Construction method for prefabricating pipe galleries

A construction method and technology of pipe gallery, applied in artificial islands, water conservancy projects, infrastructure engineering and other directions, can solve the problem of the development and application of mold development, pipe gallery, precise docking of mechanical equipment and development of workers with backward operation skills and unfavorable large section size. It is not conducive to construction safety and other issues, and achieves the effect of good structural waterproofing, solving water seepage problems, and fast construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

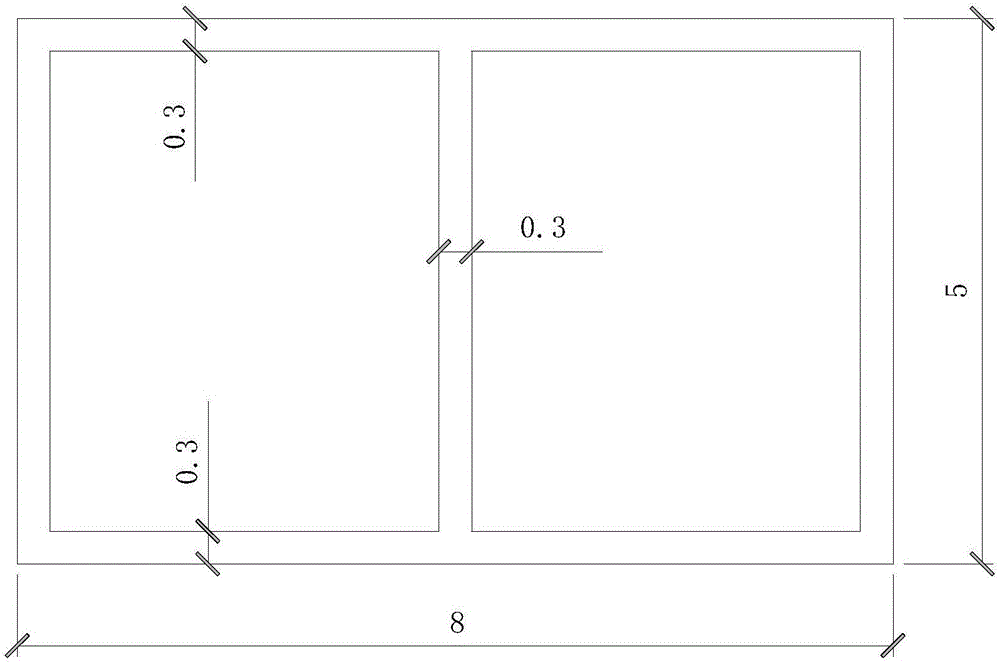

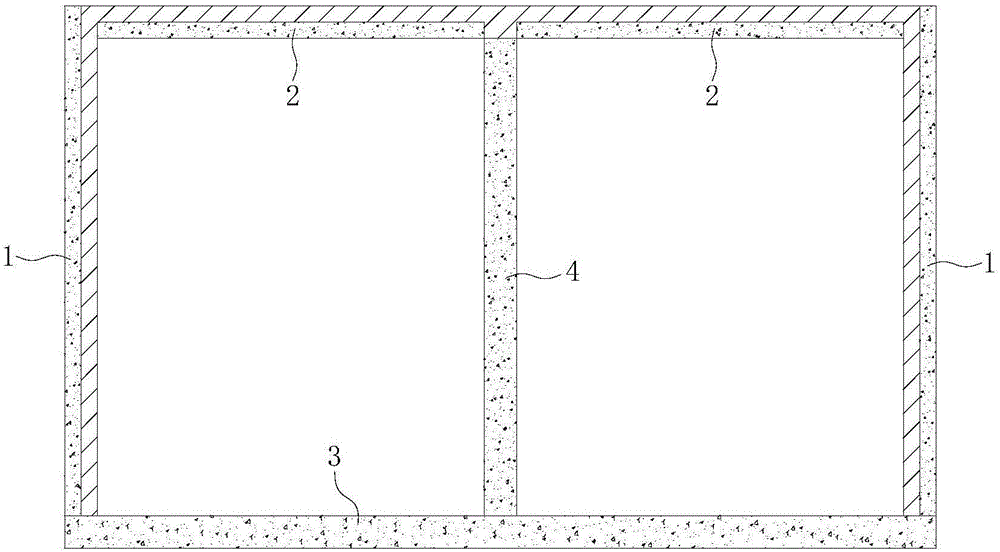

[0042] see figure 1 , taking a double-compartment rectangular pipe gallery with a cross-sectional size of 8m wide, 5m high, 0.3m thick, and 3m long in each section as an example, the construction method of a prefabricated pipe gallery according to an embodiment of the present invention is described in detail. The double warehouse formed by this method For the structural disassembly of the rectangular pipe gallery of the warehouse, see figure 2 , split into two pieces of roof 2, two pieces of outer side walls 1, one middle partition wall 4, and one bottom plate 3, where the part filled with concrete legend is the prefabricated part, and the part filled with oblique lines is the cast-in-place part.

[0043] Specifically include the following steps:

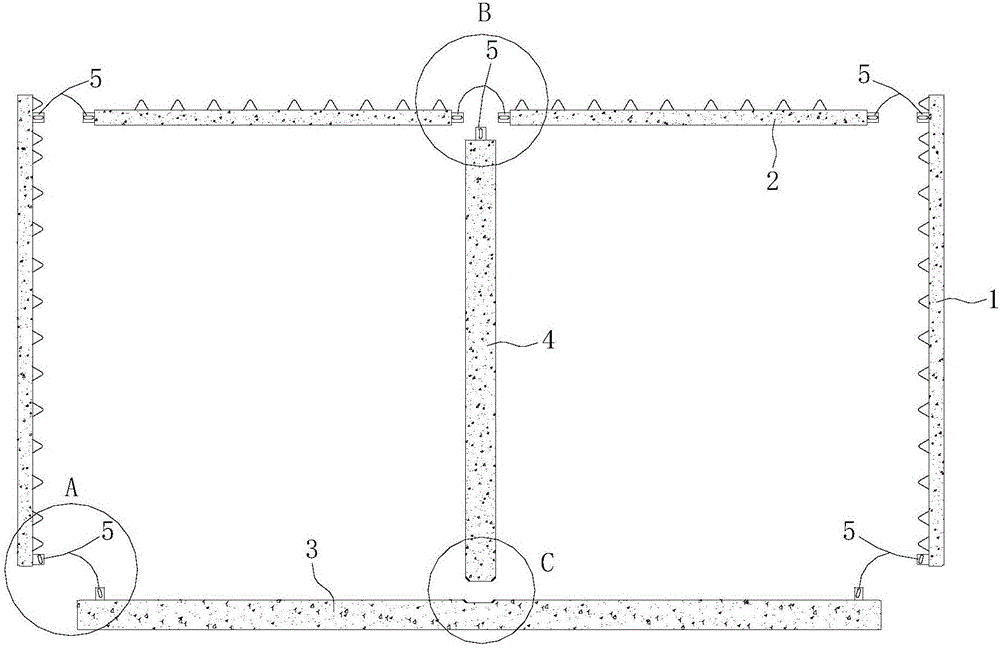

[0044] (1) Construction of prefabricated components, please refer to image 3 :

[0045] Prefabrication of the outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com