Silicon carbide fiber cloth reinforced polyimide resin base structure wave-absorbing material and preparation method thereof

A technology of polyimide resin and silicon carbide fiber is applied in the field of wave absorbing materials, which can solve the problems of low strength and no wave absorbing properties, and achieve the effects of good structural integrity, excellent molding process performance, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

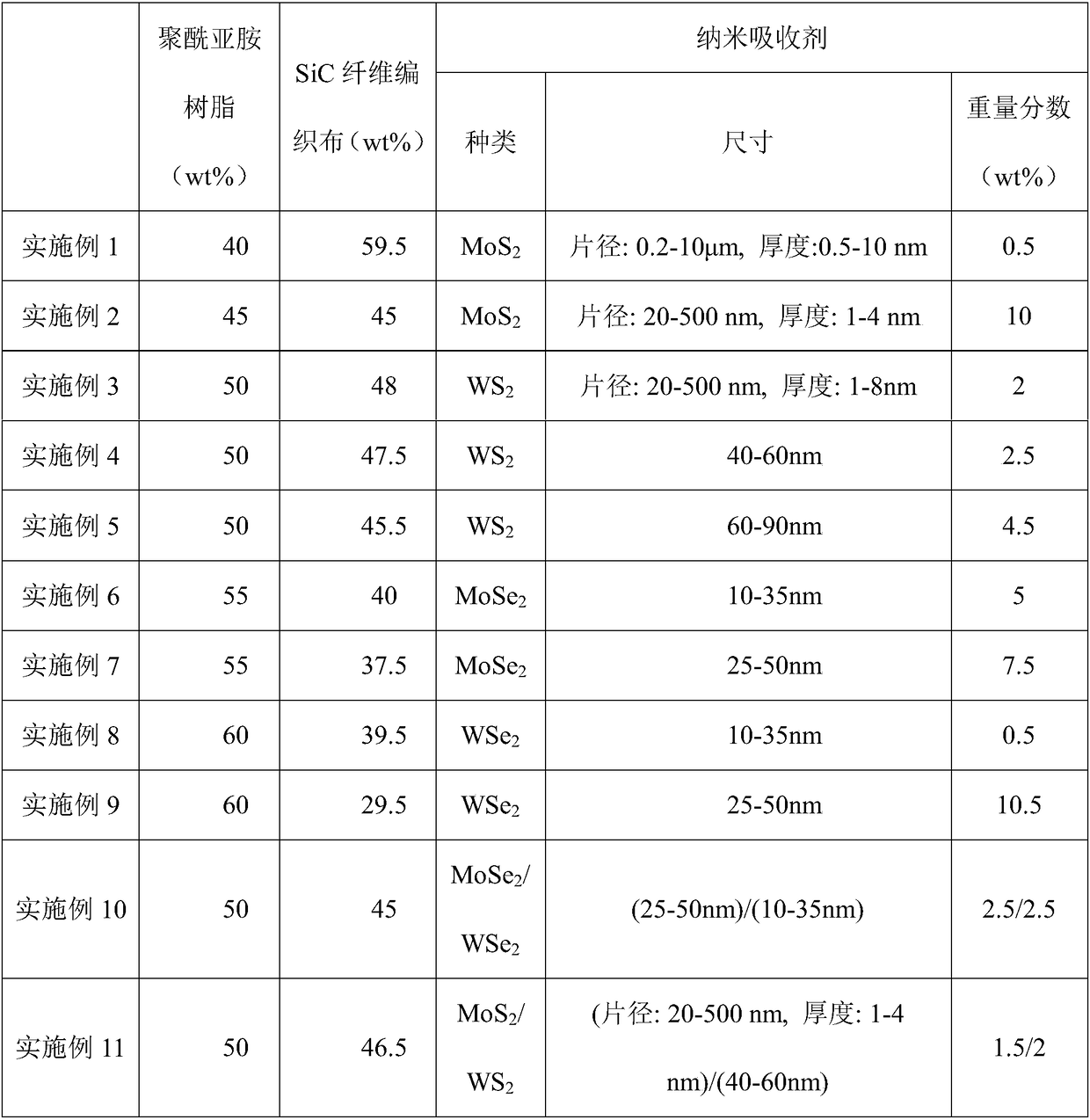

[0026] The invention relates to a preparation method of a structural wave-absorbing material, in particular to a silicon carbide fiber cloth reinforced high-temperature-resistant polyimide resin-based structural wave-absorbing material and a preparation method thereof. The reinforcement is silicon carbide fiber cloth, the matrix is polyimide resin, and the filler is nano-transition metal sulfide absorbent. Among them, the mass fraction of silicon carbide fiber cloth is 40wt% to 60wt%, the mass fraction of polyimide resin is 29.5wt% to 59.5wt%, and the mass fraction of nano absorbent is 0.5wt% to 10.5wt%. . Among them, the polyimide resin is formed by the curing of its precursor polyamic acid, the solid content of the polyamic acid used is (in N-N dimethylacetamide solvent) 20-45%, and the absorbent is nanometer Molybdenum sulfide, nano tungsten disulfide, nano molybdenum diselenide and nano tungsten diselenide or a composite of several absorbents.

[0027] The morphology o...

Embodiment 1 to Embodiment 11

[0029] The preparation method of the present invention is to mix the nano-absorbent and the polyamic acid solution uniformly, and then paint the uniformly mixed solution on the silicon carbide fiber cloth, and prepare the structural wave-absorbing composite material by hot pressing, and the structural wave-absorbing material It is composed of polyimide resin, silicon carbide fiber woven cloth and nano absorbent. Specific steps include:

[0030] Step 1. Put the silicon carbide fiber cloth cut to an appropriate size into an acetone solution for ultrasonic cleaning for 1 hour, and then put it into an oven for drying; the drying temperature is 80°C; the ultrasonic power is 100W.

[0031] Step 2. Accurately weigh the mass m1 of the silicon carbide fiber cloth with an electronic analytical balance, weigh the mass m2 of the polyamic acid solution, and weigh the mass m3 of the nano-absorbent. The nano-absorbent is mixed with the corresponding polyamic acid solution, and treated in 10...

Embodiment 12

[0042] Step 1. Put the silicon carbide fiber cloth cut to an appropriate size into an acetone solution for ultrasonic cleaning for 1 hour, and then put it into an oven for drying; the drying temperature is 80°C; the ultrasonic power is 100W.

[0043] Step 2. Accurately weigh the mass m1 of the silicon carbide fiber cloth with an electronic analytical balance, weigh the mass m2 of the polyamic acid solution, and weigh the mass m3 of the nano-absorbent. The nano-absorbent is mixed with the corresponding polyamic acid solution, and treated in 90KHz ultrasonic wave for 4 hours, so that the absorbent is uniformly dispersed in the polyamic acid solution.

[0044] Step 3. Apply the mixed solution of nano-absorbent and polyamic acid to the dried silicon carbide fiber cloth, put it into a vacuum oven, and evacuate it to remove the air bubbles in the preform. Under the condition of a vacuum degree of 0.07MPa Keep it down for 5 minutes, and then return to normal pressure. The dipped pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com