Construction method of slip-casting variable-cross section steel pipe pile and expansion and extrusion device of slip-casting variable-cross section steel pipe pile

A technology of grouting device and steel pipe pile, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc. It can solve the problems of uncontrollable grout flow path, grout running, and poor reliability, so as to increase reliability and increase the bite effect , to avoid the effect of running pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

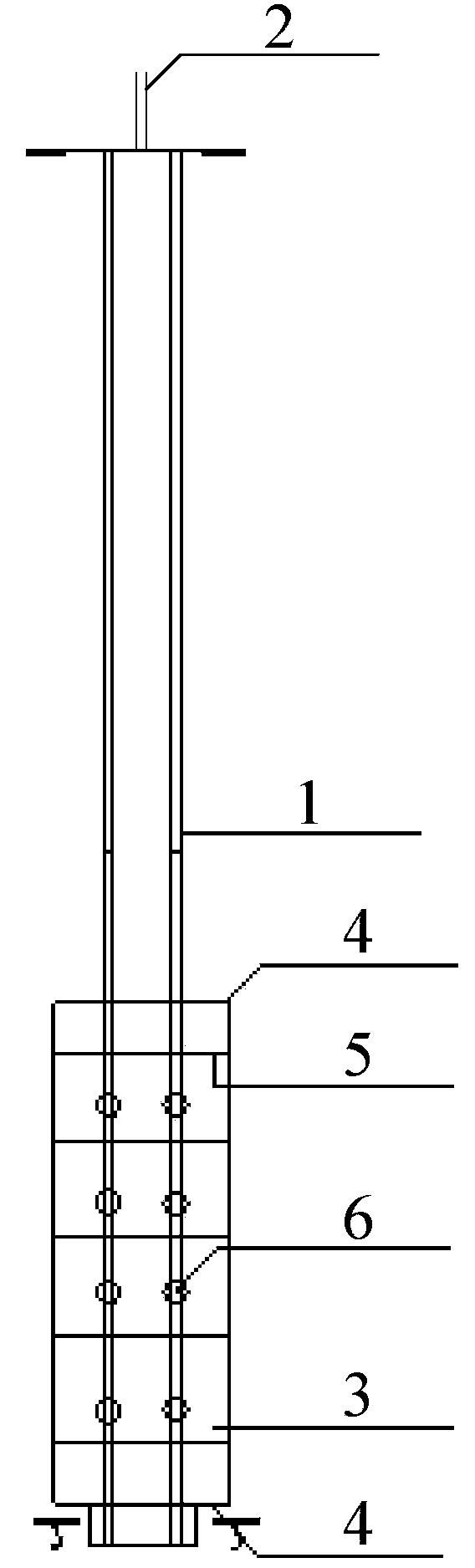

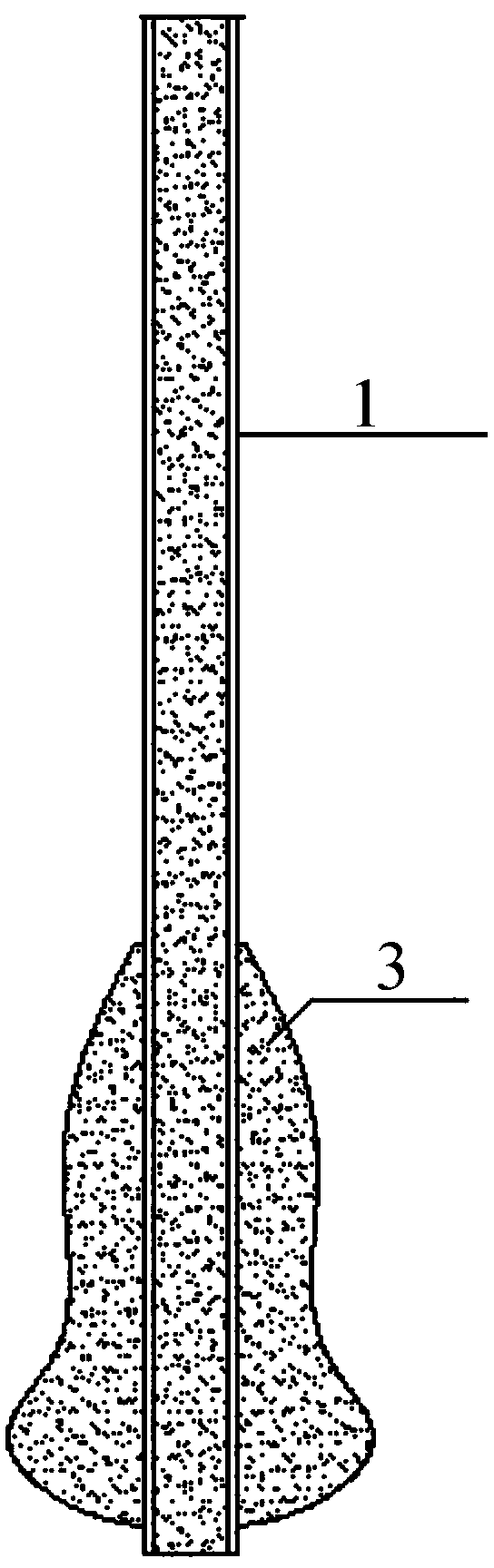

[0041] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an expansion and extrusion device, which includes at least one expansion and extrusion unit arranged on the side of the variable-section steel pipe pile and a grouting device 2 arranged at the top of the variable-section steel pipe pile 1 , the expansion and extrusion unit is bound and fixed to the variable-section steel pipe pile 1, and the grouting device 2 is connected to the variable-section steel pipe pile 1 or the expansion and extrusion unit.

[0042]Further, the bottom of the variable-section steel pipe pile 1 is provided with a pile point, and the pile point faces away from the side of the variable-section steel pipe pile 1, and the setting of the pile point is convenient for the variable-section steel pipe pile. Pile 1 is piled down, and the depth of the pile is increased, and those skilled in the art can easily implement its scheme according to the description of the ab...

Embodiment 2

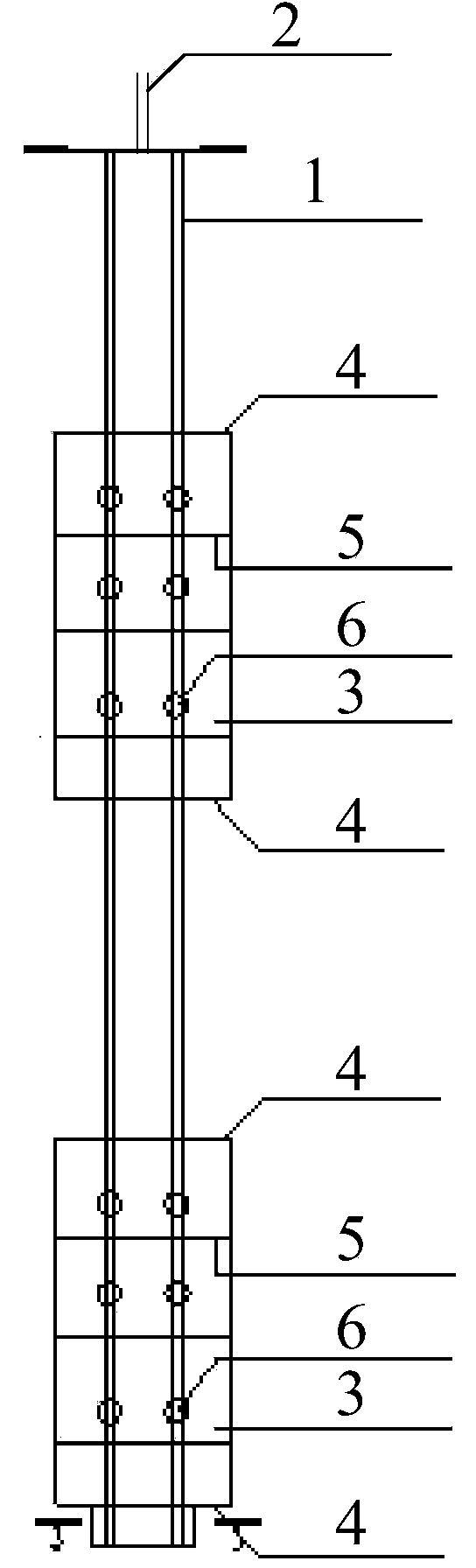

[0053] The difference between this embodiment and Embodiment 1 is that: image 3 and Figure 4 As shown, in this embodiment, the number of the expansion and extrusion units matches the number of bamboo nodes of the variable cross-section steel pipe pile 1, and the expansion and extrusion units are all geotextile bags 3, and the plurality of geotextile bags 3 are set on the surrounding side of the variable-section steel pipe pile 1 close to the soil layer with higher bearing capacity, and the upper and lower ends of the geotextile bag 3 are bound and fixed to the variable-section steel pipe pile 1 through steel wire ropes 4. The bag bodies of each geotextile bag 3 are respectively tightened to the peripheral sides of the variable-section steel pipe pile 1 through elastic bands 5, and there are several openings on the peripheral side of the variable-section steel pipe pile 1 corresponding to the position of the geotextile bag 3. hole 6, the grouting device 2 is connected to the...

Embodiment 3

[0064] The difference between this embodiment and the previous two embodiments is that: Figure 5 and Figure 6 As shown, the number of the expansion and extrusion unit is one, and the expansion and extrusion unit is a geotextile bag 3, and the geotextile bag 3 is wound on the pile side of the variable-section steel pipe pile 1, and is spirally distributed on the variable-section steel pipe pile 1. The entire pile body of the steel pipe pile 1, the geotextile bag 3 is bound and fixed to the variable section steel pipe pile 1, the grouting device 2 and the geotextile bag 3 are located at the top of the variable section steel pipe pile 1 One end connection, through this design, the grouting device 2 can grout the geotextile bag 3 without pre-embedding, and the geotextile bag 3 is spirally wound on the variable cross-section steel pipe pile 1, and the geotextile bag 3 is When the grout is stretched, it can fill the gap very well and increase the pullout force of the variable cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com