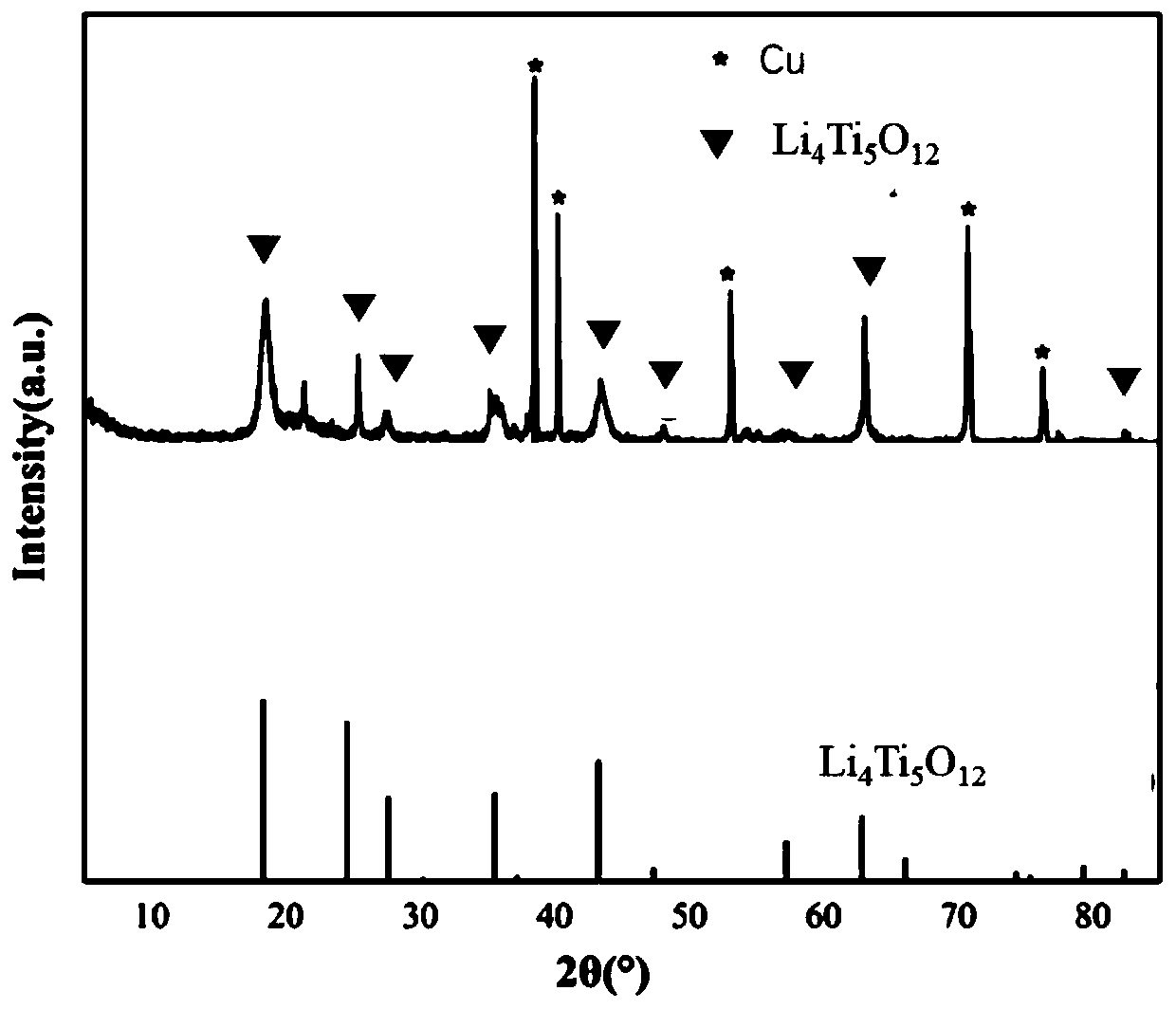

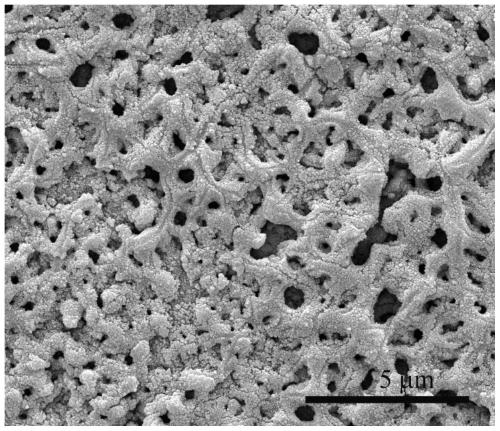

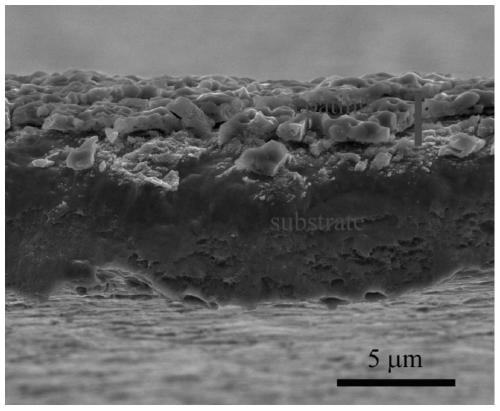

Method for preparing three-dimensional porous carbon-doped lithium titanate coating on surface of copper foil

A three-dimensional porous lithium titanate technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of complex process, harsh preparation conditions, poor electronic conductivity of lithium titanate coating, etc., to achieve simplified The effect of preparation process, reduction of preparation cost and resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A method for preparing a three-dimensional porous carbon-doped lithium titanate coating on the surface of copper foil, comprising the following steps:

[0026] Step 1. Disperse titanyl sulfate and lithium hydroxide in deionized water, stir and mix evenly to obtain mixed solution A;

[0027] Step 2. Disperse PVP (molecular weight: 5,000-20,000) or PEG (molecular weight: 3,000-20,000) polymer carbon source in absolute ethanol, stir and mix evenly to obtain mixed solution B;

[0028] Step 3. Add mixed solution B to mixed solution A, stir and mix evenly to obtain mixed solution C; in the obtained mixed solution C, the concentration of titanium source is 5g / L, the concentration of lithium hydroxide is 15g / L, and the polymer The concentration of carbon source is 2~10g / L;

[0029] Step 4. Put the prepared mixed solution C in a stainless steel tank, use copper foil as the anode and the stainless steel tank as the cathode, and use a liquid-phase plasma oxidation power supply to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com