Wing plate type advanced small pipe used for advance support of soft broken surrounding rock tunnel

A technology of leading small conduits and crushing surrounding rock, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of high labor intensity, affecting safety, difficult to fully diffuse the slurry, etc., to improve the support strength and increase the diffusion radius. , the effect of increasing the support area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

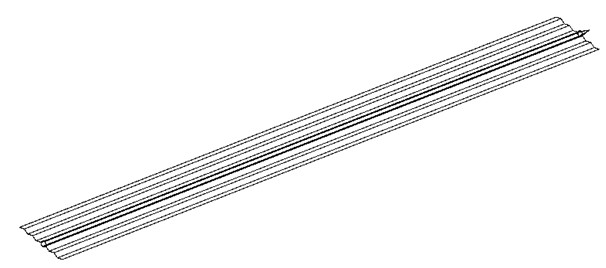

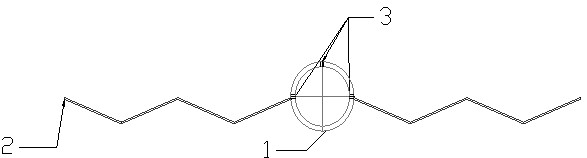

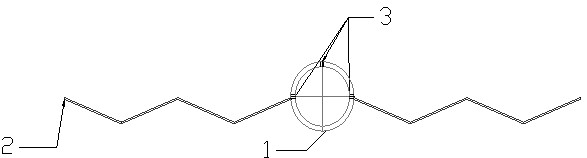

[0018] figure 1 , figure 2 Among them, the small conduit 1 is made of hot-rolled seamless steel pipe. Slurry overflow holes 3 are drilled on the upper part and the left and right sides of the small conduit 1, which are distributed in a quincunx shape; the top of the small conduit 1 is tapered and closed. The outer diameter of the small conduit 1 is φ30-50mm, the thickness is 3mm, and the aperture of the overflow hole 3 is φ8-10mm. The slurry overflow holes 3 are arranged in a quincunx shape with a spacing of 10cm, and no holes are drilled within 0.6m of the tail to prevent slurry leakage. The airfoil plate 2 is welded on the left and right sides of the small conduit 1, and the welding seam is located below the left and right slurry holes 3 of the small conduit 1. The airfoil 2 is a hot-rolled steel plate with a horizontal length of 15 cm and a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com