Voltage type automatic gain control circuit

An automatic gain control, voltage type technology, applied in gain control, amplification control, electrical components, etc., can solve the problems of poor anti-interference ability of voltage disturbance, unfavorable duplex mode operation, long locking time, etc., and achieve high locking accuracy. , Reduce the circuit response time, the effect of short locking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. While illustrations of parameters containing particular values may be provided herein, it should be understood that the parameters need not be exactly equal to the corresponding values, but rather approximate the corresponding values within acceptable error margins or design constraints.

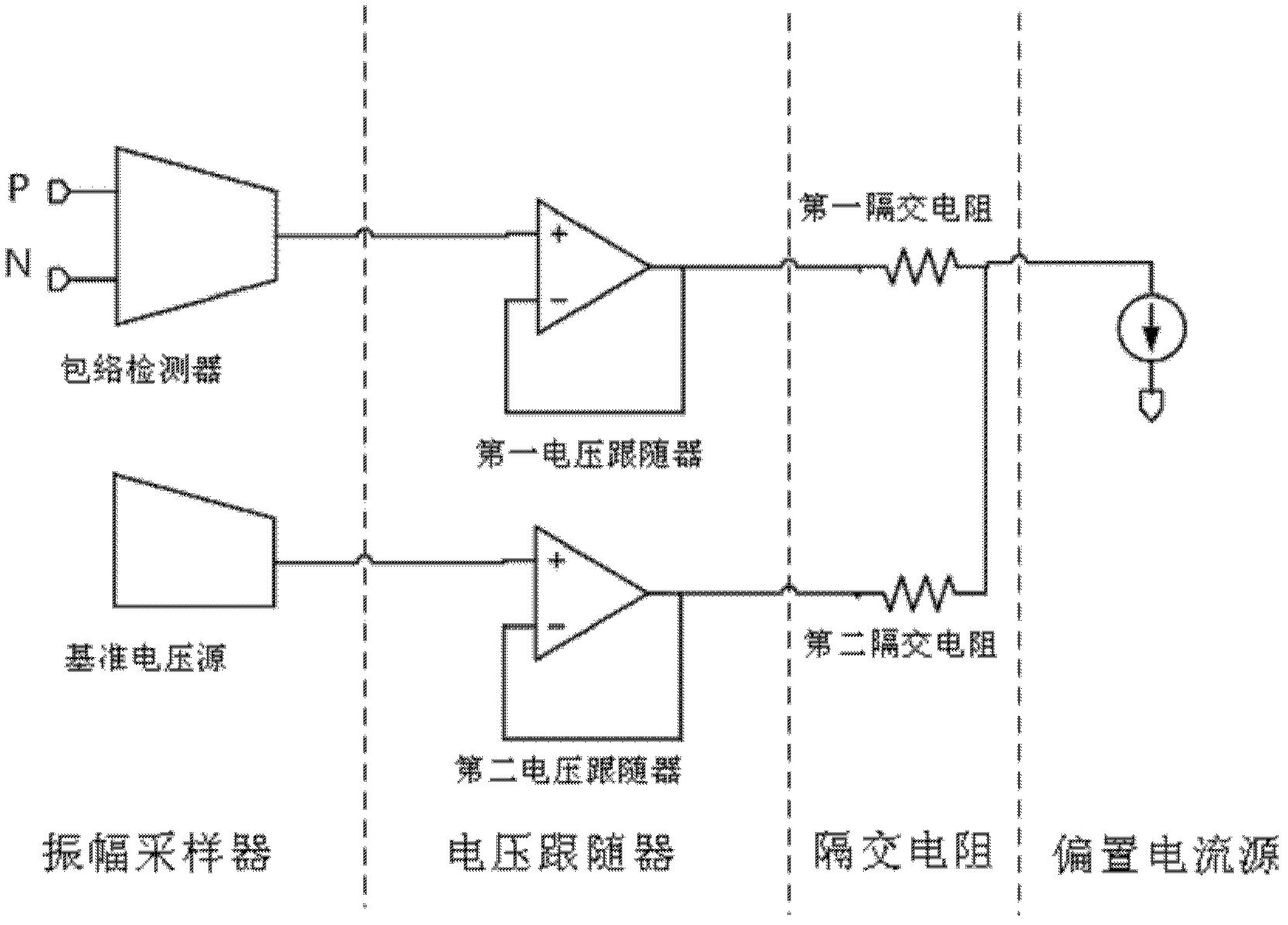

[0018] In an exemplary embodiment of the present invention, a voltage type AGC circuit is proposed. figure 1 It is a schematic diagram of the structure of the voltage type AGC circuit of the embodiment of the present invention. like figure 1 As shown, the AGC circuit in this embodiment includes: an amplitude sampler, a voltage follower, an AC isolation resistor and a bias current source. Among them, the amplitude sampler samples the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com