Patents

Literature

71results about How to "Avoid size deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of vermicular cast iron piston ring

InactiveCN103451510AMeet performance needsHigh tensile strengthPiston ringsFoundry mouldsWear resistanceToughness

The invention discloses a manufacturing method of a vermicular cast iron piston ring. The material of the vermicular cast iron piston ring comprises the following chemical components in percentage by weight: 3.4-4.0% of C, 2.4-3.2% of Si, not more than 0.3% of Mn, 0.2-0.4% of Cr, 0.2-0.6% of Mo, 0.5-1.0% of Cu, 0.05-0.15% of Ti, not more than 0.1% of P, not more than 0.05% of S, 0.009-0.02% of Mg and the balance of Fe and inevitable impurities. The manufacturing method of the vermicular cast iron piston ring comprises the following technical steps of moulding, smelting, casting, shaking out, shot blasting, mechanical processing, surface treatment and the like. By adopting the manufacturing method disclosed by the invention, the thinning of the piston ring is achieved, the production process is relatively simple, and the manufactured vermicular cast iron piston ring is high in elasticity, strength, toughness and wear resistance.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

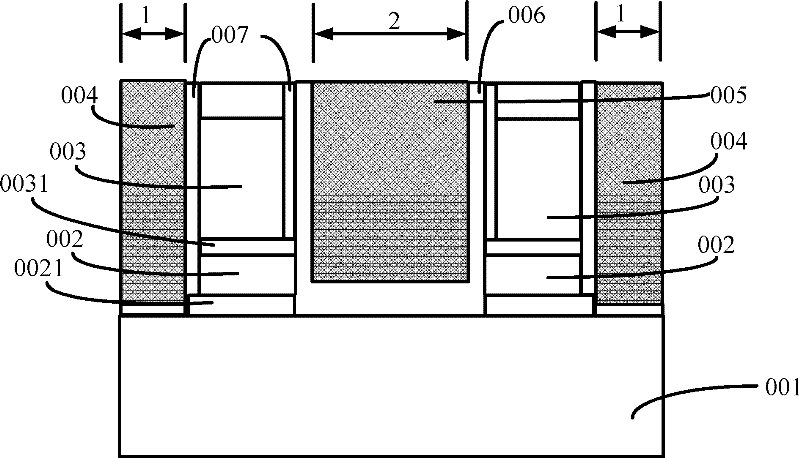

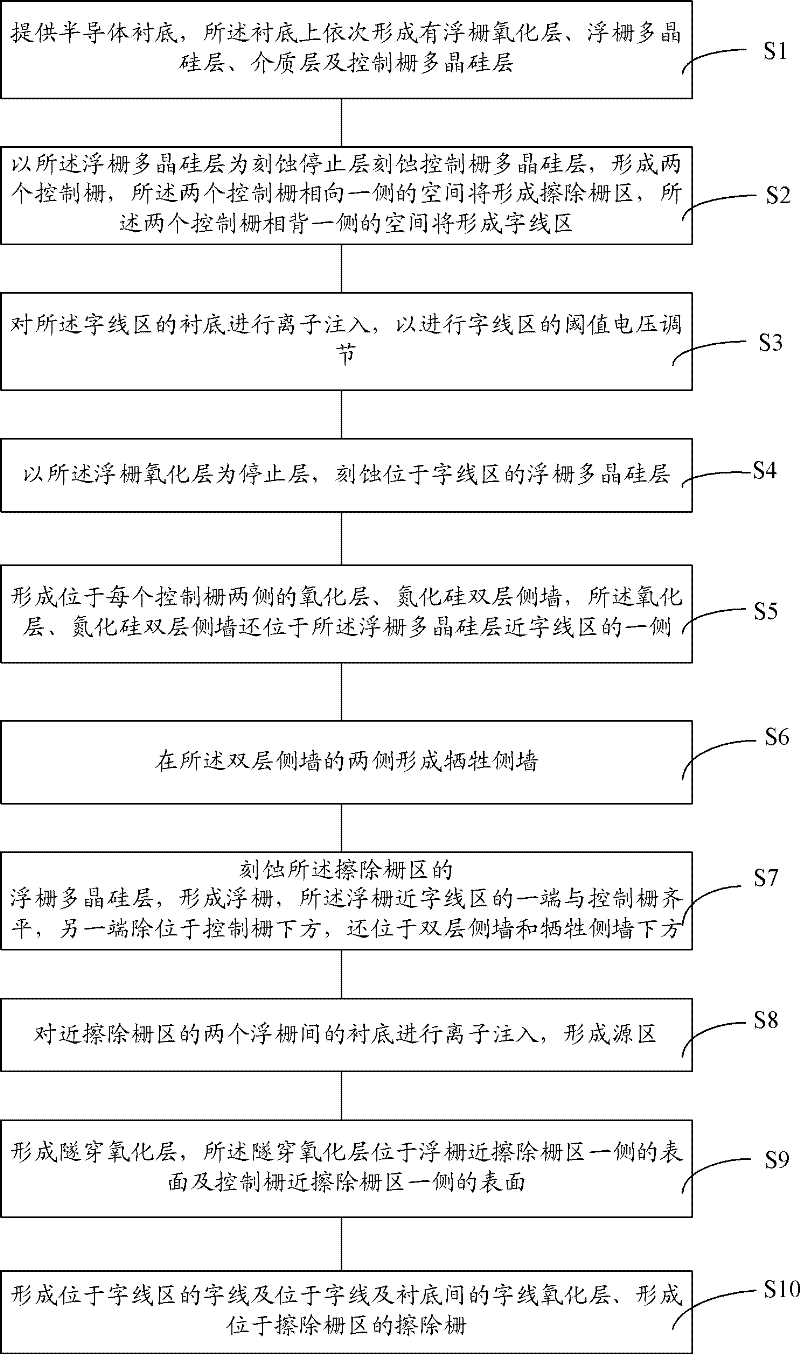

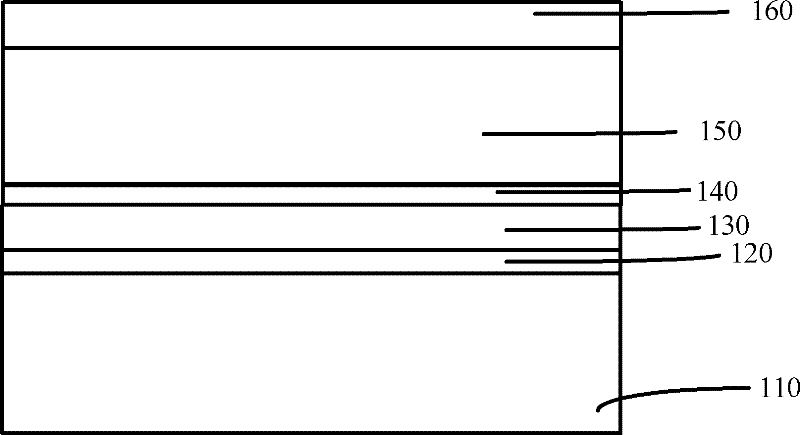

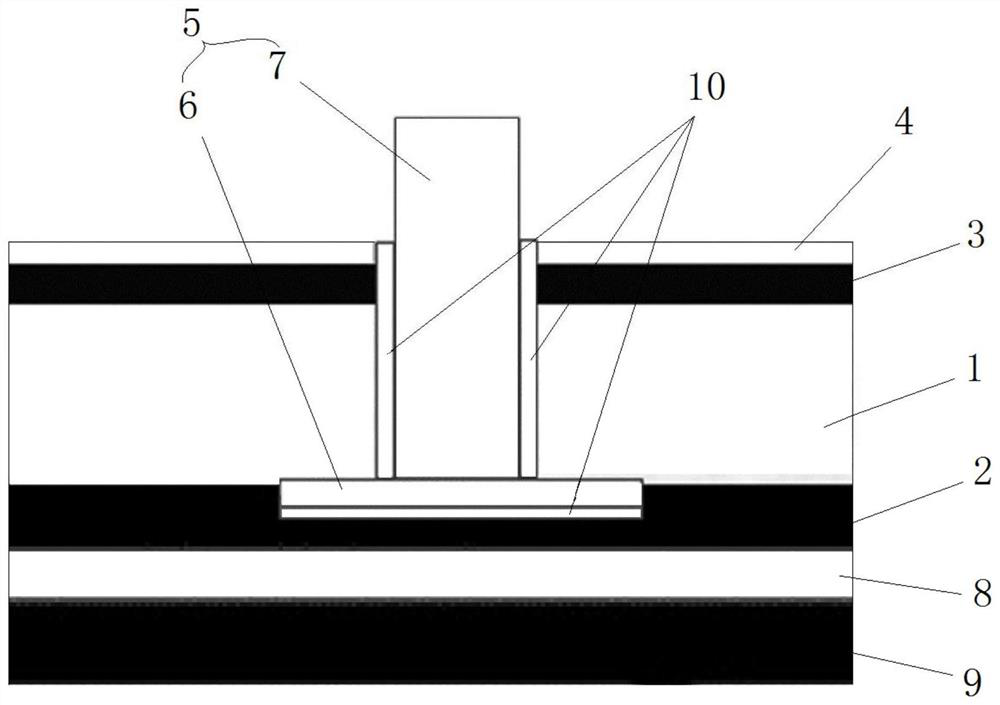

Split-gate memory device and forming method thereof

InactiveCN102543885AReduce widthIncrease erasing speedSolid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideElectrical and Electronics engineering

The invention provides a forming method of a split-gate memory device. The forming method comprises the steps of: providing a substrate; forming two control gates on the substrate, wherein a region between the two control gates is an erasing gate region, and a region outside the two control gates is a word line region; forming a side wall and a sacrifice side wall which is arranged on the side surface of the side wall; using the sacrifice side wall as a mask to form a floating gate; removing the sacrifice side wall; and forming a tunneling oxide and an erasing gate, wherein the erasing gate and the floating gate have lateral overlapped parts. The invention additionally provides the split-gate memory device. By forming the lateral protruding part of the floating gate and enabling the erasing gate and the floating gate to have the lateral overlapped parts, the overlapped parts can effectively reduce the width of the potential barrier of the tunneling oxide and can improve information erasing speed. By etching a silicon oxide layer and a silicon nitride layer in one step to form a dual-layer side wall and using the dual-layer side wall as a gap layer between word lines and the floating gate, the process of the gap layer is simplified, the uniformity of the gap layer is improved and the writing uniformity is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

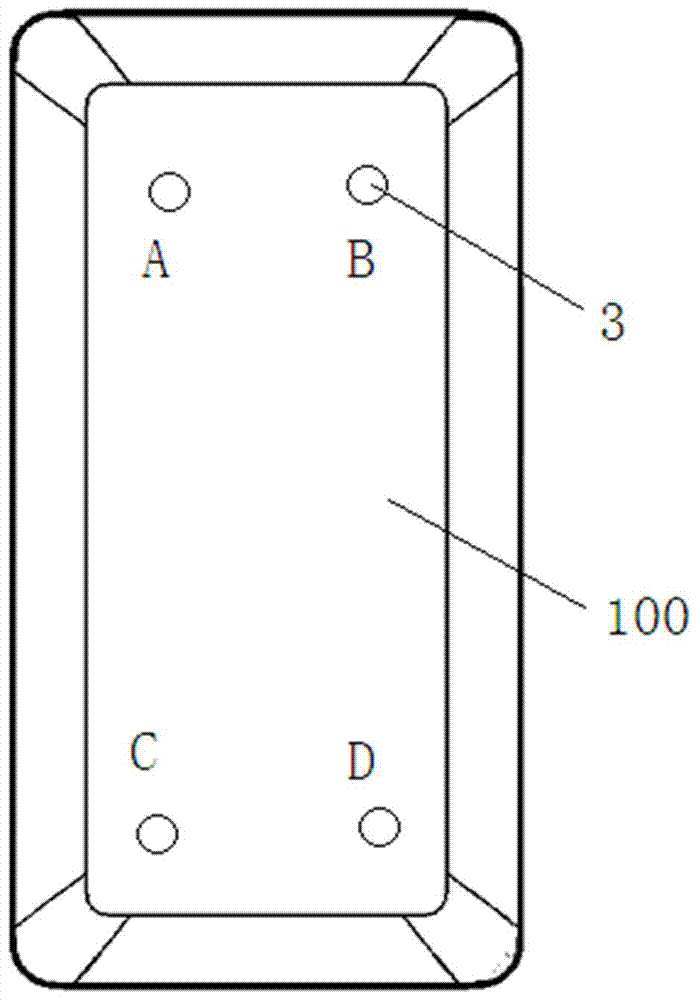

Mobile phone 3D glass positioning and processing system and method

InactiveCN107132813ASmooth edgesRounded edgesComputer controlSimulator controlNumerical controlMachine control

The invention relates to the technical field of mobile phone manufacturing and processing, and discloses a mobile phone 3D glass positioning processing system, including a CNC machine tool head, a probe and a CNC machine tool control unit. The mobile phone 3D glass is fixed on the processing table, and the probe is installed on the CNC machine tool. On the head, determine at least three thickness measurement positions on the surface of the 3D glass of the mobile phone. The control unit of the CNC machine tool controls the probe to probe at the thickness measurement position to obtain the average thickness of the 3D glass surface of the mobile phone and determine the processing amount. On the side of the 3D glass of the mobile phone Determine at least two positions in the edge direction, the control unit of the CNC machine tool controls the probe to detect the position in the direction of the edge, obtains the boundary line of the 3D glass of the mobile phone and determines the processing path, and the control unit of the CNC machine tool performs decrement machining according to the processing amount and the processing path . The invention also discloses a processing method using the above system. The invention makes the edge of the 3D glass smoother and rounder, and increases the precision and strength of the product.

Owner:浙江宇鑫光学科技有限公司

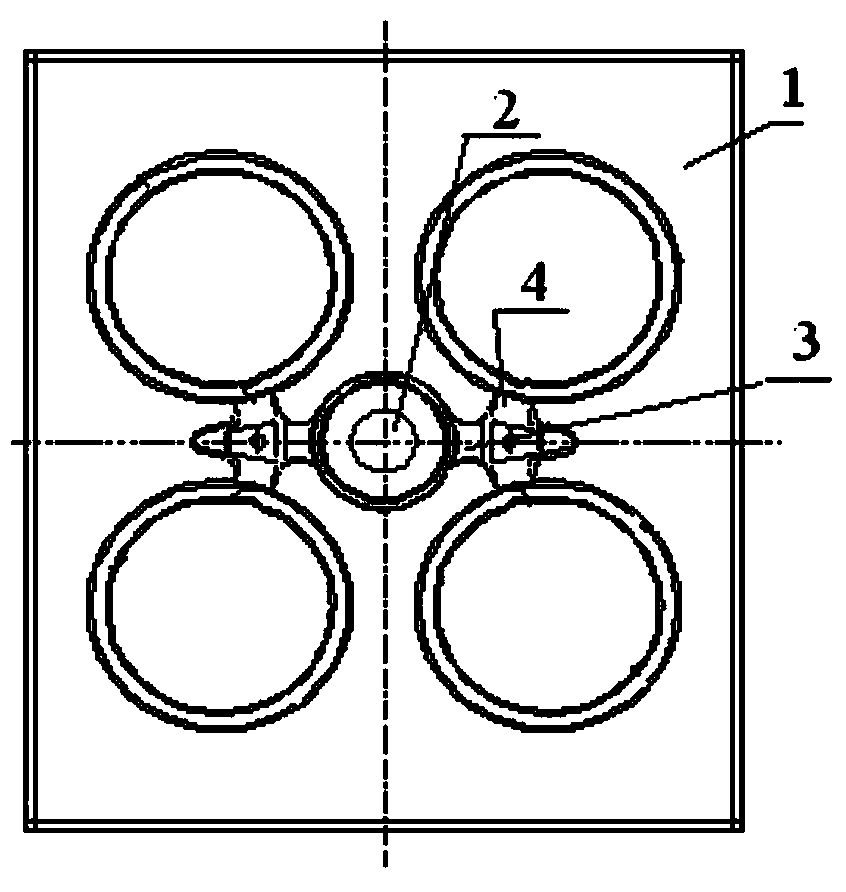

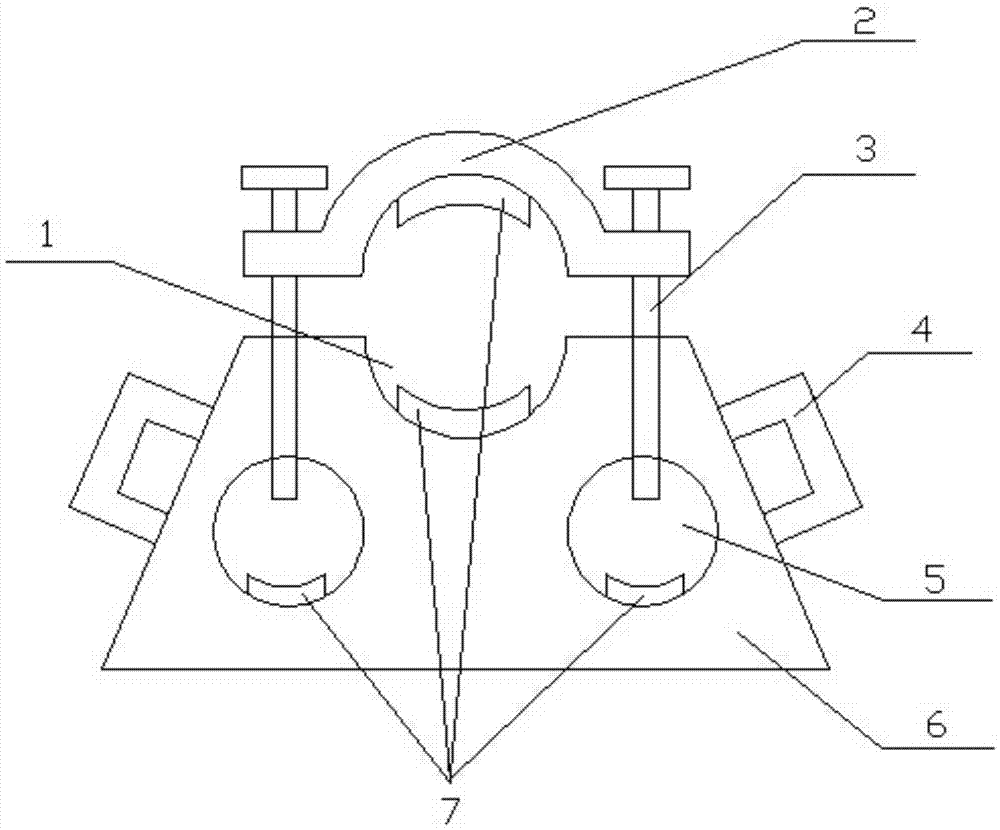

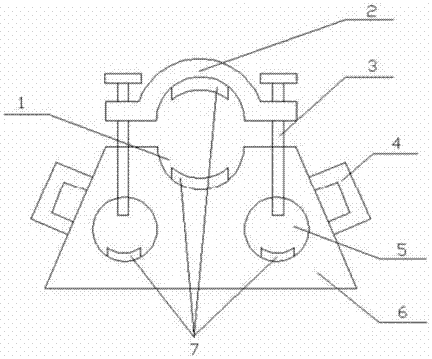

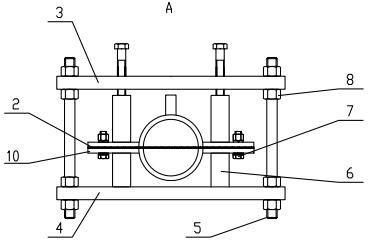

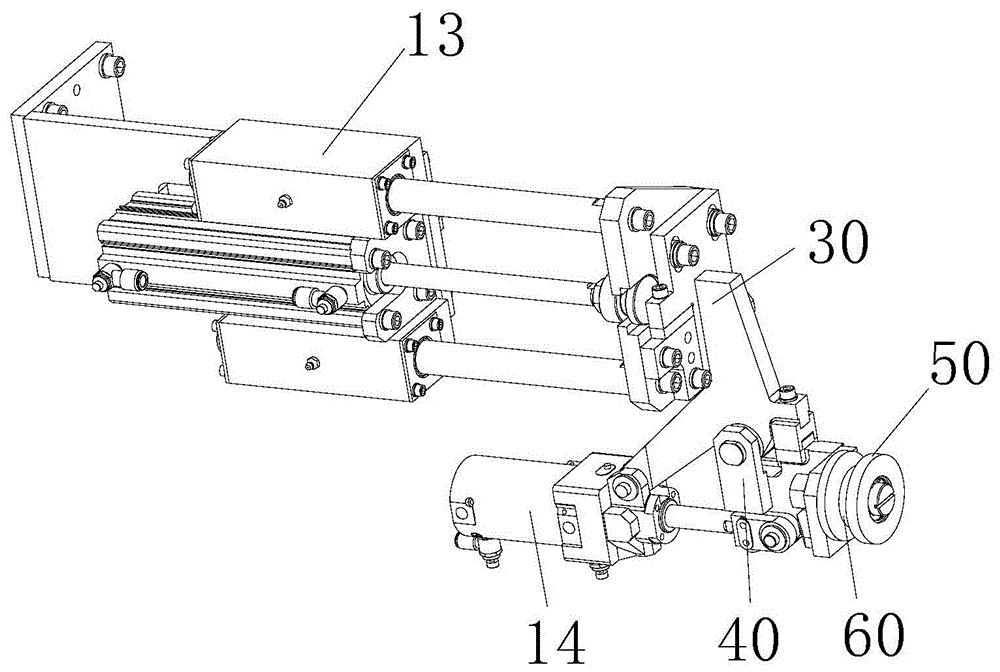

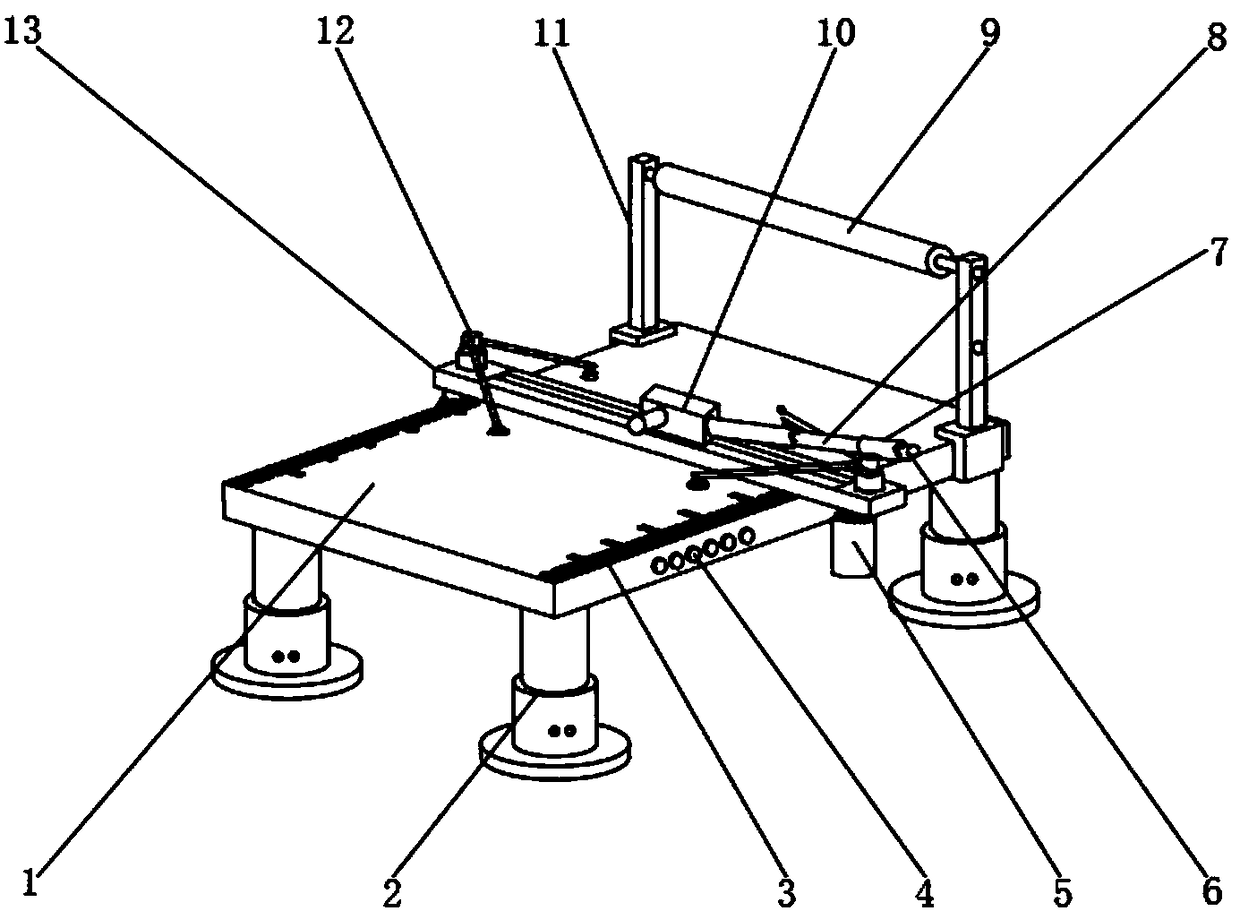

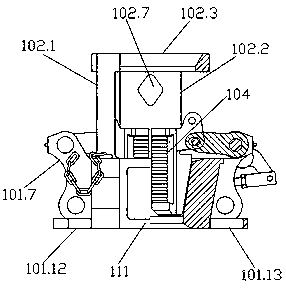

Positioning clamp

InactiveCN105436604AImprove stabilityAvoid size deviationPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a positioning clamp which comprises a base, an upper clamping block and fastening bolts. An arc-shaped groove is formed in the upper end of the base. The upper clamping block is provided with a lower groove facing downwards. The radian of the arc-shaped groove is equal to that of the lower groove. Screw holes are formed in the two sides of the upper clamping block. The fastening bolts are screwed in the screw holes respectively. Two storing holes are formed in the base and located under the screw holes. The fastening bolts stretch into the storing holes. The positioning clamp has the advantages that the design is reasonable, the stability of steel pipe clamping is improved, and dimensional deviation caused by looseness of a steel pipe in the cutting process is prevented.

Owner:TIANJIN SHENGLIDA MECHANICAL EQUIP CO LTD

Casting moulding process for preparing large ship propeller from synthetic resin

InactiveCN102125980AImprove cooling effectReduces defects on the pressure faceFoundry mouldsFoundry coresPropellerEngineering

The invention discloses a casting moulding process for preparing a large ship propeller from synthetic resin, which comprises the following steps of: A, moulding blades, namely manufacturing wood-based sections of the blades by using a wood-based machine center, making the wood-based sections have lattice shapes, filling resin sand in lattice-shaped brackets, scraping uniformly for curing, fixing the blade brackets in a core box on a blade moulding platform in a cross way, and assembling a mould by taking the center line on a mould assembling platform and base lines of blade moulds as references; B, drying the mould, namely naturally drying the blade moulds which are not subjected to mould assembling, forcibly drying the interiors of a runner and a cavity by using a blast stove until the interiors are fully dried, and keeping constant temperature of the interiors; and C, heating a riser, namely arranging a riser heater on the upper part of the riser, heating the riser in an electric heating mode, and stopping heating until the riser is completely solidified and cooled. The casting moulding process meets the requirement on dimension of the integral mould by methods such as separate moulding, unified manufacture, positioning and mould assembling, and the like.

Owner:STX DALIAN ENGINE

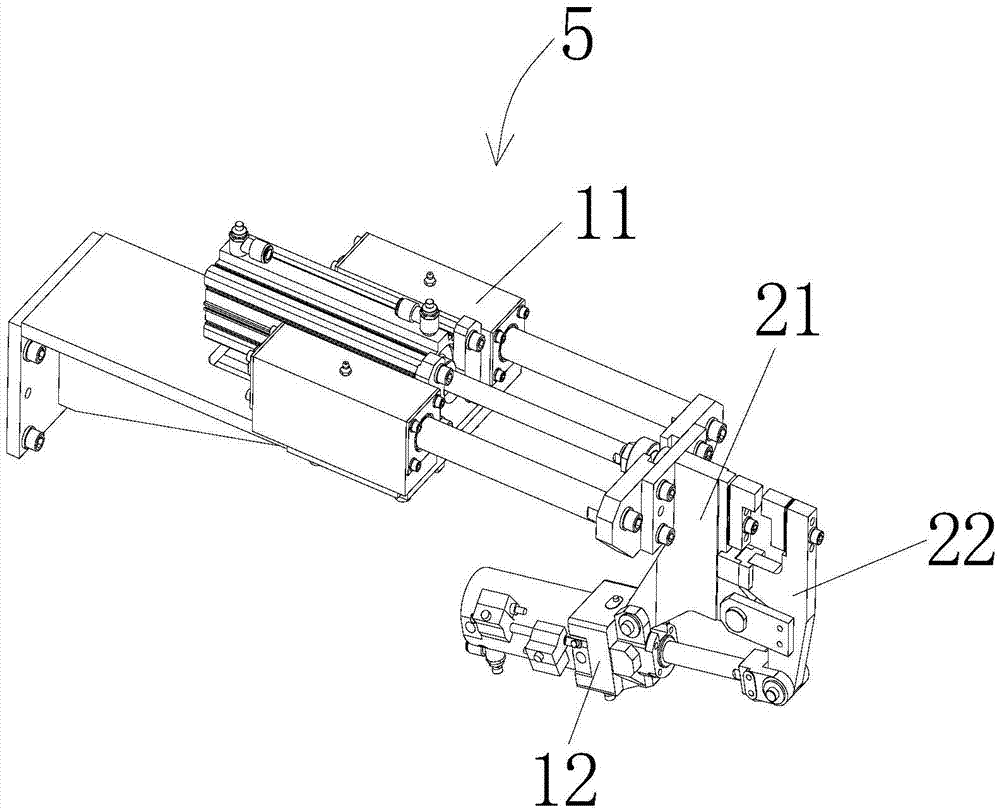

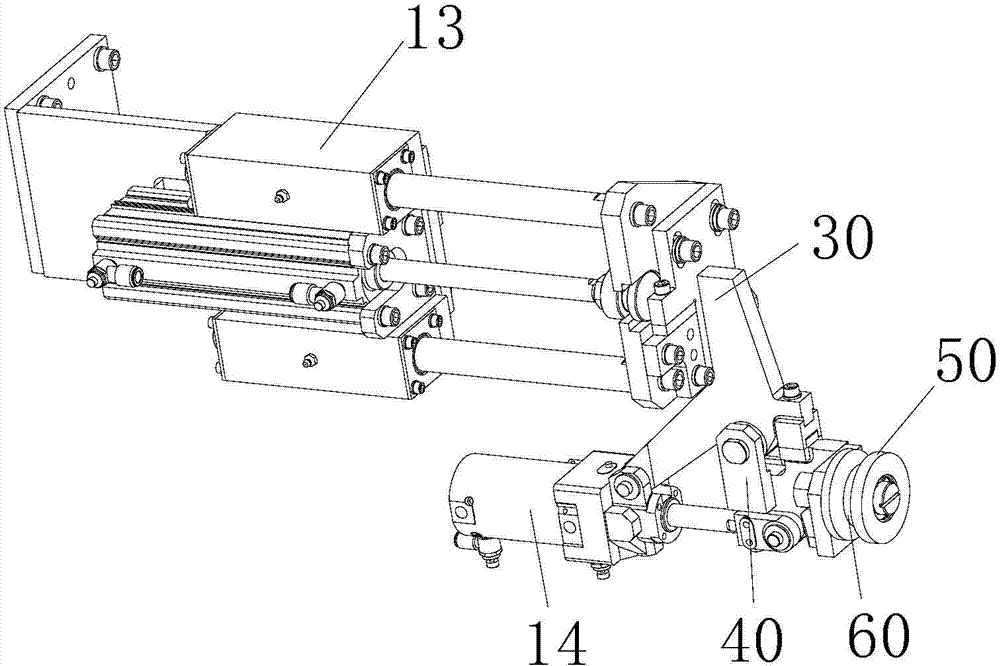

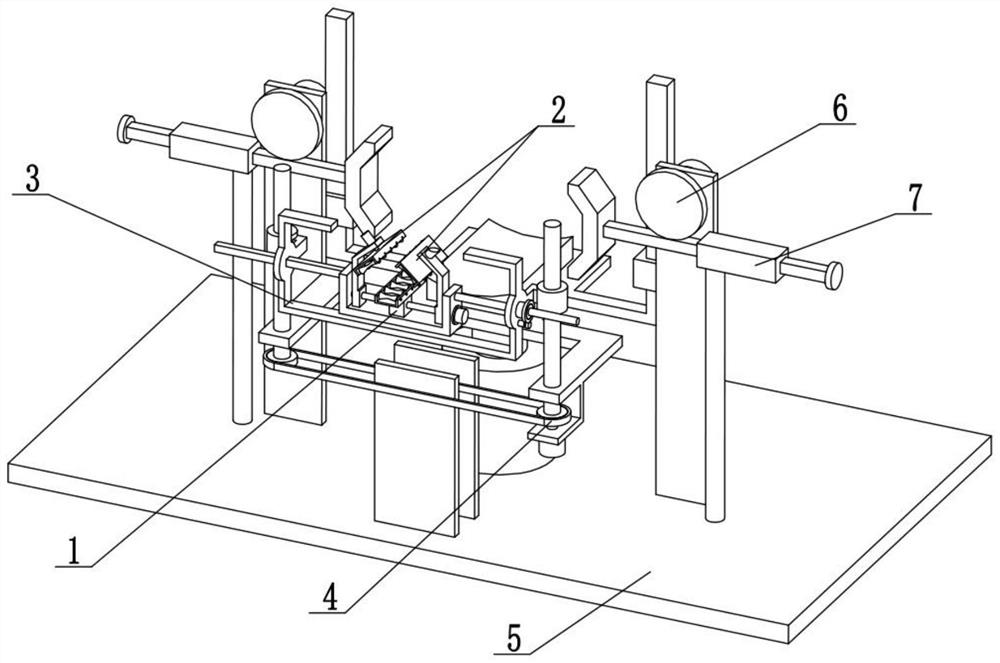

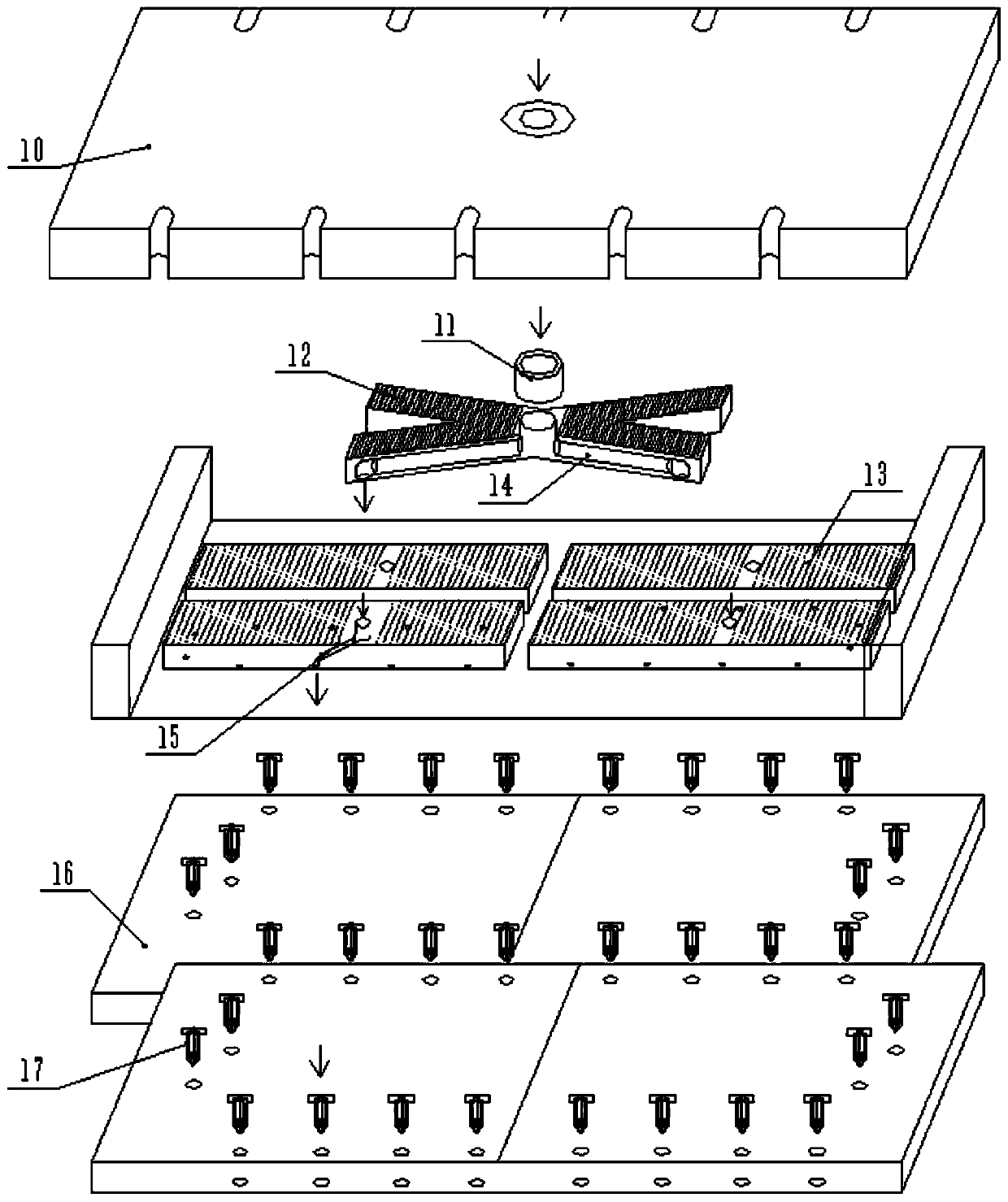

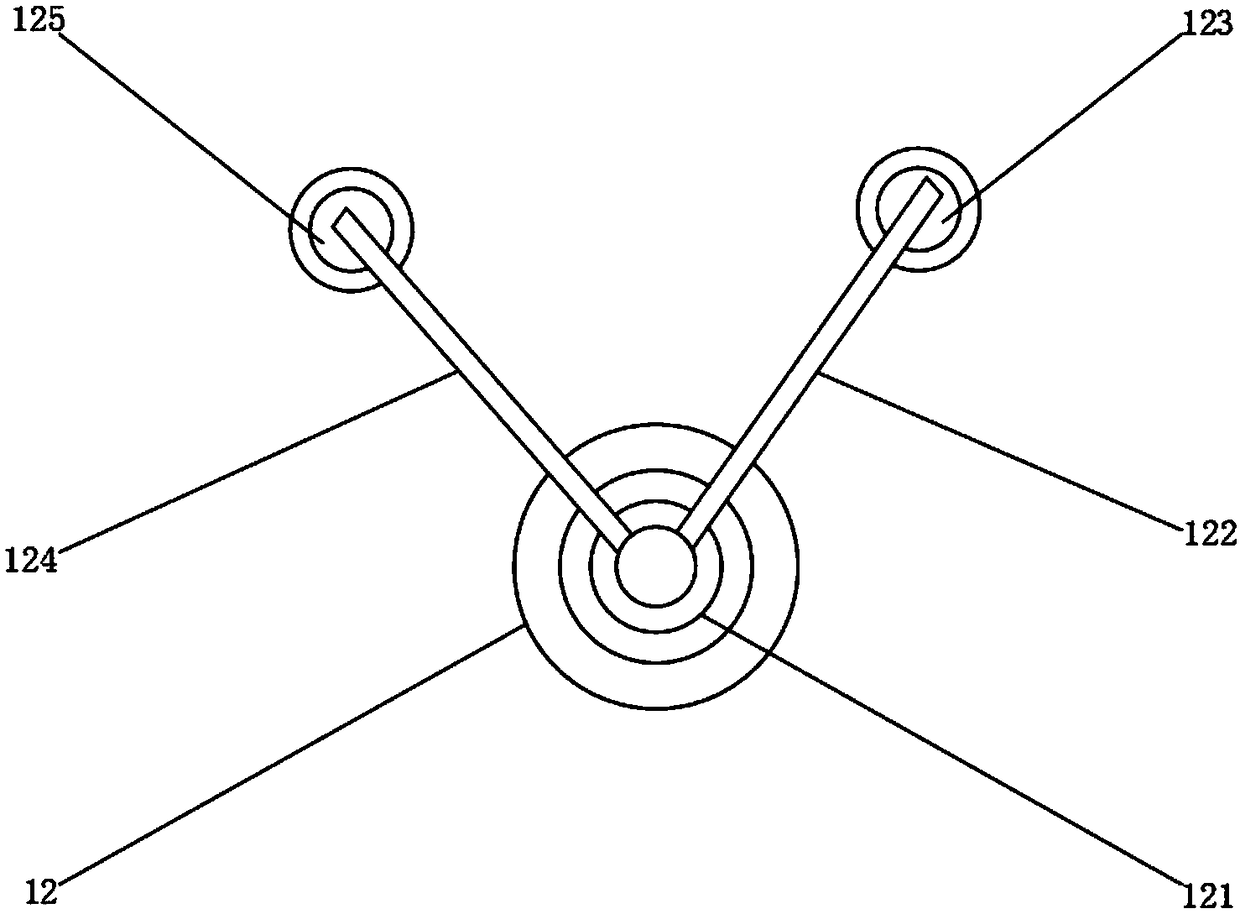

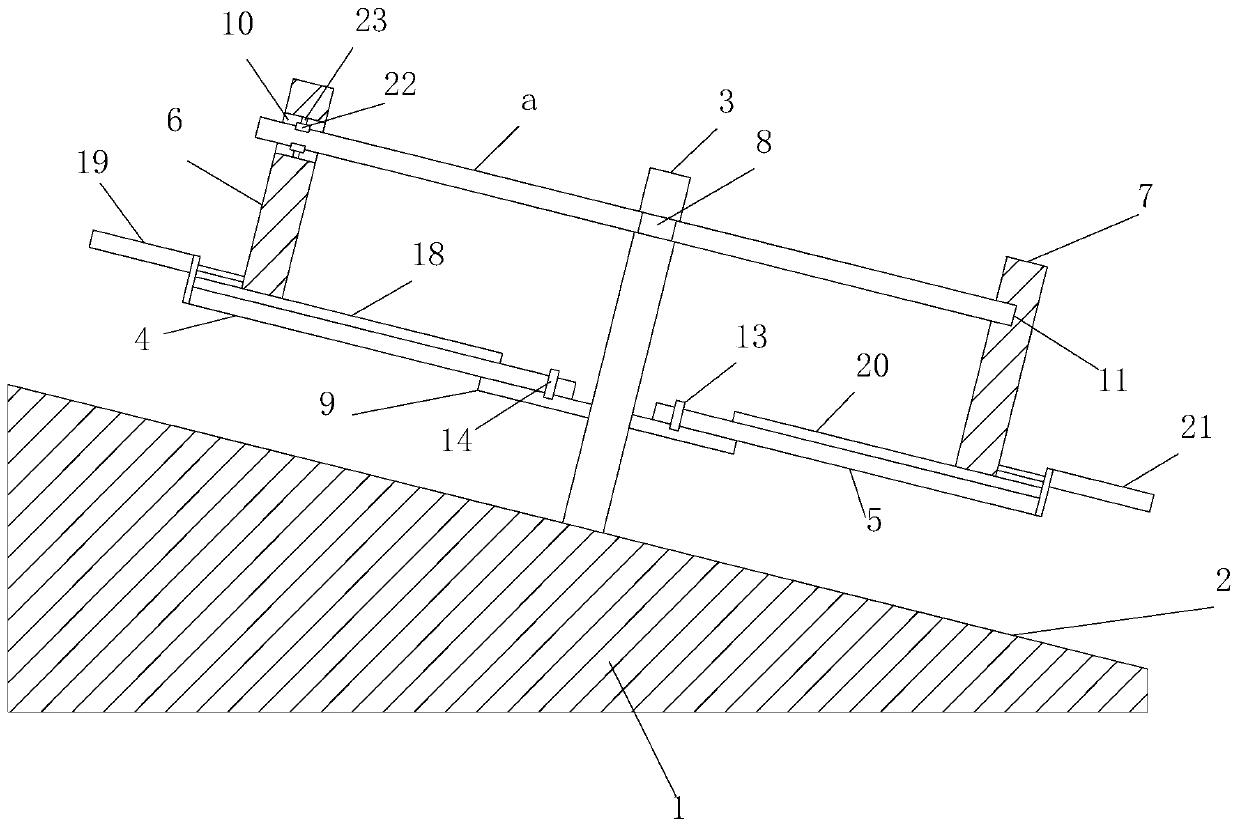

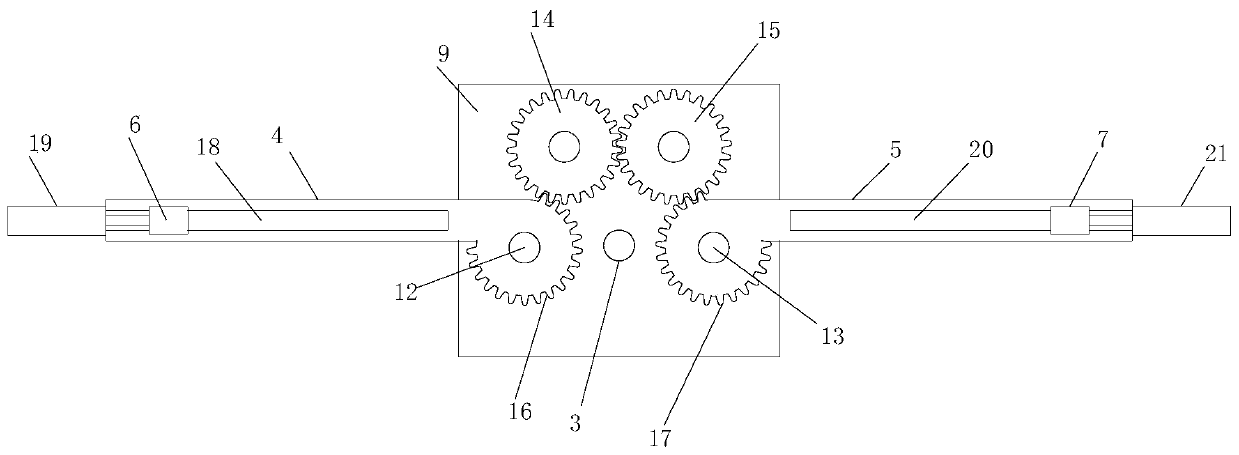

Automatic cutting-off device and cutting-off process for aluminum flat tube

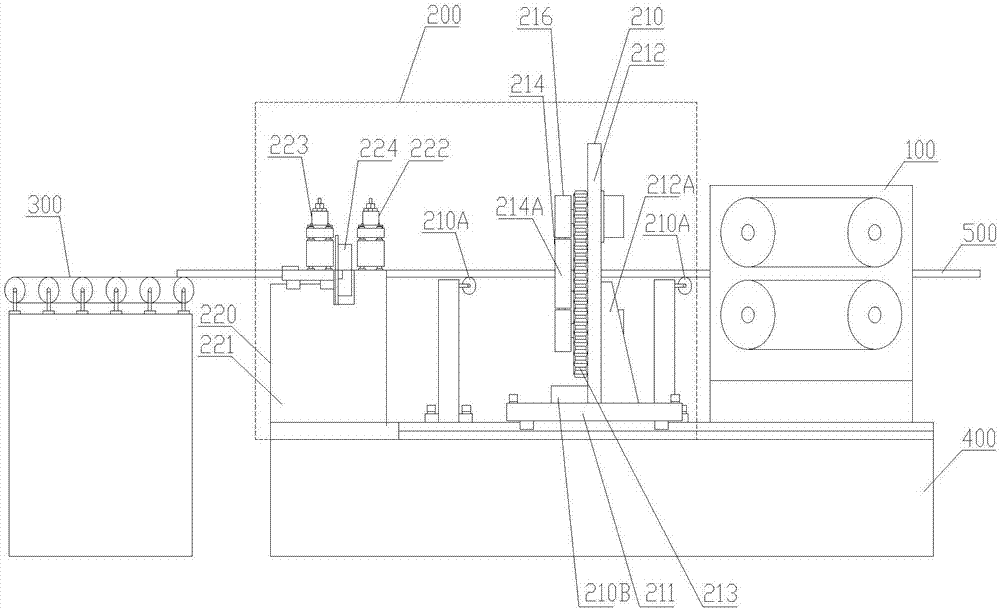

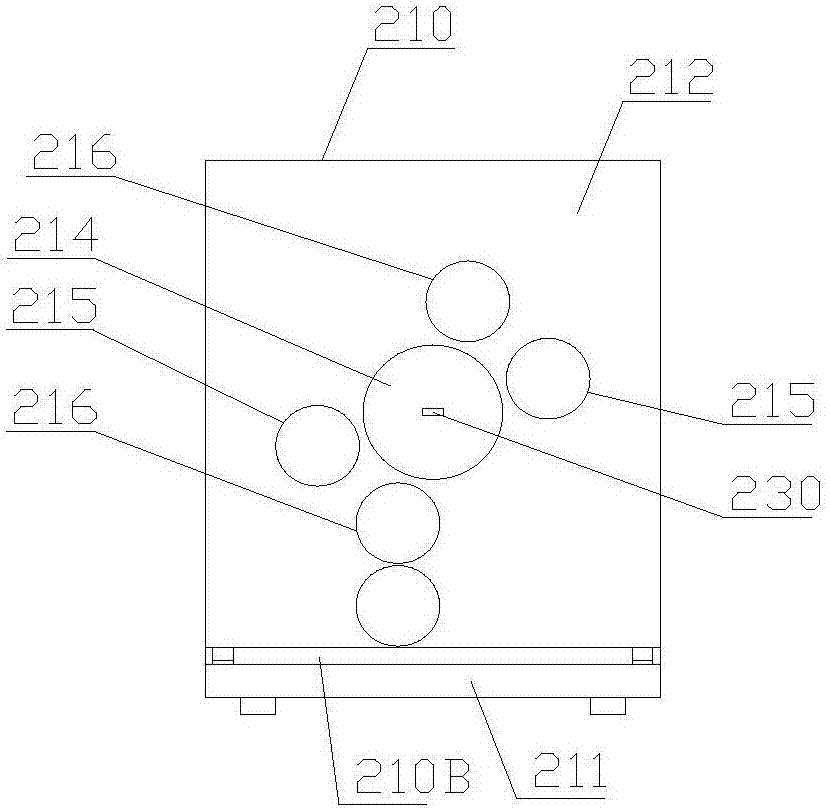

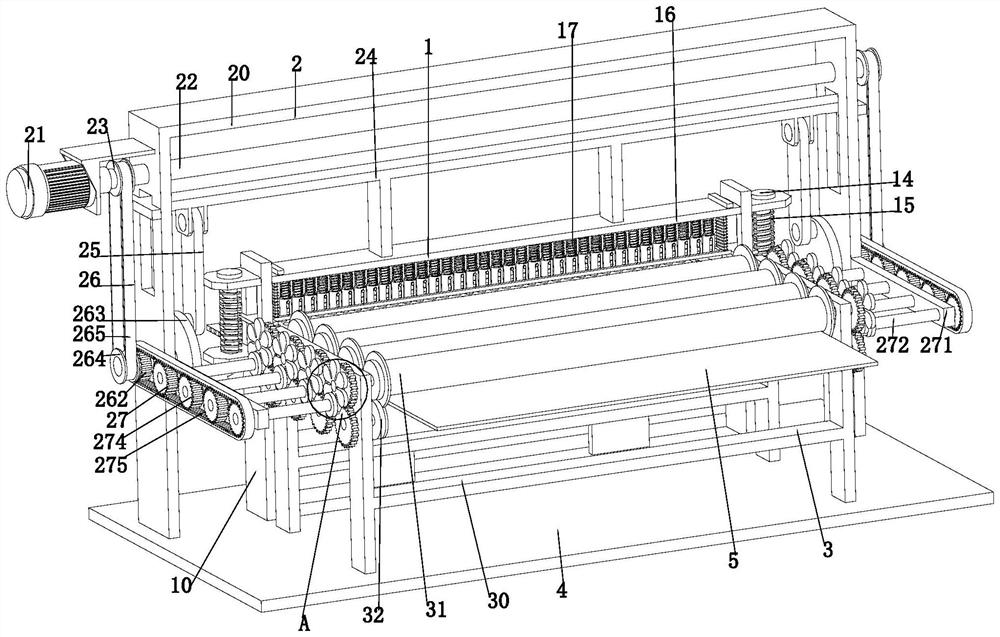

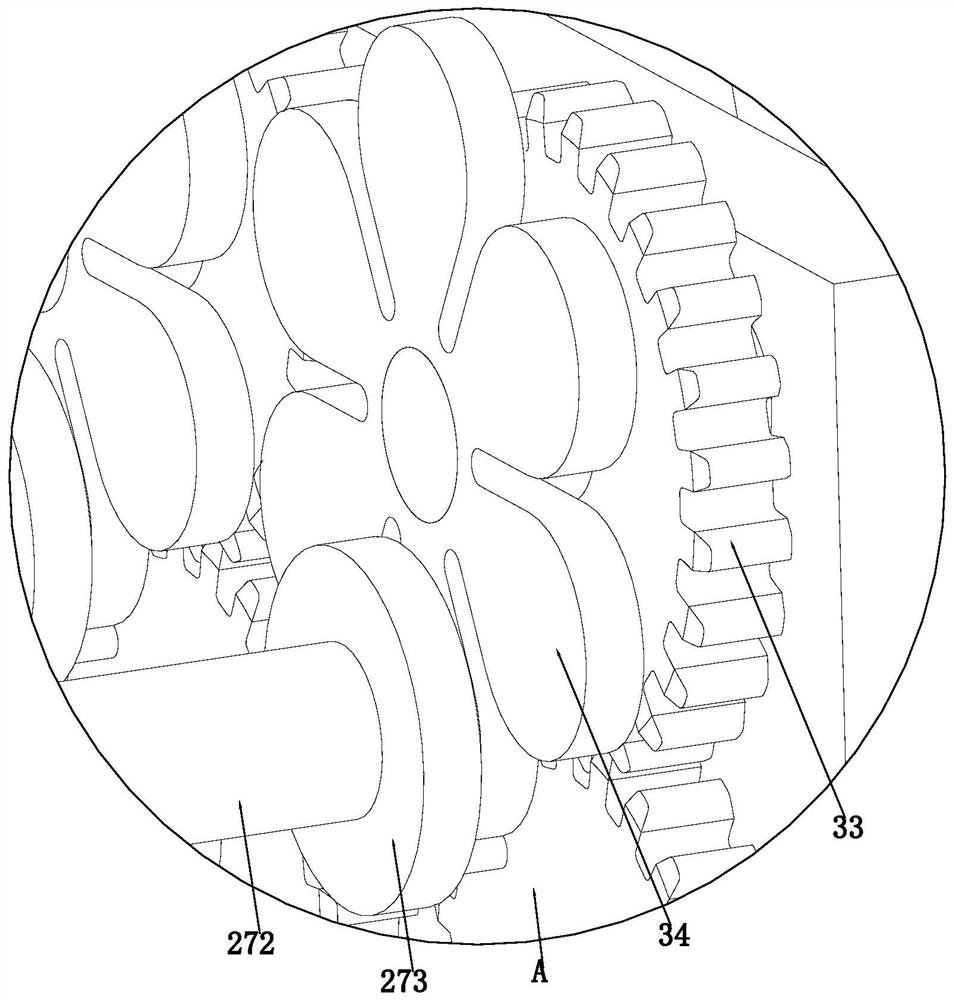

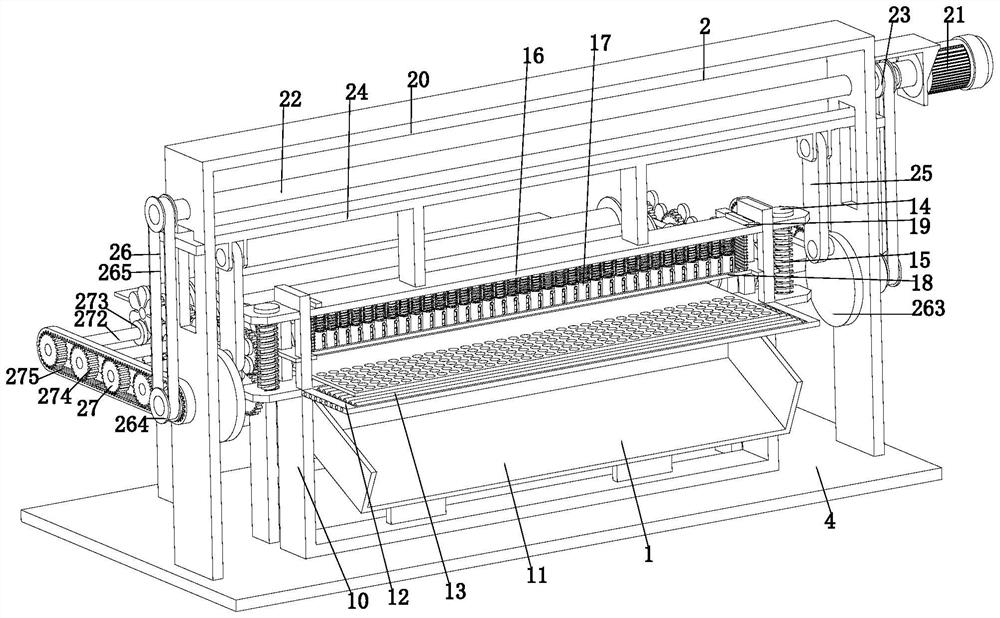

ActiveCN107953113AAutomatic cutting with high precisionEasy to assemble in batchesOther manufacturing equipments/toolsGear wheel

The invention discloses an automatic cutting-off device and a cutting-off process for an aluminum flat tube. The automatic cutting-off device comprises a cutting-off device body, wherein the cutting-off device body comprises a necking cutting device and a notch pulling-off device; the necking cutting device comprises a first base, a assembly fixing plate, a driving mechanism, a central connectinggear, a necking knife assembly and a bisection knife assembly, wherein the assembly fixing plate is fixed on the first base, the central connecting gear, the necking knife assembly, the bisection knife assembly and the driving mechanism are installed on the assembly fixing plate; and the notch pulling-off device comprises a second base, a locking device and a pulling-off device body, wherein the locking device is fixedly installed at the right end of the second base, a transverse sliding rail is arranged at the left end of the second base, a transverse sliding groove is formed in the bottom part of the pulling-off device, and the second base is in sliding connection with the pulling-off device. The cutting-off process determined by the device comprises the following steps of conveying, necking and cutting, conveying to the notch pulling-off device, pulling-off, conveying and collecting. The cutting-off device and the cutting-off process have the advantages that structure is simple, operation is stable, operation is convenient, and size deviation caused by shaking of the device is overcome, and the precision is high.

Owner:张家港市宏基精密铝材科技有限公司

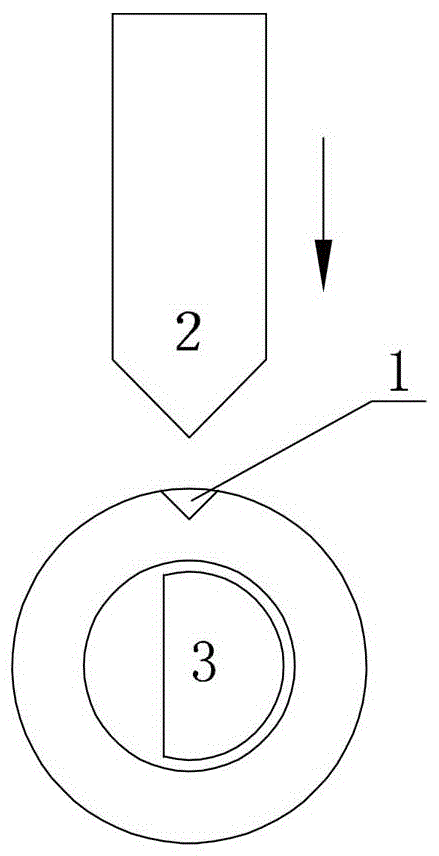

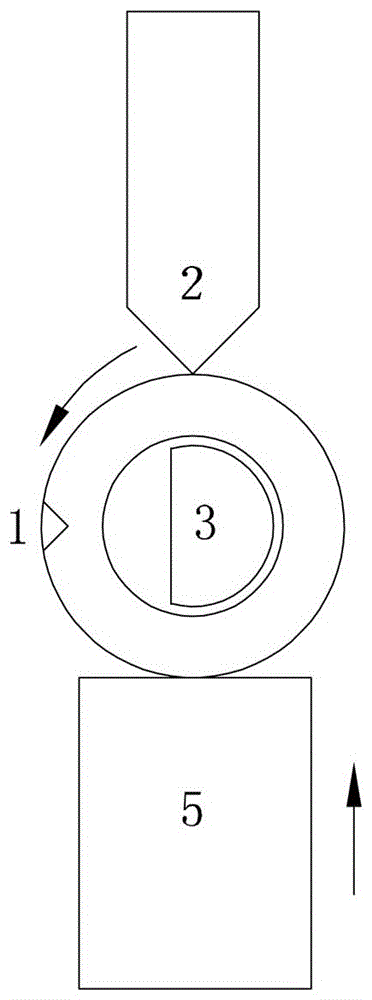

Stress breaking process of automatic spring coiler for spring wires

The invention relates to a stress breaking process of an automatic spring coiler for spring wires, after a spring wire is formed on the automatic spring coiler, a tool is used at a position where a spring is to be cut off to process at least one stress concentration point for the spring wire, and external breaking force that is inward is applied to the outer periphery of the spring or external breaking force that is outward is applied to the inner periphery of the spring such that the spring wire breaks at the stress concentrating points. The process prevents end collision and enables stability of operation, improved processing precision and production efficiency of the automatic spring coiler and greatly reduced production cost of coil springs, the bottleneck problem in the wide application of spring wires such as high-hardness spring wires and deformed spring wires is solve, and the process of coiling high-hardness spring deformed wires by the automatic spring coiler is turned into a stable and reliable process.

Owner:陶胜治

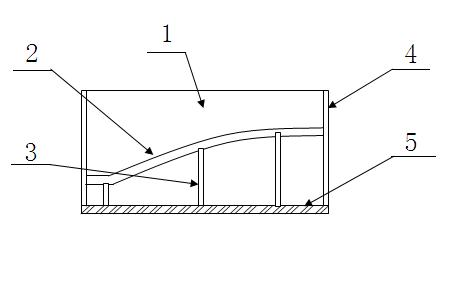

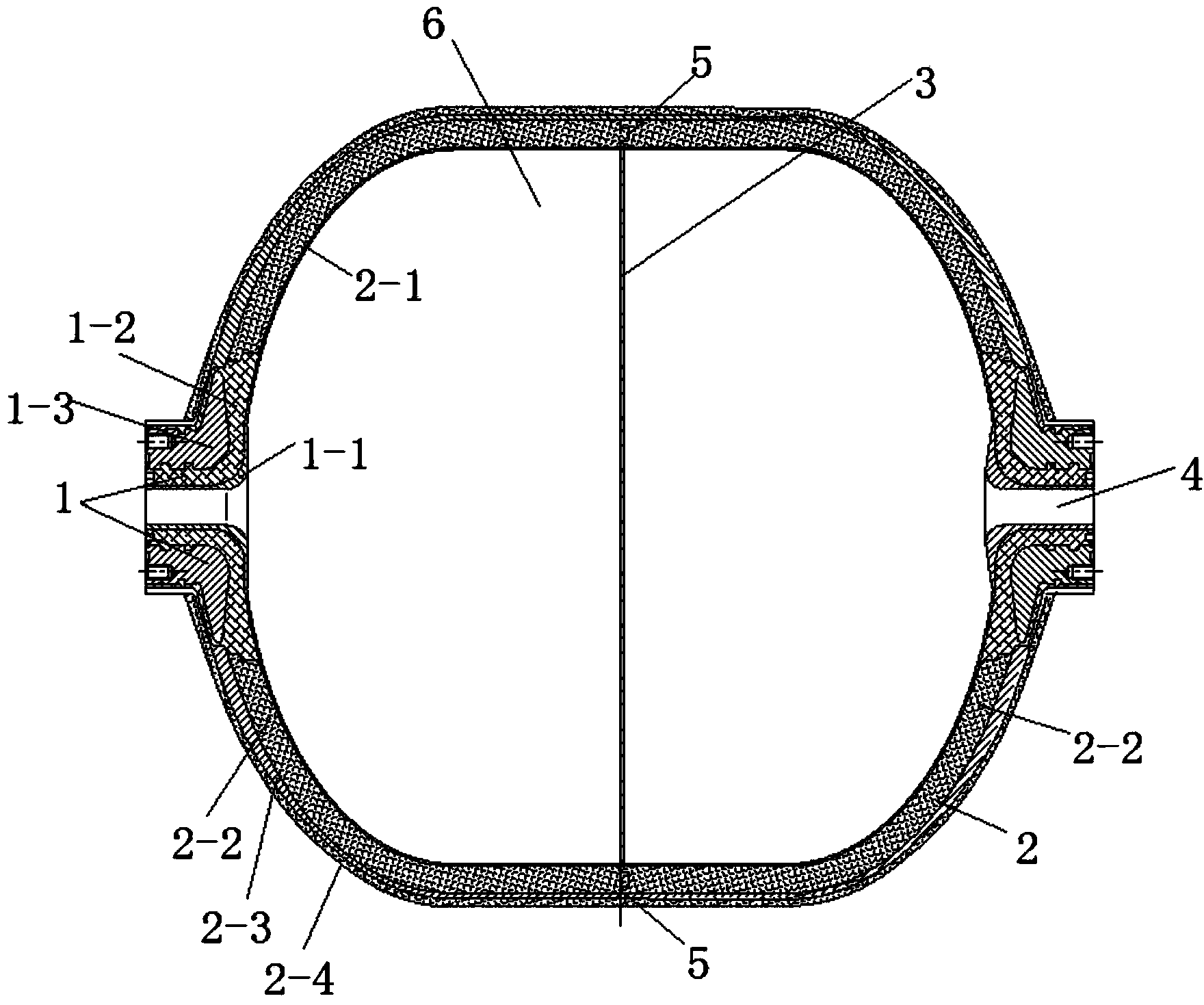

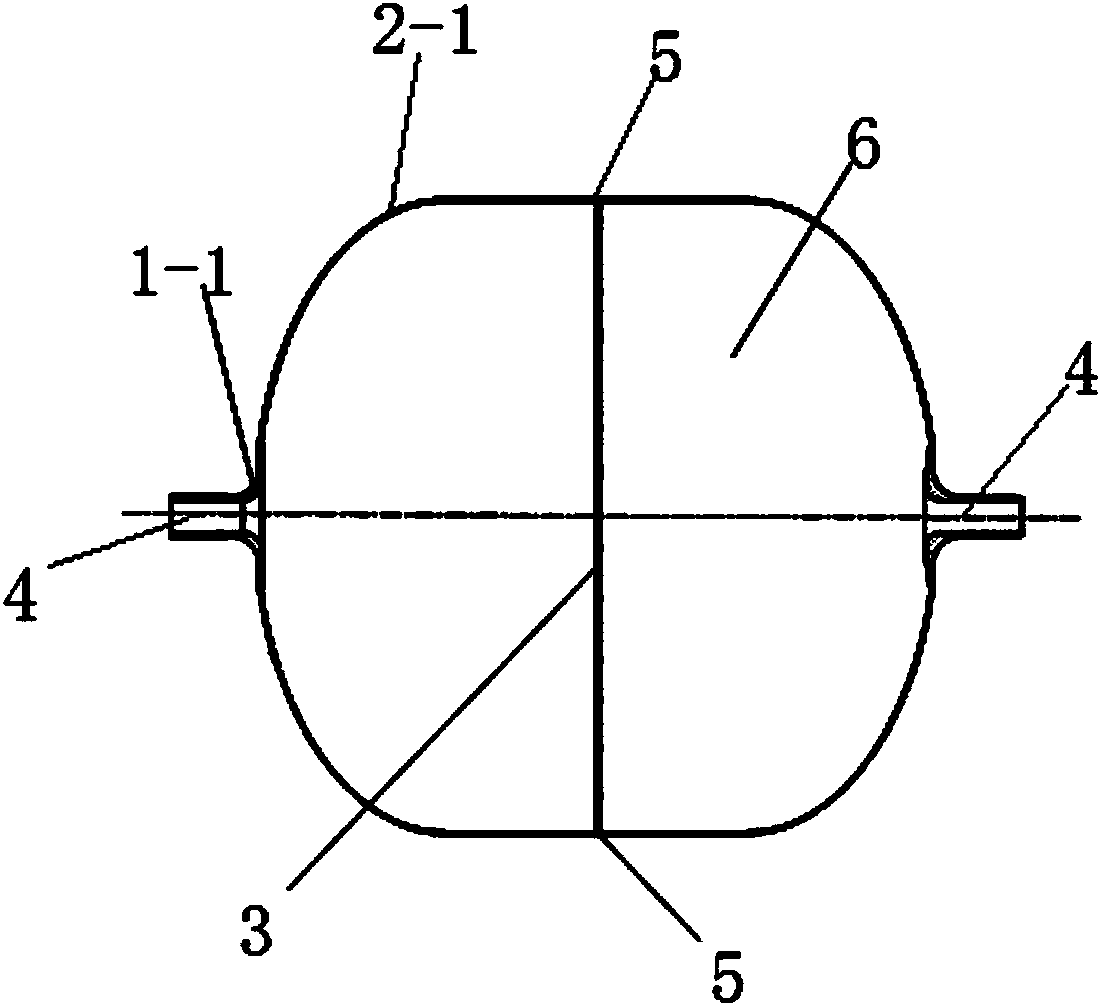

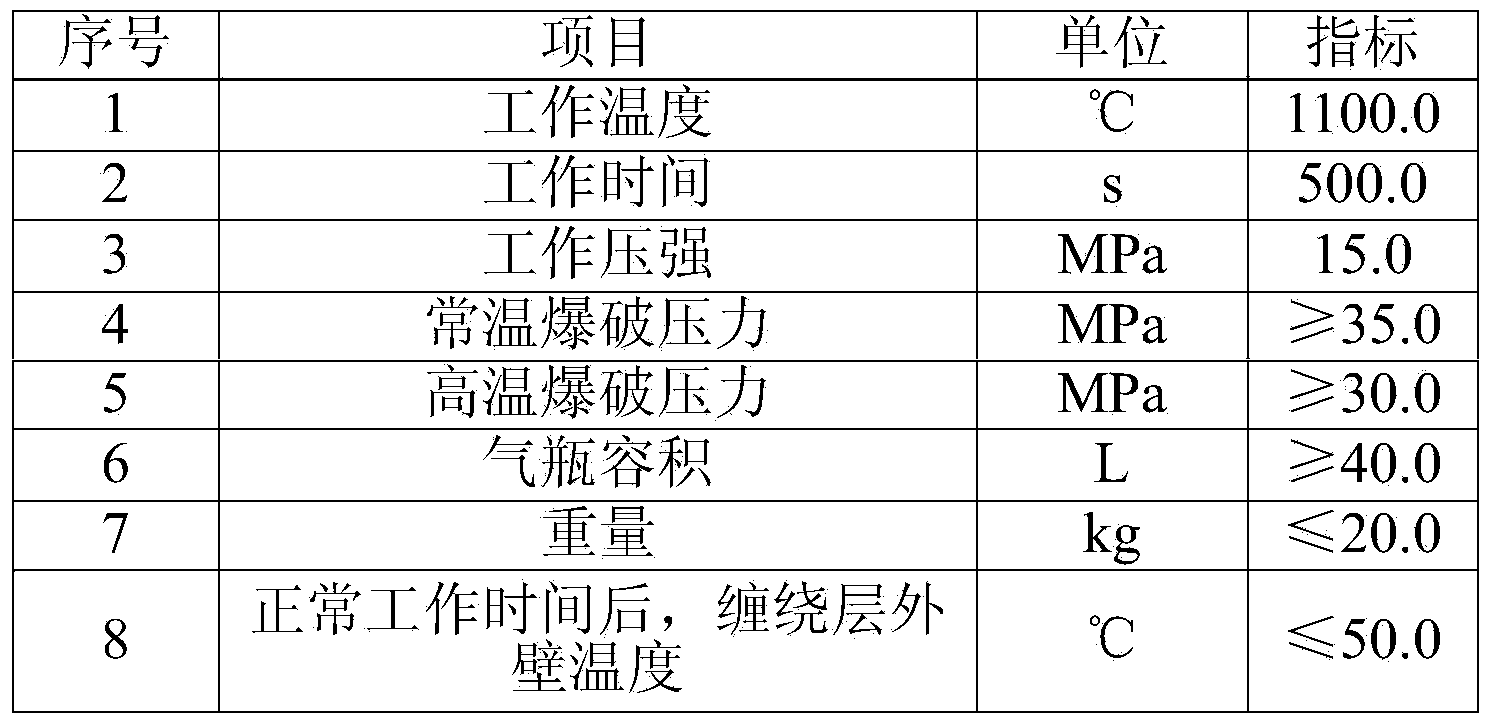

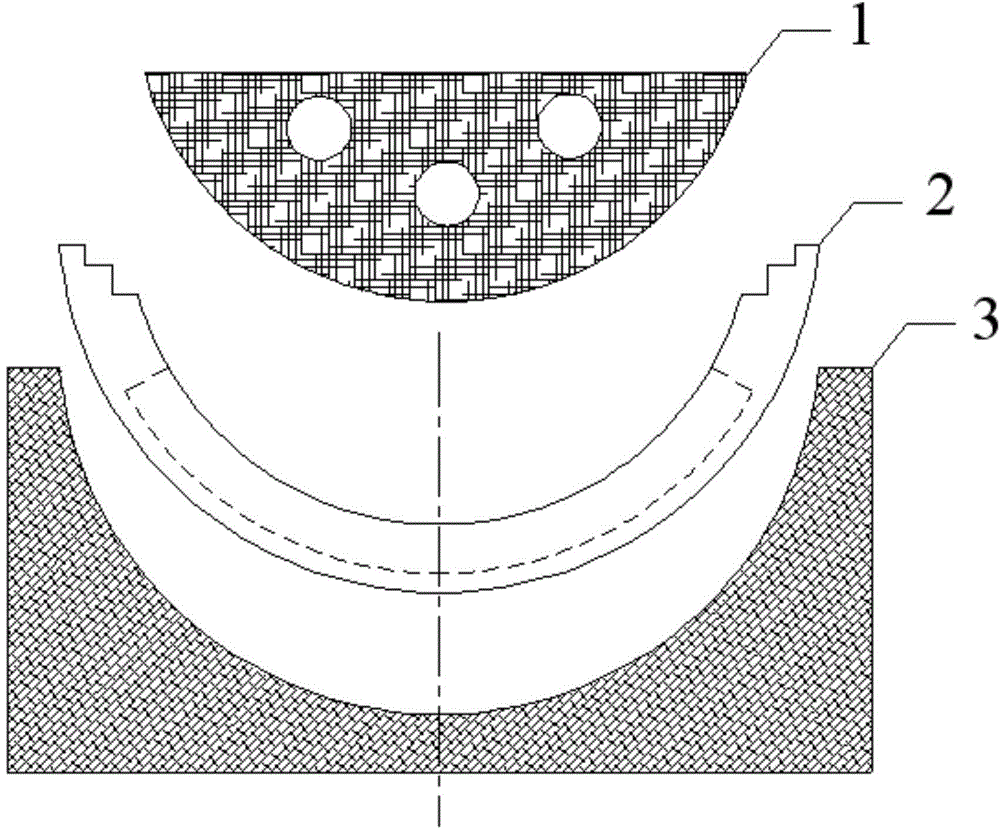

Lightened high-temperature and high-pressure composite cylinder and manufacturing method thereof

ActiveCN103883871AReduce weightImprove work efficiencyContainer filling methodsPressure vesselsCarbon fibersThermal insulation

The invention discloses a lightened high-temperature and high-pressure composite cylinder and a manufacturing method of the lightened high-temperature and high-pressure composite cylinder. The composite cylinder comprises filler necks and a bottle body, wherein the filler necks are arranged at two ends of the composite cylinder, the bottle body is arranged in the middle of the bottle body and sequentially comprises an ablation-resistant thin-wall metal liner, a ceramic tile thermal-insulation layer, a rubber thermal-insulation layer and a winding layer from inside to outside, and the winding layer is made of carbon-fiber-reinforced-resin-base composite materials. The manufacturing method comprises the following steps: (1) spheroid forming, (2) sand core forming, (3) metal liner forming, (4) thermal-insulation layer forming, (5) winding layer forming and (6) demolding and sand core dissolving. The composite cylinder has the advantages that a thin-wall metal material is taken as a liner, the light and high-temperature-resistant ceramic tile-rubber composite thermal-insulation layer is creatively utilized, and a ceramic tile in a quartz-fiber porous skeleton structure is taken as a main thermal-insulation material and is externally supplemented with a layer of rubber to be taken as an airtight layer, so that the weight of the thermal-insulation layer is reduced by 70-80% when the long-time high temperature resistance and ablation resistance are guaranteed, the working efficiency of an engine is substantially increased, and the requirements of a power system for the high total impulse and the high thrust are met.

Owner:湖北三江航天江北机械工程有限公司

Investment casting technology for transmission housing

InactiveCN107486543ALow shrinkageGood toughnessFoundry mouldsFoundry coresTemperature resistanceInvestment casting

The invention discloses an investment casting technology for a transmission housing. The investment casting technology comprises the following steps that (1) wax pouring is conducted, specifically, a mixed wax material is homogenized and then processed at the temperature of 75-80 DEG C and the temperature of 50-54 DEG C; (2) a mold housing is manufactured, specifically, four inner mold material layers and two outer mold material layers are smeared on the surface of a wax mold and subjected to drying treatment; (3) dewaxing is conducted, specifically, the dried mold housing is subjected to dewaxing at the temperature of 76-80 DEG C and washed with gasoline; (4) roasting is conducted, specifically, the dried mold housing is roasted at the temperature of 450-500 DEG C and the temperature of 800-850 DEG C; (5) pouring is conducted, specifically, molten iron is subjected to still standing treatment at the temperature of 900-930 DEG C after pouring and subjected to vacuum cooling; and (6) polishing and inspection are conducted, specifically, the transmission housing subjected to precision casting is polished, and the inspection precision and internal damage are inspected. The transmission housing produced through the investment casting technology has the characteristics of being high in percent of pass, tensile strength and percentage reduction of area, and is good in abrasion resistance and high temperature resistance.

Owner:HEFEI CITY TENVER PRECISION CASTING

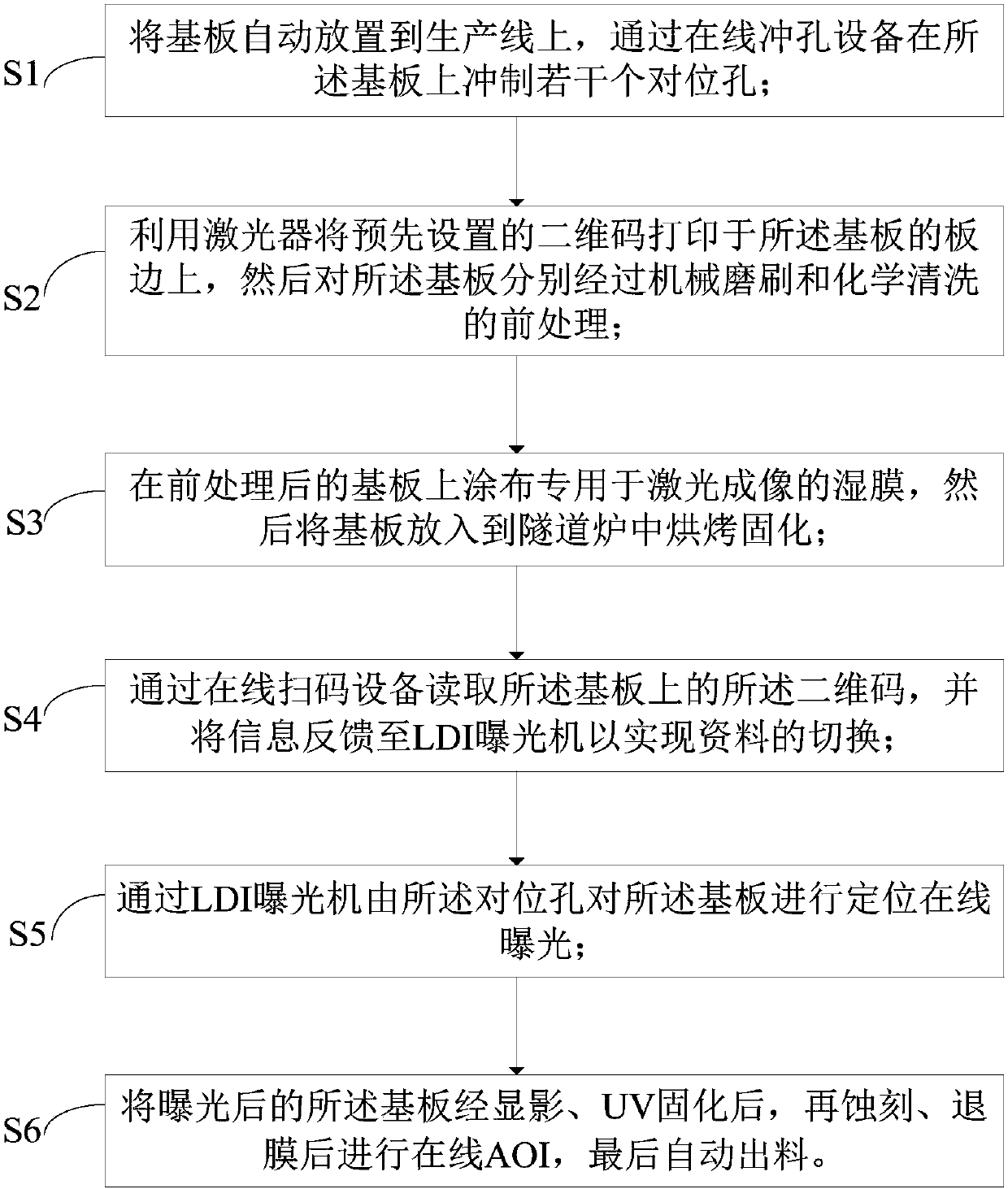

Fabrication method for inner-layer pattern of printed circuit board (PCB)

InactiveCN108055783AFacilitate automatic productionAvoid size deviationConductive material chemical/electrolytical removalGraphicsUV curing

The invention belongs to the field of manufacturing of a printed circuit board (PCB), and provides a fabrication method for an inner-layer pattern of the PCB. The fabrication method comprises the steps of sequentially performing document fabrication according to a two-dimensional code, performing on-line punching on a substrate, printing the two-dimensional code on the substrate by laser, pre-processing the substrate (including mechanical polishing-brushing and chemical cleaning), coating a wet film special for laser direct imaging (LDI), braking and curing the substrate coated with the wet film in a tunnel furnace, scanning the two-dimensional code, determining a type of a product, performing exposure, developing, uv curing, etching and film removal on connection line LDI, performing on-line automatic optic inspection (AOI), and finally, discharging a finished product. By the design, the problems that size deviation caused by size change and exposure alignment of a film is difficult to eliminate by an existing fabrication process and continuous and automatic production is difficult to achieve by a traditional fabrication process can be solved.

Owner:SHENZHEN KINWONG ELECTRONICS

Method for controlling deformation of snap-ring parts through heat treatment

ActiveCN104404232AEffective controlEasy process controlFurnace typesHeat treatment process controlEngineeringMachining process

The invention discloses a method for controlling deformation of snap-ring parts through heat treatment. The method comprises the following steps: (1) confirming the treatment process parameters of a blank T6; (2) carrying out first stabilizing treatment; (3) carrying out second stabilizing treatment; (4) carrying out tooling and sizing; (5) carrying out third stabilizing treatment; (6) carrying out tooling and sizing again; (7) carrying out fourth stabilizing treatment. Through adoption of the method, the defects that the deformation of snap rings during the cold-working process is high and the final sizes of parts deviate from the original design are overcome, the needs for subsequent assembly can be effectively met, and the performance indicators meet the design requirements.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

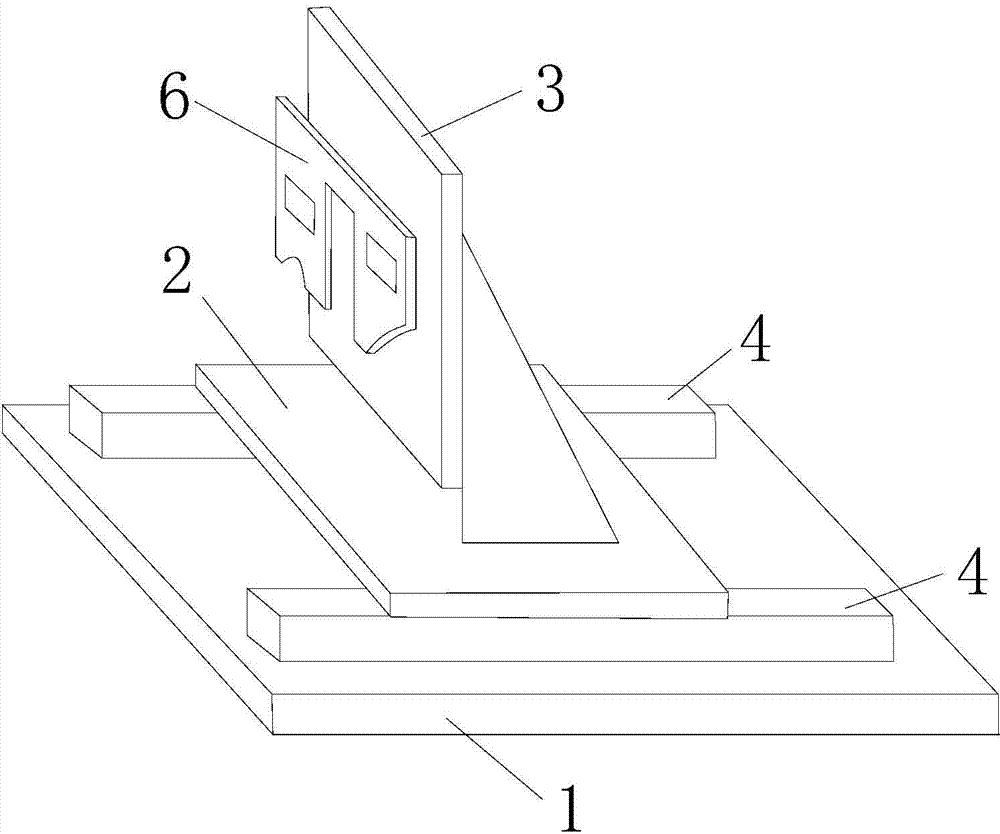

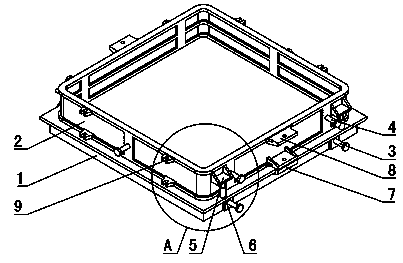

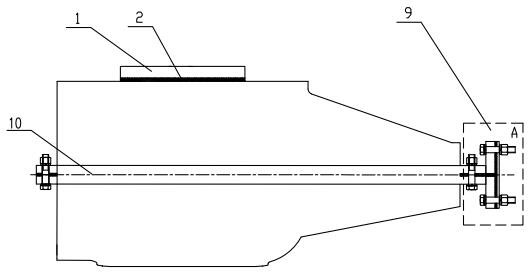

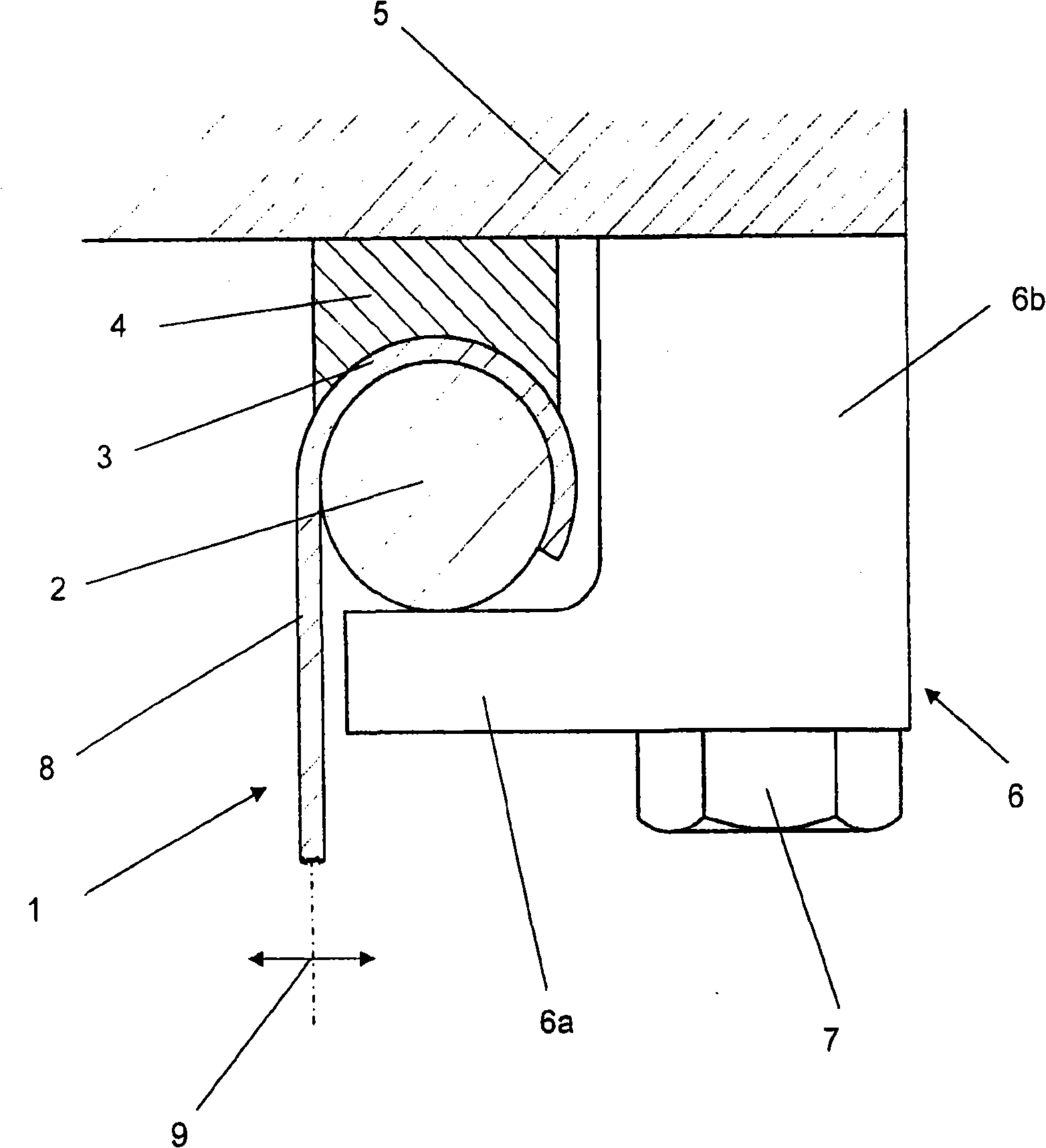

Vehicle body side wall total assembly device and vehicle body side wall total assembly system and method

ActiveCN104842106AImprove installation accuracyAvoid size deviationWelding/cutting auxillary devicesAuxillary welding devicesAssembly systemsWelding

The invention discloses a vehicle body side wall total assembly device and a vehicle body side wall total assembly system and method, wherein the vehicle body side wall total assembly device comprises a base (1), a slide base (2) and a side wall fixture platform (3); a guide rail (4) is arranged on the base (1); the slide base (2) is movably arranged on the guide rail (4); the side wall fixture platform (3) is vertically fixed on the slide base (2), and is provided with a clamping mechanism (5); and the clamping mechanism (5) can receive and clamp a side wall assembly (6) in a vertical state. Through the scheme, before the assembly welding of the side wall assembly (6) and a lower vehicle body, the side wall assembly (6) is in the vertical state, and the side wall fixture platform (3) is not needed to be overturned, so that the size deviation caused by overturning the side wall fixture platform (3) is prevented, the mounting precision of the side wall assembly is improved, and the side wall assembly efficiency is enhanced.

Owner:BEIQI FOTON MOTOR CO LTD

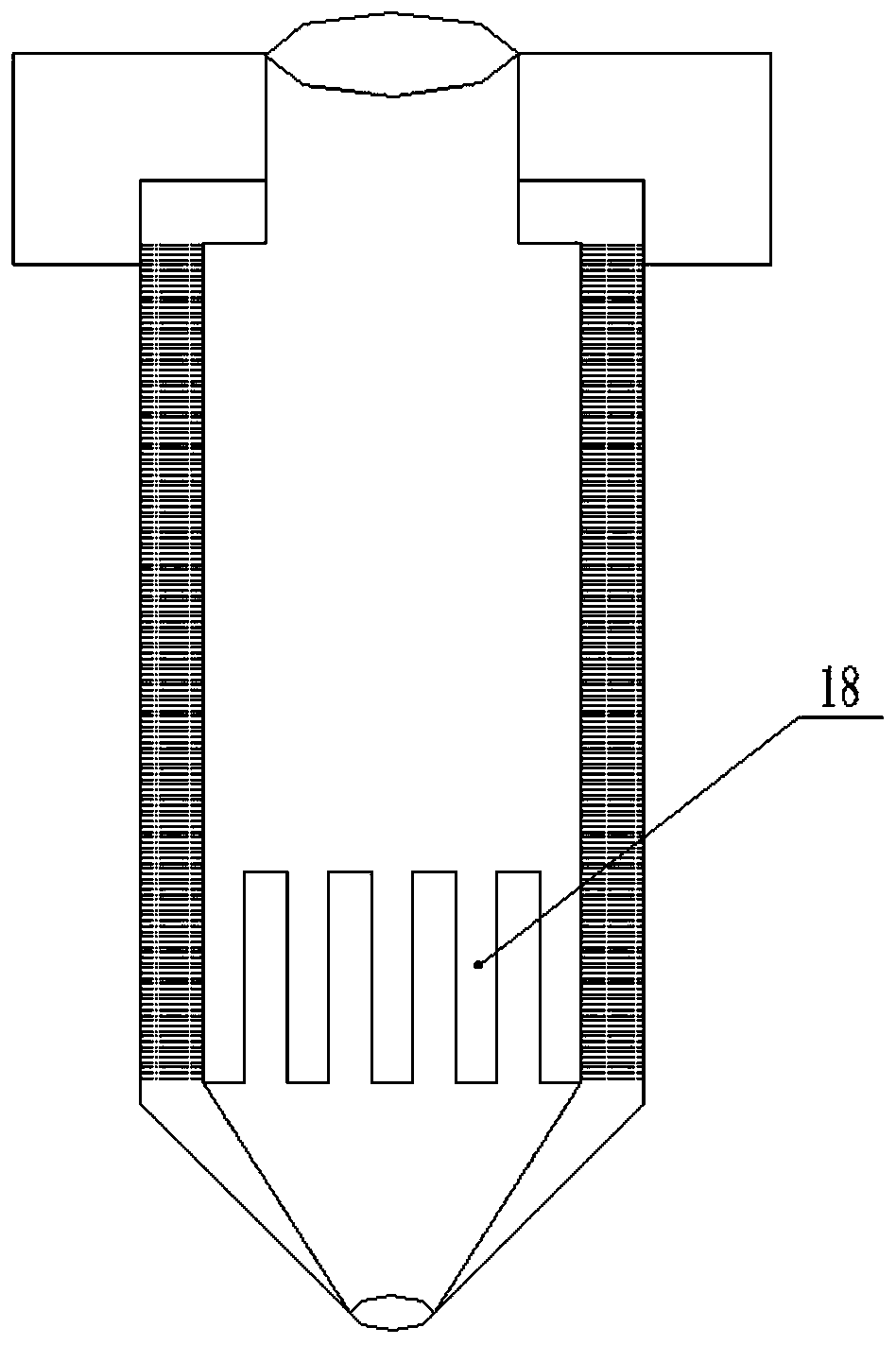

Large vacuum pump impeller casting method

The invention relates to a large vacuum pump impeller casting method and belongs to the technical field of production of a vacuum pump impeller. The large vacuum pump impeller casting method is characterized by comprising the following steps: 1) mounting a mold in a sand box; 2) filling a sand box main body (2) with molding sand, tamping, scraping the redundant molding sand, and arranging a casting head and a vent hole; 3) drawing the sand box main bodies (2) one by one from top to bottom, lifting the corresponding sand box main body (2) by a lifting device, lifting the sand box main body (2)through a travelling crane, and synchronously lifting by the lifting device corresponding to the same layer of sand box main body (2); 4) taking out the mold and sequentially performing mold closing on the sand box main body (2) through the travelling crane; and 5) fixedly connecting a pedestal (1) with the adjacent sand box main body (2) as well as each adjacent two layers of sand box main bodies(2). By the large vacuum pump impeller casting method, the operation of lifting the sand box main bodies by the travelling crane, rapidly lifting the mold and separating from the mold is facilitated.

Owner:ZIBO WATER RING VACUUM PUMP FACTORY +2

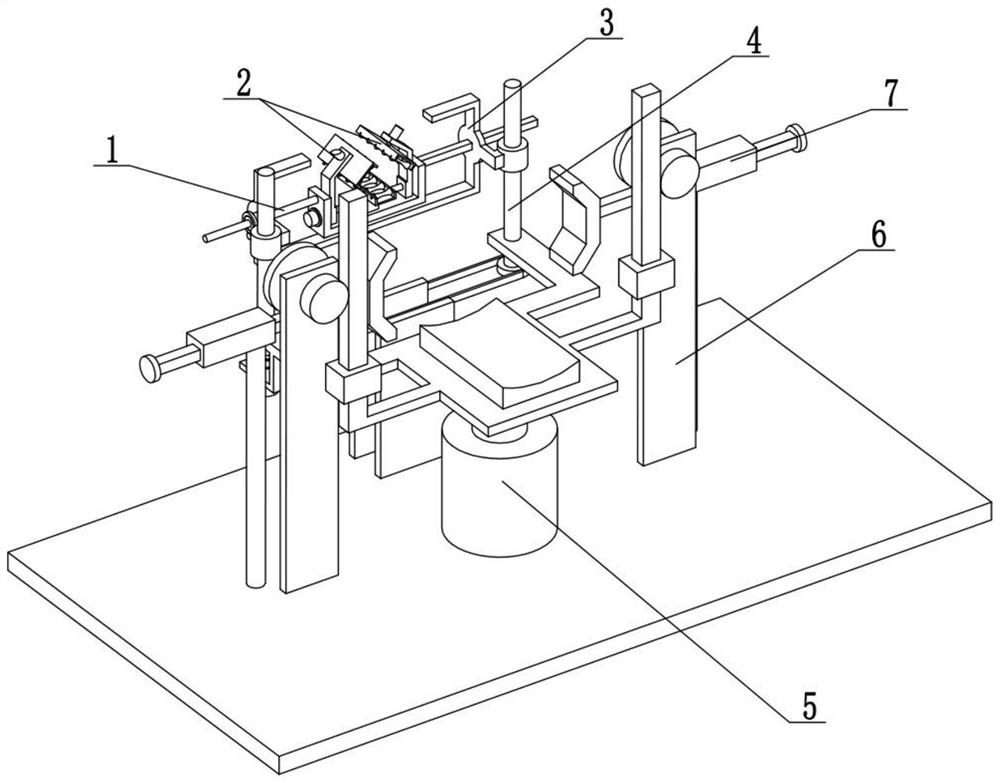

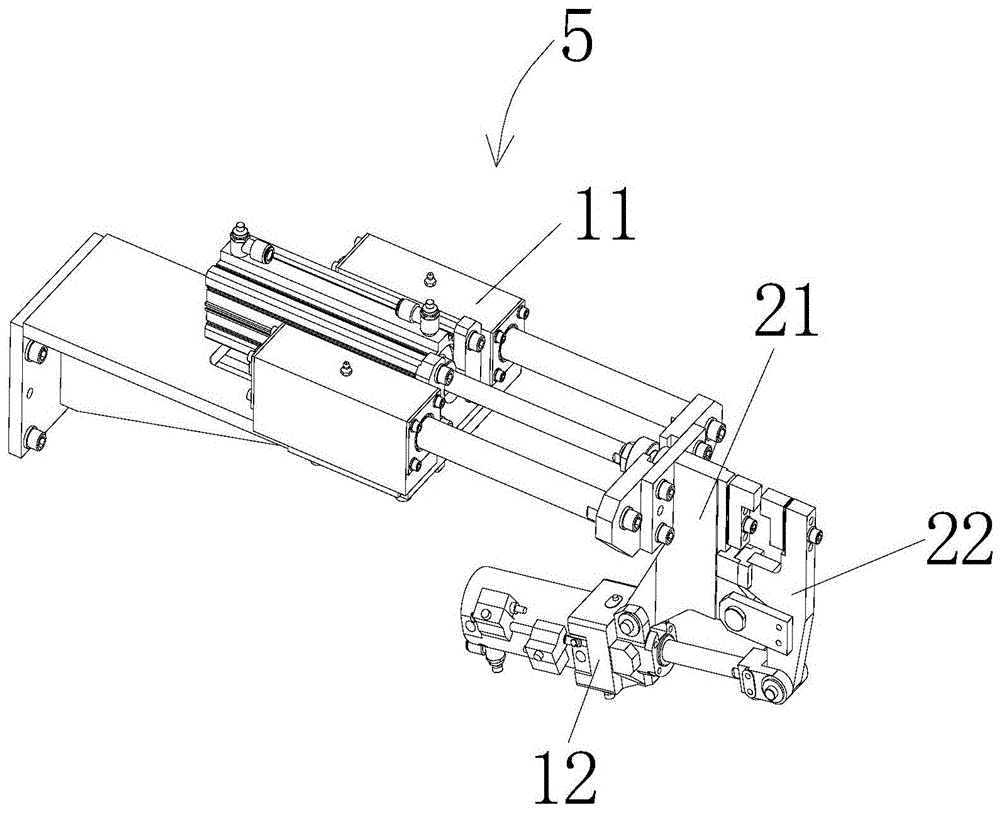

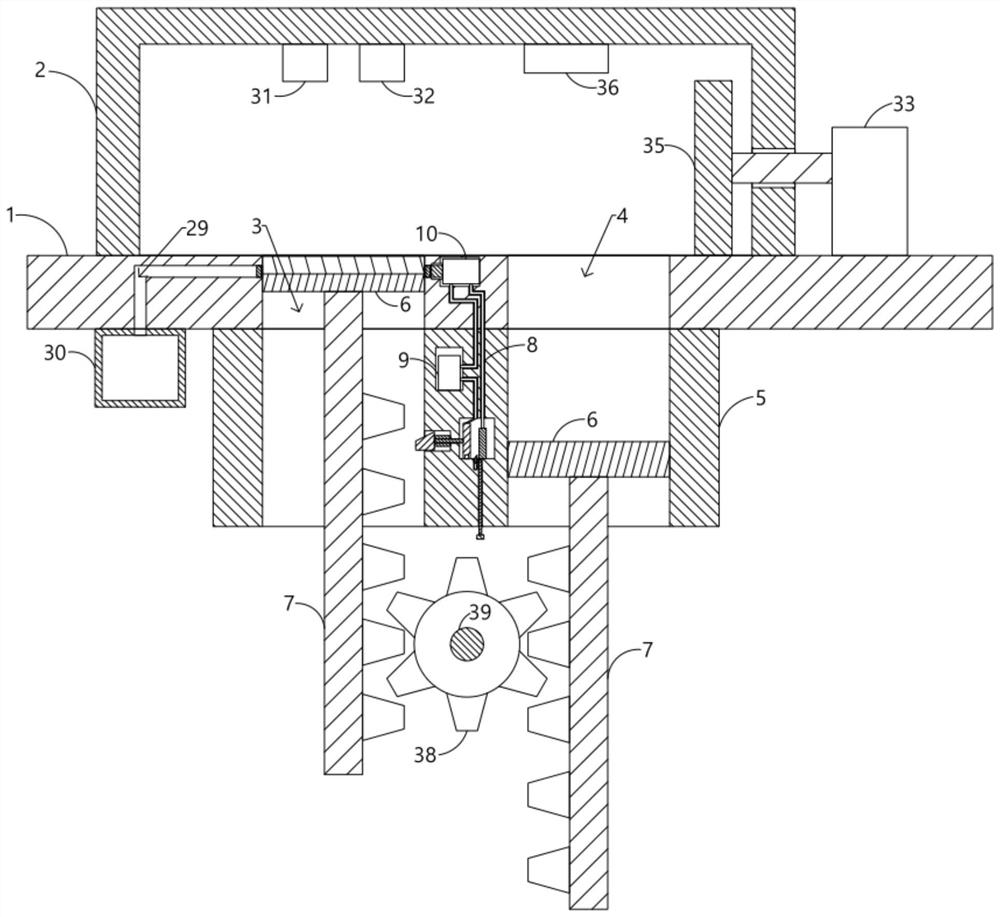

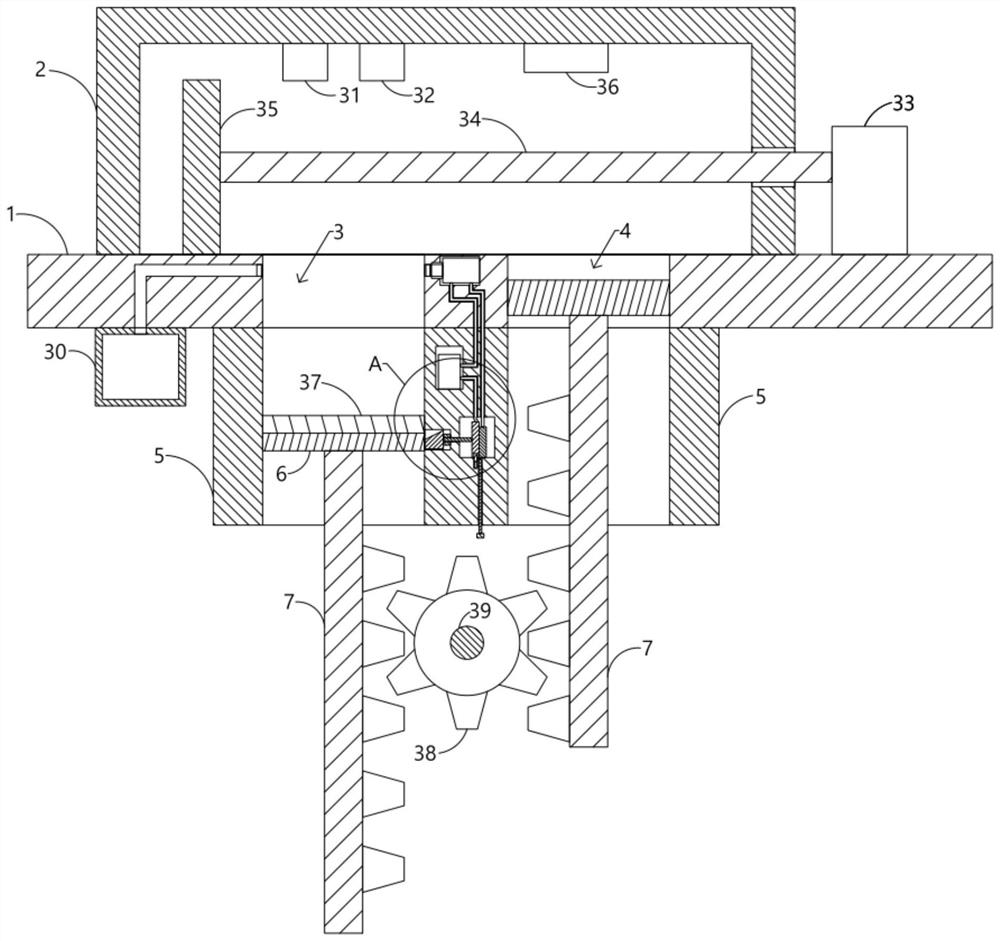

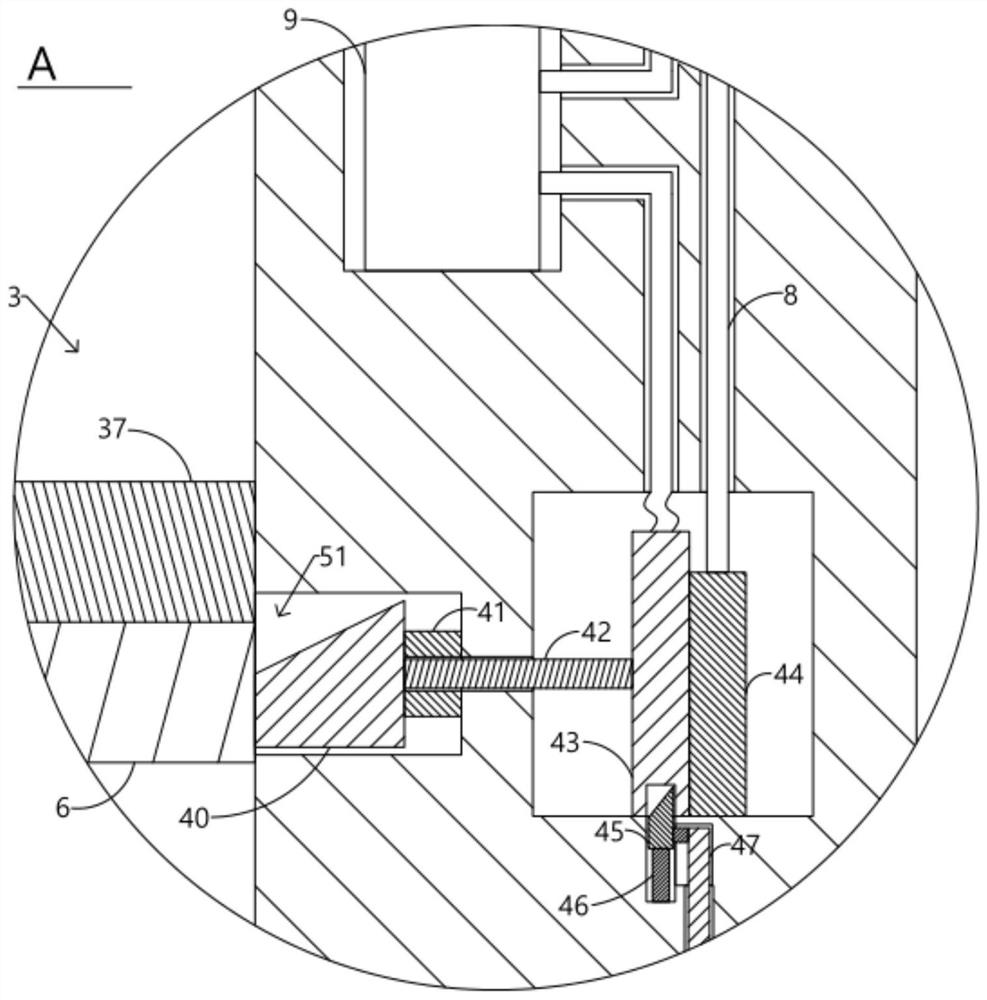

Motor assembly machine and method

ActiveCN112398293AAvoid size deviationAvoid damageManufacturing dynamo-electric machinesControl engineeringElectric machinery

The invention relates to the technical field of motor assembly, in particular to a motor assembly machine and a method, and a main shaft can be positioned and assembled according to motor casings withdifferent sizes. The motor assembly machine comprises a main shaft erecting mechanism, a main shaft conveying mechanism, a horizontal fine adjustment mechanism, a vertical fine adjustment mechanism,a machine body positioning mechanism, a clamping linkage mechanism and a machine body clamping mechanism. The method comprises the steps of: 1, placing a motor casing and a main shaft on a machine base and a plurality of pulleys respectively, enabling the rear end of the main shaft to abut against a shaft positioning plate, and enabling the front end of the motor casing to abut against a casing positioning plate; 2, employing two air cylinders to drive a plurality of conveying wheels to clamp the main shaft, using a telescopic rod to drive the motor casing and the main shaft to ascend together, and using two clamping jaws to clamp the motor casing; 3, starting a linkage motor, enabling two vertical lead screws to drive the main shaft to move to a mounting position according to the positionof the motor casing; and 4, employing a plurality of conveying motors to drive a plurality of conveying wheels to rotate, and enabling the main shaft to enters the motor shell to be installed.

Owner:山东兴恒电机有限公司

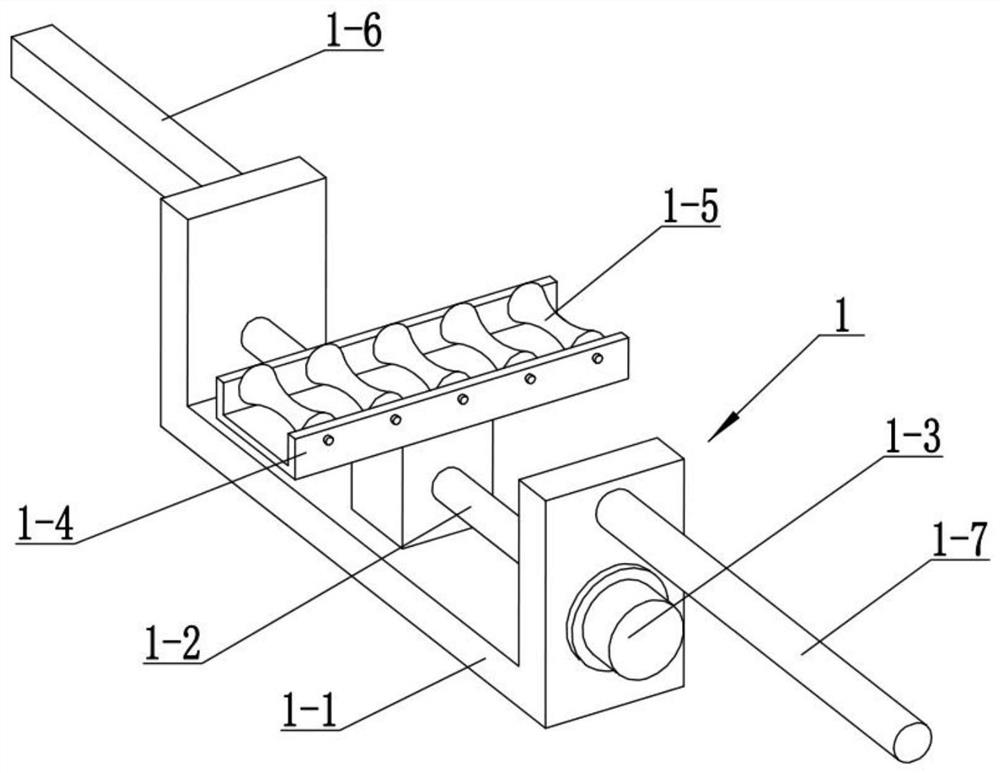

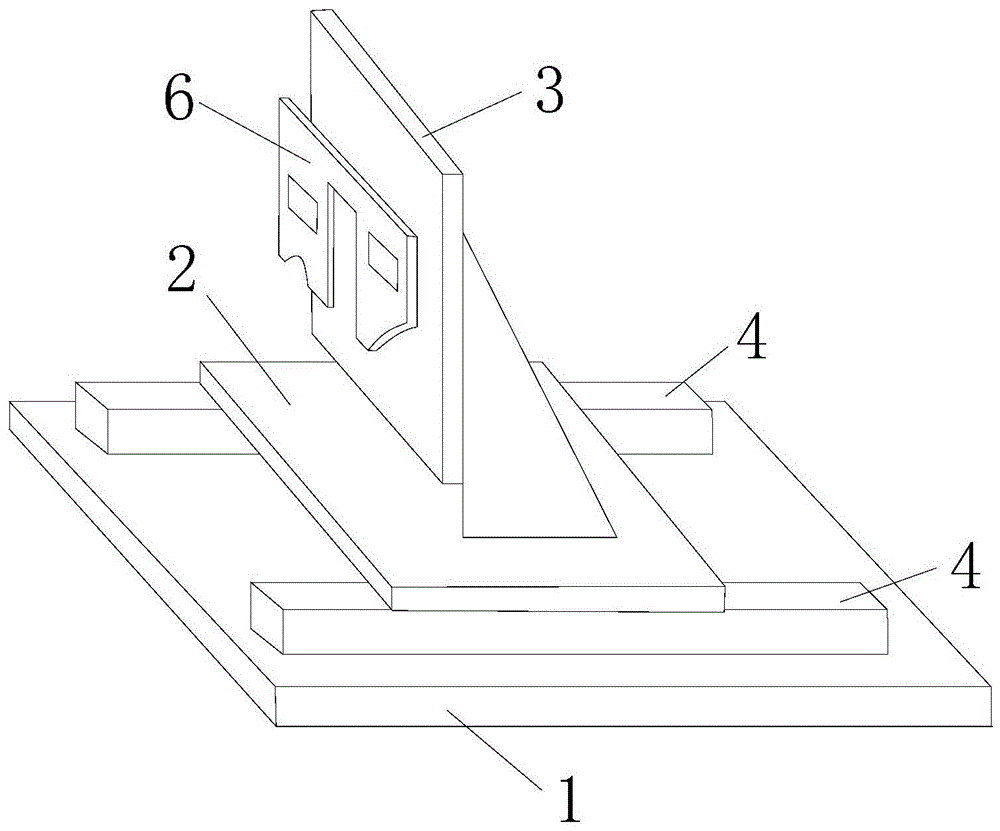

Steel pipe fixing device

InactiveCN107186272AImprove stabilityPrevent size deviationShearing machine accessoriesEngineeringMechanical engineering

The invention relates to a steel pipe fixing device, which includes a base and an upper clamping block. The base is a ladder column structure. Corresponding handles are provided on both sides of the base, and a downwardly concave arc is provided at the center of the upper end surface of the base. Groove, the upper clamping block includes linear parts arranged horizontally on both sides and a circular arc part placed between the straight parts. Facing the installation, and a cavity for the steel pipe to be embedded is formed between the arc part and the arc groove. There are placement holes inside the base and on both sides of the arc groove, which run through the straight part of the upper clamping block. , The base is provided with a fastening bolt arranged vertically, the lower end of the fastening bolt extends into the placement hole, and the upper end of the fastening bolt is provided with a nut and the nut is engaged with the upper end surface of the linear part. The invention has the advantages of simple structure and preventing dimensional deviation caused by loosening of the steel pipe during the cutting process.

Owner:不二新材料科技有限公司

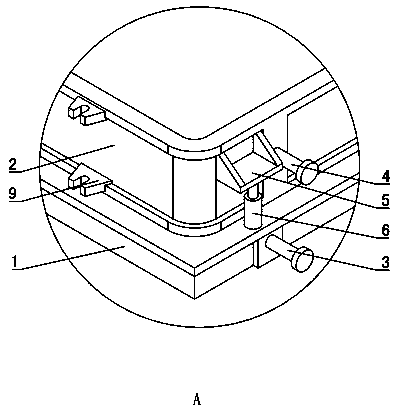

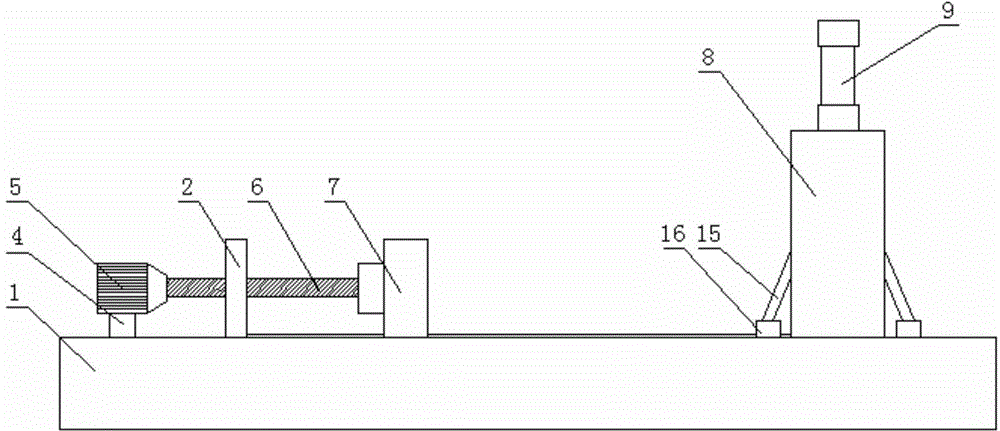

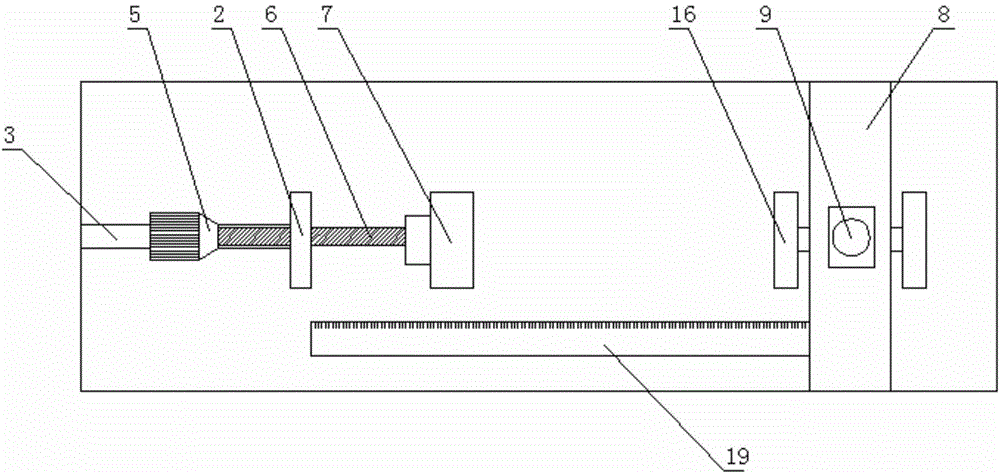

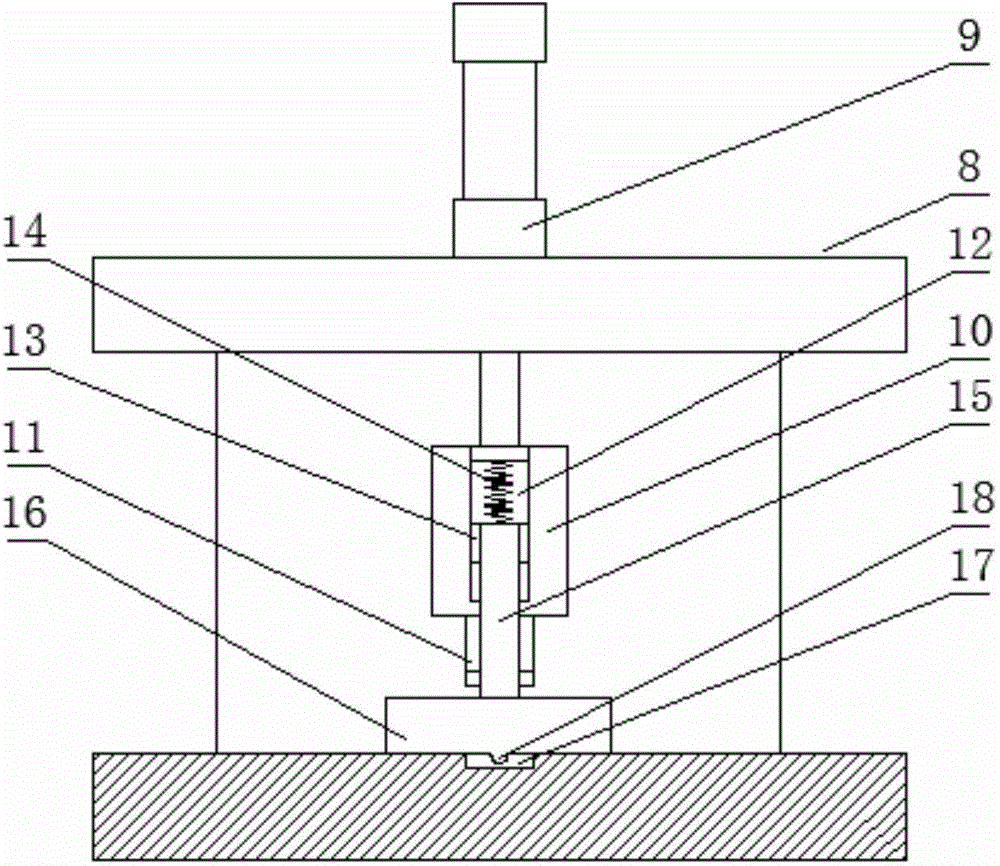

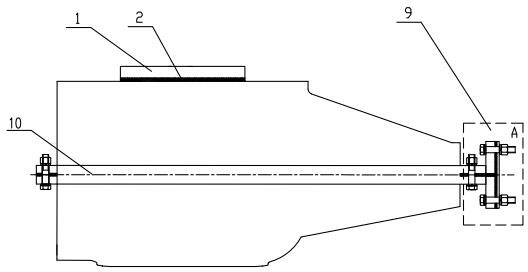

Automatic cable cutting off machine

InactiveCN104384398AEasy to measureAvoid size deviationMetal working apparatusMechanical engineeringEngineering

The invention provides an automatic cable cutting off machine which comprises a base, a measuring device and a shearing device. The measuring device comprises a fixed plate fixed on the base. A slideway is arranged on the base on the left of the fixed plate. A slider is disposed in the slideway. A motor is fixed on the slider. The output end of the motor is connected with an adjusting screw. The adjusting screw penetrates the fixed plate to be rotatably connected with the measuring plate. The shearing device comprises a support fixed on the base. An air cylinder is disposed on the top plate of the support. The front end of the piston rod of the air cylinder penetrates the top plate of the support to be connected with a cutter fixing block. A cutter is disposed at the bottom of the cutting fixing block. Rectangular grooves are symmetrically formed in the left and right sides of the cutter fixing block. Movable blocks are slidably connected into the rectangular grooves. A spring is fixedly connected to the top of each movable block, and the other end of the spring is connected with the top surface of the corresponding rectangular groove. A connecting rod is fixed on the outer side of each movable block, and a pressing plate is connected to the other end of the connecting rod. The automatic cable cutting off machine has the advantages that cable cutting precision and production efficiency are increased.

Owner:TIANJIN OULIN ELECTRONICS

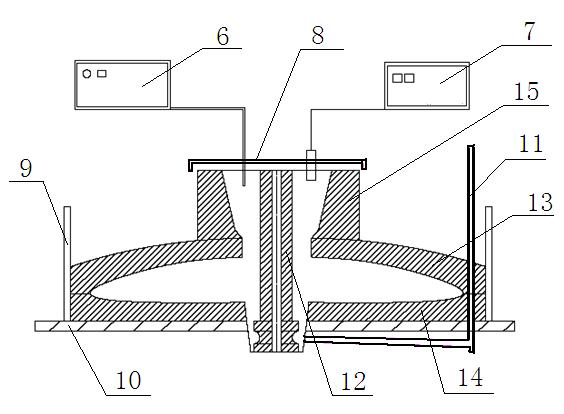

Water pressure test device for junction box of explosion-proof motor

InactiveCN102435491AEasy to manufactureReduce processing difficultyMeasurement apparatus housingsStrength propertiesEngineeringJunction box

The invention provides a water pressure test device for a junction box of an explosion-proof motor. The water pressure test device comprises a press plate, sealers, an end part upper press plate, an end part lower press plate, a connecting screw, a press block, a bolt and a nut, wherein the press plate is pressed between an internal pin hole and a power interface hole of the junction box; the sealers are respectively placed between explosion-proof surfaces of the junction box as well as between the upper surface of the junction box and the press plate; an end part compressing structure is composed of the end part upper press plate, the end part lower press plate, the connecting screw, the press block and the bolt so as to realize compressing of the explosion-proof surfaces. The water pressure test device provided by the invention has simple structure, is convenient to manufacture, is easy to mount and dismount, is particularly suitable for a water pressure test of the processed junction box of the explosion-proof motor, and has a significant action effect.

Owner:SEC ELECTRIC MACHINERY

Vehicle body side panel assembly device, vehicle body side panel assembly system and method

ActiveCN104842106BImprove installation accuracyAvoid size deviationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses a vehicle body side wall total assembly device and a vehicle body side wall total assembly system and method, wherein the vehicle body side wall total assembly device comprises a base (1), a slide base (2) and a side wall fixture platform (3); a guide rail (4) is arranged on the base (1); the slide base (2) is movably arranged on the guide rail (4); the side wall fixture platform (3) is vertically fixed on the slide base (2), and is provided with a clamping mechanism (5); and the clamping mechanism (5) can receive and clamp a side wall assembly (6) in a vertical state. Through the scheme, before the assembly welding of the side wall assembly (6) and a lower vehicle body, the side wall assembly (6) is in the vertical state, and the side wall fixture platform (3) is not needed to be overturned, so that the size deviation caused by overturning the side wall fixture platform (3) is prevented, the mounting precision of the side wall assembly is improved, and the side wall assembly efficiency is enhanced.

Owner:BEIQI FOTON MOTOR CO LTD

Production method of floors capable of being quickly installed in side sliding mode

ActiveCN111005524AHigh locking precisionPrevent overflowDomestic articlesCoatingsVegetable oilStructural engineering

The invention discloses a production method of floors capable of being quickly installed in a side sliding mode, and belongs to the technical field of floor production. The production method includesthe following steps that step 1, floor blanks are sorted; step 2, the floor blanks are subjected to curing; step 3, the floor blanks are subjected to sanding; step 4, the floor blanks are subjected tothickness setting; step 5, the floor blanks are subjected to surface treatment; step 6, the floor blanks are subjected to length setting and molding processing; step 7, the floor blanks are sprayed with anti-cracking oil; step 8, the floor blanks are plastic-packaged; step 9, the floor blanks are painted with back paint; and step 10, the floor blanks are painted or painted with vegetable oil. After injection molding, lock catch frames are hidden under bosses of the floor blanks, and lock catches are high in dimensional accuracy and firmly assembled.

Owner:ANHUI YANGZI FLOORING

Continuous stamping device for metal processing

PendingCN114589246ALarge travel rangeMeet pre-pressing needsMetal-working feeding devicesShaping safety devicesPunchingMetal machining

The invention relates to the technical field of metal processing, in particular to a continuous stamping device for metal processing, which comprises a pressing and cutting mechanism, a linkage mechanism, a grading mechanism and a base plate, and solves the following problems of an existing stamping processing device for a perforated plate: the perforated plate is easy to move during punching operation; due to the fact that punching holes of the perforated plate are deviated, a non-punching area is deformed, the quality problem of the perforated plate is caused, punching conveying of the perforated plate mostly depends on manual conveying, manual conveying has the defect of low efficiency, the punching effect is poor, continuous punching operation cannot be conducted, and the production efficiency is high. And in addition, the conveying distance cannot be accurately controlled through manual conveying, so that the punching position of the perforated plate does not meet the machining requirement.

Owner:SHAOXING UNIV YUANPEI COLLEGE

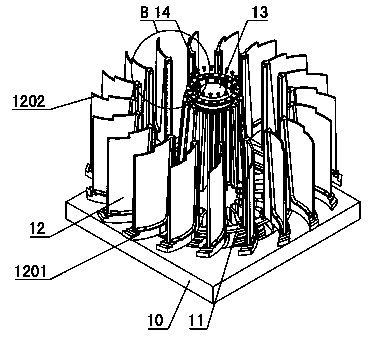

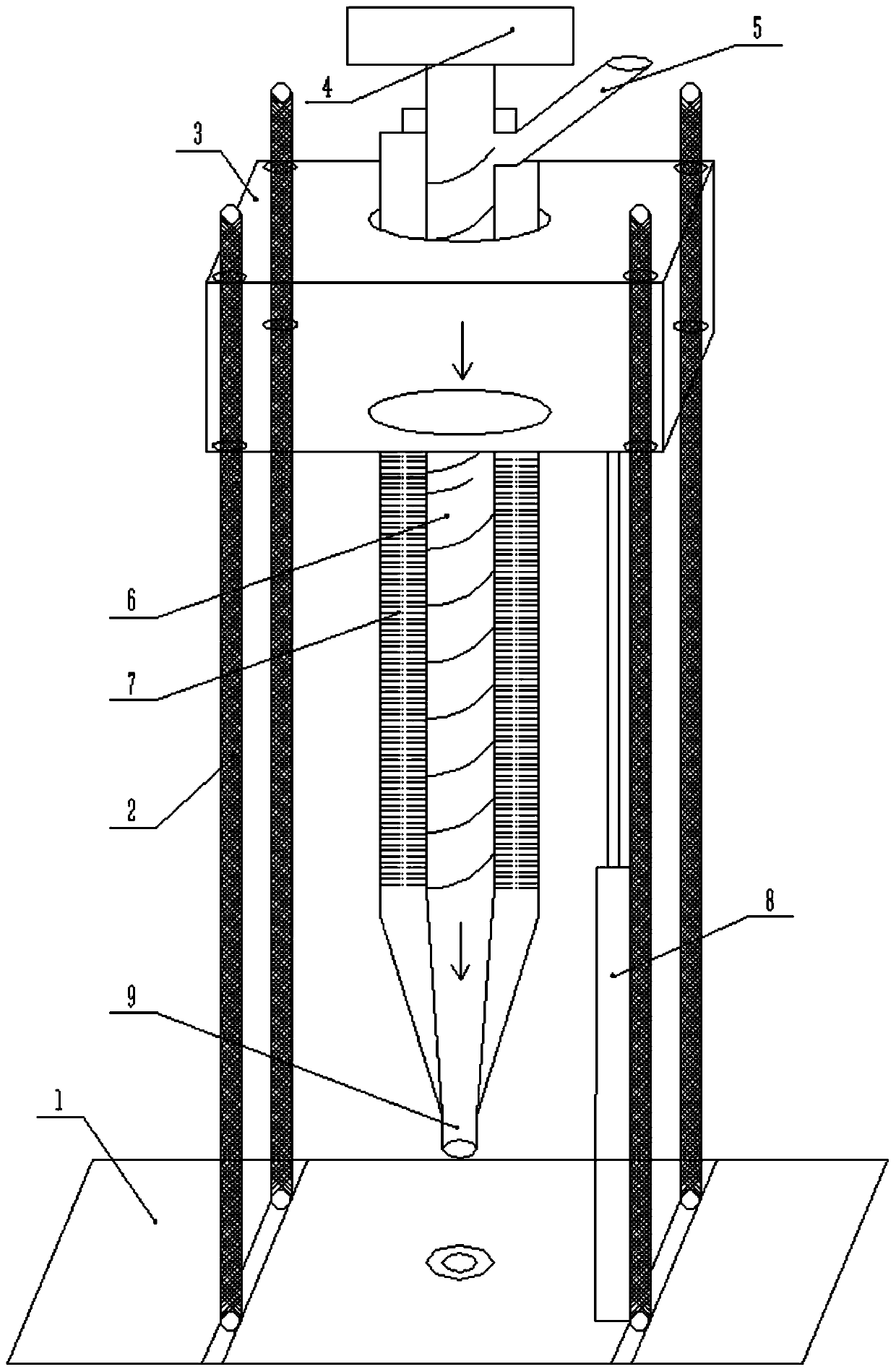

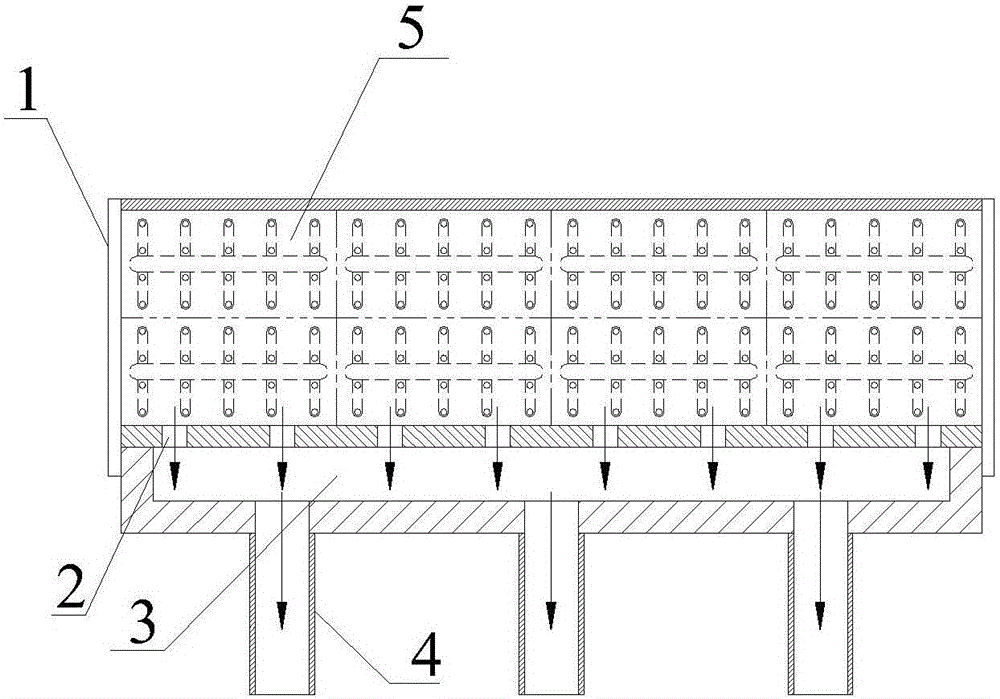

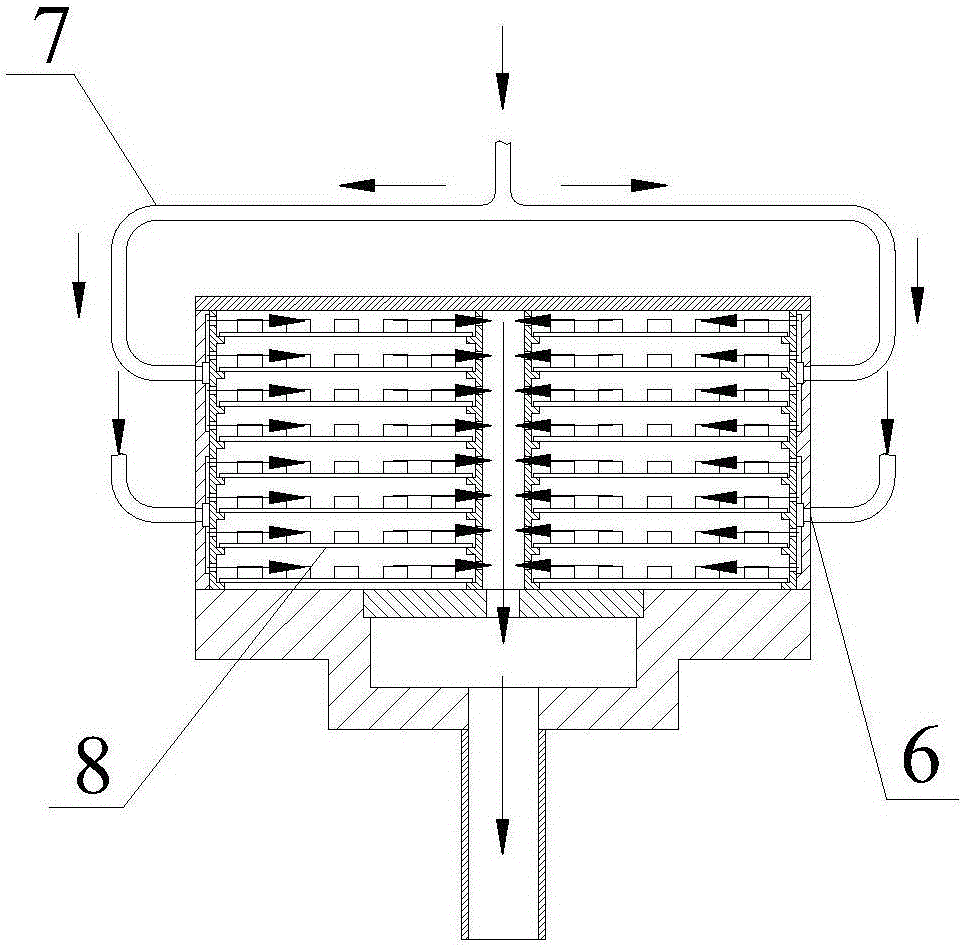

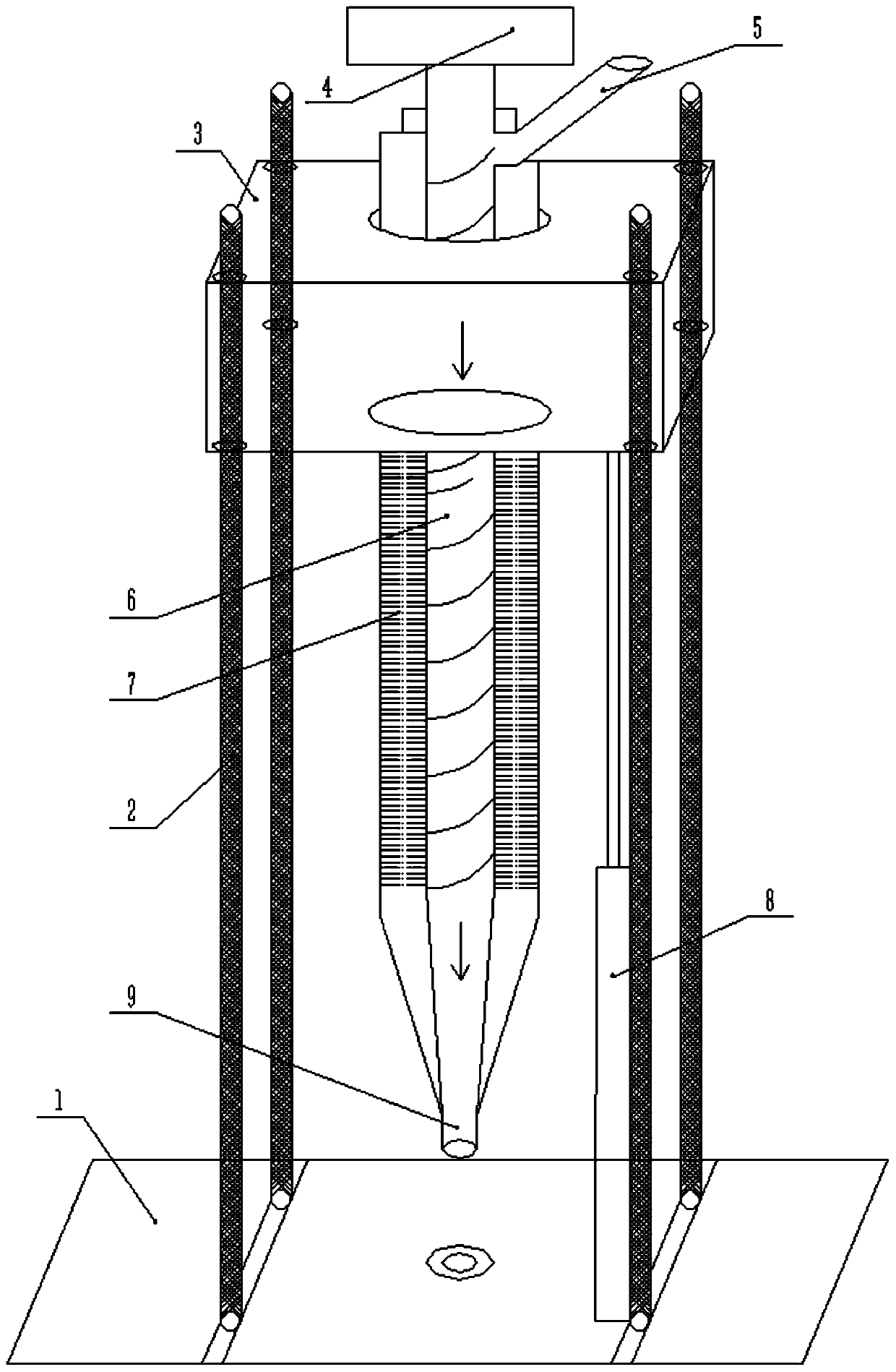

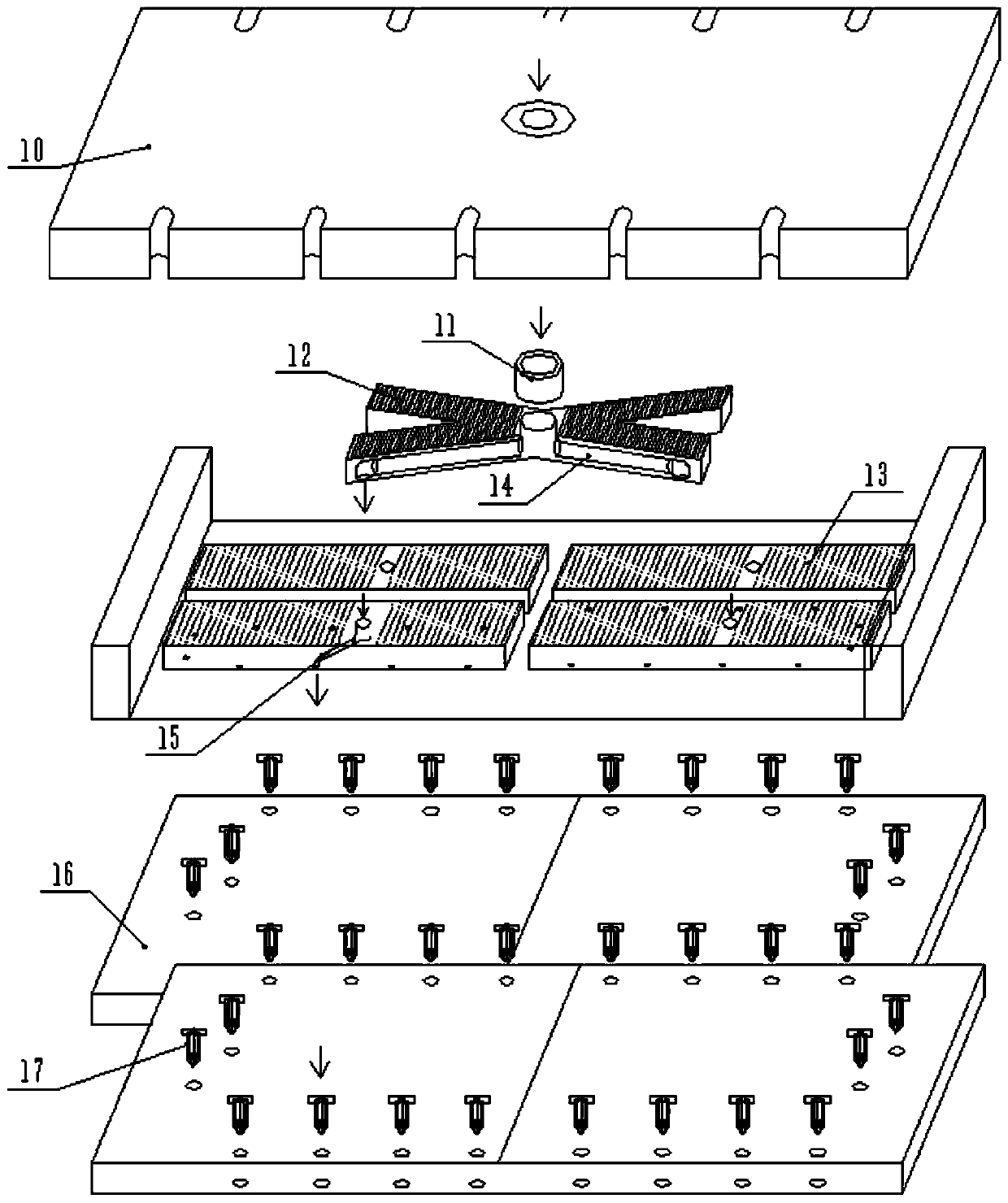

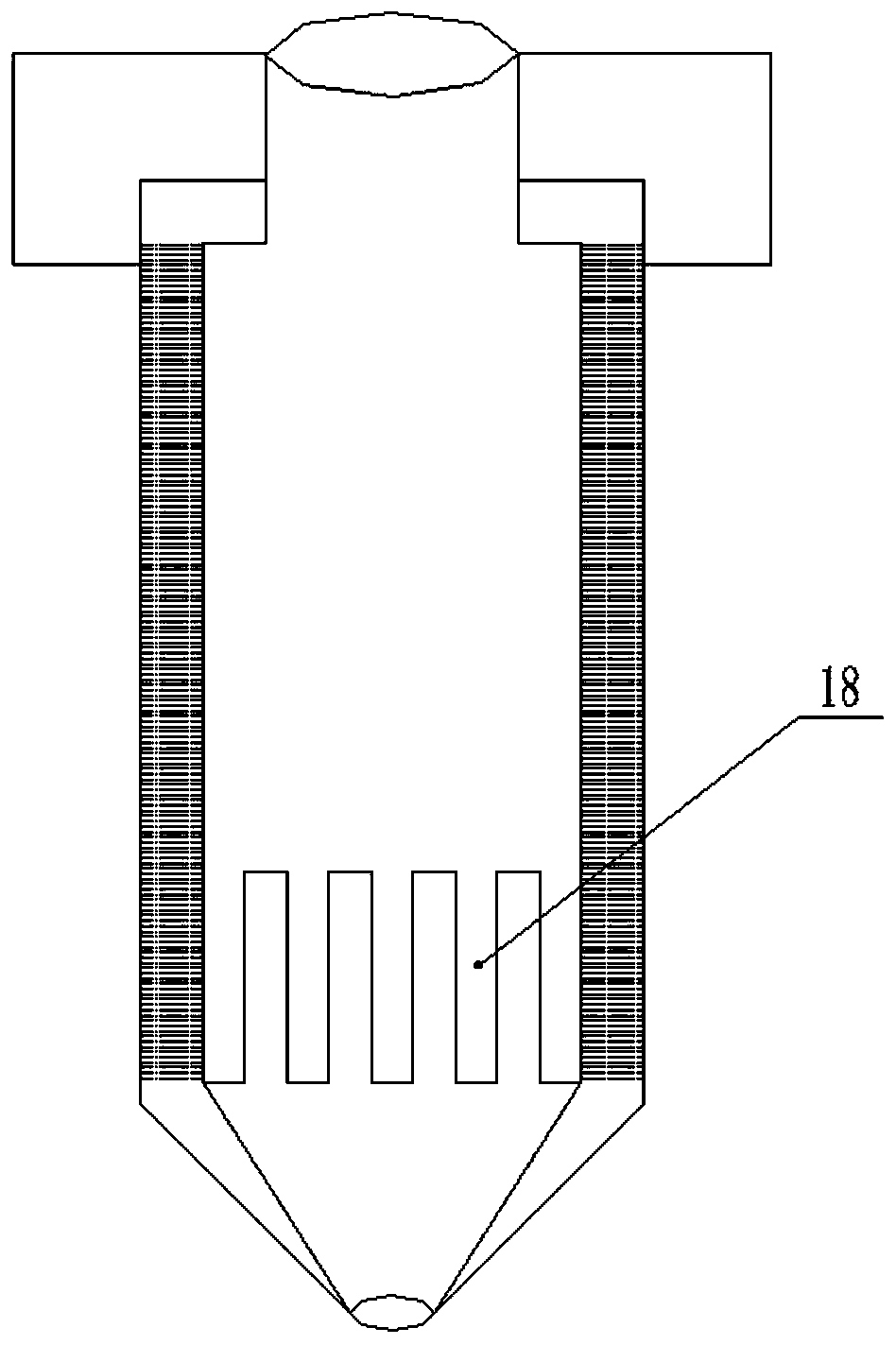

Multi-area atmosphere control metal injection molding vacuum sintering furnace

ActiveCN106735226ASolve the problem of little or no flowShorten the flow distanceInlet valveAtmosphere

The invention discloses a multi-area atmosphere control metal injection molding vacuum sintering furnace which comprises a material box, at least two layers of material plates, air inlet valves, at least two division holes, a convergence groove and an air outlet pipe. The material box is provided with air inlets which communicate with the air inlet valves. The material box is internally provided the material plates. To-be-machined products are stored on the material plates. Each side plate of the material box is provided with at least two sets of division grooves which divide the material box into a plurality of areas. Each set of division grooves corresponds to one air inlet. The bottom of the material box communicates with the convergence groove through the division holes. The convergence groove communicates with the air outlet pipe. According to the multi-area atmosphere control metal injection molding vacuum sintering furnace, through multi-area division and width direction air inflow, the atmosphere uniformity in the material box is ensured, and the size deviation of the products in the areas is adjusted and controlled by adjusting the airflow in all the areas.

Owner:NINGBO HIPER VACUUM TECH CO LTD

Production method of rapid sideslip mounting floor

InactiveCN110067358AHigh locking precisionPrevent overflowDomestic articlesCoatingsPlastic packagingEngineering

The invention discloses a production method of a rapid sideslip mounting floor, and belongs to the technical field of floor production. The manufacturing method comprises the following steps that stepone, floor blanks are sorted; step two, the floor blanks are conserved; step three, the floor blanks are sanded; step four, the floor blanks are subjected to thickness fixing; step five, the surfacesof the floor blanks are treated; step six, the floor blanks are subjected to fixed-length forming processing; step seven, anti-cracking oil is sprayed to the floor blanks; step eight, the floor blanks are subjected to plastic packaging; step nine, the floor blanks are coated with back paint; and step ten, the floor blanks are coated with oil paint or plant oil. After injection molding, a lock catch frame is hidden under a boss of each floor blank, the precision of the size of a lock catch is high, and the assembly is firm.

Owner:ANHUI YANGZI FLOORING +1

Strengthening device and method for selective laser melting additive manufacturing component

PendingCN114131054AAvoid size deviationBreak up and improveAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingReciprocating motion

The strengthening device comprises a control circuit which is electrically connected with a trigger switch, a power source, an air blower, a rotating motor and an electromagnet assembly through wires, and a magnetic plate, an elastic connecting rod, an electromagnet, a sliding push plate and a cleaning block which are fixedly connected in sequence are arranged in an extending groove; the cleaning block is provided with a threaded groove internally provided with a threaded rod, the threaded rod is fixedly connected with an impact head and a rotating blade, the threaded rod is rotationally connected with a rotating connecting plate, the rotating connecting plate is fixedly connected with a trigger rod, and the trigger rod is fixedly connected with a power connection rod connected with the two power connection plates in a matched mode. And the rotating blades rotate to stir, shake off and scatter the condensed metal powder on the outer side of the component, through cooperative arrangement of a trigger rod, a power connection plate and a power connection rod, a cleaning block and an impact head do reciprocating motion, and the scattering and cleaning effect on the condensed metal powder is further improved.

Owner:HUANGSHAN UNIV

Oil sump and method of its production

ActiveCN101358551AAvoid size deviationAvoid crackingGear lubrication/coolingOilsumpsCombustionReduction drive

The invention relates to an oil sump and a processing method. The oil sump is used in internal combustion engines or transmissions, where the oil sump consists of sheet metal shaped by deep drawing and has a reinforced edge, by means of which it rests, in its mounted state, in the internal combustion engine or the transmission with a seal positioned between them. The reinforcement consists of at least one separate metal part, which is mounted on the edge of the oil sump by positive locking and / or nonpositive locking with deformation of the edge of the oil sump.

Owner:MAN TRUCK & BUS AG

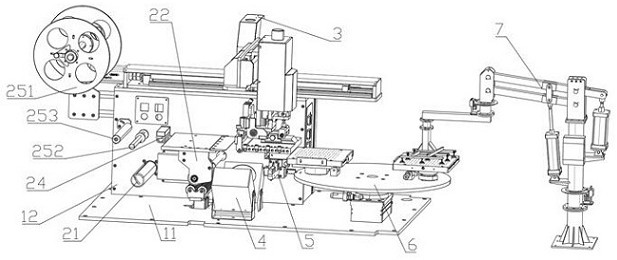

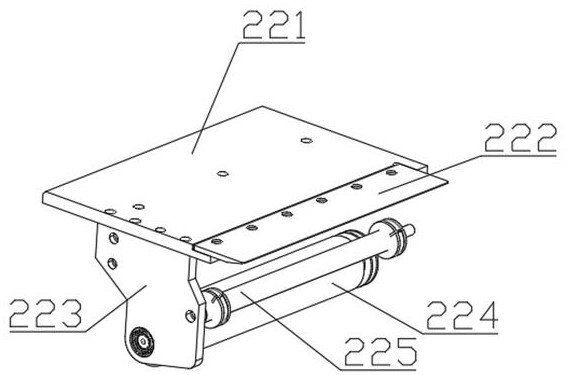

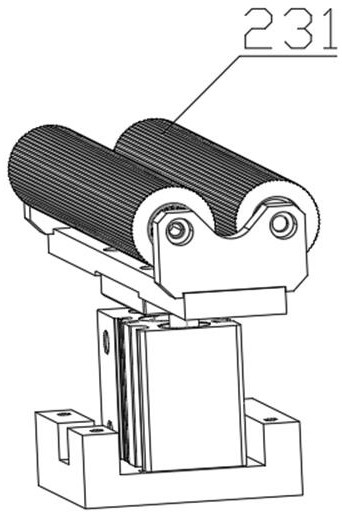

Optical composite film assembling machine of backlight module

ActiveCN113263736AAvoid wrinklesAvoid size deviationMetal working apparatusComposite filmEngineering

The invention discloses an optical composite film assembling machine of a backlight module. The optical composite film assembling machine is provided with a workbench, a winding and unwinding tension assembly, a cutting and pressing machine, an ion fan, a CCD detector, a rotary pressing station and a mechanical arm, wherein the workbench is provided with a square box and a bottom face, and the square box is installed on the left side of the bottom face; the winding and unwinding tension assembly is installed on the workbench; a cutting and pressing machine is mounted on the square box; the ion fan is mounted on the bottom surface, and the rotary pressing station is mounted on the bottom surface; the ion fan is located between the winding and unwinding tension assembly and the rotary pressing station; the CCD detector is installed on the right side of the square box and located in front of the winding and unwinding tension assembly; and the mechanical arm is positioned in front of the rotary pressing station. Automatic control over liquid crystal screen film pasting operation can be achieved, and the liquid crystal screen film pasting efficiency can be improved to a large extent.

Owner:深圳市橙信科技有限公司

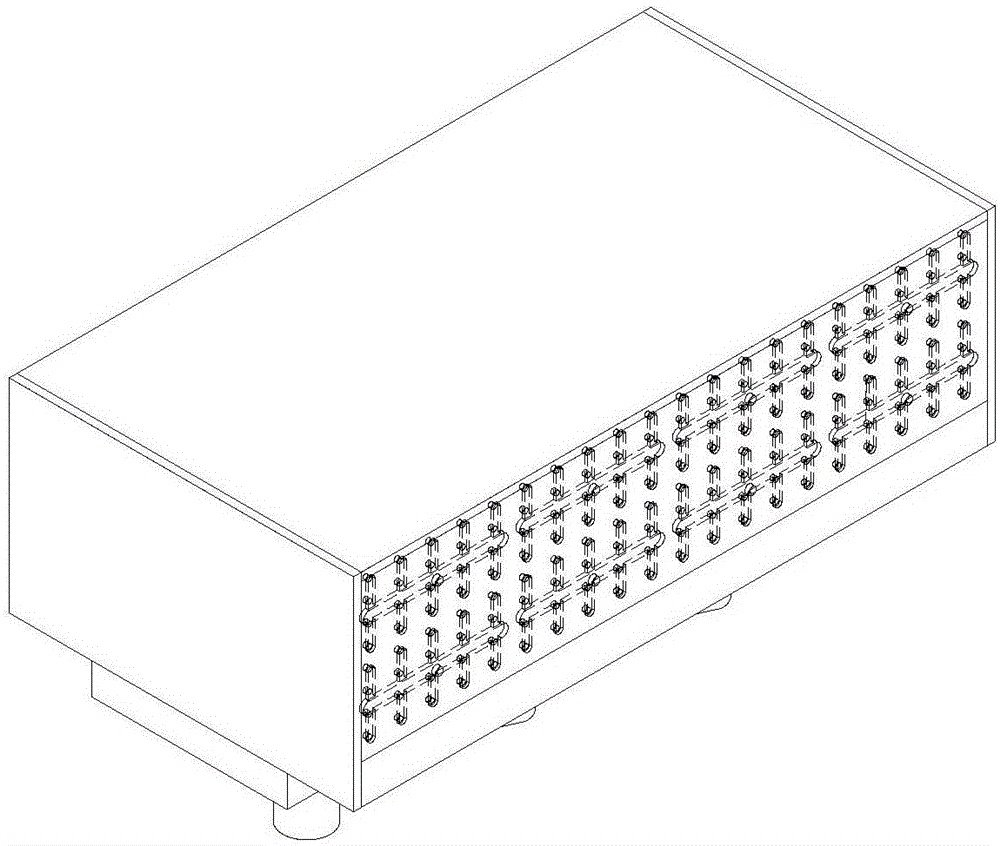

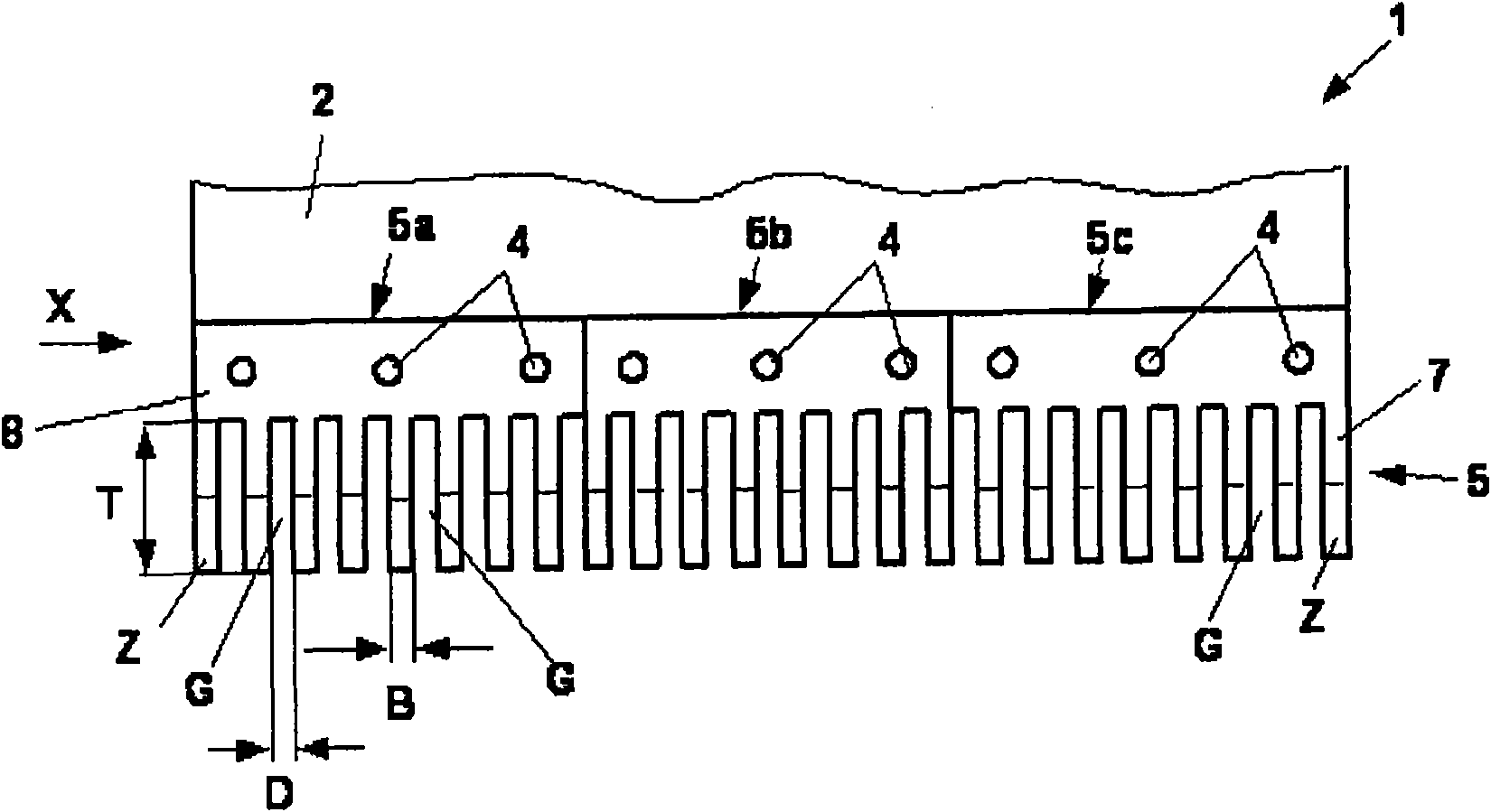

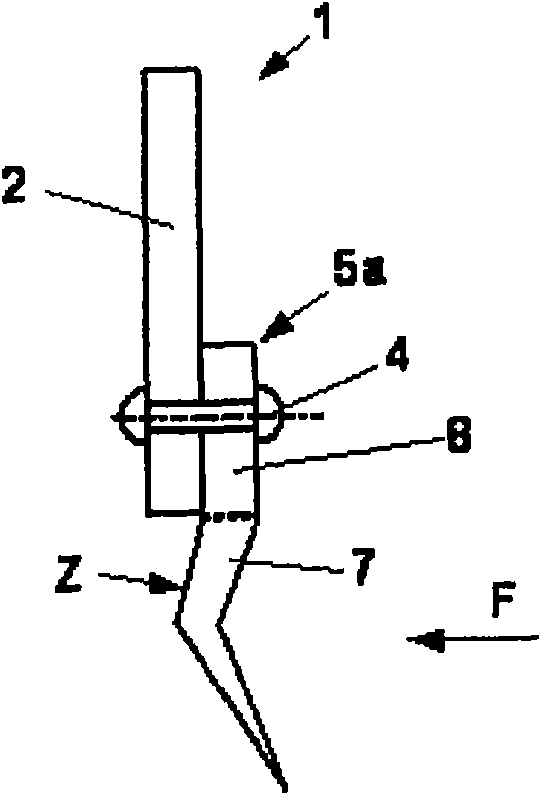

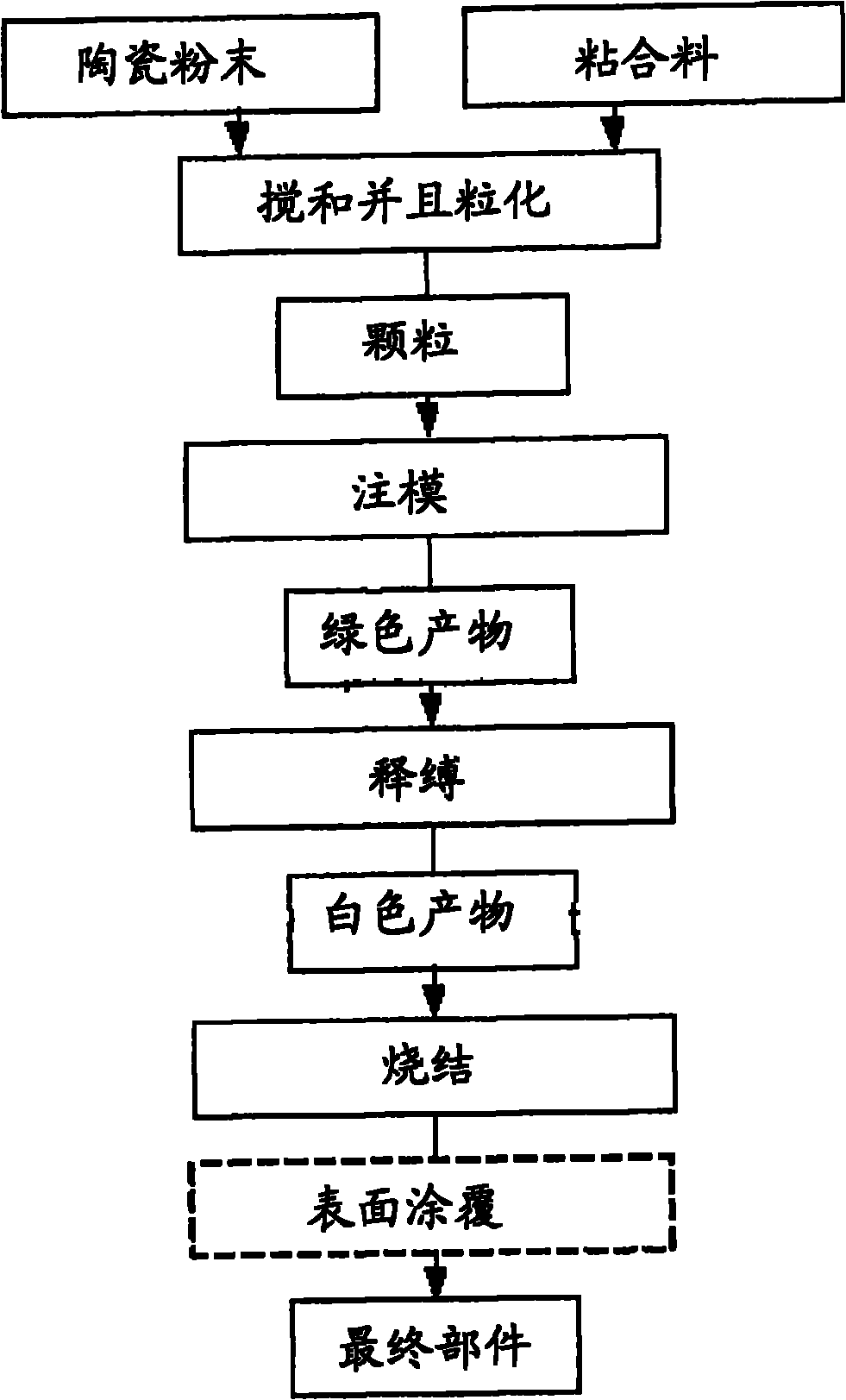

Comb fitting for a combing machine

InactiveCN101838866AHigh dimensional accuracyHigh strengthCombing machinesCarding machinesMechanical engineeringPower injection

The present invention relates to a comb fitting for a combing machine. The invention provides a method for manufacturing an integrated comb fitting (5) of a combing machine. The comb fitting is provided with a plurality of teeth (Z) which are provided adjacently and are spaced with a certain distance. The root areas (7) of the teeth form a common rod (8). For producing the comb fitting more simply with accurate dimension or even enlarging the tooth density, a final form for manufacturing the comb fitting (5) by means of power injection mold (PIM) is provided.

Owner:MASCHINENFABRIK RIETER AG

Cloth breaking machine for spinning

InactiveCN108381623AAvoid sizeReduce cost wasteSevering textilesMetal working apparatusEngineeringControl switch

The invention discloses a cloth breaking machine for spinning. The cloth breaking machine comprises a table surface, wherein cylinders are arranged at the bottom of the table surface, scale rulers arearranged on the surface of the table surface, a cutting sliding table is arranged at the position, close to the scale rulers, of the upper portion of the table surface, vertical columns are arrangedat the positions, close to one side of the cutting sliding table, of the table surface, a control switch is embedded in one side of the table surface, and a first electric telescopic rod is arranged at the position, close to one side of the control switch, of one side of the table surface. The scale rulers are arranged, so that the weaving cloth to be cut can be accurately measured through the scale rulers, the problem that the size of the cut weaving cloth is not inconsistent with the size of the required size is avoided, the cost is reduced, the working efficiency is improved, and the laborintensity is reduced. Clamping devices are arranged, and the weaving cloth to be cut can be fixed through the clamping devices, so that the problem that the size deviation is caused by weaving deviation in the cutting process is solved and the size accuracy is guaranteed.

Owner:响水县嘉亿纺织有限公司

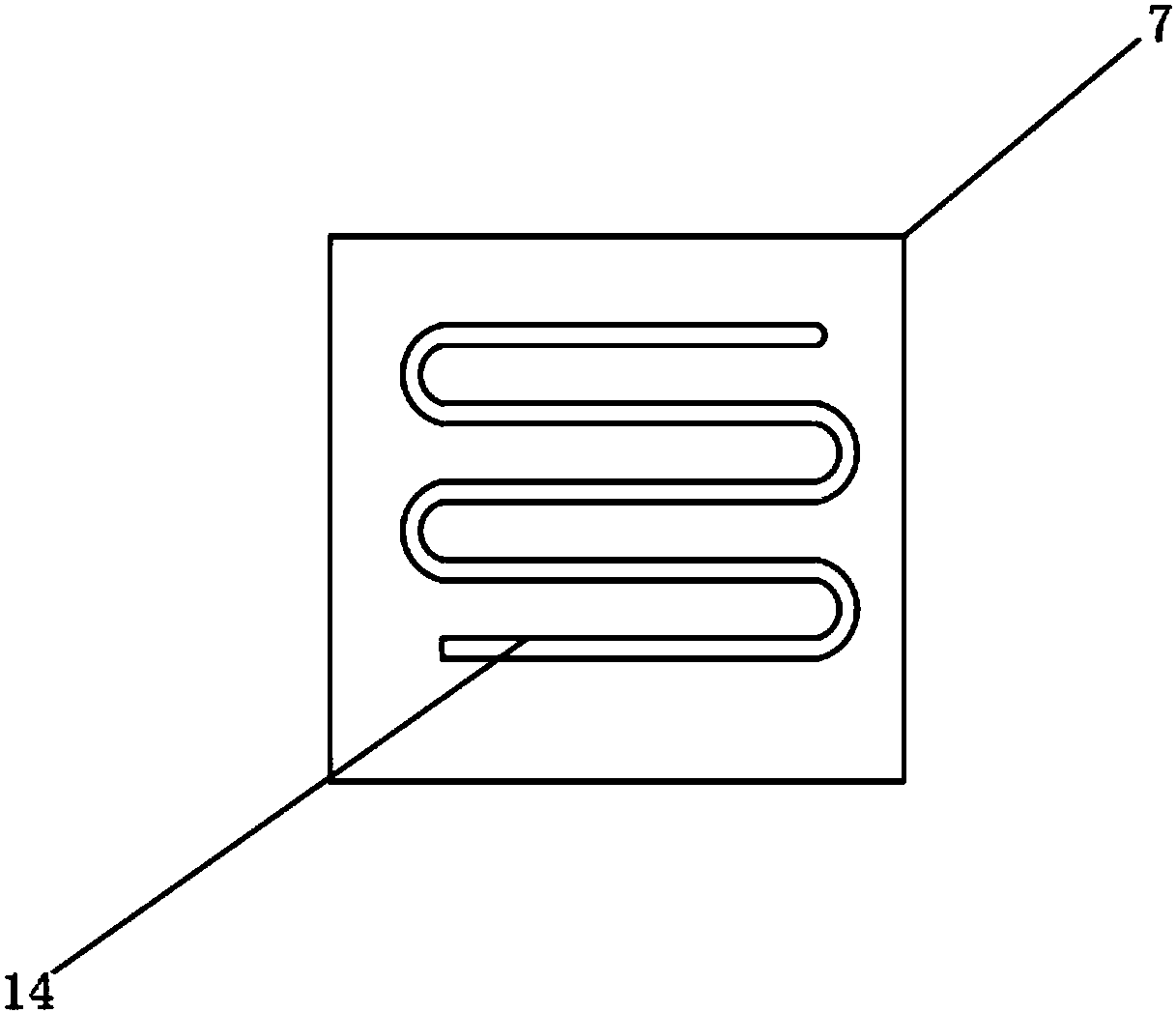

Battery cooling pipe bending equipment

PendingCN110605314APrevent slidingAvoid size deviationMetal-working feeding devicesPositioning devicesPipe fittingEngineering

The invention provides battery cooling pipe bending equipment. The battery cooling pipe bending equipment comprises a base and a pipe bending mechanism; the pipe bending mechanism comprises a bent guide column, a first rotating plate, a second rotating plate, a first fixed column, a second fixed column and a driving piece; a guide annular groove is bent on the bent guide column; a mounting plate is fixed under the bent guide annular groove on the bent guide column; the first rotating plate and the second rotating plate are oppositely arranged on the two sides of the bent guide column, and oneends of the first rotating plate and the second rotating plate are rotationally connected with the mounting plate; the first fixed column and the second fixed column are vertically connected with thefirst rotating plate and the second rotating plate; and the driving piece is connected with the first rotating plate and the second rotating plate for driving opposite or deviated rotation of the first rotating plate and the second rotating plate. Under cooperation of the base with an inclined surface, the inclined mounting plate, the first rotating plate, the second rotating plate and the drivingpiece, the automatic unloading of bent pipe fittings is realized, and the production efficiency is effectively improved.

Owner:ANHUI ZHONGDING KEUMAH AUTO HOSE & PIPE ASSEMBLY

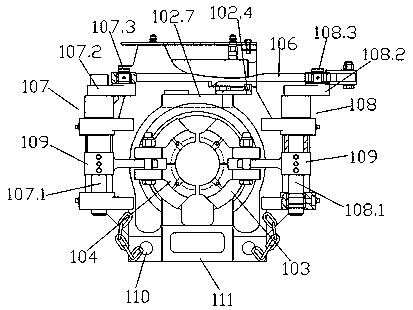

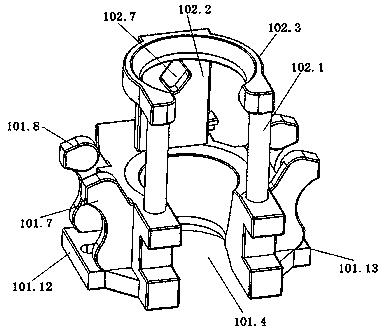

C-type pneumatic chuck and production method thereof

PendingCN109812234AReduce the difficulty of processing and manufacturingAvoid size deviationDrilling rodsFoundry mouldsEngineeringUltimate tensile strength

The invention relates to a C-type pneumatic chuck. The C-type pneumatic chuck comprises a chuck main body, a slip body and a power mechanism, wherein the chuck main body comprises a base and a centering frame, an insert is arranged in the slip body; the power mechanism comprises a cylinder assembly, a connecting rod driven by the cylinder assembly, a left crank assembly connected with the connecting rod, and a right crank assembly connected with the connecting rod; the left crank assembly comprises a left shaft, a left crank arm and a left connecting shaft; the right crank assembly comprises aright shaft, a right crank arm and a right connecting shaft; the left connecting shaft and the right connecting shaft are both fixedly connected with the connecting rod; the left shaft and the rightshaft are respectively fixedly connected with the slip body through a rotating arm; a valve is connected between a left front section and a right front section of the base through a valve pin. The C-type pneumatic chuck has the advantages of being low in processing and manufacturing difficulty, high in connecting strength, long in service life, and convenient to mount.

Owner:江苏佰恰利机械有限公司

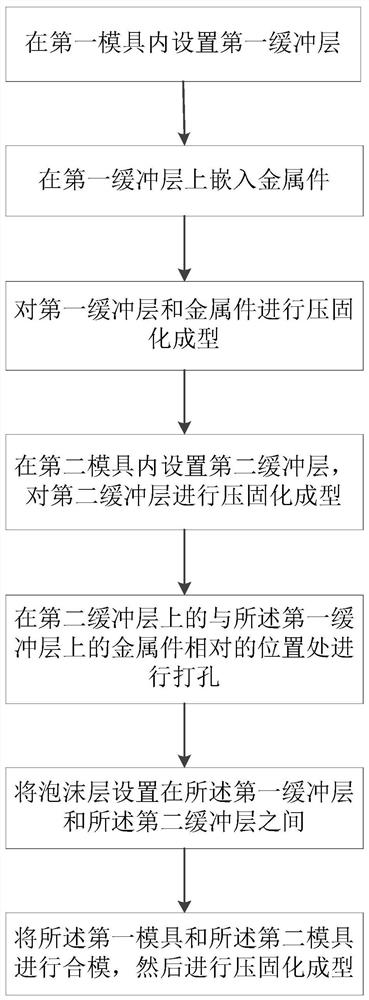

Cab hood of maglev vehicle and manufacturing method thereof

PendingCN111775985AAvoid Defective Embedded Metal Parts DefectsReduce weightAxle-box lubricationDomestic articlesGlass fiberMechanical engineering

The invention provides a cab hood of a maglev vehicle and a manufacturing method thereof, which belong to the technical field of vehicle body parts of railway vehicles. The cab hood of the maglev vehicle comprises a hood body which comprises a foam sandwich layer and buffer layers which are arranged on the upper surface and the lower surface of the foam sandwich layer and mainly adopt carbon fiberprepregs, and a metal piece which is embedded in the foam sandwich layer and the buffer layers, wherein one end of the metal piece extends out of the hood body. According to the cab hood of the maglev vehicle, glass fiber reinforced plastic is replaced with the carbon fiber composite material; compared with an original hood, the cab hood has the advantages that the weight can be reduced by 15% to30% under the same requirement, and the light weight effect is remarkable; besides, an innovative metal piece embedding technology is adopted, the metal piece is embedded in the buffer layers, a cementing co-curing process is adopted, the metal piece and the product are integrally formed, and the defect that the metal piece is destructively embedded in a traditional glass fiber reinforced plasticcab hood is overcome.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com