Pouring tool for a nodular cast iron jacking pipe and working method thereof

A technology for ductile iron and pipes, applied in the field of pouring tooling, can solve the problems of easy to run slurry, no special sealing treatment on the socket, affecting product consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

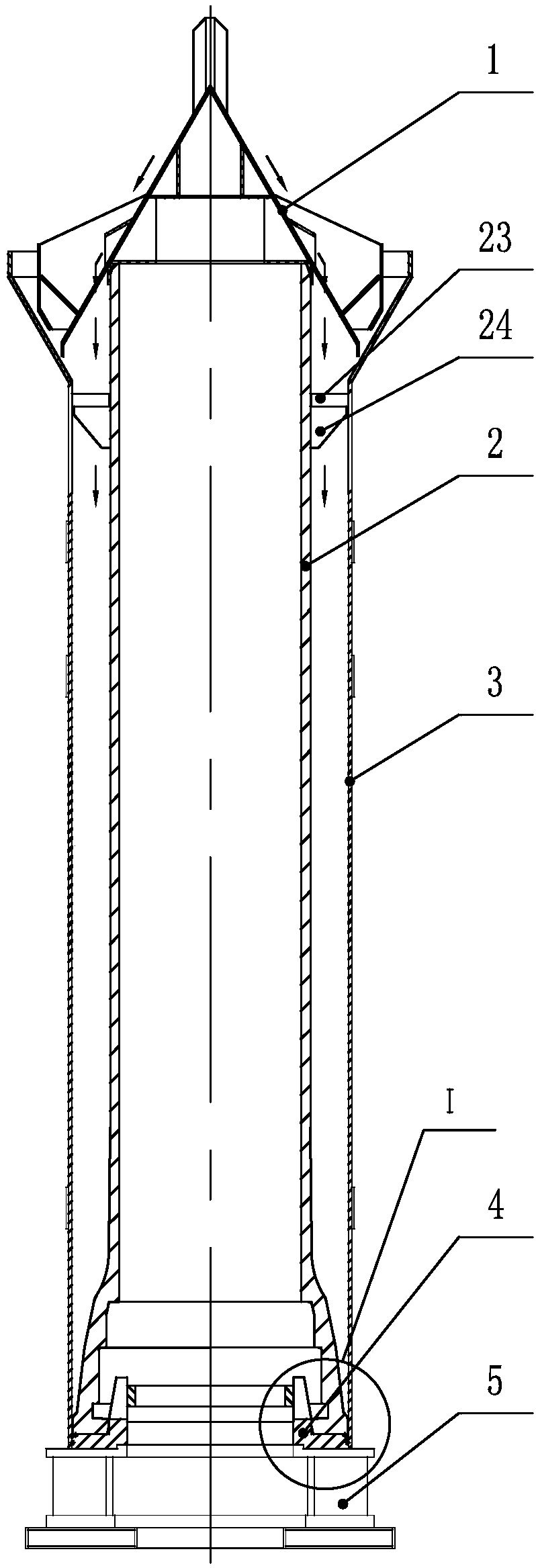

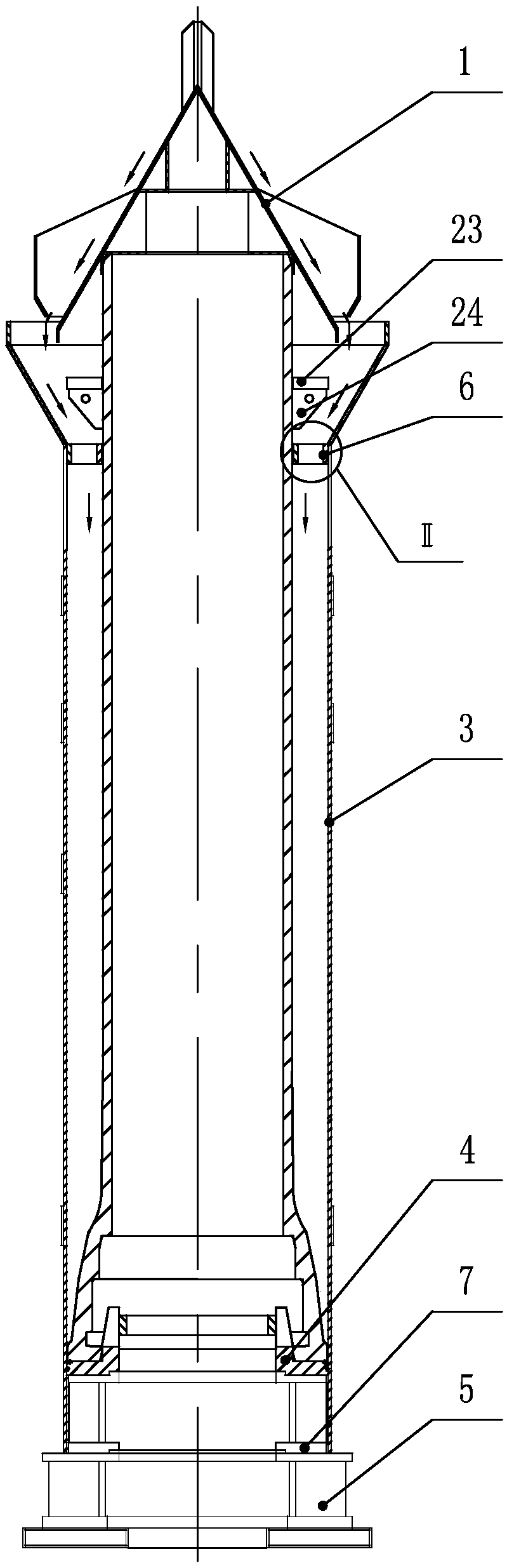

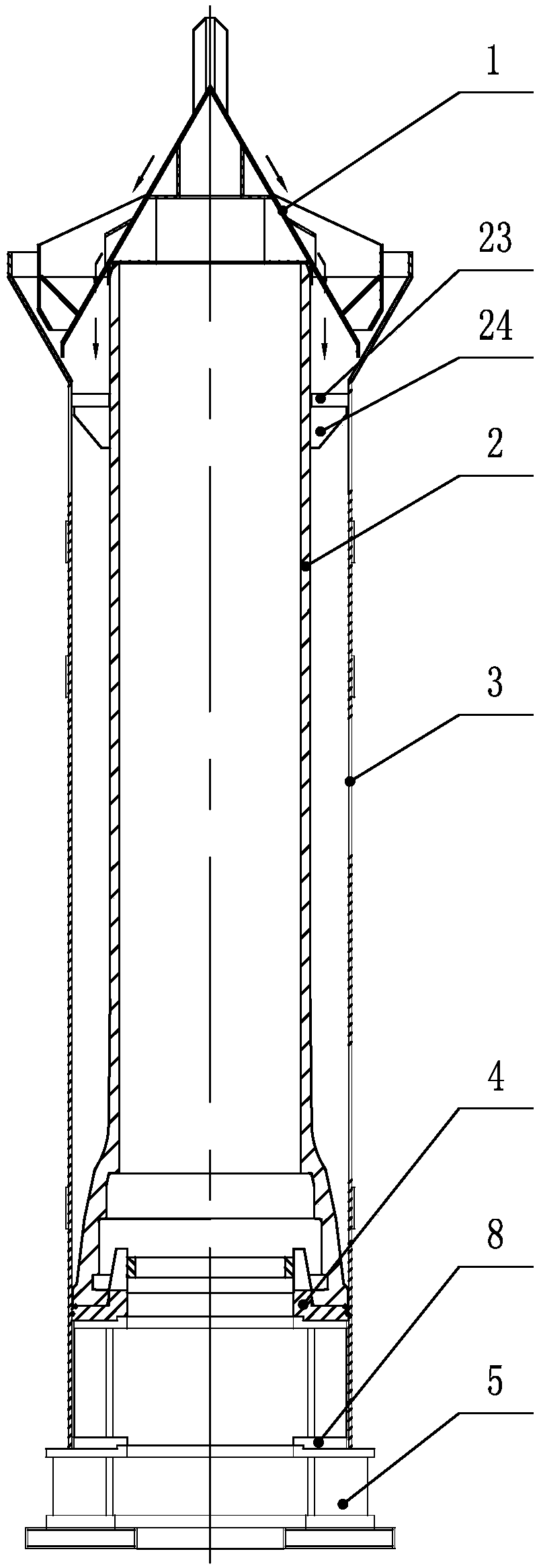

[0032] Such as figure 1 , 5 , 7, and 8, a casting tooling for ductile iron pipe jacking, comprising a perforated blanking cone 1, a flexible outer mold 3, a movable bottom mold 4 and a fixed bottom mold 5 placed sequentially from top to bottom; the fixed bottom mold 5 The lower part is fixed to the ground, the upper part is fixedly connected with the movable bottom mold 4, and a flexible outer mold 3 is installed on the outer side of the upper part; The ductile iron pipe jacking 2 is composed of a ductile iron pipe jacking socket 21, a ductile iron pipe jacking socket 22, a pushing flange 23, a flange rib plate 24 and a pipe body.

[0033]The upper part of the movable bottom mold 4 is provided with a guide slope 42, a support ring 41, a positioning cylinder 43, an end face seal groove 44 and a ring seal groove 45, and the support ring 41 is located on the inner side of the guide slope 42. Below the guide slope 42 is a positioning cylindrical surface 43, and the edge of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com