High polymer grouting method for lifting ballastless track of high speed railway

A ballastless track and high-speed railway technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems affecting the operation of the railway network, difficulty in accessing small sites, huge construction equipment, etc., to achieve good resistance to chemical solvent corrosion performance, The effect of restoring the design elevation of the track and ensuring the smoothness of the track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing, the present invention will be further described.

[0043] A high-speed railway ballastless track lifting polymer grouting method, which comprises the following steps:

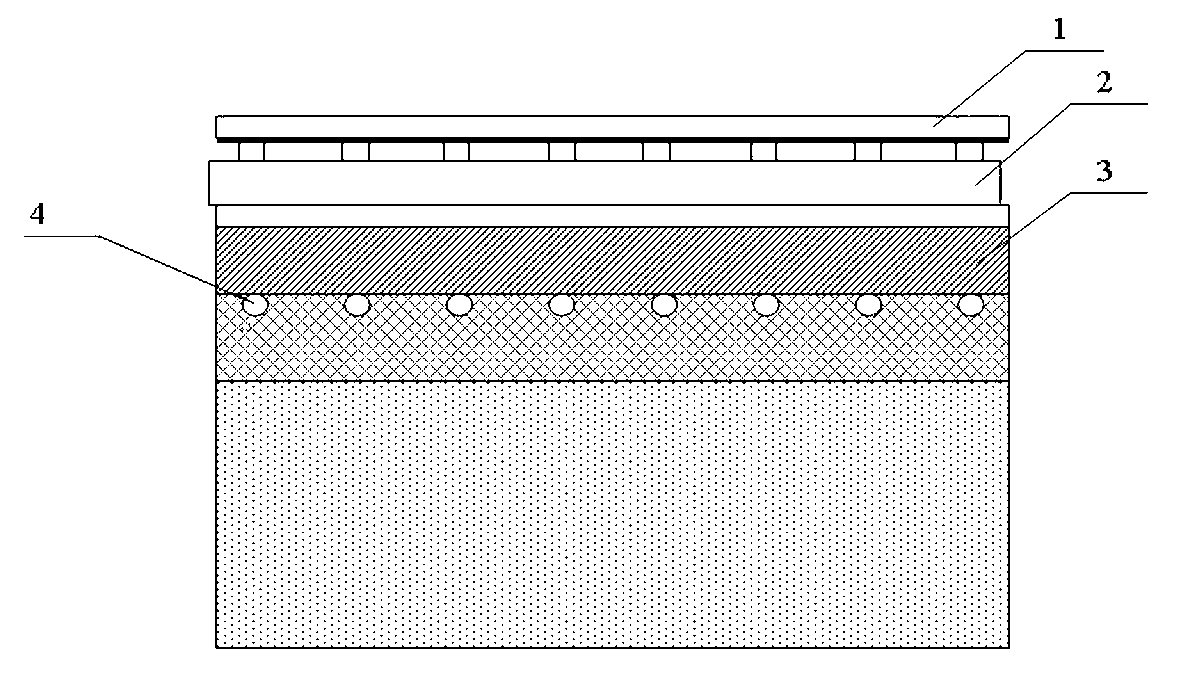

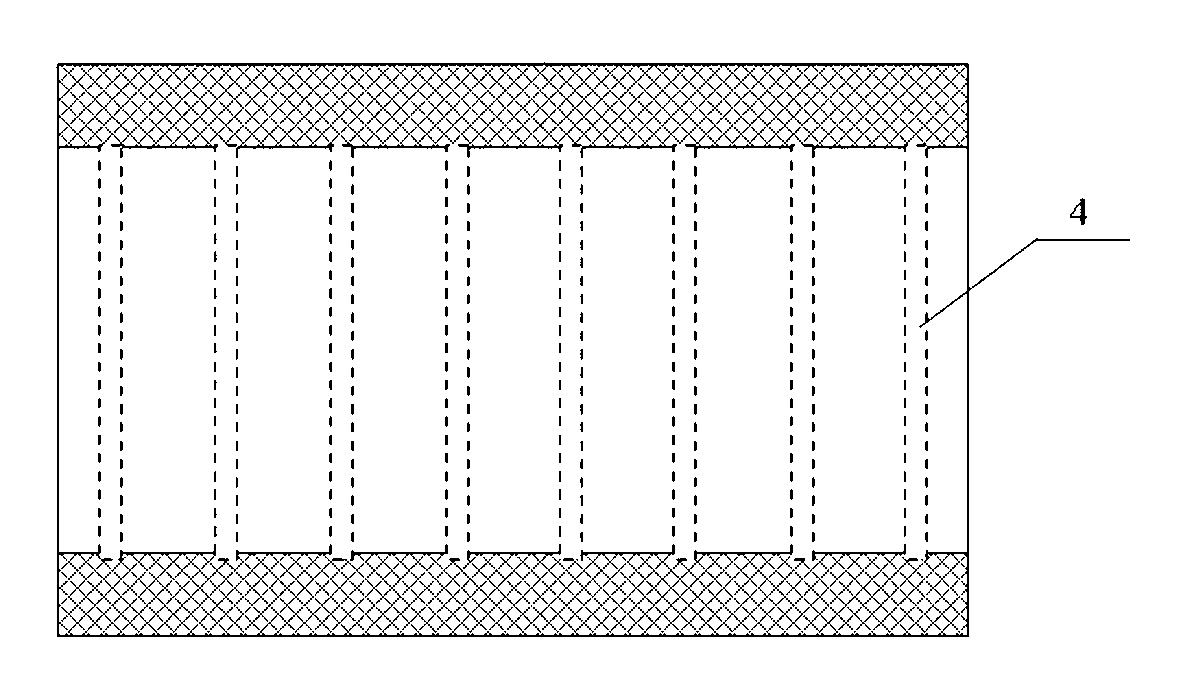

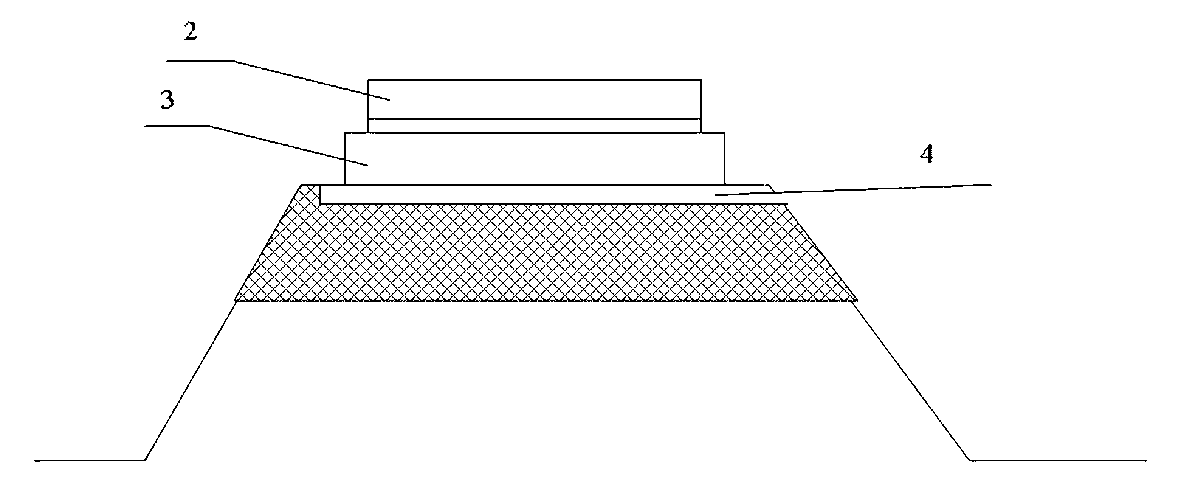

[0044] (1) Drilling grouting holes: such as figure 1 , figure 2 , image 3 As shown, the horizontal grouting hole 4 is horizontally drilled on the lower side of the concrete base plate 3 of the high-speed rail track 1 that needs to be lifted, the track plate 2 supports the track 1, and the diameter of the grouting hole 4 is 50 ~ 80mm. The diameter of the preferred grouting hole in the present invention is 50mm, the length of the grouting hole 4 is consistent with the width of the track concrete base plate 3, and the grouting hole is arranged below the axis of each row of spikes;

[0045] (2) Make geotextile bags, and bind geotextile bags and grouting pipes: the number of geotextile bags 5 is the same as the number of grouting holes 4, the length of geot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com