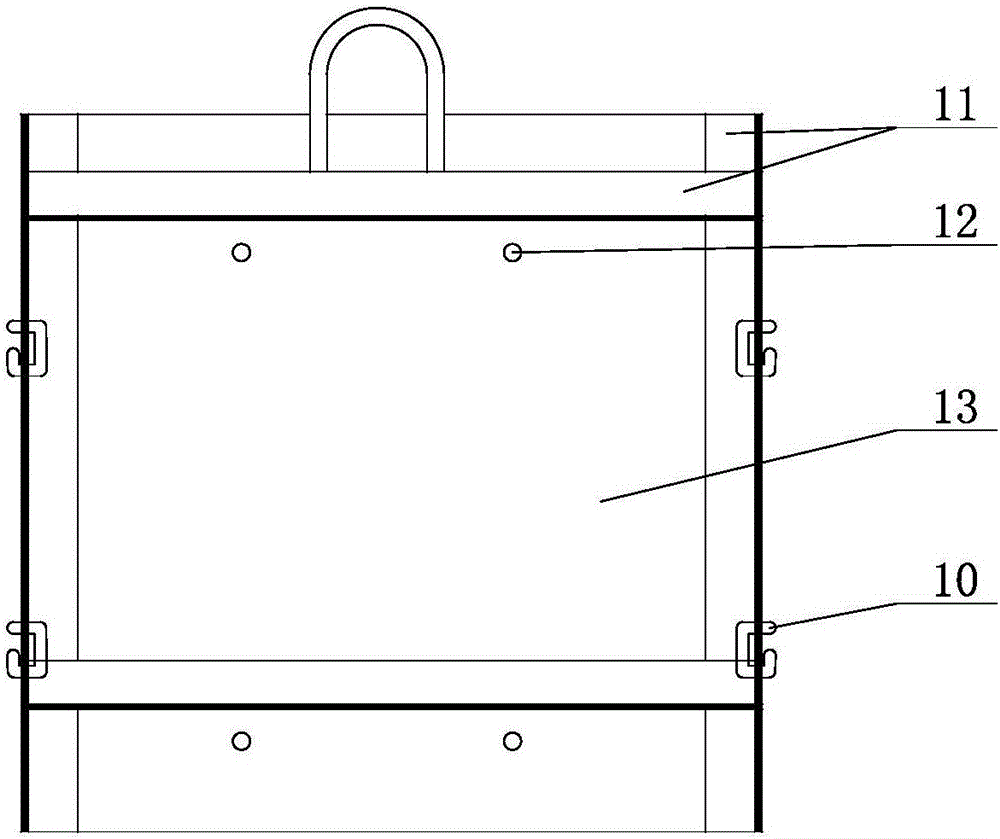

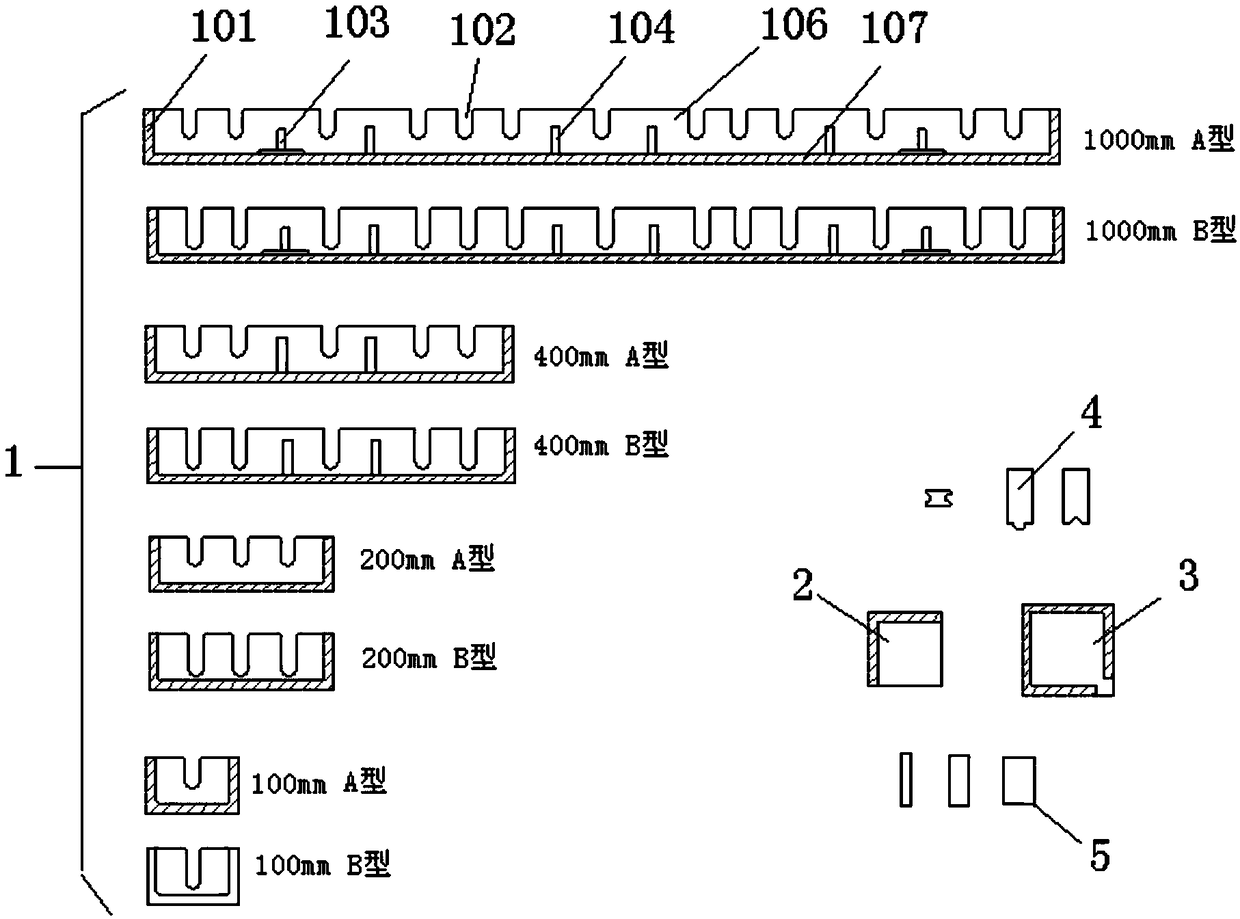

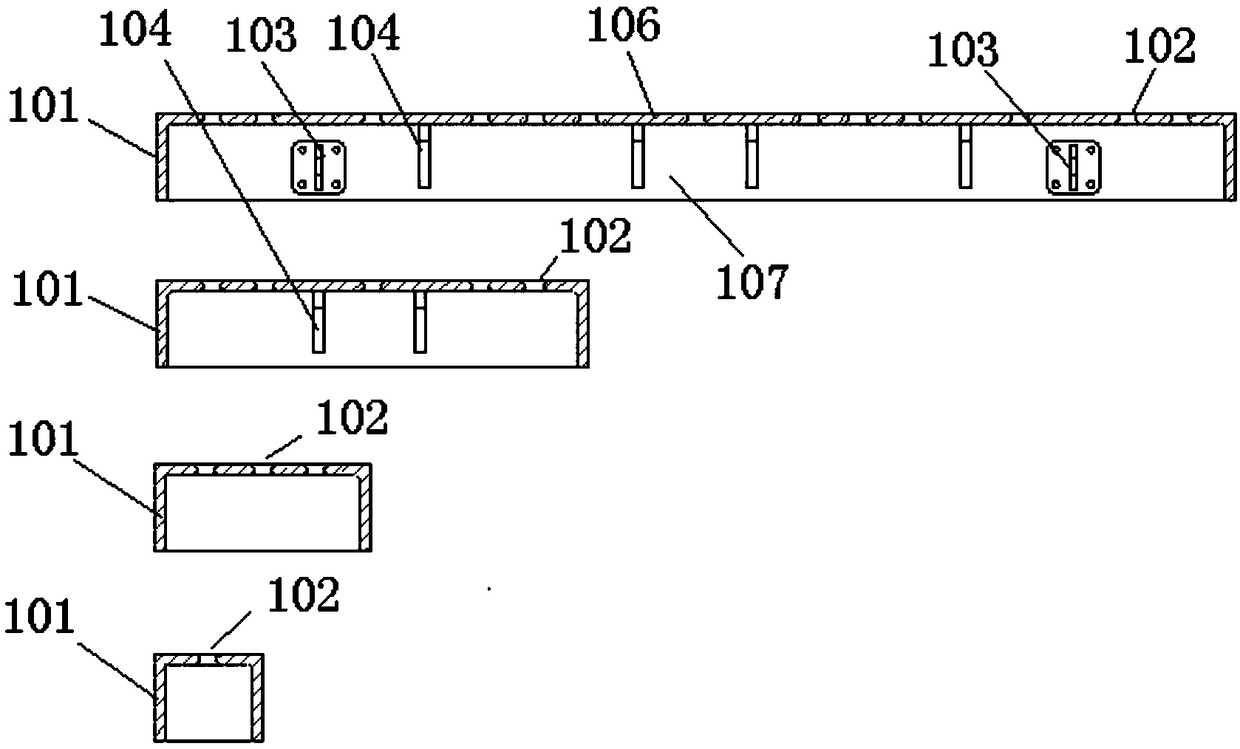

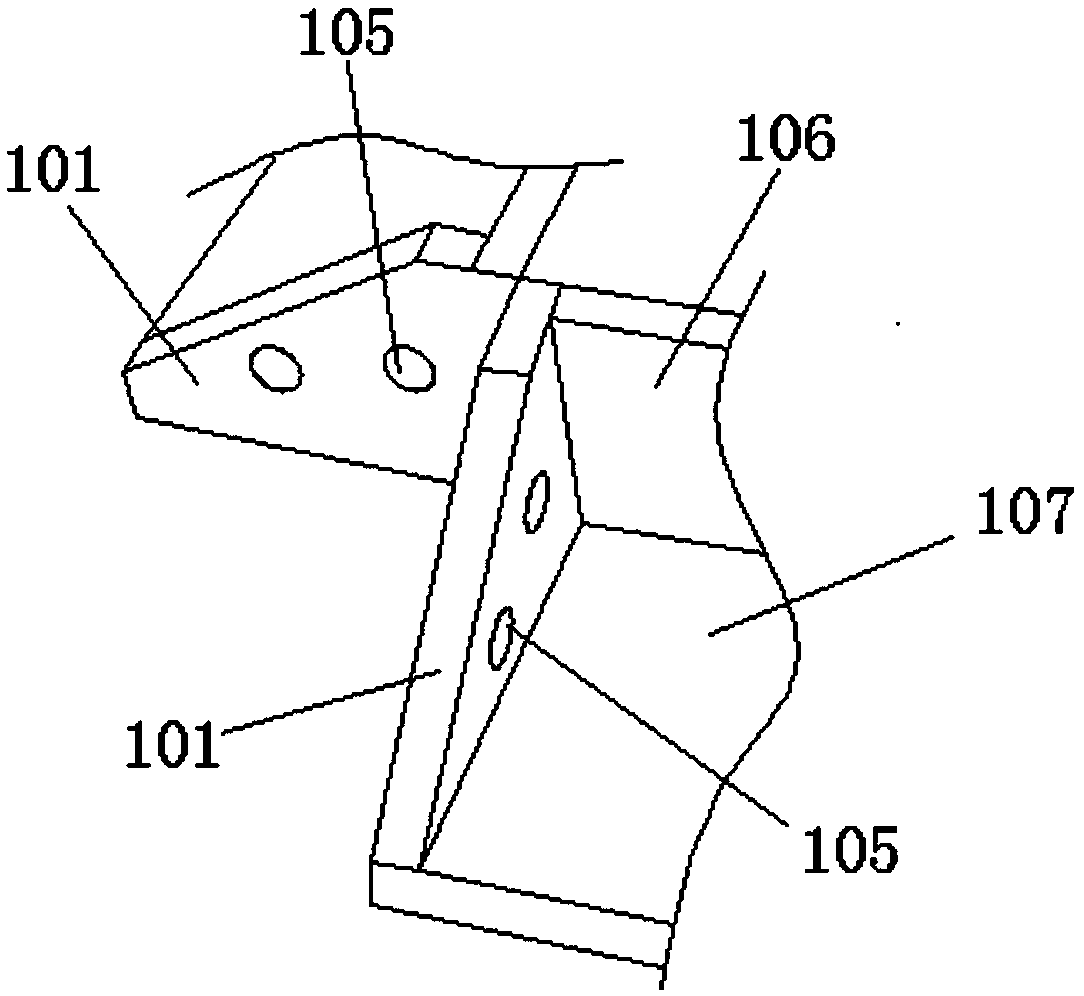

Quick-splicing combination prefabricated composite floor formwork

PendingCN109262811AEasy to use and flexibleReduce manufacturing costMouldsMould auxillary partsRebarMechanical engineering

The invention relates to the technical field of production of prefabricated composite flooring, in particular to a quick-splicing combination prefabricated composite floor formwork, comprising a sideform component, first corner forms, second corner forms and plug components. The side form component includes side forms having different lengths; side form connection plates are arranged at the two ends of each side form; when two side forms are connected perpendicularly, the two side forms are connected via the first corner forms or the second corner forms; one side of each second corner form isprovided with second corner form connection plates perpendicular to each other and connected with the side form connection plates, and the other side of each second corner form is provided with second corner form retainers perpendicular to each other; each side form retainer at the front of each side form is provided with side form notches; each plug component includes an insert plug and an orifice block. In use, the side form notches that are not needed are inserted into the insert plugs, rebars extended out of the side form notches are inserted into the orifice blocks; the lower end of eachinsert plug is provided with a plug; the lower end of each orifice block is provided with an opening. The quick-splicing combination prefabricated composite floor formwork can be accurately combinedinto a required shape according to actual needs, is flexible and convenient to use and is reusable so that production nicest is effectively reduced.

Owner:国嘉嵘

Electric pole

The invention provides an electric pole which comprises an electric pole main body. A plurality of longitudinal reinforcing bars and a plurality of force loading rings which are in surrounding connection onto the longitudinal reinforcing bars in a ring shape are arranged in the electric pole main body. Both the top part and the tail part of the electric pole main body are provided with steel rings. The phenomenon of slurry overflow at both ends of the electric pole can be avoided. Both ends of the electric pole are difficult to damage. The electric pole has high head quality, high qualification rate and low scrappage.

Owner:浙江永达电力实业股份有限公司

Prefabricate building block used for assembling wall of well

InactiveCN103132641AWith super anti-slurry functionSimple structureArtificial islandsWallsStructural engineeringUltimate tensile strength

Owner:蒋云

Construction method of constructional column after completion of secondary masonry structure

PendingCN112459472AAvoid quality defectsIncrease profitWallsForms/shuttering/falseworksFloor slabArchitectural engineering

The invention discloses a construction method of a constructional column after the completion of secondary masonry structure. A formwork device comprises a shaped steel formwork, square pipes, split bolts, a sealing pad and fixing pins, the shaped steel formwork is integrally in a U shape and comprises two side plates and an end plate connected between the ends of one sides of the two side plates,and a plurality of split bolt holes are correspondingly formed in the two side plates of the shaped steel formwork in the height direction. The square pipes are correspondingly arranged on the outerside of each side plate, bolt holes corresponding to split bolt holes in the side plates are formed in the square pipes, the square pipes on the two sides and the side plates are connected through thesplit bolts, the two fixing pins are correspondingly arranged at the upper ends and the lower ends of the square pipes, and one ends of the fixing pins are fixed to a cast-in-place floor slab. A feeding port is fixedly connected to the upper part of the end plate of the shaped steel formwork, and when the formwork is installed, the side plates on the two sides of an opening end of the shaped steel formwork are correspondingly in lap joint with the outer side of the secondary masonry structure. According to the construction method of the constructional column after the completion of the secondary masonry structure, the appearance quality of the constructional column is improved, and disturbance to completed brickworks is reduced.

Owner:SHANDONG SANJIAN CONSTR ENG MANAGEMENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com