Construction method for one-time formation of concrete pool wall

A construction method and concrete technology, which is applied in the direction of building type, building material processing, construction, etc., can solve the problems of high material cost and labor cost, staggered upper and lower pool walls, and leakage during use, so as to ensure integrity, The effect of cross operation is small and the project cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

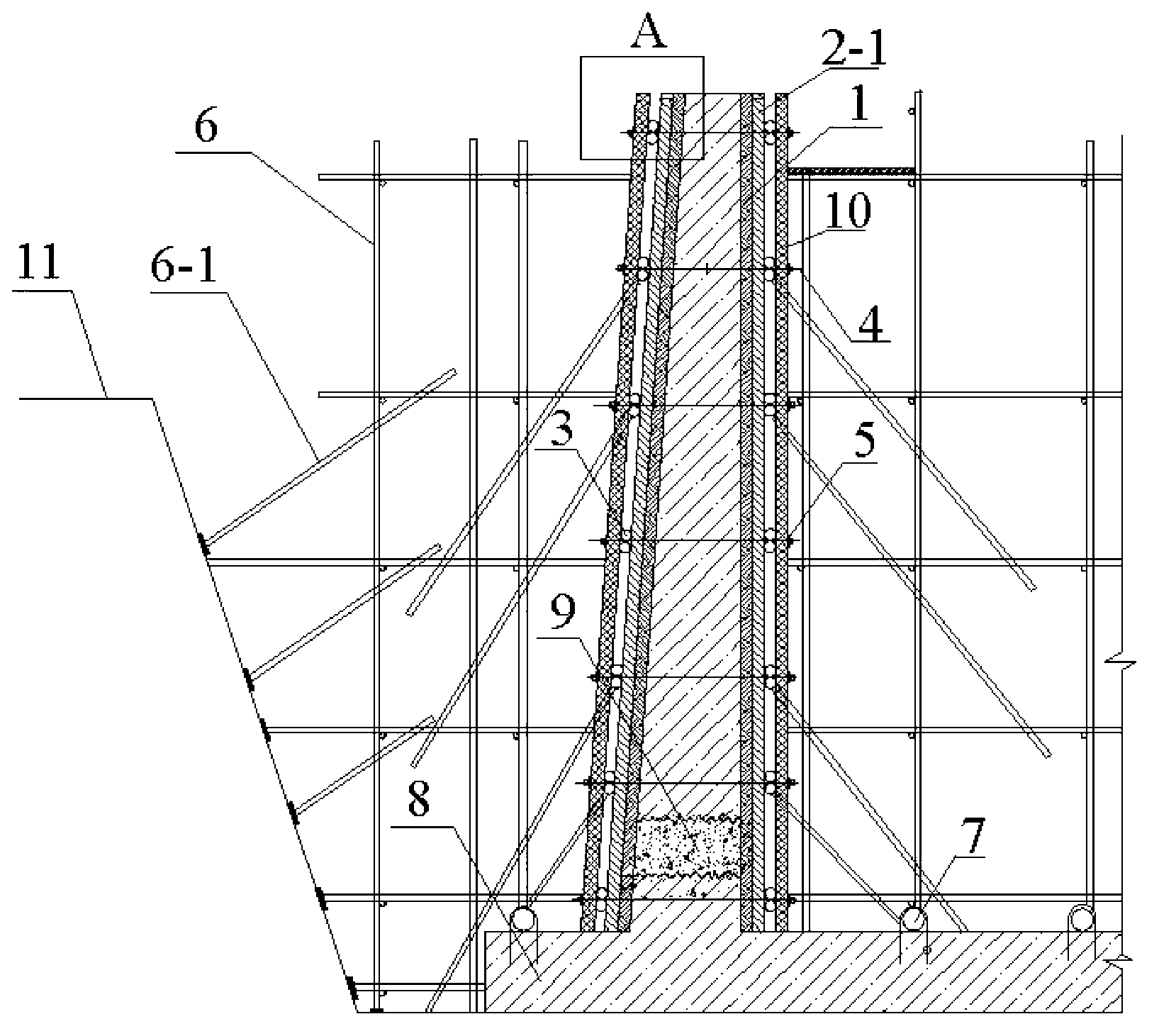

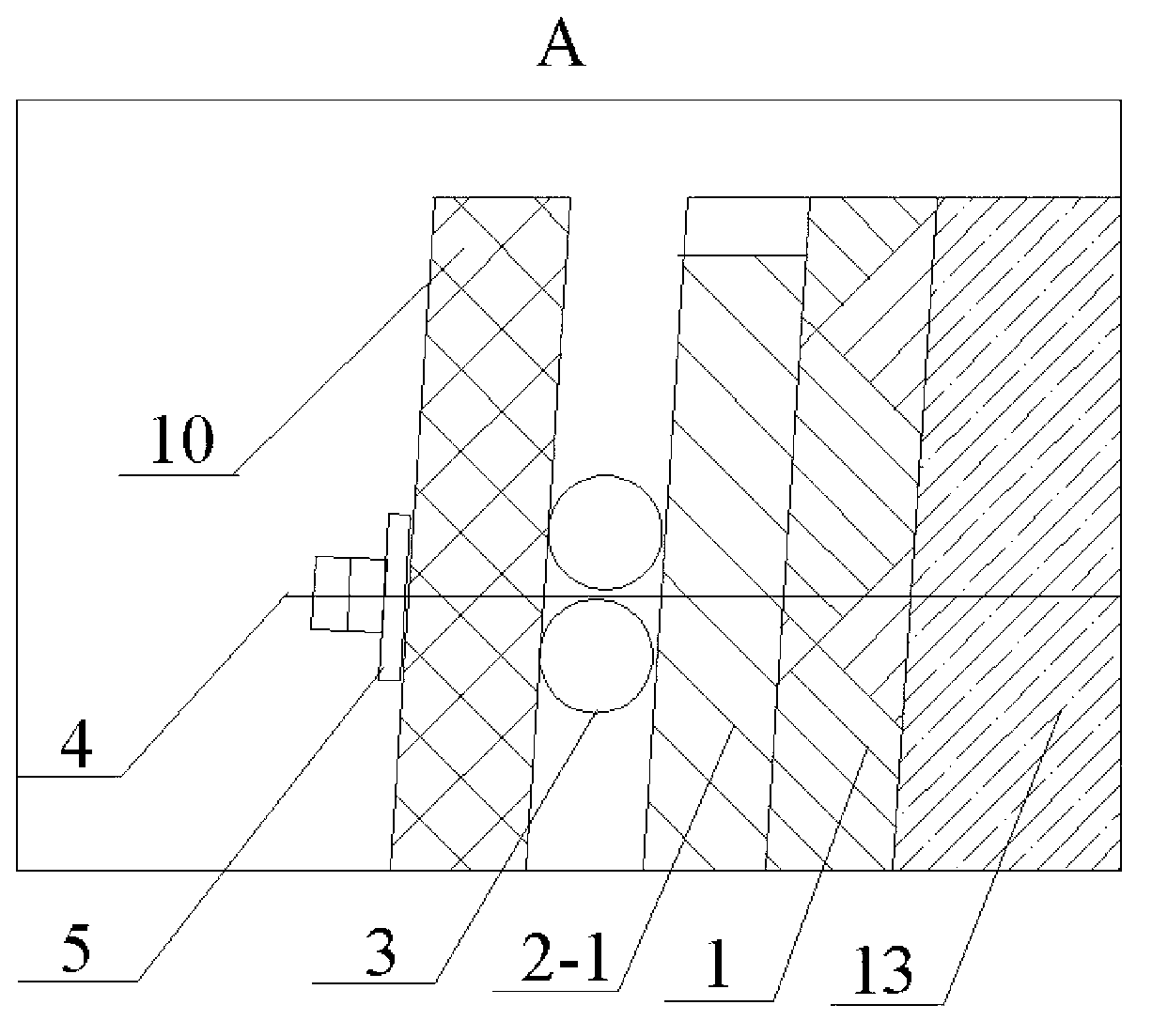

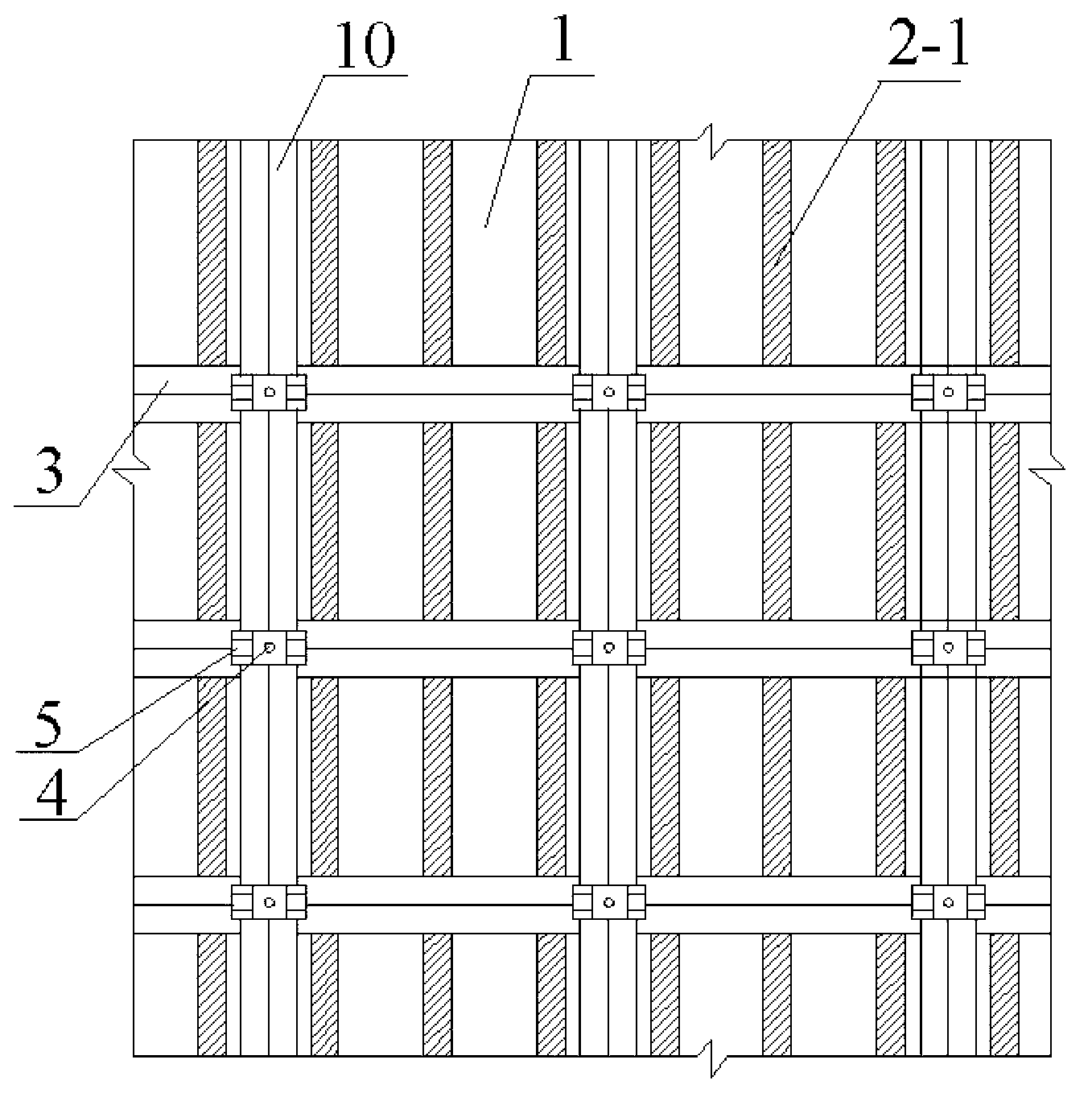

[0045] A construction method for forming a concrete pool wall at one time, the height of the pool wall 13 is 9m, the thickness of the top of the pool wall 13 is 500mm-1100mm, and the side of the pool wall 13 opposite to the side wall 11 of the foundation pit is an inclined surface, such as figure 1 , figure 2 and image 3 shown, including the following steps:

[0046] A. Erection of pool wall steel frame

[0047] Bind the pool wall reinforcement frame at the design position of the precast floor concrete 8, the pool wall reinforcement frame is arranged between two adjacent precast concrete columns, and the pool wall reinforcement frame is bounded by several horizontal and vertical reinforcement bars made.

[0048] B. Installation of pool wall formwork

[0049] a. The erection of the template

[0050]The side template 1 is vertically spliced by a plurality of 18mm thick multi-layer board structure templates, the height of the template corresponds to the height of the poo...

Embodiment 2

[0067] A construction method for one-time forming of the concrete pool wall, the height of the pool wall 13 is 9m, the thickness of the pool wall 13 is 300mm, and the inner and outer surfaces of the pool wall 13 are directly facing the side walls of the foundation pit, such as Figure 4 , Figure 5 and Image 6 shown, including the following steps:

[0068] A. Erection of pool wall steel frame

[0069] Bind the pool wall reinforcement frame at the design position of the precast floor concrete 8, the pool wall reinforcement frame is arranged between two adjacent precast concrete columns, and the pool wall reinforcement frame is bounded by several horizontal and vertical reinforcement bars made.

[0070] B. Installation of pool wall formwork

[0071] a. The erection of the template

[0072] The side template 1 is vertically spliced by a plurality of 18mm thick multi-layer board structure templates, the height of the template corresponds to the height of the pool wall 13, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com