Quick-splicing combination prefabricated composite floor formwork

A composite floor slab and combined technology, which is applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., can solve the problems of increasing the production cost of prefabricated laminated floors, increasing labor costs and production costs, molds cannot be reused, etc. Lightweight, flexible and convenient to use, and easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

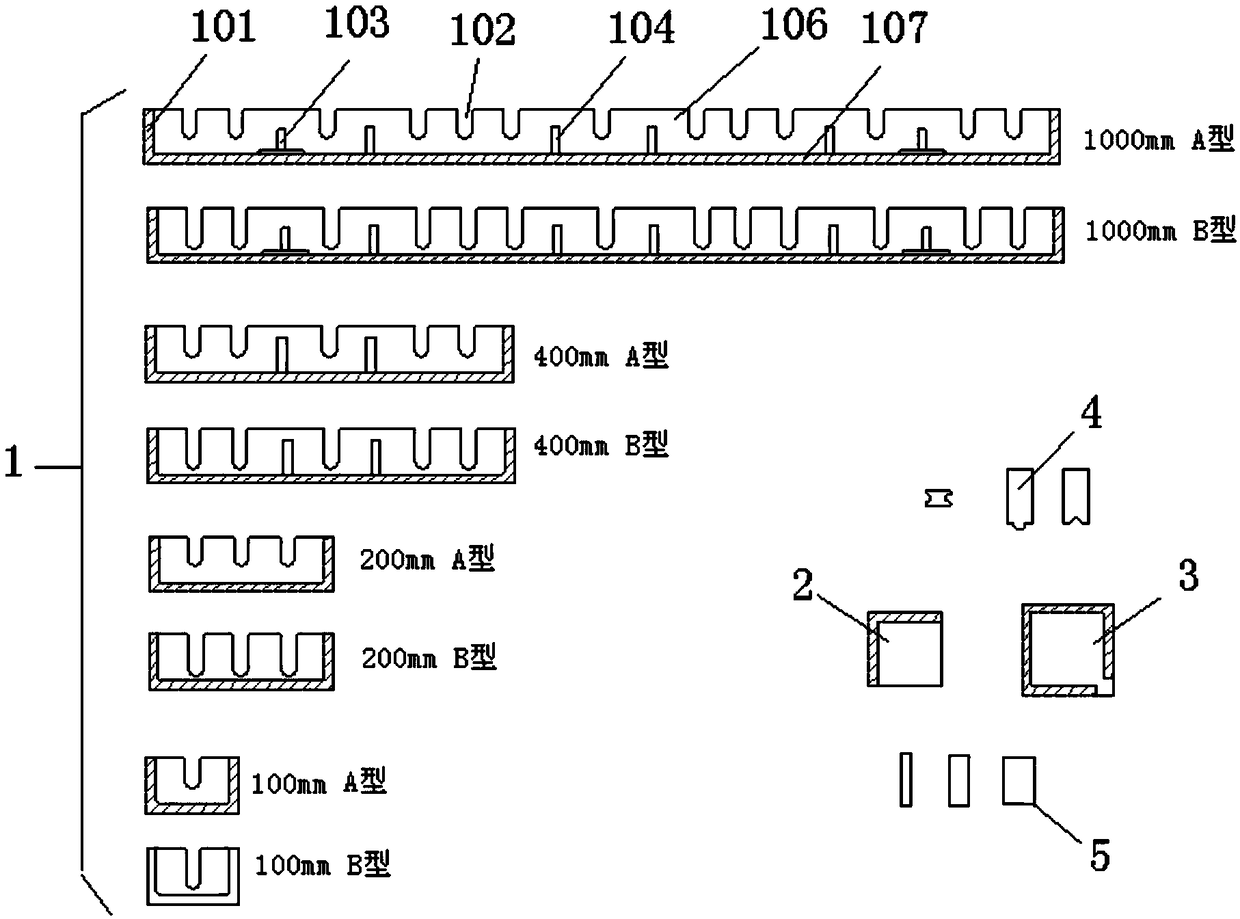

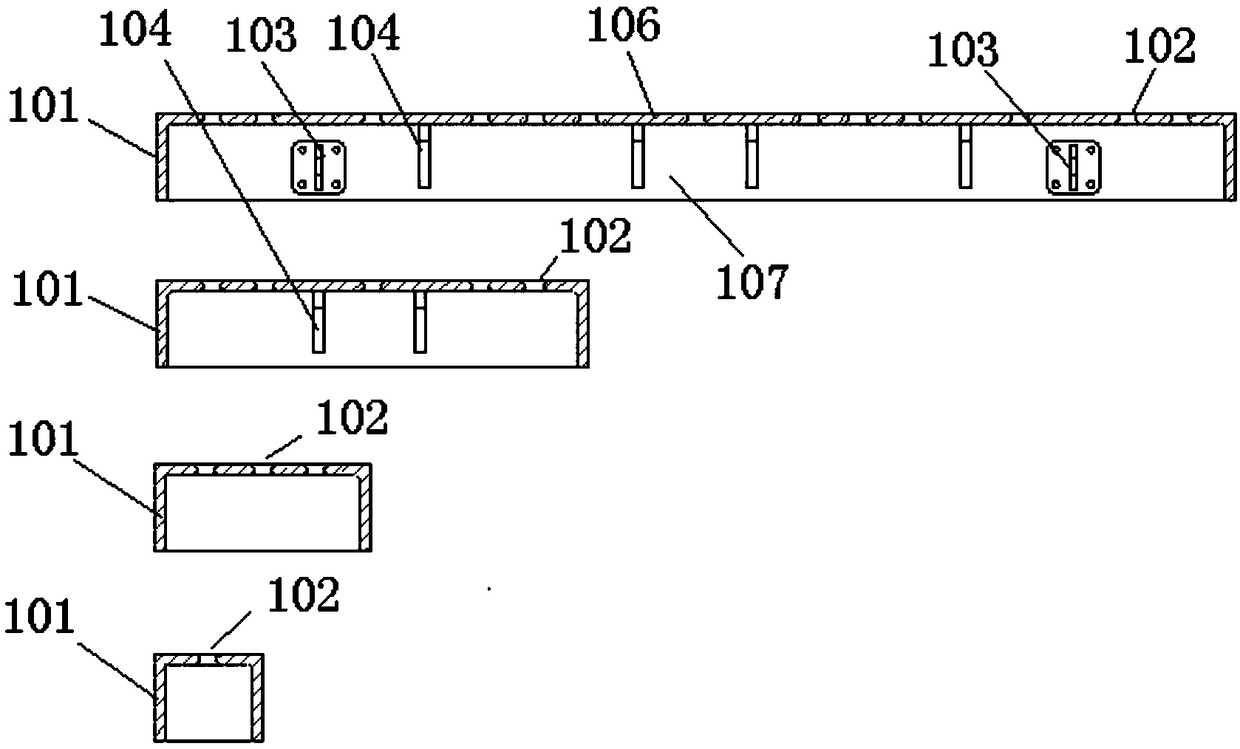

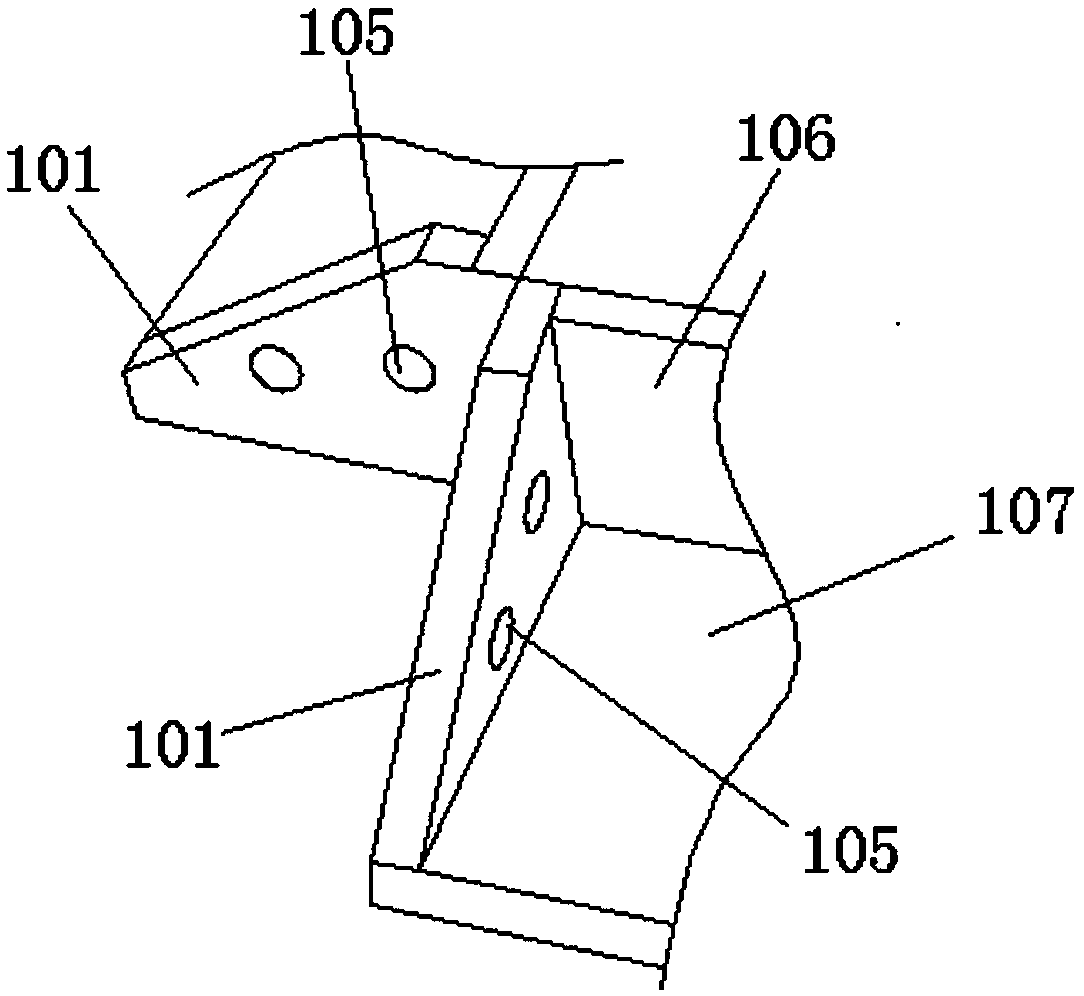

[0046] Such as Figure 1-14As shown, the present invention includes a sideform assembly 1, a first angle formwork 2, a second angle formwork 3 and a block assembly 4, and the sideform assembly 1 includes a plurality of sideforms with different lengths, as shown in Figure 3 , the side form includes a side form bottom plate 107 and a side form baffle plate 106 vertically arranged on the front side of the side form bottom plate 107, and side form connecting plates 101 are provided at both ends of the side form, and the side form The mold connecting plate 101 is vertically connected with the side mold bottom plate 107 and the side mold baffle plate 106, and a side mold connecting hole 105 is provided on the side mold connecting plate 101, and the adjacent side molds pass through the side molds at the adjacent ends when they are connected in a straight line. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com