Method for controlling deformation of snap-ring parts through heat treatment

A technology of heat treatment deformation and control method, applied in the direction of heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problems of final size deviation and large deformation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

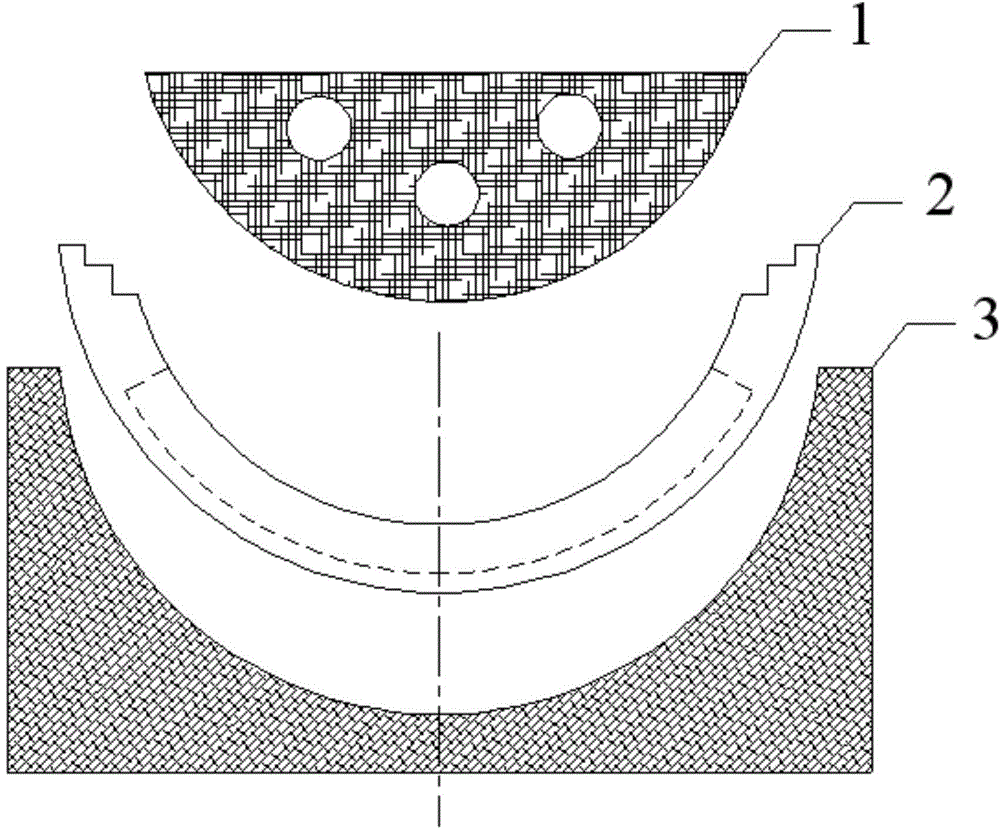

[0022] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] The method for heat treatment deformation control of snap ring parts includes the following steps:

[0024] The first step is to determine the T6 processing parameters of the blank: heat the blank forging to 510-520°C, keep it warm for 120±10min, put it into water quickly within 15s, the water temperature is 20-30°C, and the aging temperature is 150-160°C (at 150 -160℃ aging), keep warm for 8-15h, and air cool to room temperature;

[0025] The second step, the first stabilization treatment: heat the parts after the abandoned car to 170±5°C, keep it warm for 4 hours, cool it to room temperature in air, then keep it warm at -50~-80°C for 2 hours, turn the oven vertically, and heat it at 170°C Insulate in an oven at ±5°C for 4 hours, and finally cool to room temperature with the furnace;

[0026] The third step, the second stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com