Fastening type cylindrical timber formwork concrete casting construction method

A construction method and technology of wooden formwork, which is applied in the direction of formwork/formwork/work frame, building, building structure, etc., can solve the problems of large lifting equipment hoisting, heavy installation of steel formwork, low pass rate of columns, etc., and reduce construction costs. Difficulty, prevention of pulp running, excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

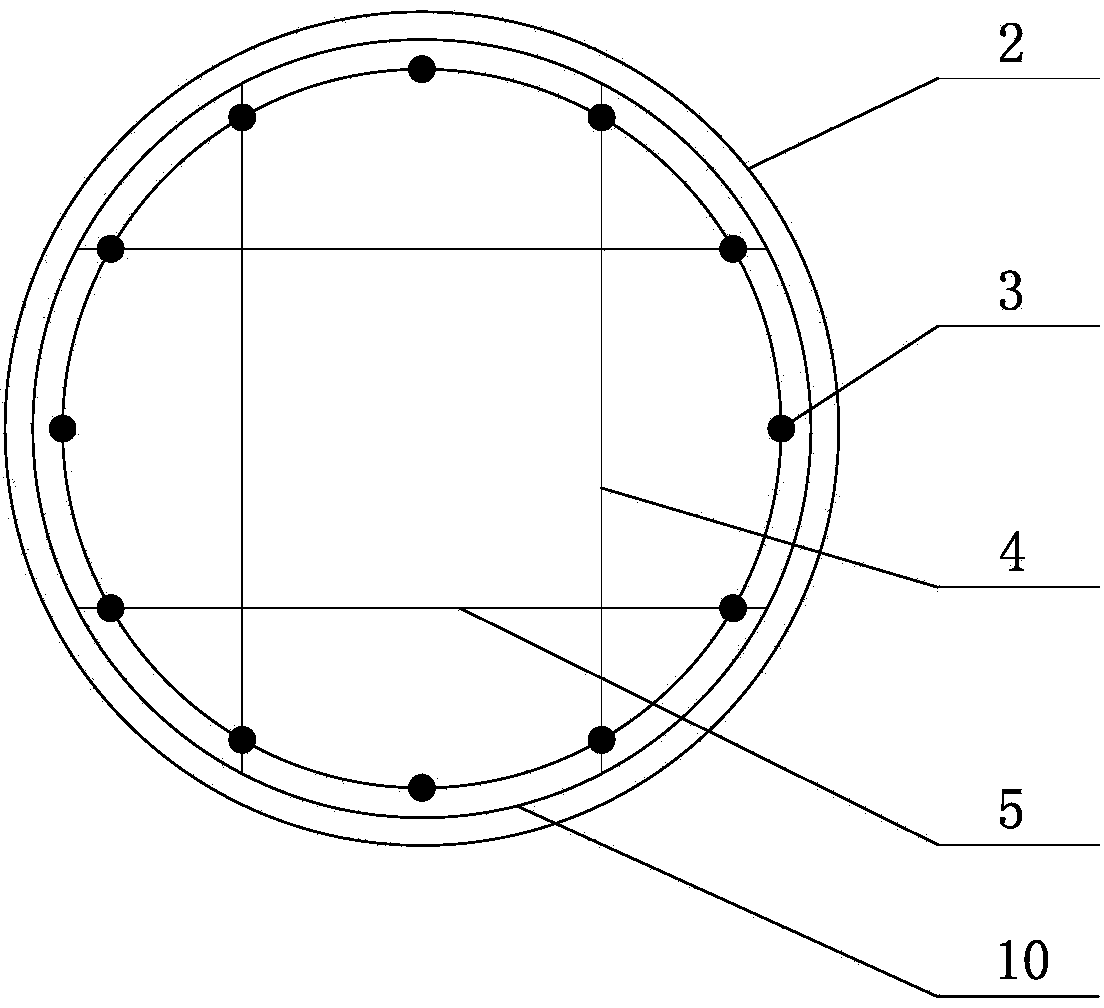

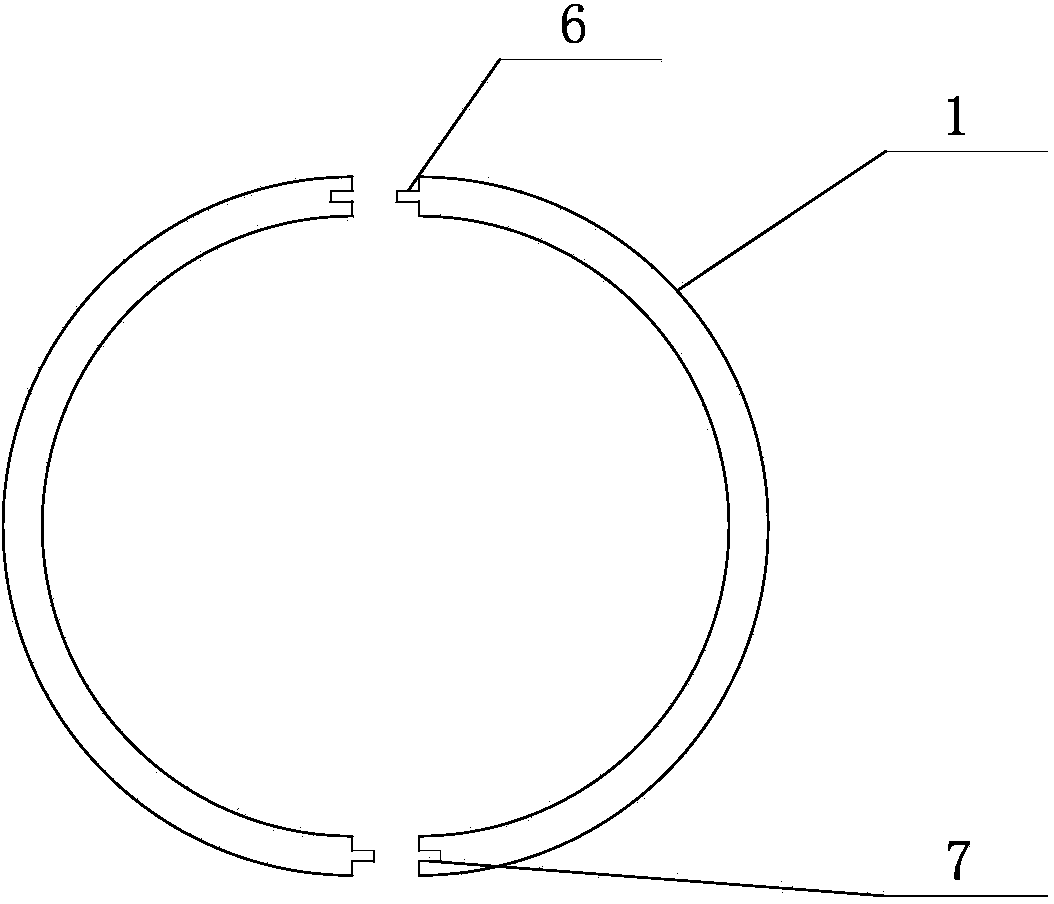

[0032] like Figure 1 to Figure 4 Shown, the fastening type wooden formwork cylindrical concrete pouring construction method of the present invention comprises the following steps:

[0033] 1) Binding the cylindrical steel frame 3;

[0034] 2) Positioning: Measure the outer edge 2 of the cylindrical formwork and release the line. The diameter of the outer edge 2 of the cylindrical formwork is the diameter of the outer edge 10 of the column to be poured plus twice the thickness of the formwork 1. Positioning reinforcing bars are arranged respectively, and the positioning reinforcing bars and the cylindrical reinforcing bar skeleton 3 are tied together with binding wires, and the positioning reinforcing bars are welded together by two horizontal reinforcing bars 5 and two vertical reinforcing bars 4;

[0035] 3) Template making: template 1 is a wooden template, and template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com