Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, transistors, etc., can solve problems such as high performance, underlying substrate consumption, film layer shedding, etc., achieve good electrical performance, inhibit substrate oxidation, The effect of good structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

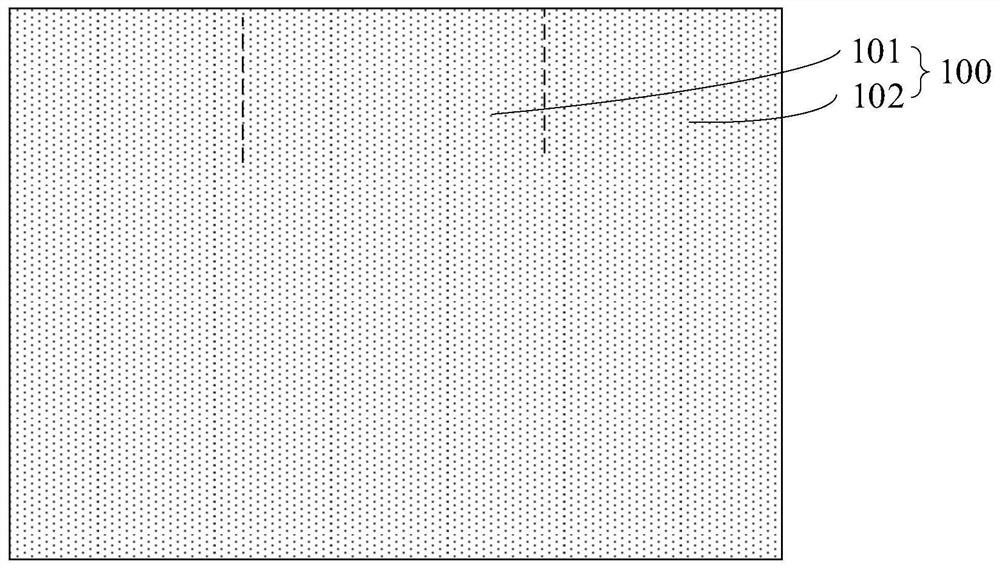

[0023] refer to figure 1 , a substrate 100 is provided, the substrate 100 includes an active region 101 and an isolation region 102 located between adjacent active regions 101 , the active region 101 includes a corner region adjacent to the isolation region 102 .

[0024] The material of the substrate 100 includes polysilicon, and the subsequent removal process for the substrate 100 is mostly performed in an atmospheric environment, where polysilicon will naturally oxidize.

[0025] It should be noted that the dividing line used to divide the active region 101 and the isolation region 102 in the illustration herein is only used for illustration. In fact, the dividing line is not necessarily perpendicular to the surface of the substrate 100, and the dividing line may also have a certain inclination angle. , the inclination angle of the dividing line may be equal to the inclination angle of the sidewall of the trench formed by subsequent etching.

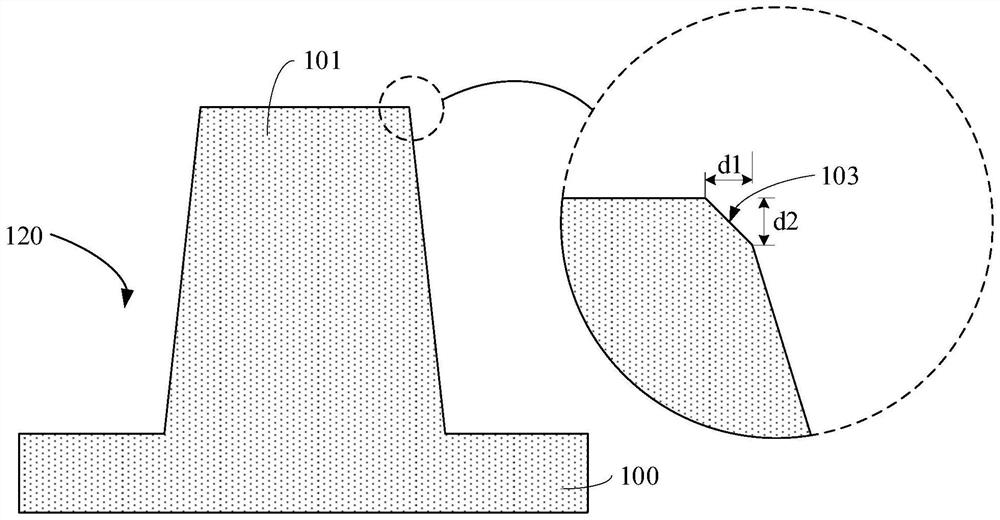

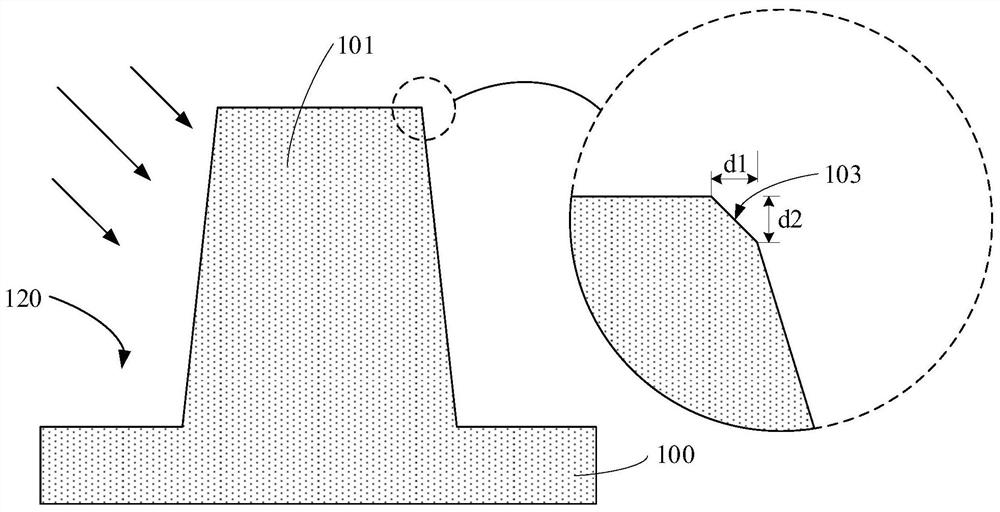

[0026] refer to figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com