Production method of floors capable of being quickly installed in side sliding mode

A production method and floor technology, which can be applied to other home appliances, floors, coatings, etc., can solve problems such as affecting the beauty, affecting the effect, and changing the natural characteristics of wood, so as to improve production efficiency, high locking accuracy, and firm assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

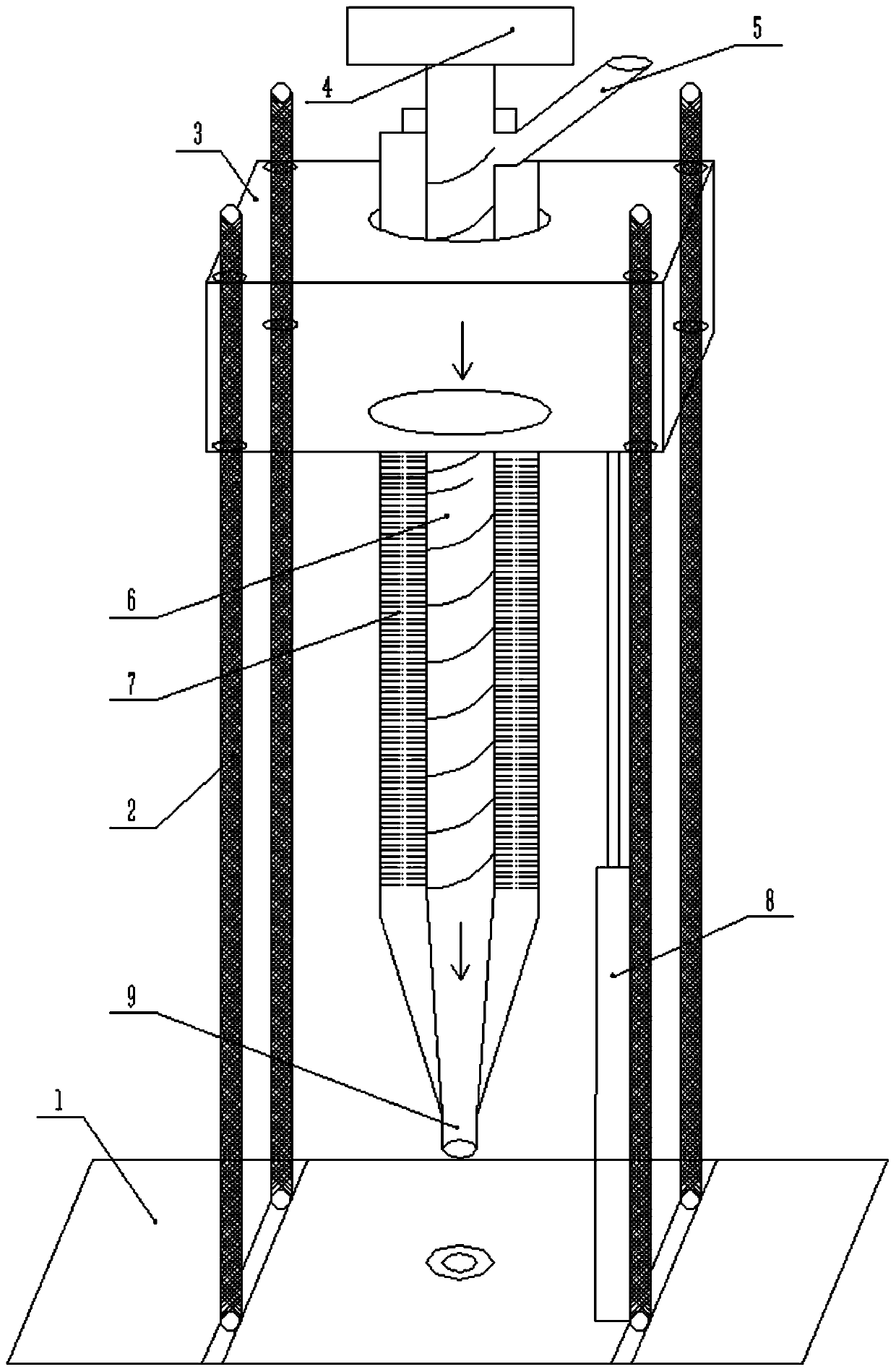

[0063] A production method for fast side-slip floor installation, comprising the following steps:

[0064] Step 1: Sorting of floor blanks:

[0065] Carry out a piece inspection of the floor blanks, and test the moisture content, size specifications and appearance quality of each floor blank; the requirements, the moisture content is controlled at 6-11%; the size specifications meet the production requirements; the appearance quality meets LY / T 2058-2012 solid wood flooring Billet requirements;

[0066] Step 2: Preservation of floor blanks:

[0067] Stack the floor blanks that have been sorted and qualified in step 1 in the health care area for health preservation, keep ventilation and avoid sun and rain; the relative humidity of the health care area is 25%-55%, and the temperature is 20-25°C; the health care time is 25-25°C. 30 days; for each stack of floor blanks, 5 pieces of floor blanks are placed in three rows at equal distances as a cushion, and stacked in layers. In e...

Embodiment 2

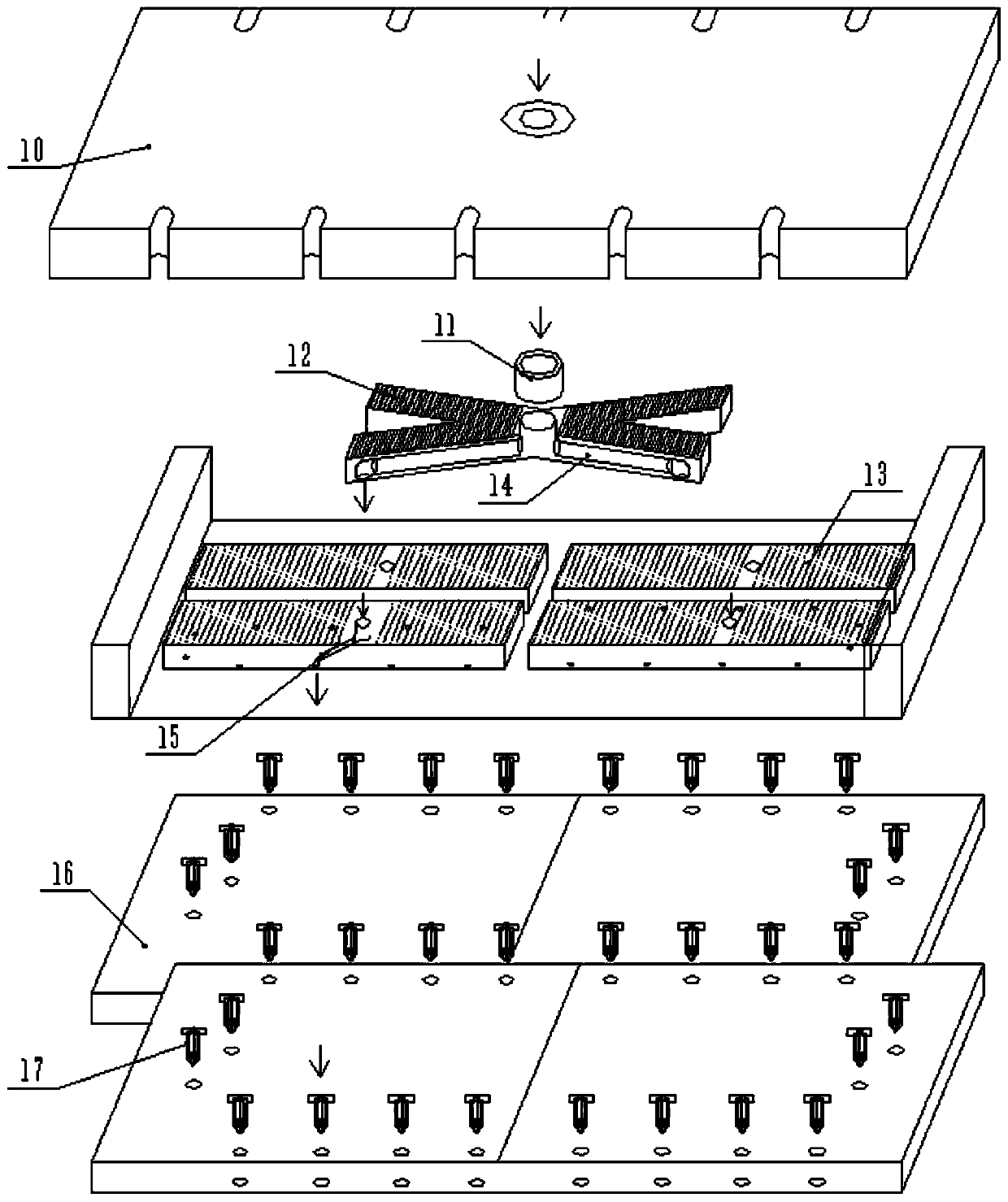

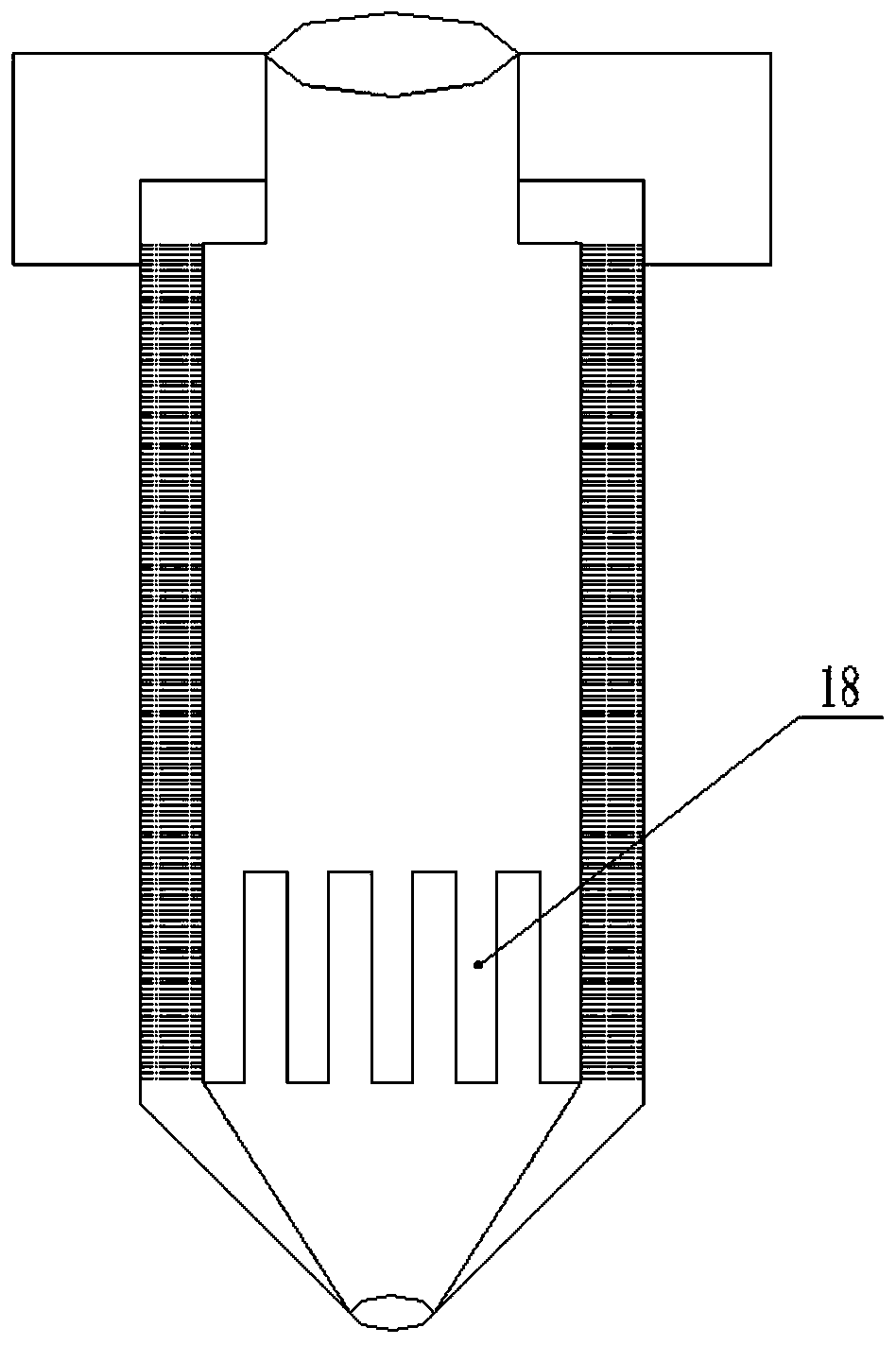

[0096] Such as figure 2 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, in the eighth step , when using the injection head to inject molten material in the lock button cavity, the weight of the molten material injected into the injection molded part lock of the single-piece injection molded floor blank is 130 grams, and the pressure of the molten material when it passes through the injection nozzle 9 to the straight channel 12 is 78bar, the flow rate is 96%, and the stroke is 65mm; when the molten material passes through the straight channel 12 to the curved channel 13, the pressure is 32bar, the flow rate is 72%, and the stroke is 42mm; the molten material passes through the curved channel 13 to the lock point pouring pipe At 17 o’clock, the pressure is 21bar, the flow rate is 52%, and the stroke is 32mm; when...

Embodiment 3

[0098] Such as figure 2 As shown, this implementation is further optimized on the basis of Embodiment 2. This embodiment focuses on the improvements compared with Embodiment 2, and the similarities will not be repeated. In this embodiment, in the eighth step , when using the injection head to inject molten material into the lock button shape cavity, the weight of the molten material injected into the injection molded part lock button of the single-piece injection molded floor blank is 120-130 grams, and the molten material passes through the injection nozzle 9 to the flow channel 12. The pressure is 75bar, the flow rate is 95%, and the stroke is 60mm; when the molten material passes through the straight channel 12 to the curved channel 13, the pressure is 30bar, the flow rate is 70%, and the stroke is 40mm; the molten material passes through the curved channel 13 to the locking point The pressure of pouring pipe 17 is 18bar, the flow rate is 50%, and the stroke is 30mm; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com