Synchronous construction method for cantilever structure and tower body of lookout tower

A technology of synchronous construction and tower body, which is applied to the preparation of building components on site, building structure, and processing of building materials. It can solve the problems that the overall performance is not as good as one-time integral pouring, and the location of construction joints is unreasonable. Achieve the effect of good structural integrity and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Project objectives:

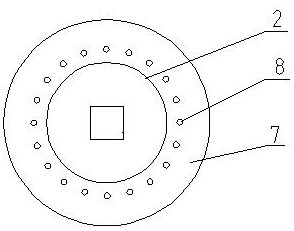

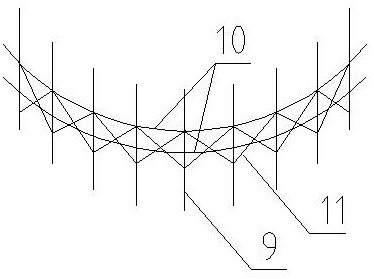

[0017] The main body of the watchtower is a circular silo with a total height of 101.50 m. There is a ring-shaped cantilevered structural layer with a floor height of 4 m at 43 m to 47 m. The upper and lower floors of the cantilevered structural layer are designed to have a thickness of 0.2 m.

[0018] 2. Construction steps:

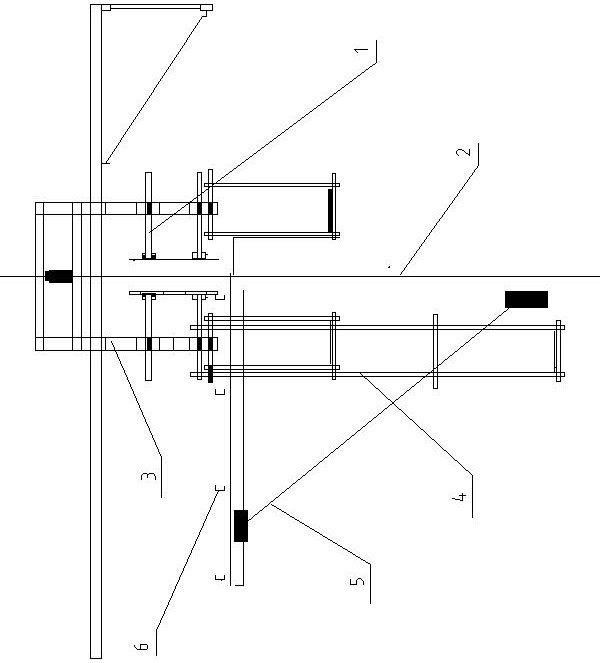

[0019] Such as figure 1 , 2 , as shown in 3:

[0020] 1. Through the sliding system 1, the main body 2 of the 43 m circular silo watchtower from the ground is constructed using normal sliding formwork.

[0021] When the initial height of the sliding form reaches the height of the hanger required for installation, a plurality of sets of temporary hangers 4 are connected through the hanger 3 on the sliding system outside the main body of the tower.

[0022] During the concrete pouring process of the main body of the tower, a number of embedded parts protruding from the outer surface of the outer wall of the main body of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com