House construction method and house

A construction method and house technology, applied in the direction of building structure, construction, building components, etc., can solve the problems of long construction period, complicated operation and high construction cost, and achieve the effect of high construction efficiency, good safety and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Contraction below Figure 1-22 The embodiment given further illustrates the specific embodiments of the housing construction method of the present invention. The housing construction method of the present invention is not limited to the description of the following embodiments.

[0062] The construction method of the present invention, including the module room production step, the module room production steps include the following sub-steps:

[0063] Step 1, including the following synchronization or subsequent subsections:

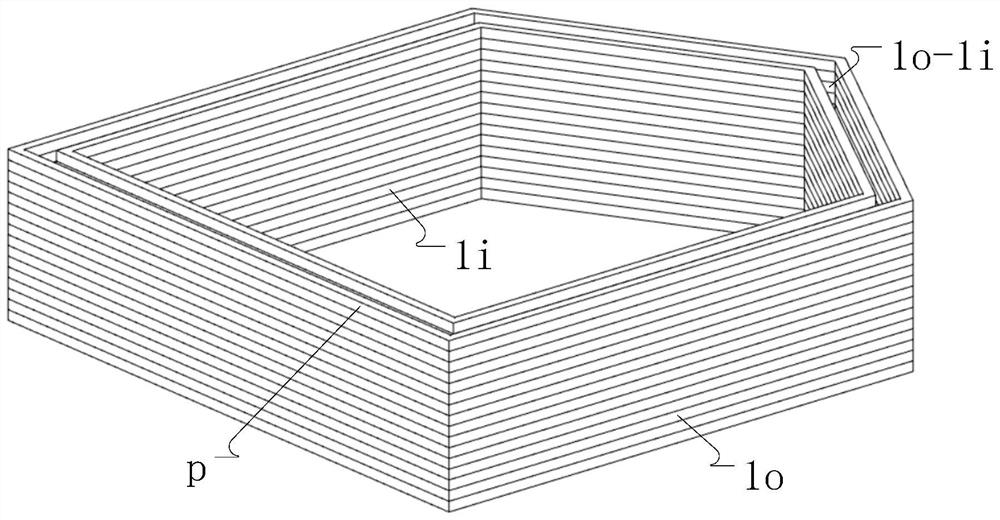

[0064] Step 1A, such as figure 1 As shown, the module room wall 1i and module room outer ring 1i, module room outer ring 1 套 is set in the module room wall 1i exterior and module room outer ring 1O and module room There is a pouring cavity 1O-1i between the wall 1i.

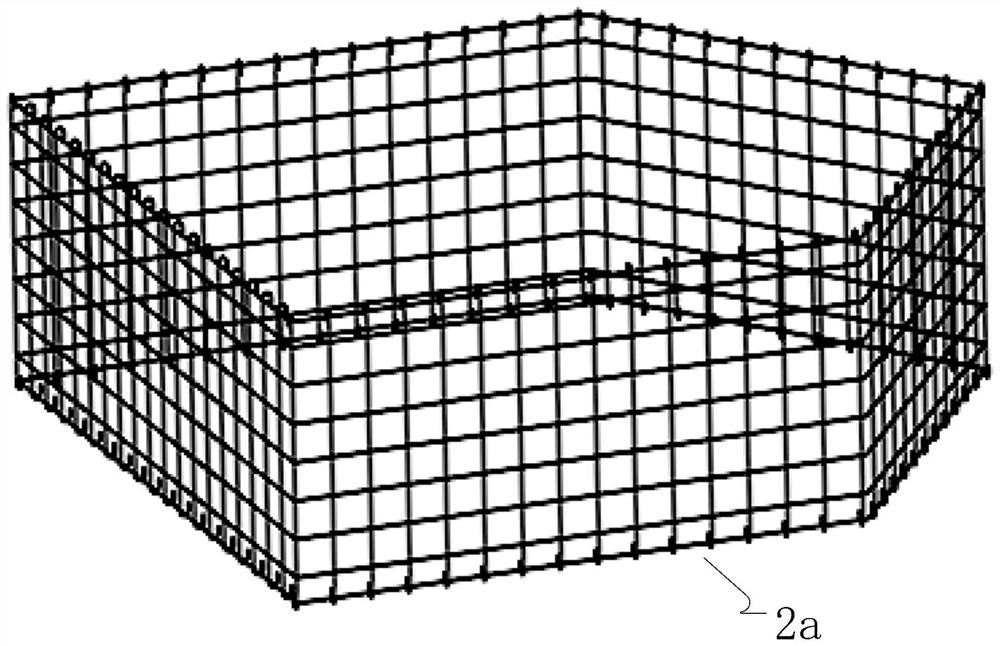

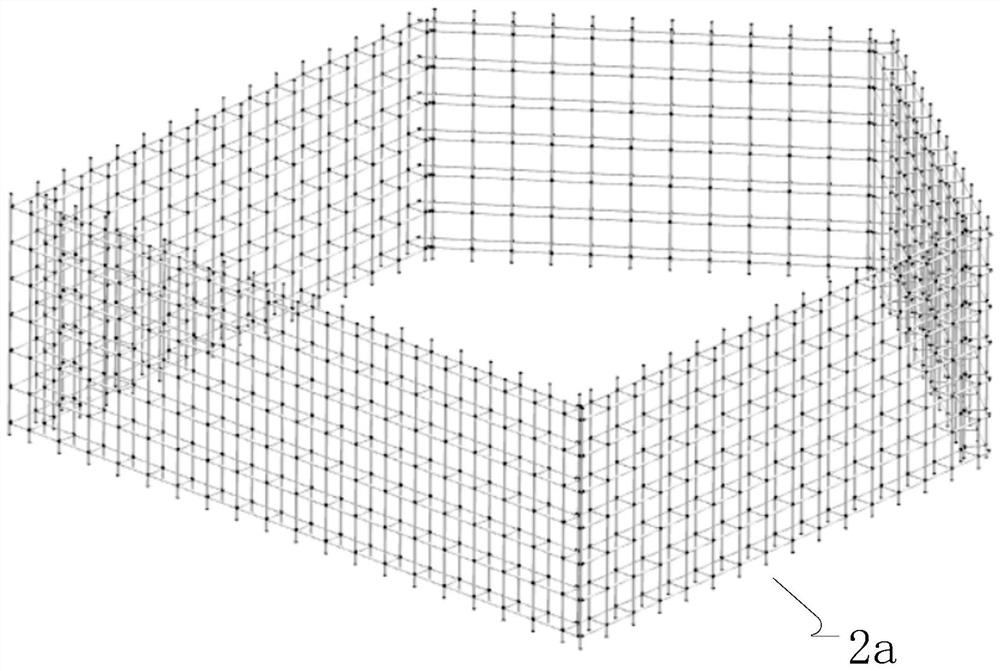

[0065] Step 1b, the reinforcing rib structure is produced; the reinforcing rib structure includes a reinforcing cage 2a, and the shape of the reinforcing rib cage 2a is adapted to the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com