Construction method of constructional column after completion of secondary masonry structure

A technology of masonry structure and construction method, which is applied in the direction of building structure, preparation of building components on site, building components, etc. It can solve the problem of affecting the safety of secondary structure walls, formwork devices cannot be reused, and wooden squares are placed irregularly and other issues, to achieve the effect of reducing template cost, reducing quality defects, and improving the quality of perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

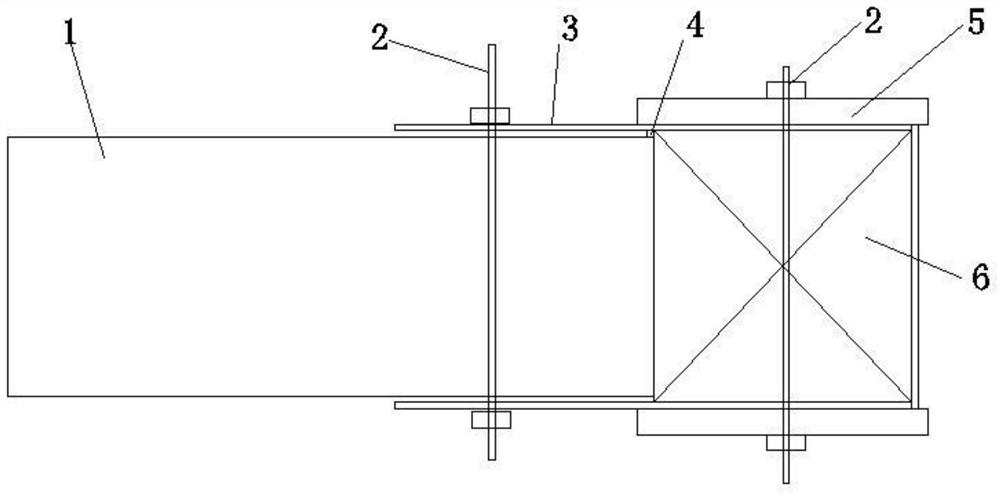

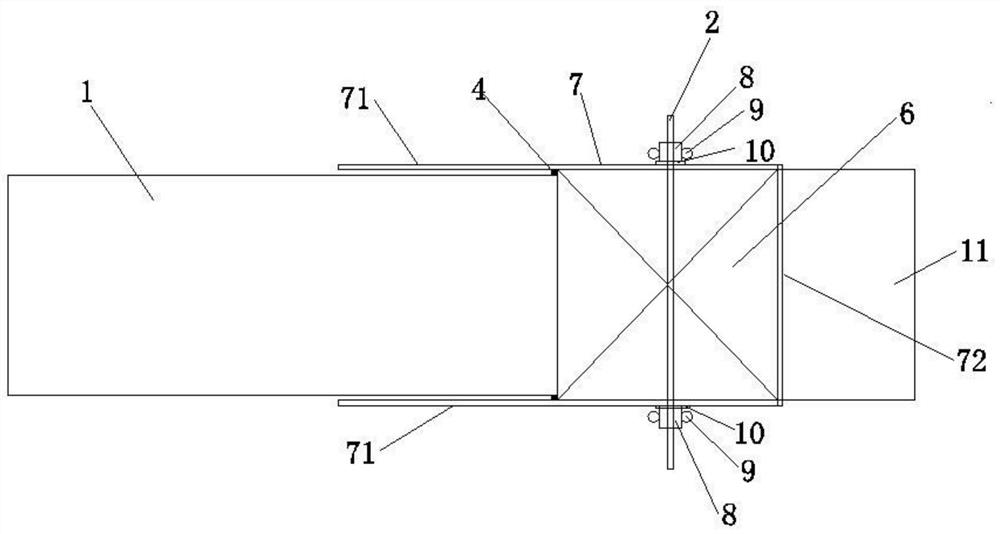

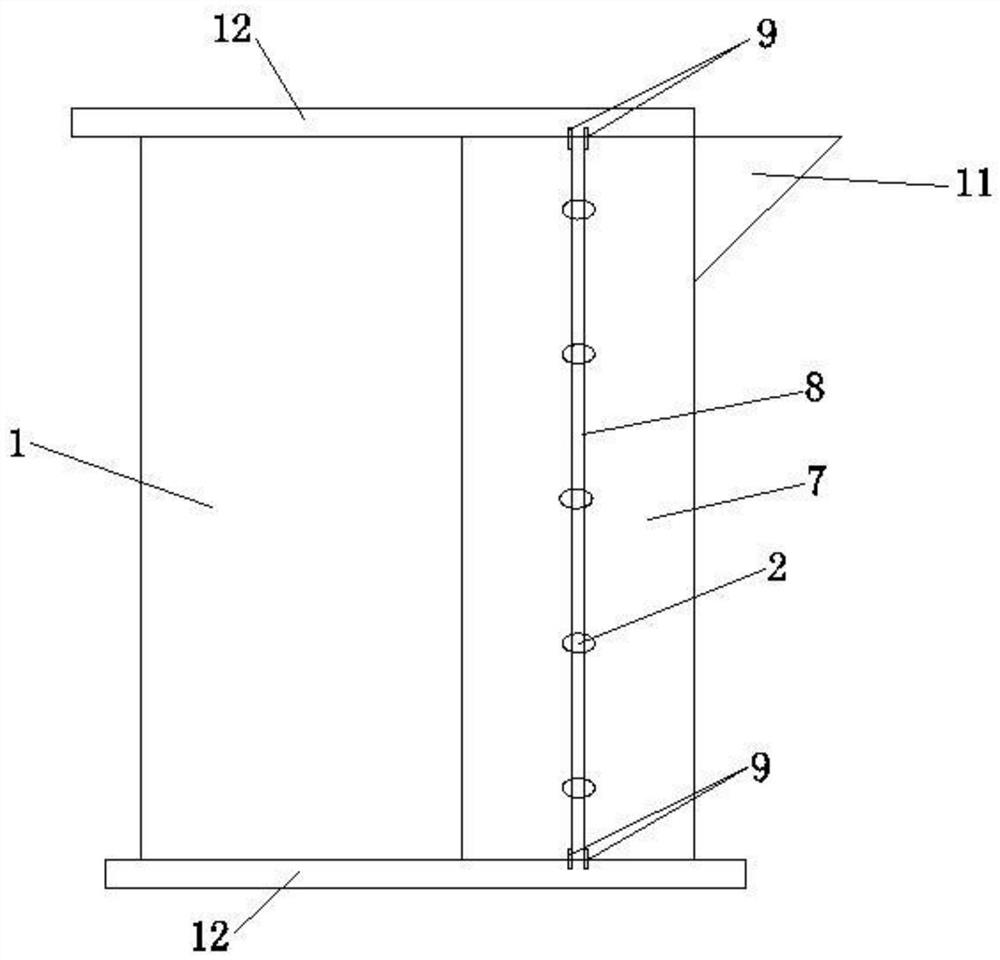

[0021] as attached Figure 2-Figure 3 As shown, a construction method of a structural column after the secondary masonry structure is completed, the formwork device used includes a shaped steel formwork 7, a square tube 8, a pull bolt 2, a closing pad 10, and a fixing pin 9. The shaped steel formwork 7 is processed from a steel plate, and the shaped steel formwork 7 includes two oppositely arranged side plates 71 and an end plate 72 vertically connected between the ends of one side of the two side plates 71. The stereotyped steel template 7 has a U shape as a whole, and the side plate 71 and the end plate 72 are connected by welding. The two side plates 71 of the stereotyped steel formwork 7 are correspondingly provided with several tension bolt holes along the height direction, and the centers of the tension bolt holes are located on the same st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com