Foam cement pouring die

A technology for pouring molds and foamed cement, which is applied in the field of building materials processing, can solve the problems of the leather-making cloth wrapping frame is not tight, the foamed cement is not flat, and achieves the effects of saving mold investment, simple structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

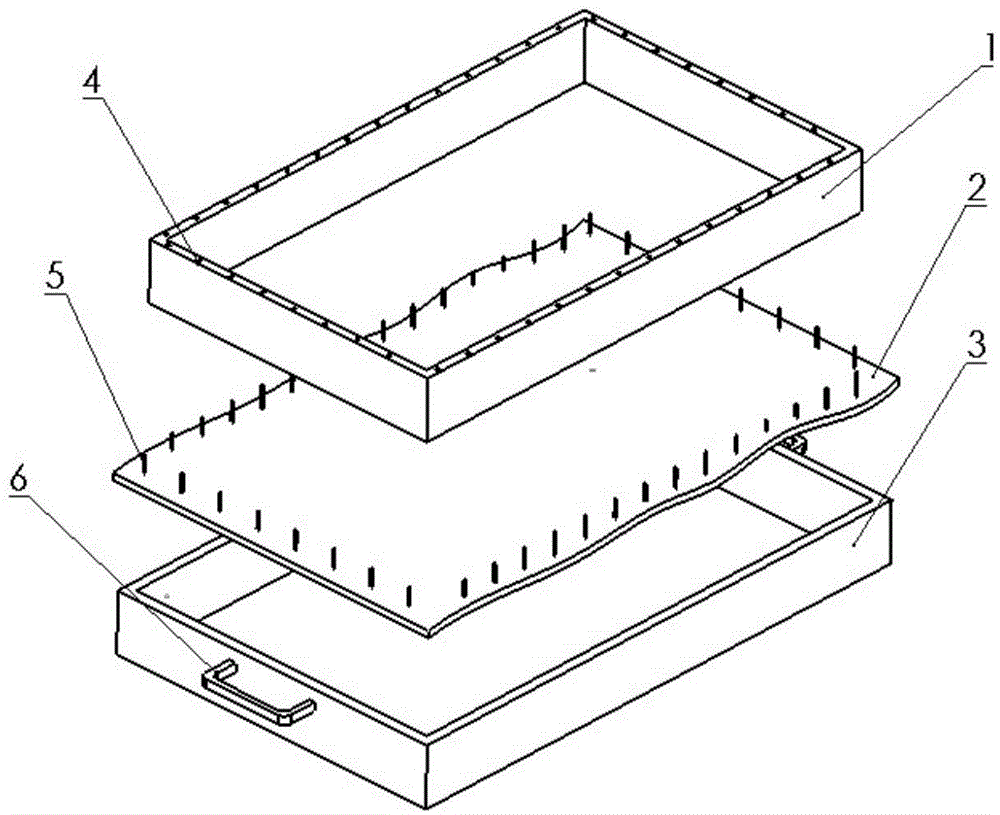

[0015] A foam cement pouring mold, comprising an inner frame 1, a cloth pad 2 and an outer frame 3;

[0016] Both the inner frame 1 and the outer frame 3 are rectangular, and the outer wall of the inner frame 1 matches the inner wall of the outer frame 3;

[0017] The cloth pad 2 is made of artificial leather, and the upper end surface is provided with a heat-resistant coating, which is laid flat in the outer frame 3, and partly placed on the frame of the outer frame 3;

[0018] The inner frame 1 is placed on the heat-resistant coating.

[0019] A number of pin holes 4 are evenly opened on the frame of the inner frame 1, and a number of pins 5 matching the pin holes 4 are evenly provided on the edge of the upper end surface of the cloth pad 2, and each pin hole 4 corresponds to A pin 5.

[0020] Two handles are arranged symmetrically on both ends of the outer frame 3 .

[0021] The embodiments of the present invention have been described in detail above, but the content des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com