Optical composite film assembling machine of backlight module

An optical composite film and backlight module technology, which is applied in metal processing and other directions, can solve the problems of affecting display imaging, inconsistent size of backlight module, and inability to meet assembly requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

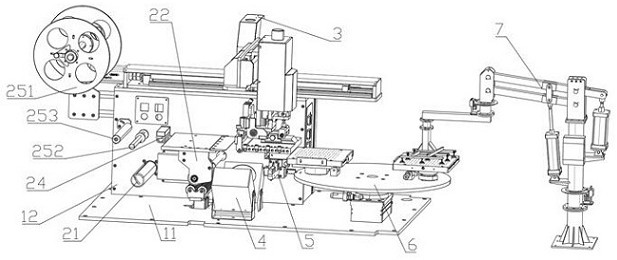

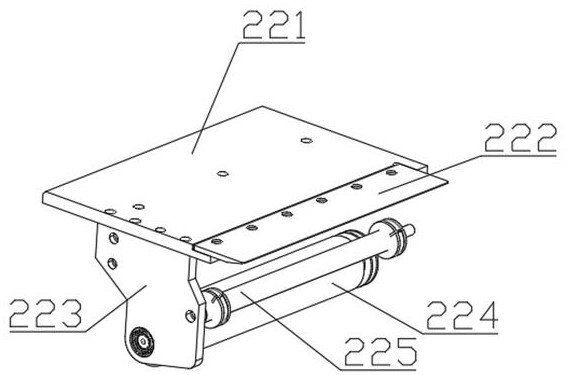

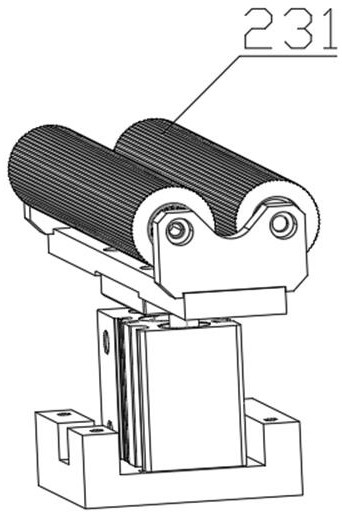

[0036] Embodiment 1: as figure 1 As shown, an optical composite film assembly machine for a backlight module is provided with a workbench, unwinding and unwinding tension components, a cutting and pressing machine 3, an ion fan 4, a CCD detector 5, a rotary pressing station 6 and a manipulator 7. The workbench is provided with a bottom surface 11 and a square box 12, and the square box is installed on the left side of the bottom surface; the winding and unwinding tension assembly is provided with a discharge device 21, a cutting table 22, and an adjustment roller assembly 23. Horizontal splint 24 and winding device; the cutting table is provided with a table top 221, a cutter 222, a bracket 223, a dust removal drum 224 and a discharge adjustment drum 225; the adjustment drum group is provided with an adjustment drum 231 and a cylinder, A layer of sticky paper is attached to the surface of the dust removal drum 224; the winding device is provided with a winder 251, a transition...

Embodiment 2

[0037] Embodiment 2: as figure 2 As shown, there is a cutter on the cutting table. When the type of optical composite film used is an optical composite film that has been cut and formed and pasted on the base film, the optical composite film will be cut when it slides over the cutter. The knife can separate the optical composite film from the base film; when using the optical composite film that needs to be cut, the optical composite film is cut by the cutting and pressing device. The optical composite film assembly machine of the backlight module can be applied to various Types of optical composite films.

Embodiment 3

[0038] Embodiment 3: as figure 2 with image 3As shown, in order to ensure the cleanliness of the optical composite film and avoid the assembly failure caused by the sticking of sundries on the optical composite film, an adjustment roller assembly, a dust removal roller and an ion fan are set up; When the film passes under the dust removal roller, the roller assembly is adjusted to rise, so that the optical composite film and the dust removal roller are closely bonded, and the dust removal roller performs a dust removal on the optical composite film; after the optical composite film is cut and transferred to the pressing station, it passes above the ion fan , The ion fan can eliminate the static electricity on the surface of the optical composite film, prevent static electricity from adsorbing dust and other sundries in the air on the optical composite film, and the electrostatic fan can perform secondary dust removal on the optical composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com