Patents

Literature

68results about How to "Easy process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-alloy high-strength C-Mn-Al Q & P steel and method of manufacturing the same

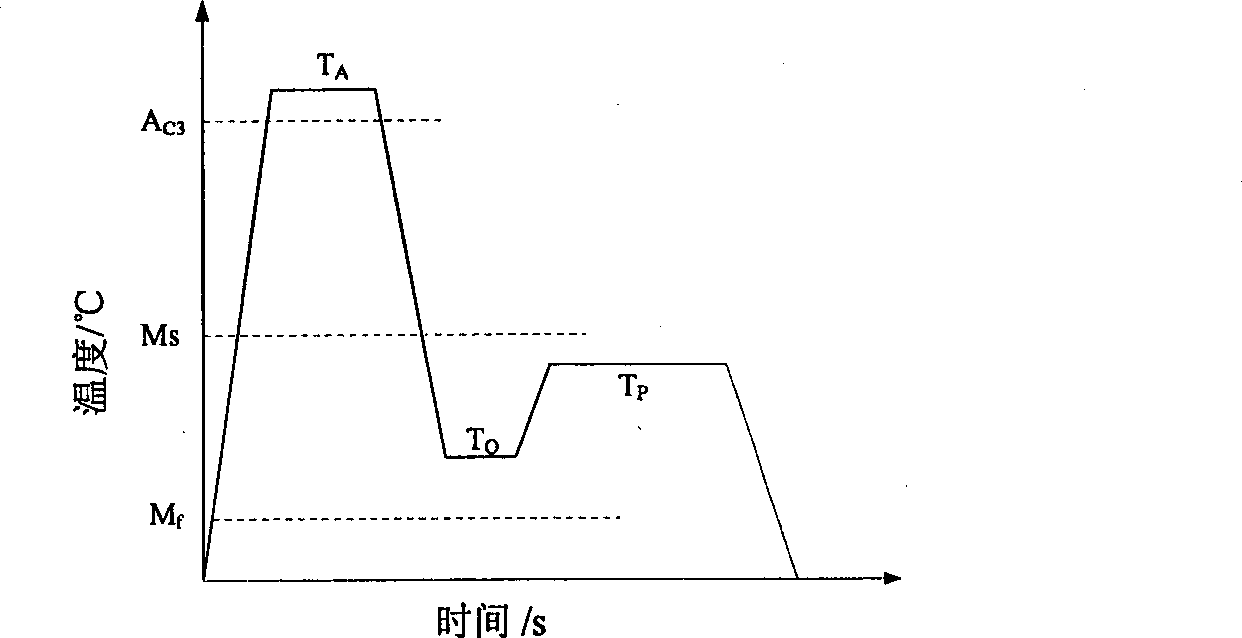

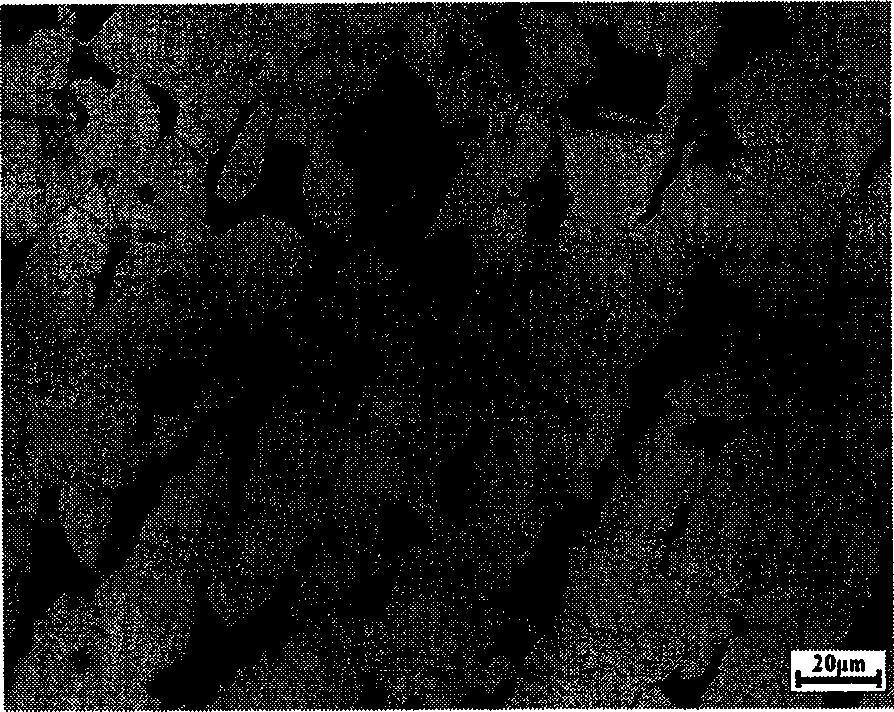

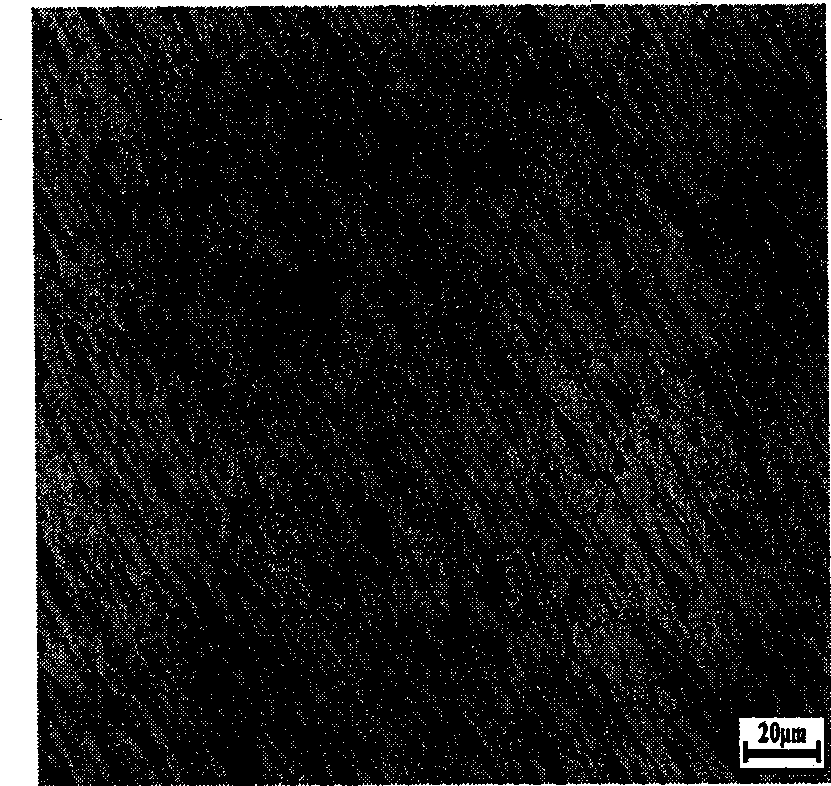

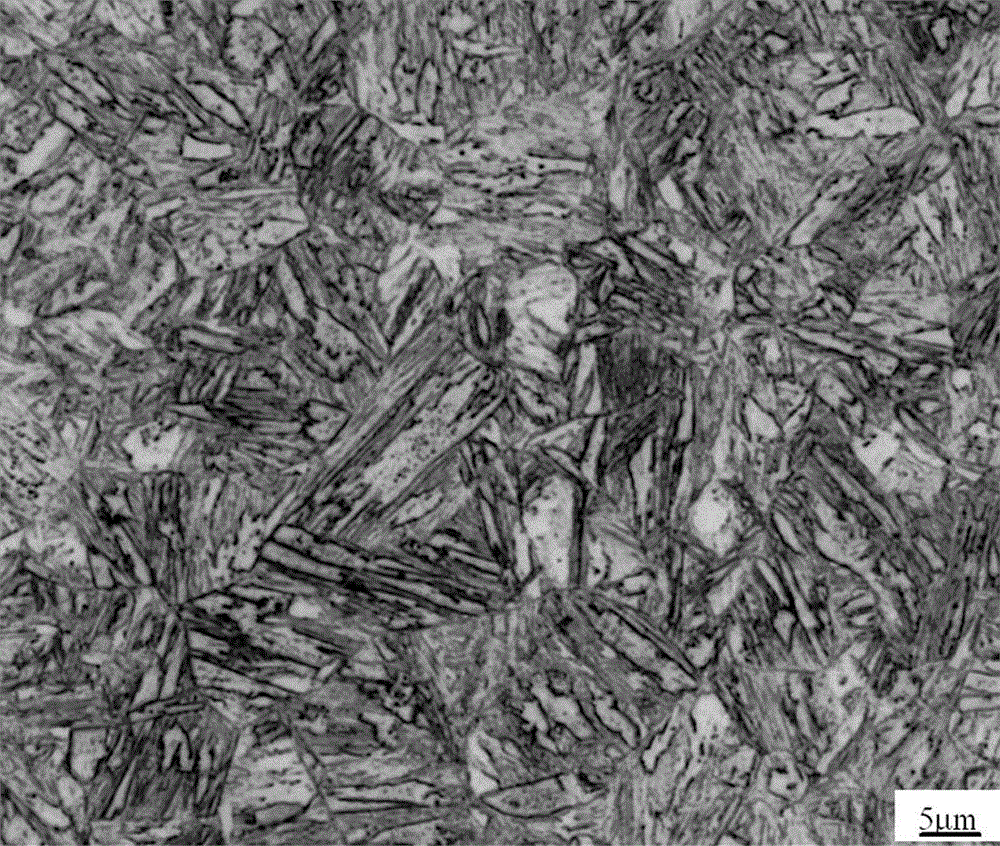

The invention relates to a low-alloyed and high-strength Q and amp of a C-Mn-Al system; P steel; and a manufacturing method thereof, which belong to the technical field of metal materials. The method comprises the following processing steps of: (1) smelting and cast blocking: the mass percentages of the components are as follows: 0.16 percent to 0.25 percent of C, less than or equal to 0.40 percent of Si, 1.20 percent to 1.60 percent of Mn, 1.0 percent to 1.5 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.008 percent of S and the balance of ferrite. (2) rolling: after the multi-pass hot-rolling of rough rolling and finish rolling, wherein, the deformation of roughing pass is 10 percent to 30 percent, the total deformation of the finish rolling is more than 60 percent, a hot rolled plate is subjected to multi-pass cold rolling, the deformation is 5 percent to 50 percent, and the plate is rolled to be a thin plate with the thickness being 0.6 to 2.0mm. (3) heat treating: firstly, austenitizing of 850 to 930 DEG C is carried out in a heating furnace, temperature is kept for 100 to 200 seconds and then rapid quenching is carried out to reach 230 to 250 DEG C, the temperature is kept for 20 to 40 seconds, after that the temperature is kept in 300 to 400 DEG C for 120 to 3600 seconds, at last fast cooling is carried out to room temperature (the speed of the cooling is not less than 10 DEG C / s). The Q and amp and the P steel have economic components, good quality of the surface, high strength and good shaping resistance. The strength and ductility product can reach over 37000MPa question mark percent.

Owner:UNIV OF SCI & TECH BEIJING

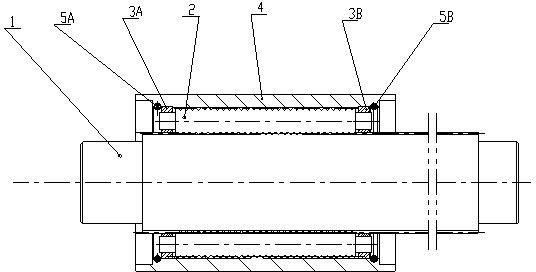

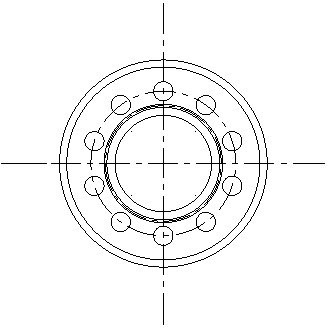

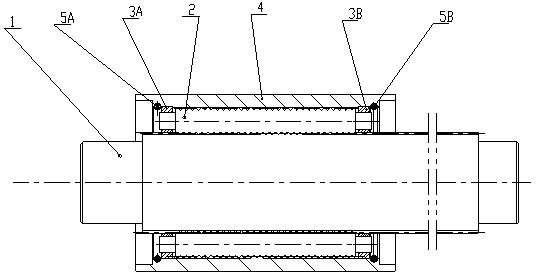

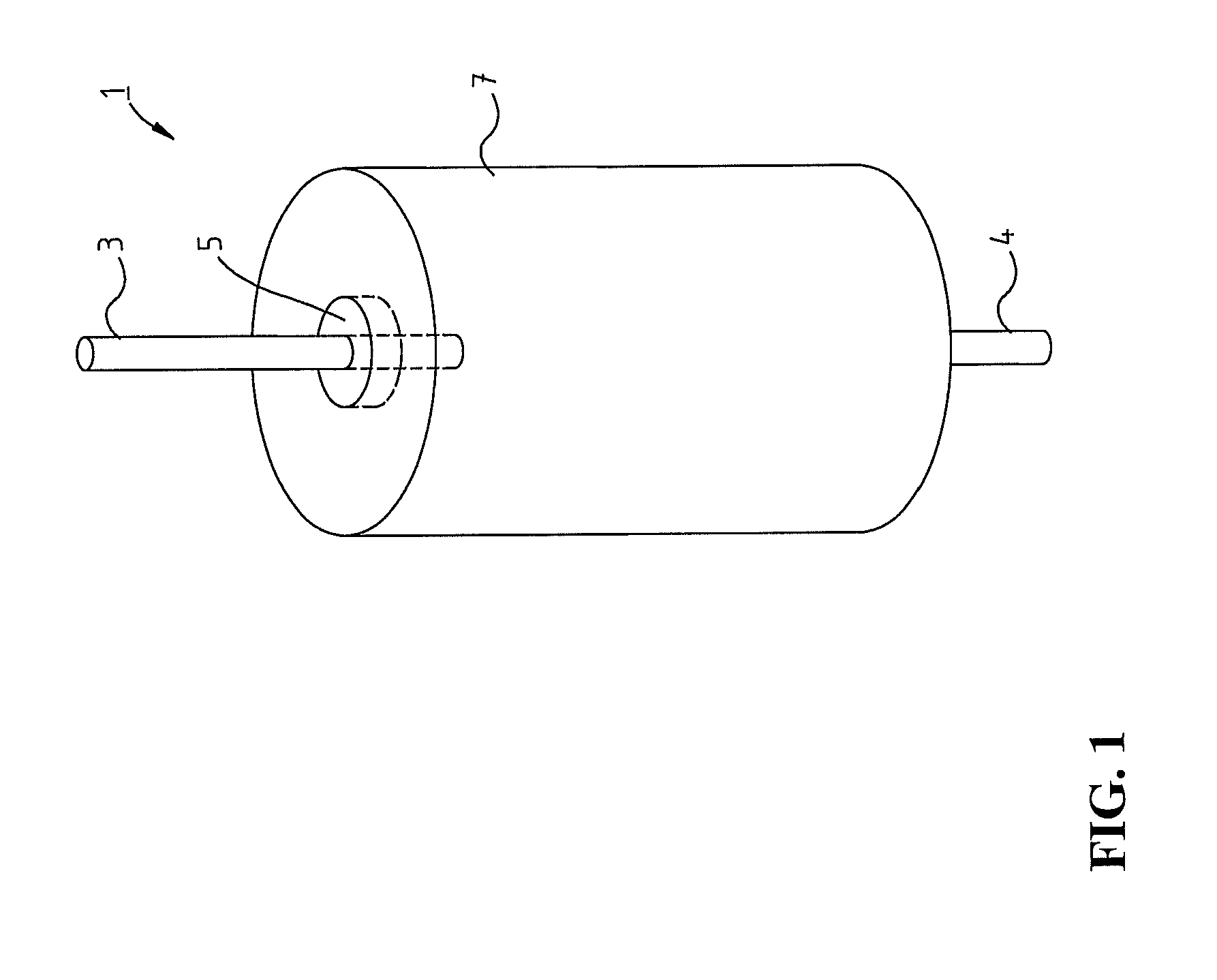

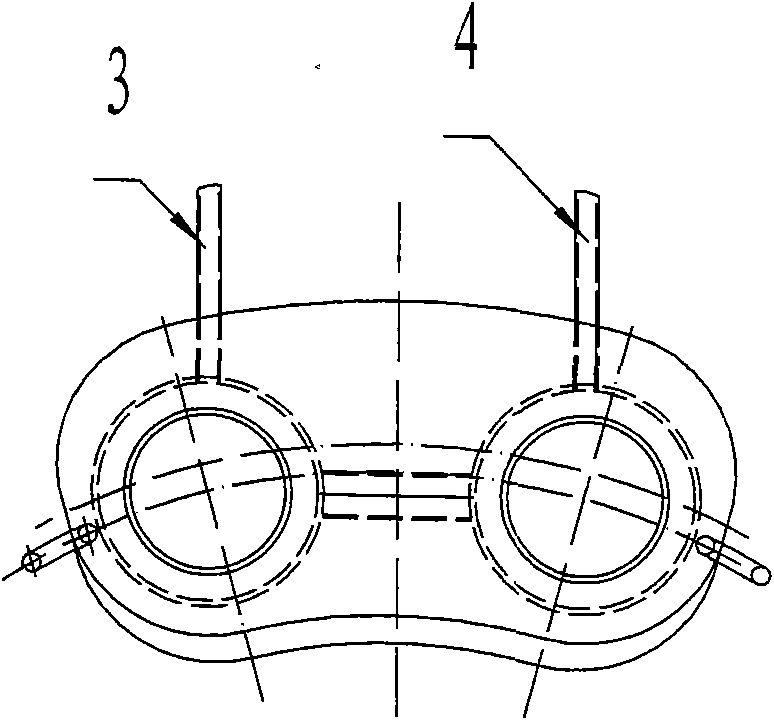

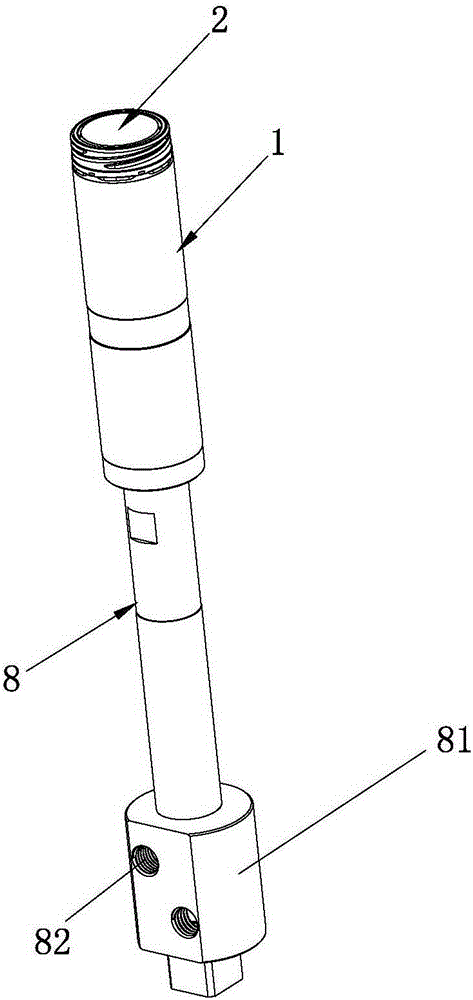

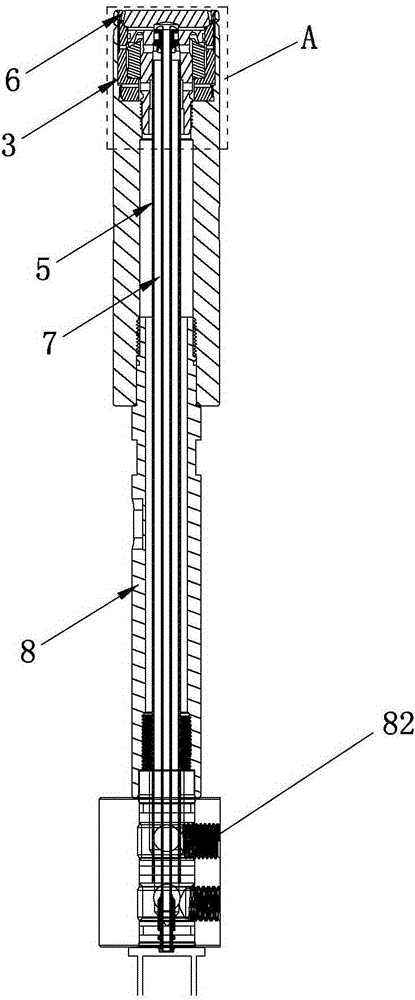

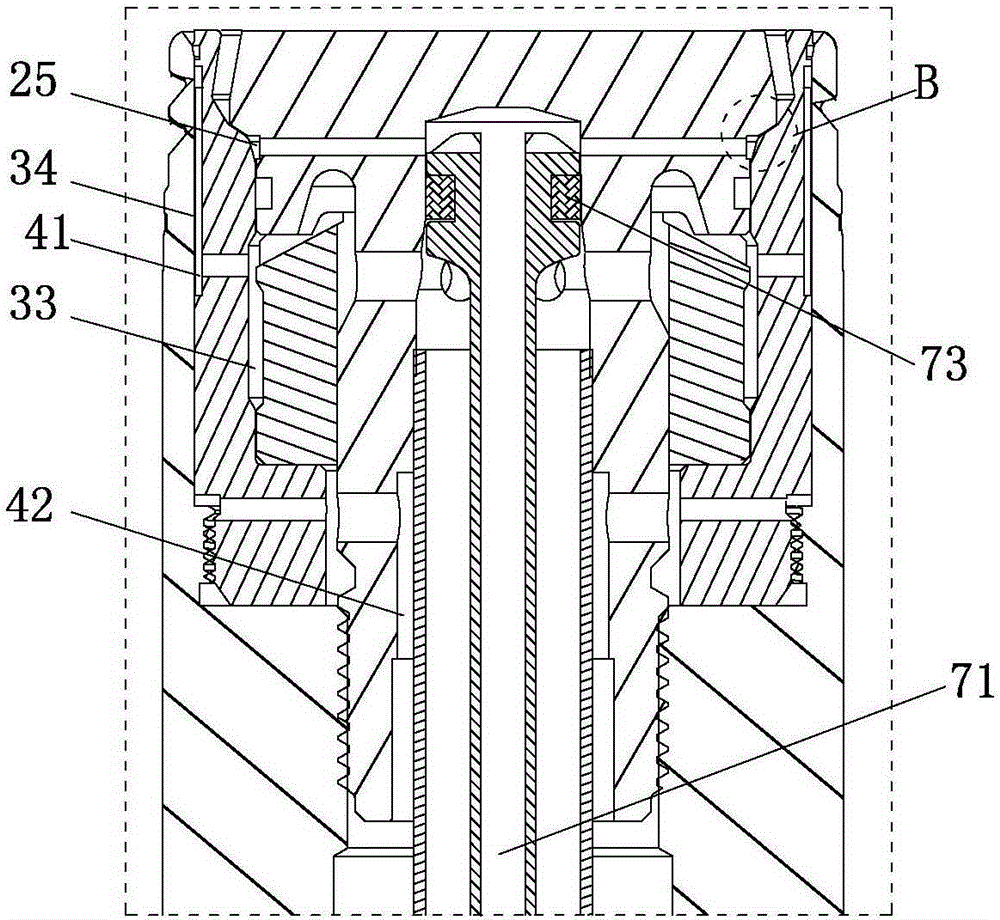

Planetary roller screw

The invention provides a planetary roller screw which is simple and compact in structure, large in bearing ability, difficult to wear, wide in screw pitch range, capable of realizing high-speed operation and high in reliability. The structure of the planetary roller screw comprises a screw, one or more rollers, two roller planetary retainers, a nut and two limiting spacer rings. The planetary roller screw is small in axial gap, high in transmission efficiency and capable of realizing high-speed transmission from a small screw pitch to an extra large helical pitch, not only can realize conversion of rotary motion and linear motion, but also can realize high-speed rotation of the screw and the rotary motion of the nut in a corresponding speed ratio.

Owner:扬州众孚传动科技有限公司

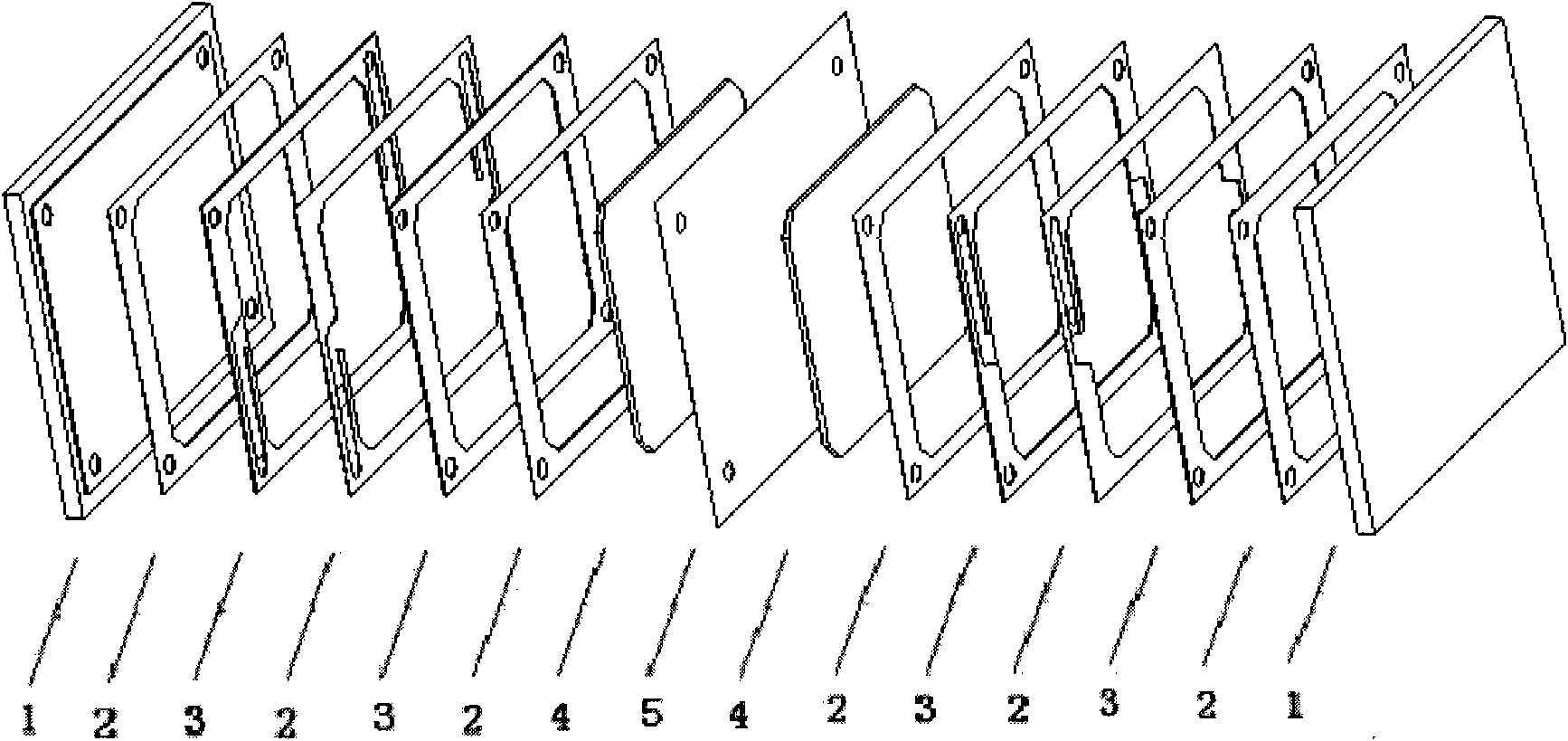

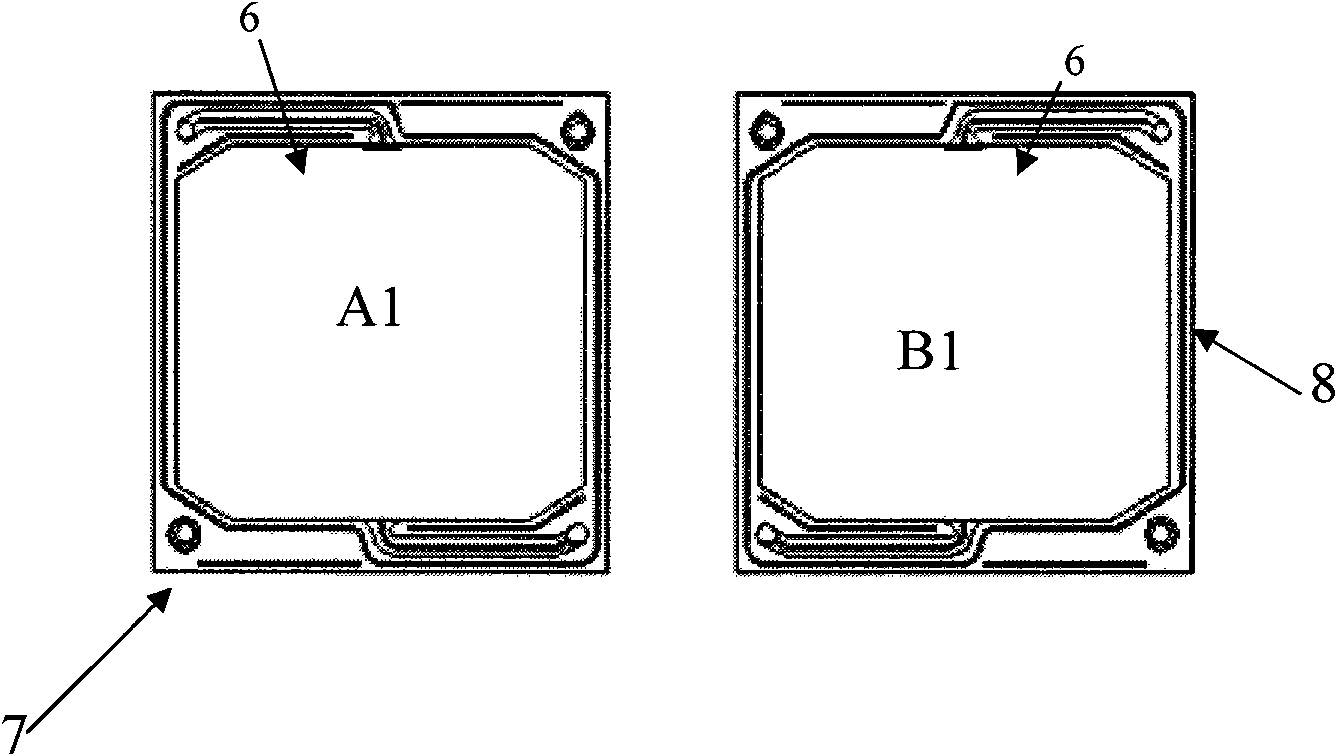

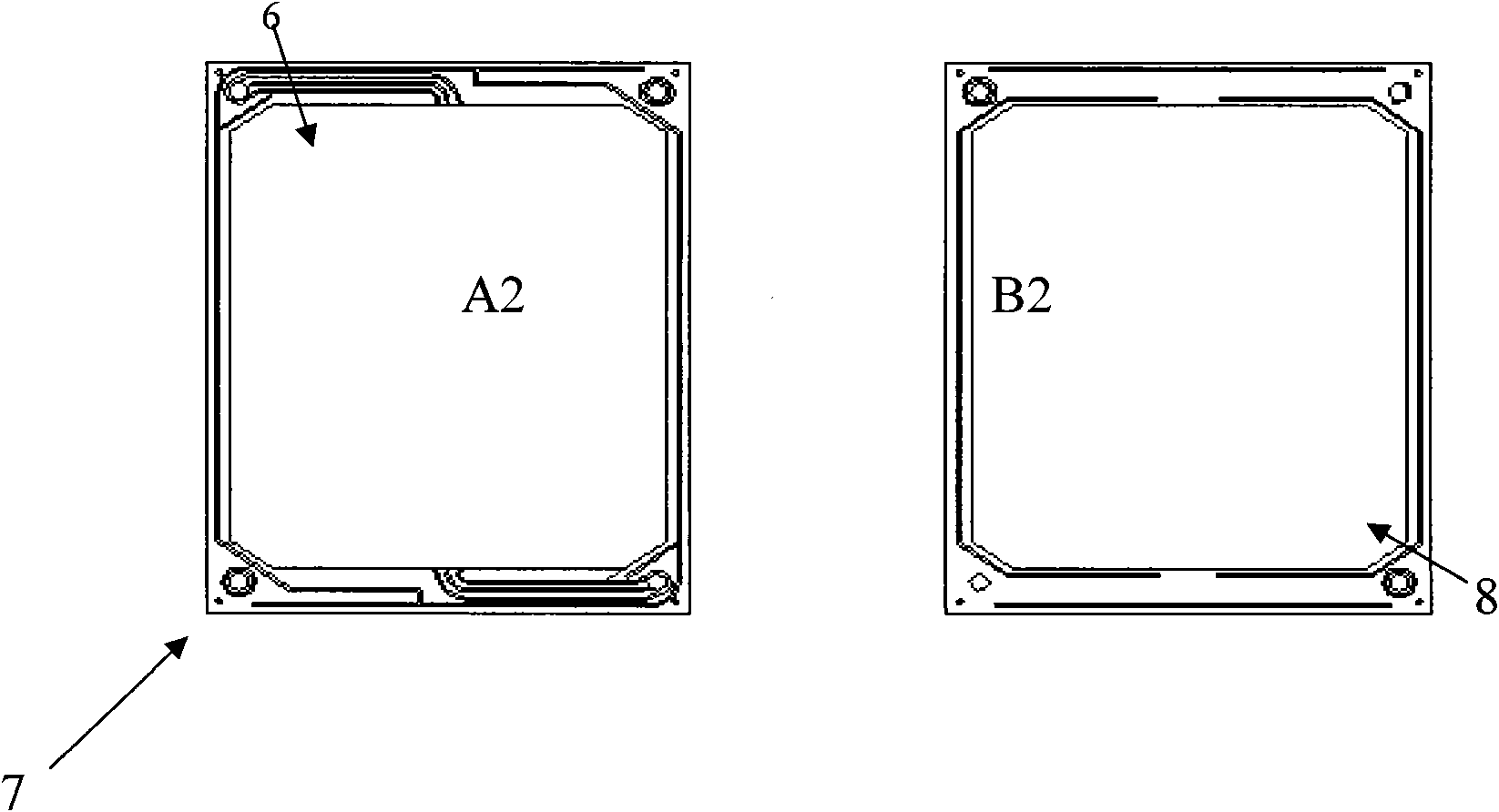

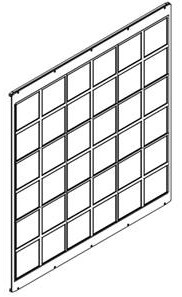

Electrode frame structure for redox flow cell

InactiveCN101667646ASimple structureLow costFuel cell detailsElectrical resistance and conductanceVanadium redox battery

The invention relates to an electrode frame for a redox flow cell, in particular to an electrode frame structure for an all-vanadium redox flow cell, which is formed by fastening two frame bodies of which the shapes and sizes are completely same; a plane where the two frame bodies are mutually fastened is a fastening surface; and the fastening surface of at least one frame body is provided with afluid channel which is fastened into a border to form an embedded-structure electrolyte inlet and outlet channel. The structure increases the resistance of an electrolyte channel branch, reduces leakage current, avoids thermogalvaniccorrosion in charging and discharging processes, and prolongs the service life of the cell (stack).

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

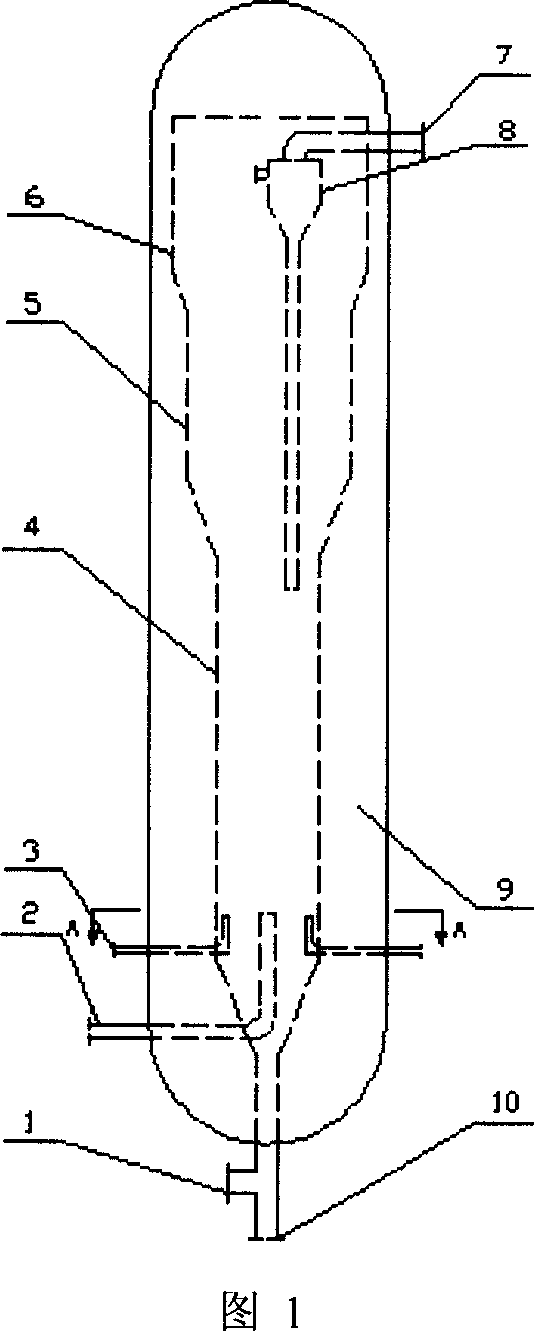

Multi-jet composite fluidized bed coal and biomass gasifier

InactiveCN1974733ARealize gasificationGood fluidization effectCombined combustion mitigationGranular/pulverulent flues gasificationFluidized bedWater vapor

The multi-jet composite fluidized bed coal and biomass gasifier consists of a fluidized bed, a synthesized gas outlet, a water vapor inlet and jet pipes. The fluidized bed consists of three parts, including the lower conic bed body, the middle expanding section and the upper expanding section, and has one cyclonic separator inside the upper expanding section. The synthesized gas outlet is in the top of the cyclonic separator. The jet pipes in the lower bed body include radial auxiliary material feeding jet pipes in two layers and main material feeding jet pipes in the center of bed body. The bed body has cinder outlet in the conic bottom and water vapor inlet beside the cinder outlet and the fluidized bed has outside heat insulating layer. The present invention has the advantages of simple structure, low cost and easy operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

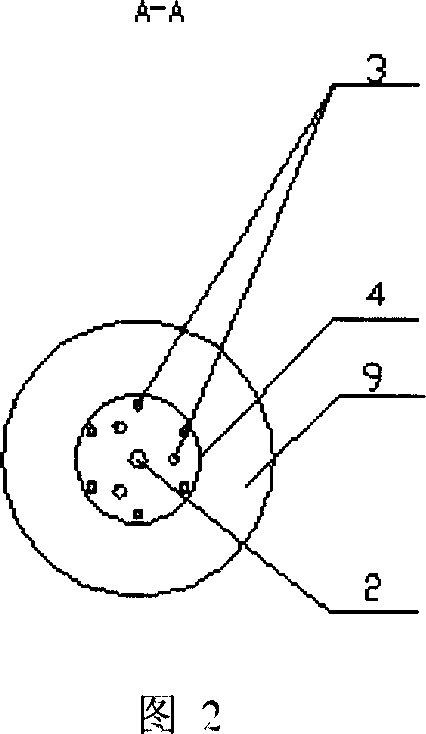

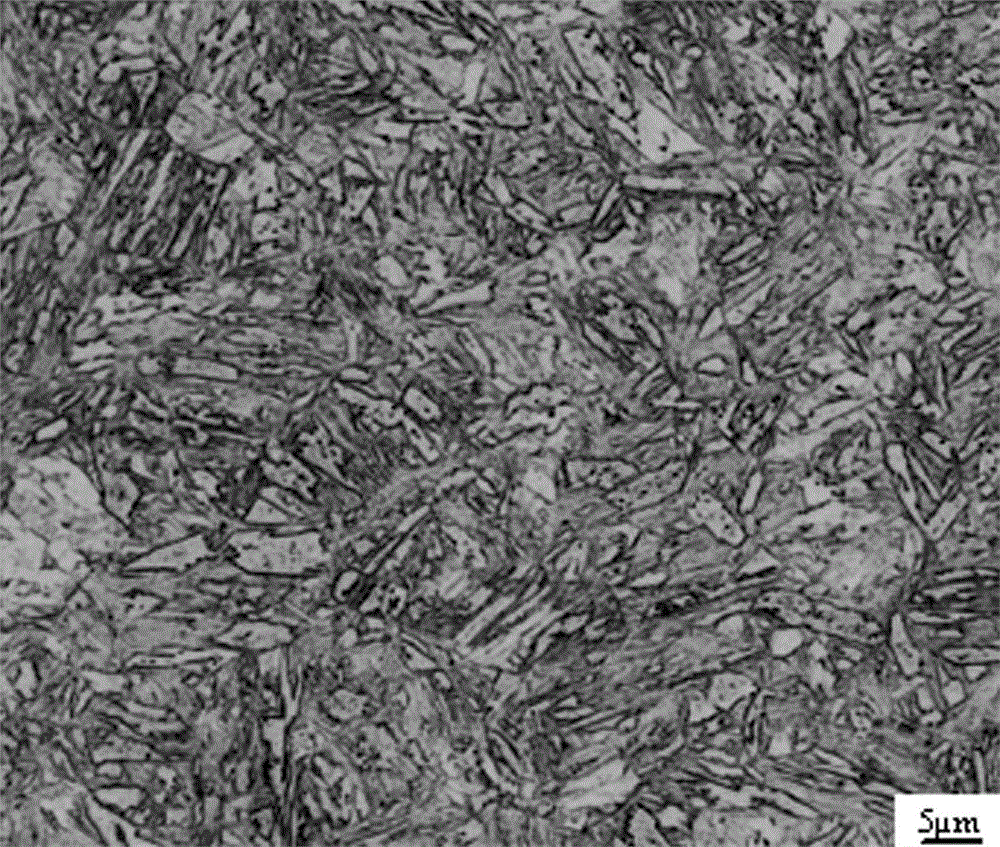

Hot-rolled polyphase steel plate and method for manufacturing same

ActiveCN101270436AGood extensibilityGood formabilityTemperature control deviceSheet steelYield ratio

The invention provides a hot-rolled multiphase steel plate and a preparation method thereof. The invention has the advantages of the economical, reasonable, environmental-friendly design of steel component, being favorable for effective utilization and recycling of resources, being implemented and controlled easily, the simple and convenient process control, the high strength of steel plate and the good performance of cold bending and welding. The thickness of plate is 2.5 to 6 milimeter, the tensile strength of the hot-rolled steel plate is larger than 1000Megapascal, the yield strength is greater than or equal to 500Megapascal, the yield ratio is low, the minimum yield ratio is equal to 0.51 and the maximum is not higher than 0.80, the elongation A80 i.e. the sample of 80 milimeter of JIS13A standard distance is greater than or equal to 11 percent and the highest value reaches 20 percent, and the longitudinal direction and the transverse direction of cold bending meets the requirement of not cracking when d is equal to 4t. The microstructure is mainly Bainite and Martensite of higher than 90 percent and few ferrite of possible residual Austenite.

Owner:BAOSHAN IRON & STEEL CO LTD

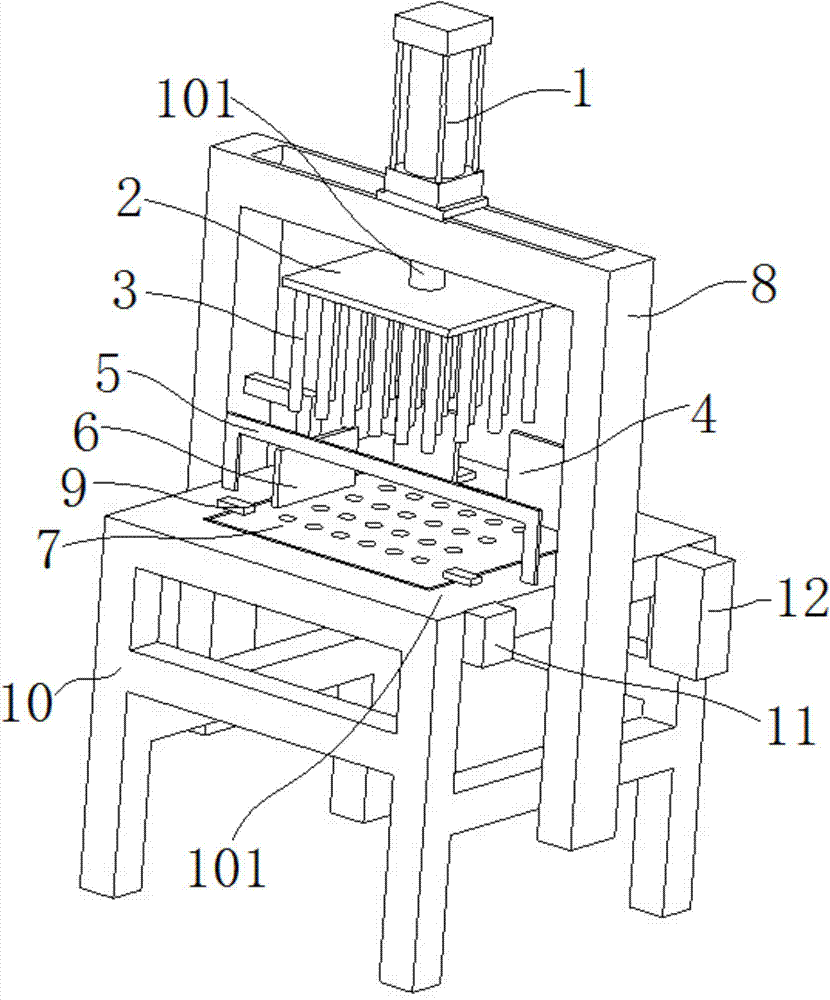

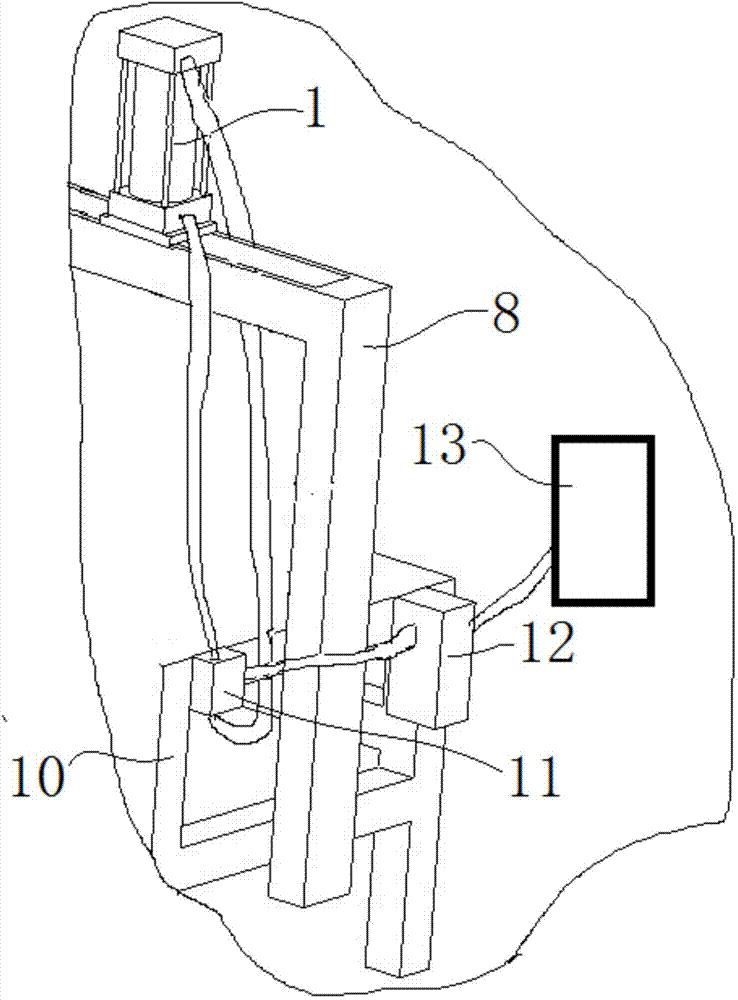

Pneumatic punching machine

InactiveCN103878822AEasy to installEasy to disassembleMetal working apparatusPunchingLocking mechanism

The invention discloses a pneumatic punching machine, and belongs to the field of punching machines. The pneumatic punching machine comprises an upper die plate, a punch, a bolt locking mechanism, a worktable, a manual reversing valve fixed to a lateral surface of the worktable, a pressure regulating valve and a positioning device, wherein the pressure regulating valve and the positioning device are fixed to another lateral surface of the worktable, the upper portion of the worktable is a work platform, a concave die is embedded in the work platform and fixed to the worktable through the bolt locking mechanism, the worktable is fixedly connected with the positioning device used for positioning a workpiece to be punched, a machine frame is fixedly installed on the worktable, an air cylinder is installed at the top end of the machine frame, a piston rod of the air cylinder is fixedly connected with the upper die plate vertically moving relative to the machine frame, the upper die plate is provided with the punch corresponding to the concave die, the air cylinder is communicated with the pressure regulating valve through the manual reversing valve, and the pressure regulating valve is communicated with an air compressor. The pneumatic punching machine is convenient to operate, high in work efficiency and accurate in positioning, and lowers punching error rate.

Owner:江苏东方印务有限公司

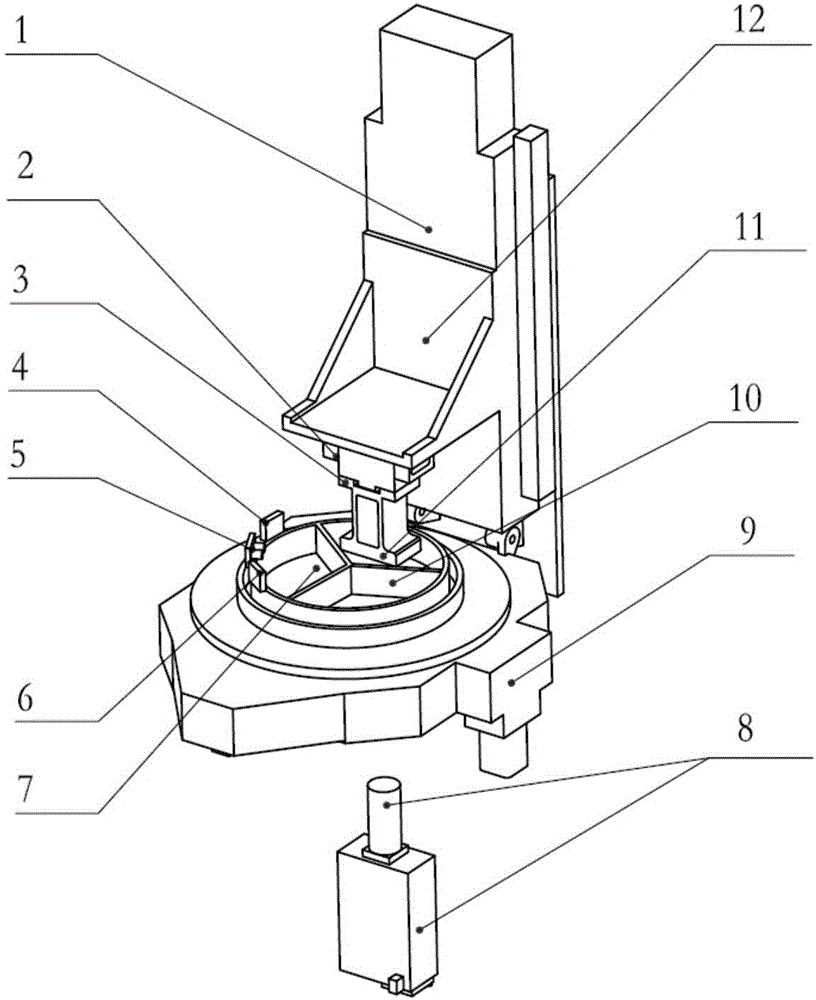

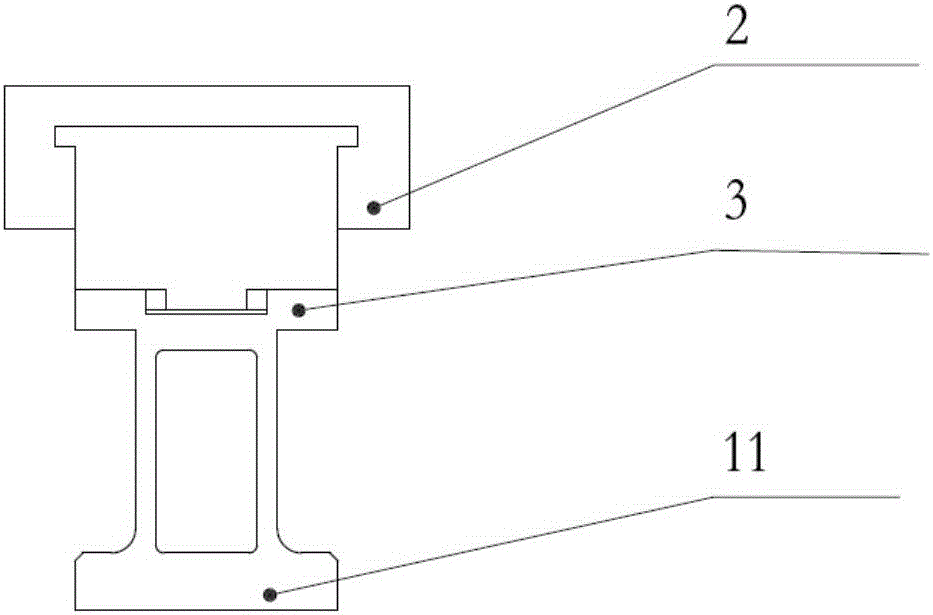

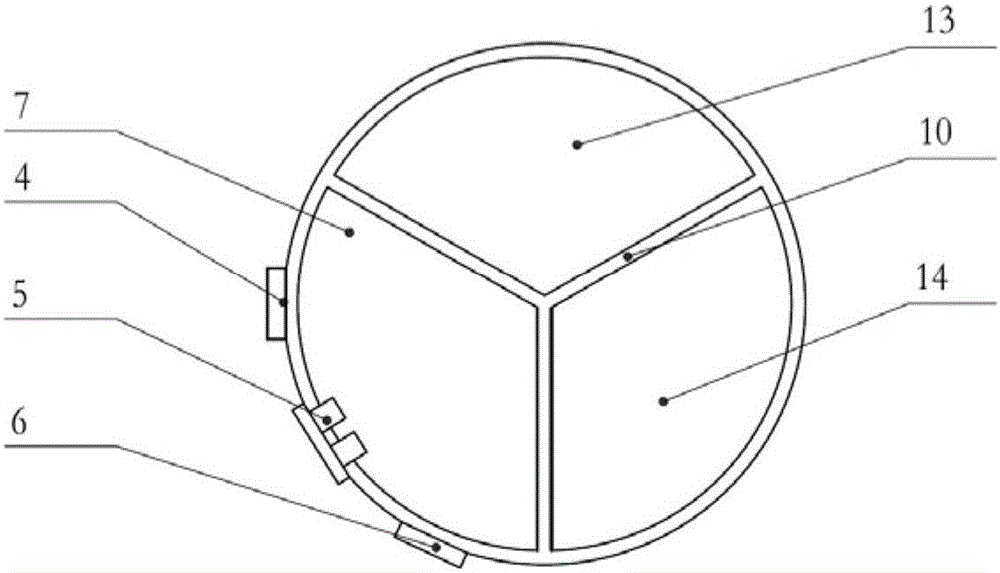

Rotary exchange groove type multi-material mask exposal additive manufacturing device and method

InactiveCN106079451AReduce processing timeReduce modeling difficultyAdditive manufacturing apparatusCeramic shaping apparatusMulti materialEngineering

The invention discloses a rotary exchange groove type multi-material exposure additive manufacturing device and method. The mask exposal technology is applied by the device to serve as a light-sensitive material forming technology, and meanwhile, a multi-partition rotary type material groove is applied to serve as a supply mechanism for machining different materials. During machining, a plurality of material portions of one part are subject to modeling, and then subject to layer shearing and mask generation treatment; a plurality of mask queues are guided into a control module, and the control module determines whether multiple materials are contained in layers with the same height; if the multiple materials are contained, the layers are subject to multi-material machining, and if the multiple materials are not contained, the layers are subject to single-material machining of corresponding materials; during machining of multiple materials on the same layer and machining of different materials in different layers, the cleaning step of machined parts is automatically executed, and therefore it is ensured that multiple materials are not polluted by one another. Through replacement of material grooves containing different light-sensitive materials and corresponding masks in the machining process, automatic precise machining of the parts containing the multiple different materials is achieved.

Owner:XI AN JIAOTONG UNIV +1

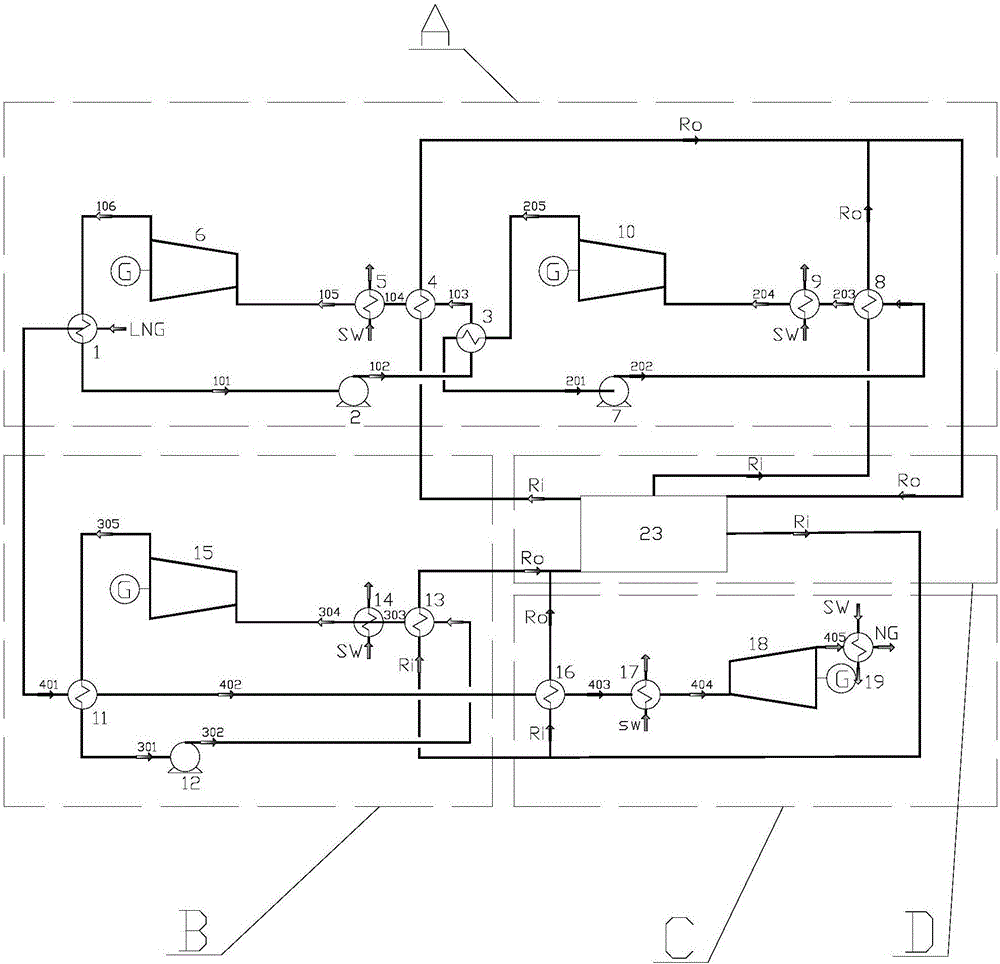

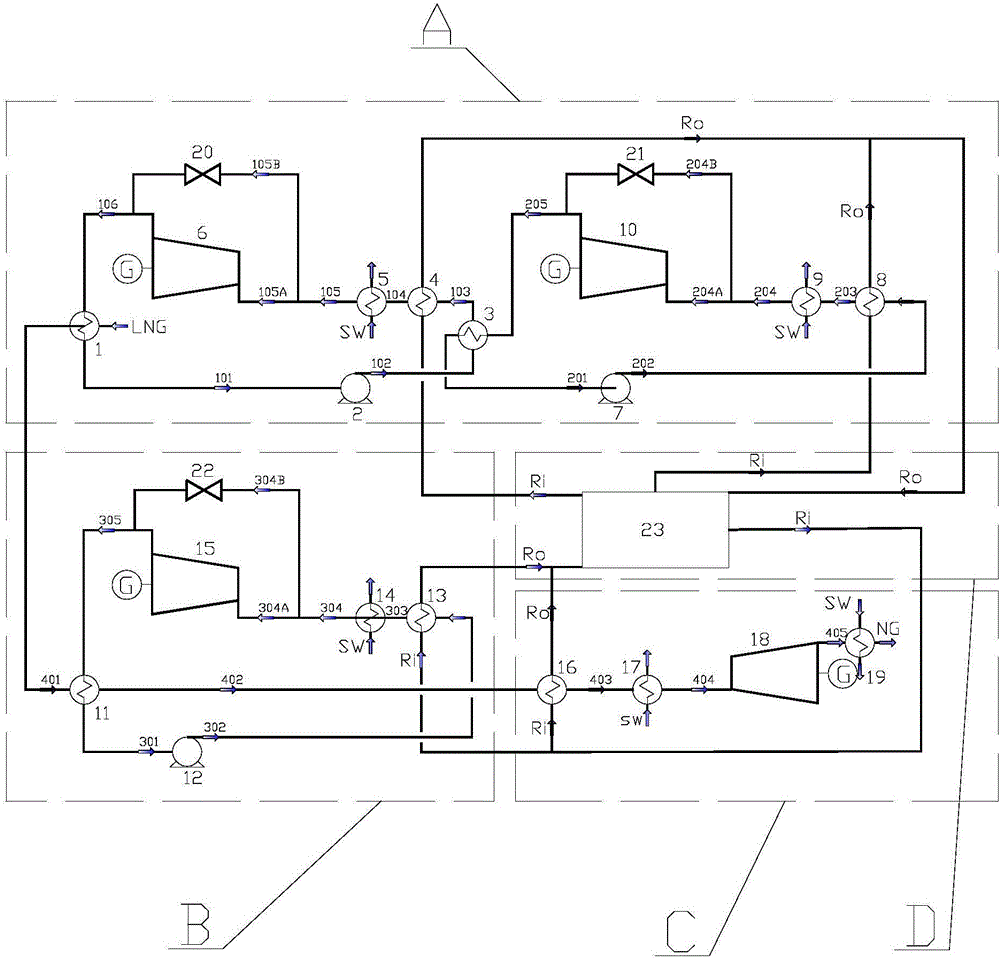

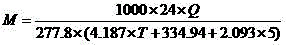

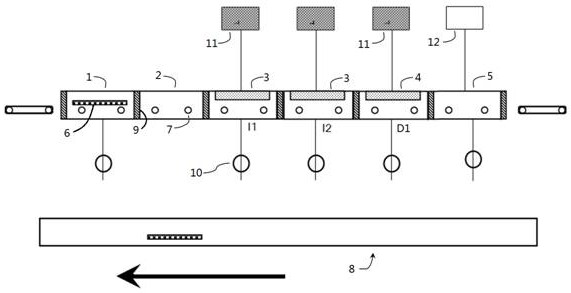

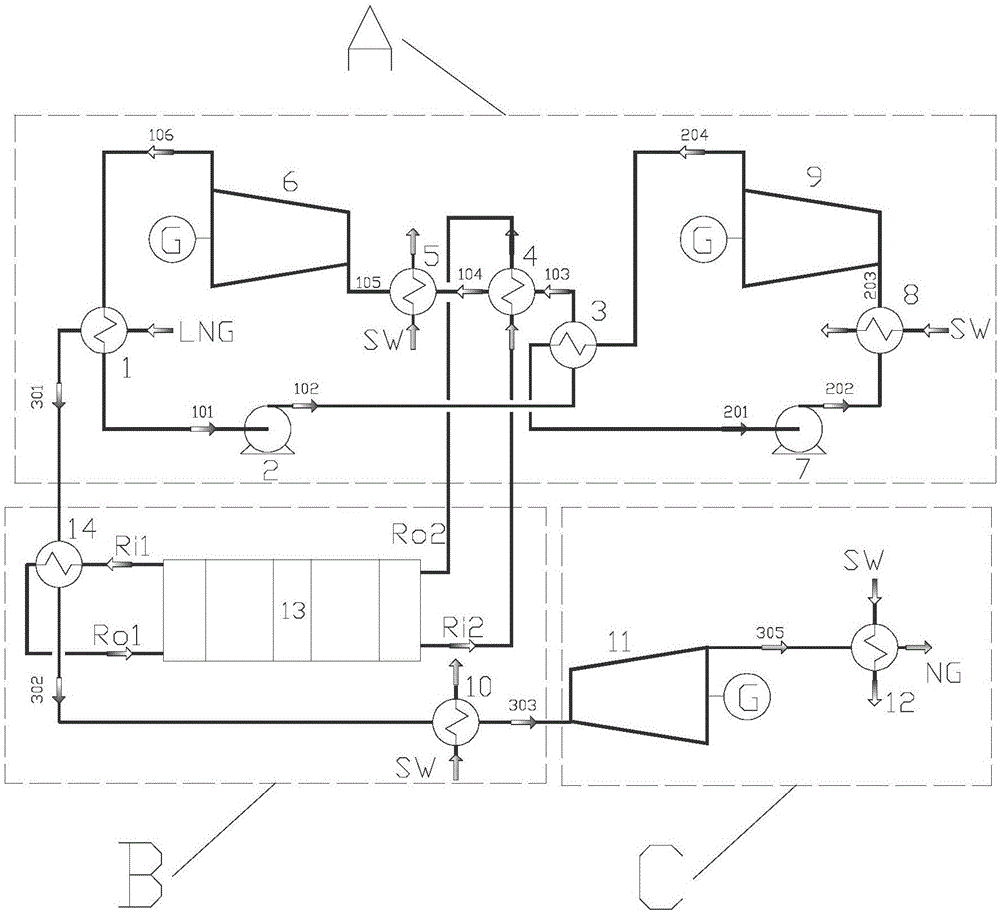

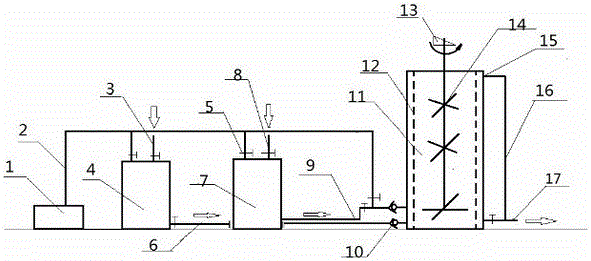

System and method for comprehensively utilizing cold energy of LNG

ActiveCN106194302AEasy process controlTake advantage ofLighting and heating apparatusIce productionElectronic systemsSuperheater

The invention relates to a system for comprehensively utilizing cold energy of LNG. The system comprises a composite Rankine cycle power generation sub-system, a single-working-medium Rankine cycle power generation sub-system, an ice-making sub-system and a direct expansion power generation sub-system, wherein the composite Rankine cycle power generation sub-system comprises an LNG evaporator, a mixed-working-medium booster pump, a heat exchanger, a mixed-working-medium evaporator, a mixed-working-medium superheater, a mixed-working-medium expander, a first single-working-medium booster pump, a first single-working-medium evaporator, a first single-working-medium superheater and a first single-working-medium expander; the single-working-medium Rankine cycle power generation sub-system comprises a first NG superheater, a second single-working-medium booster pump, a second single-working-medium evaporator, a second single-working-medium superheater and a second single-working-medium expander; and the direct expansion power generation sub-system comprises a second NG superheater, a third NG superheater, a fourth NG superheater and an NG expander. The system disclosed by the invention realizes the most abundant comprehensive utilization for the cold energy of LNG by virtue of the cold energy from minus 162 DEG C to minus 10 DEG C of the LNG.

Owner:AEROSUN CORP

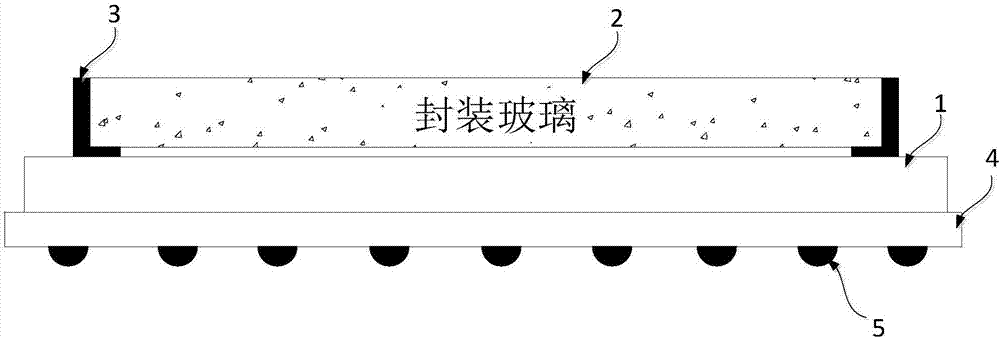

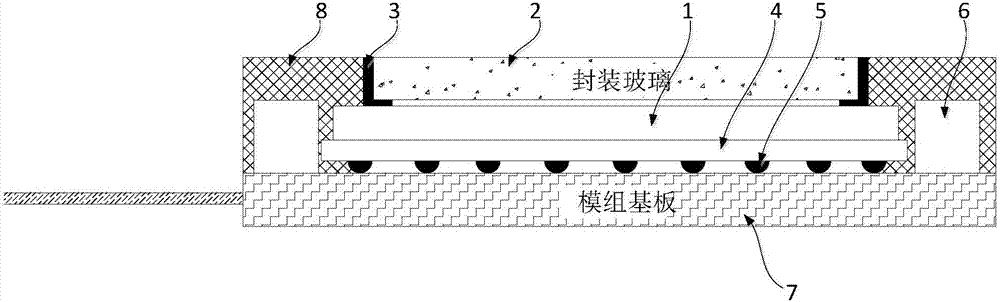

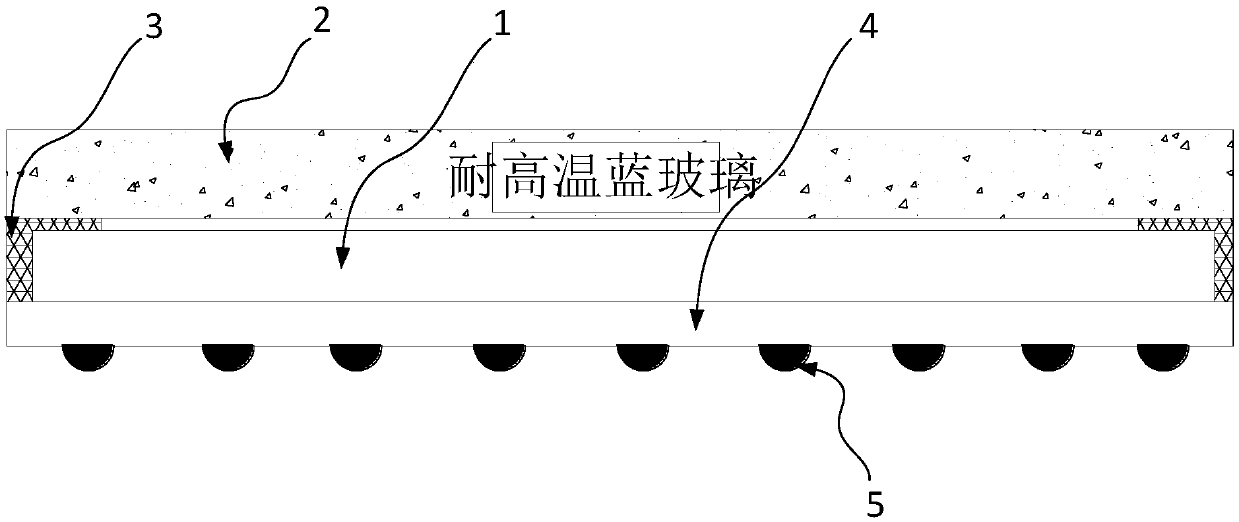

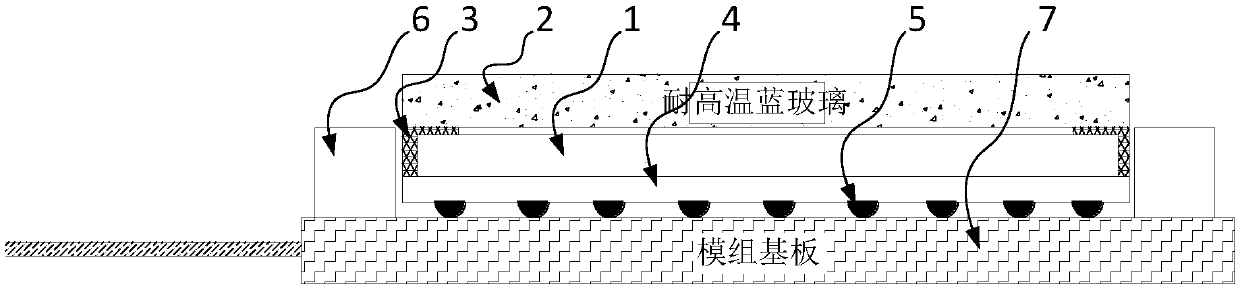

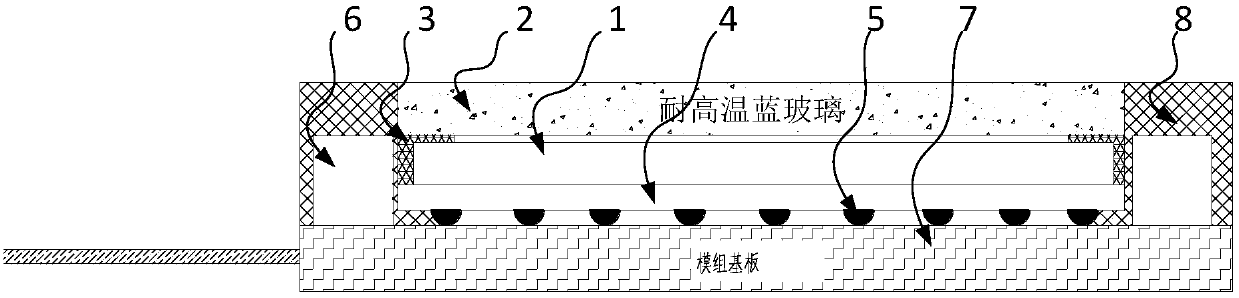

Camera module package process and structure

InactiveCN108012056AGuaranteed impactReduce the risk of contaminationTelevision system detailsColor television detailsCamera lensPlastic injection molding

The invention discloses a camera module package process and structure. The package process comprises the following steps: sticking a package layer on a photosensitive region of a photosensitive chip in degradable mucilage glue; connecting the photosensitive chip and the component to a module substrate; injection-molding an annular plastic layer on the module substrate, wrapping the component in the plastic layer and wrapping the photosensitive chip from the circumference; degrading the degradable mucilage glue, and peeling off the package layer from the photosensitive region of the photosensitive chip; clearing the degradable mucilage glue, and loading an optical filter and a lens on the annular plastic layer. Through the adoption of the above process, the package layer is firstly stuck onthe photosensitive chip by using the degradable mucilage glue, thereby preventing the photosensitive region of the photosensitive chip from being polluted in the subsequent manufacturing procedure, and achieving the aims of facilitating manufacturing procedure control and improving the yield; after the module semi-finished product is completely manufactured, namely, after the annular plastic injection-molding is finished and the optical filter and the lens are loaded, the package layer is peeled off from the photosensitive region, thereby preventing the package layer from causing light ray refraction, reflection and energy loss, and achieving an aim of improving the image effect.

Owner:TRULY OPTO ELECTRONICS

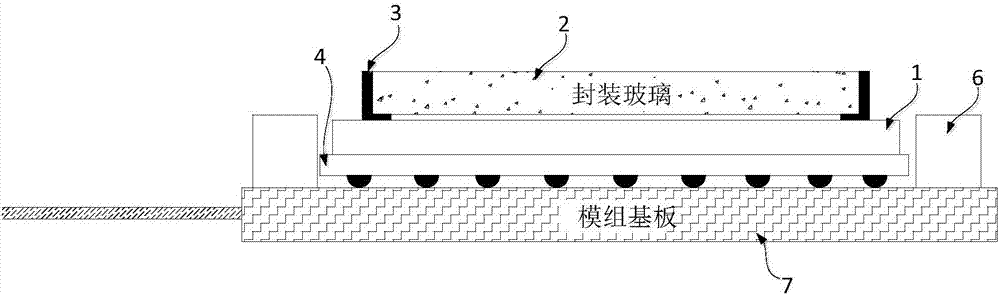

Camera module encapsulation process and structure

ActiveCN107911587AGuaranteed impactReduce the risk of contaminationTelevision system detailsColor television detailsCamera lensEngineering

The invention discloses a camera module encapsulation process and structure. The encapsulation process comprises the following steps: encapsulating a light filter on a photosensitive area of a photosensitive chip; connecting the photosensitive chip and a component to a module substrate; injection-molding an annular plastic layer on the module substrate, wrapping the component in the annular plastic layer and wrapping the photosensitive chip and the light filter from the circumference; and loading a lens on the annular plastic layer. The above process is the improvement of the existing CSP process, the light filter is directly used for encapsulating the photosensitive chip at the beginning of the manufacturing process, thereby avoiding the pollution on the photosensitive area of the photosensitive chip in the subsequent manufacturing process, and an operation of adding additional encapsulation structure is unnecessary; the process is simpler, the bad influence on the image effect by theencapsulation structure is avoided, and the aims of conveniently controlling the manufacturing process and improving the yield are achieved.

Owner:TRULY OPTO ELECTRONICS

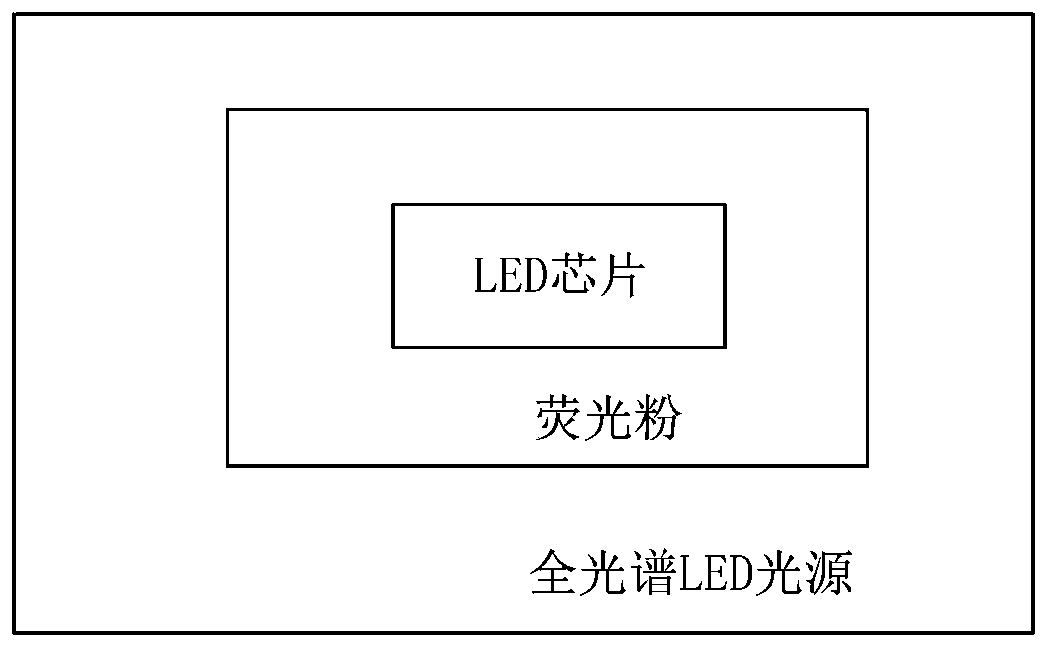

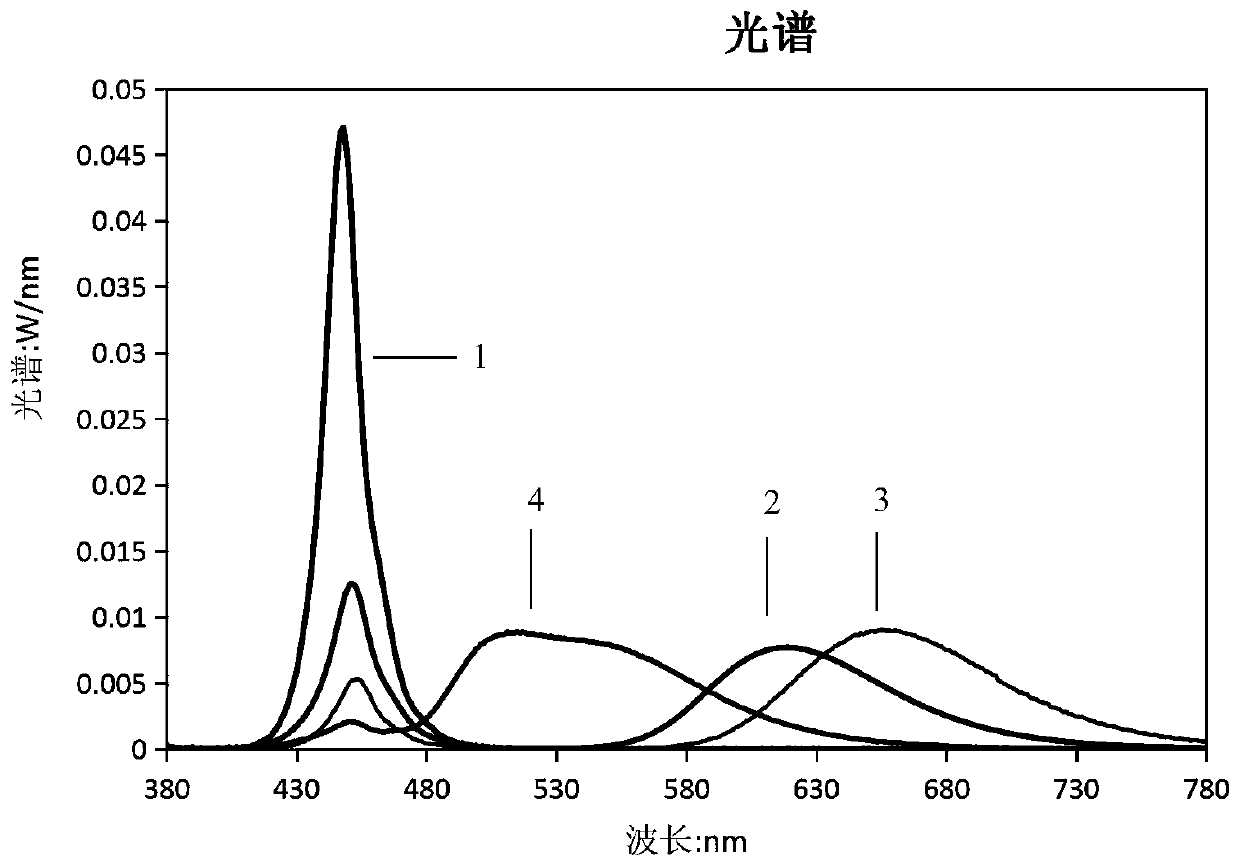

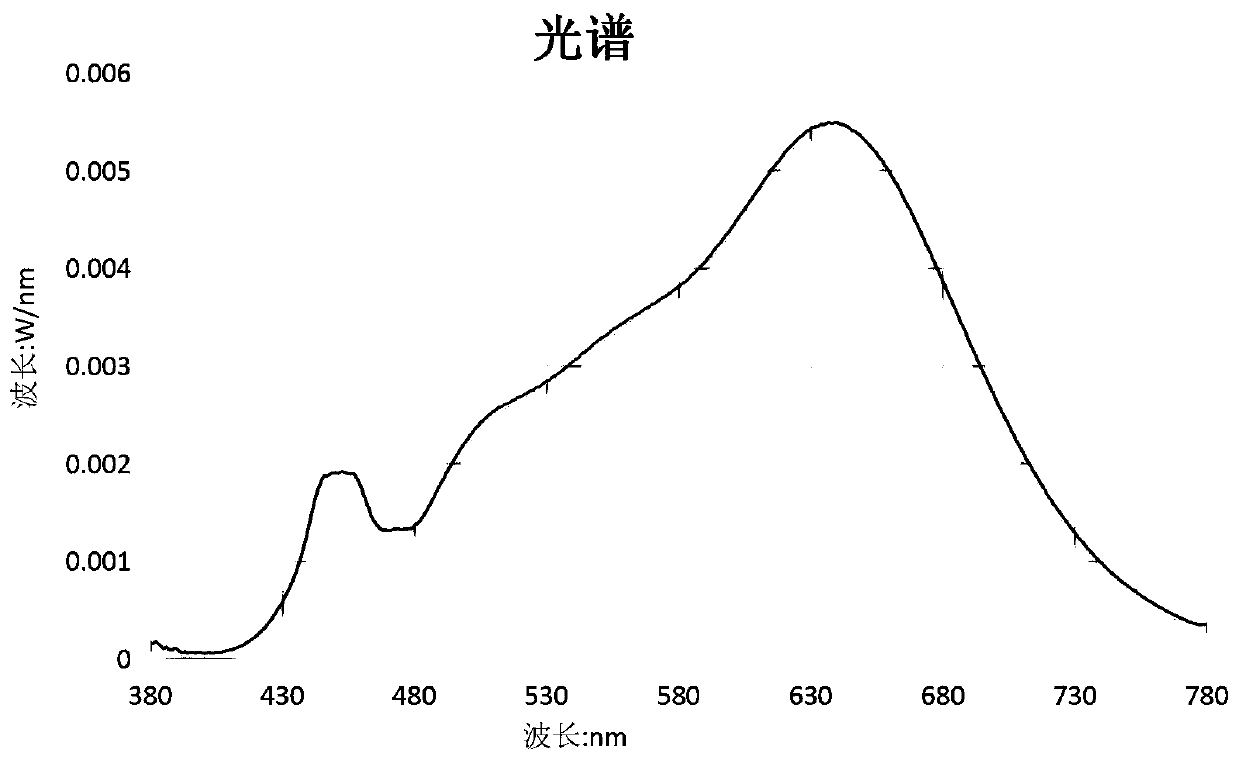

Full-spectrum LED light source and LED lamp

InactiveCN111081852ABreak through low spectral color gamutBreak through the problem of low color rendering indexSemiconductor devicesFull-spectrum lightLED lamp

The invention provides a full-spectrum LED light source and an LED lamp. The full-spectrum LED light source comprises an LED chip and fluorescent powder. The LED chip emits blue light with at least one wavelength, and the wavelength of the blue light is 440-470 nm; the fluorescent powder comprises first red fluorescent powder, second red fluorescent powder and green fluorescent powder, the periphery of the LED chip is coated with a mixture of the first red fluorescent powder, the second red fluorescent powder and the green fluorescent powder to form a full spectrum, the emission wavelength ofthe first red fluorescent powder is shorter than that of the second red fluorescent powder, and the green fluorescent powder is LuAG fluorescent powder. According to the invention, the real color of an object can be better restored, and the health of human eyes is better facilitated; through setting of different proportion formulas, simulation of sunlight in different time periods is achieved, thesimilarity Rf with sunlight is larger than 90, the fidelity and saturation are close to those of sunlight, health and comfort are achieved, common materials on the market are used, the price cost islow, the thermal stability is high, and manufacturing process management and control are easy.

Owner:GUANGZHOU LEDTEEN OPTOELECTRONICS CO LTD

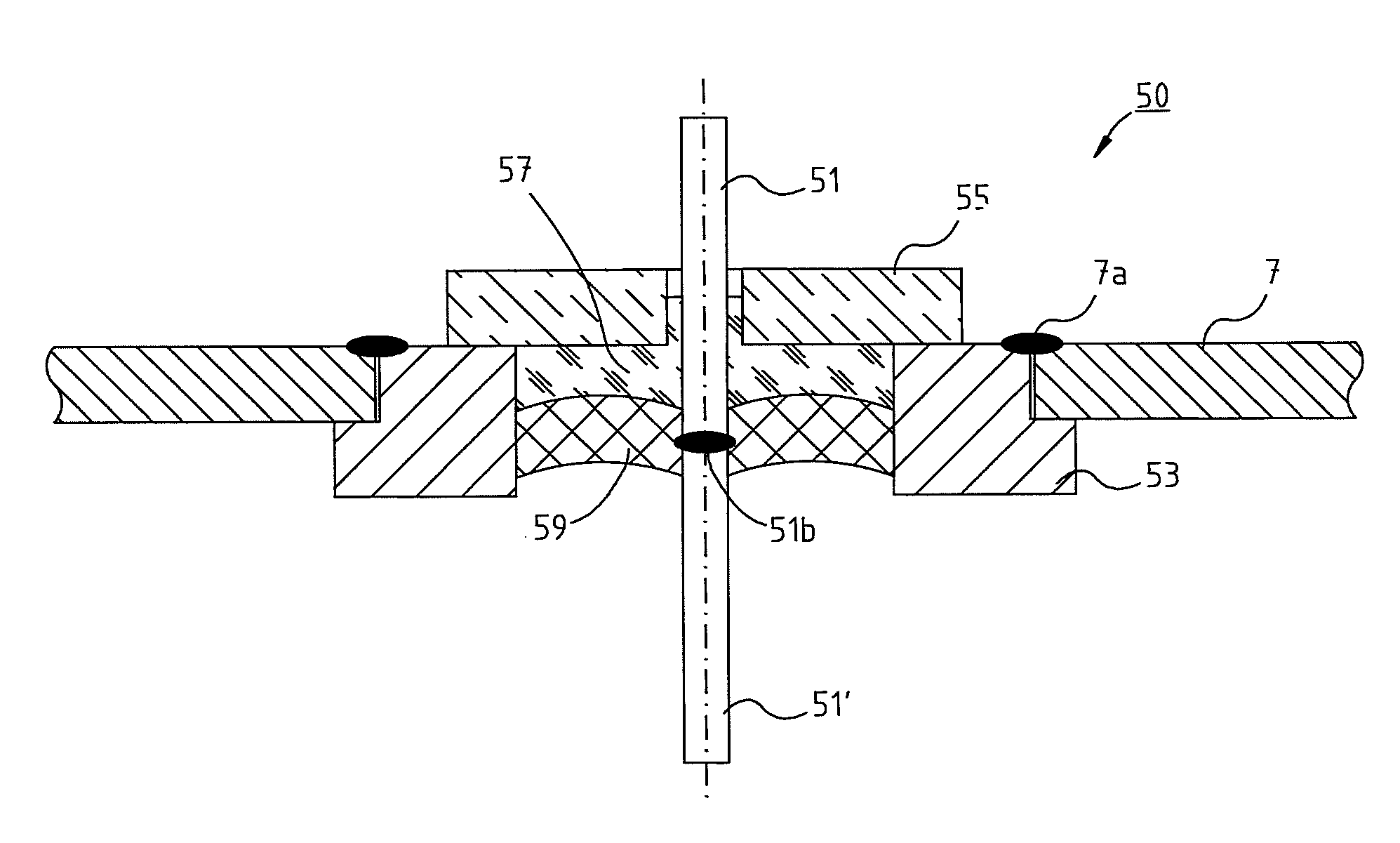

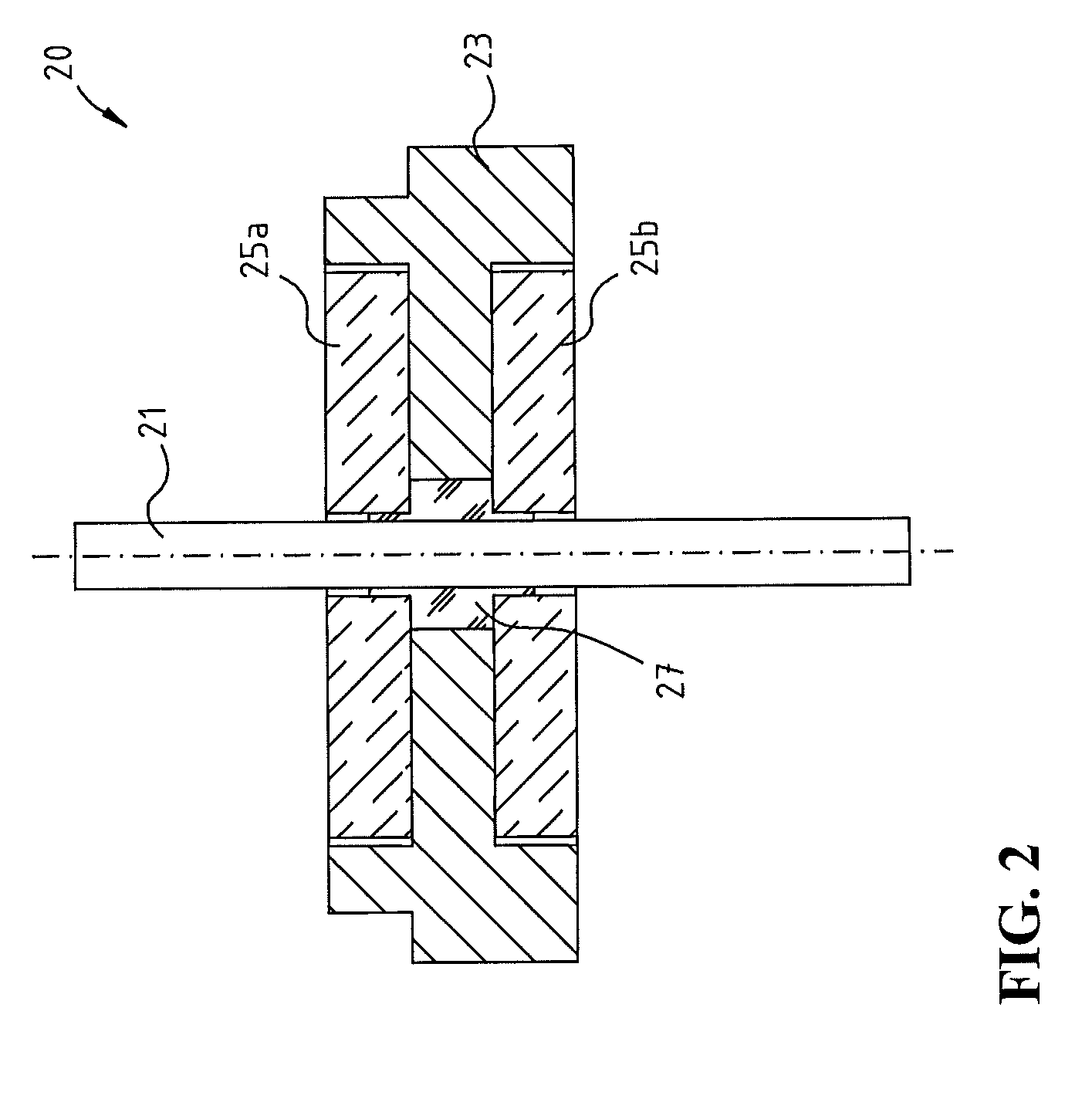

Electrical feedthrough of a capacitor for medical implants and method for the production and use thereof

A feedthrough of an electrolyte or other capacitor, in particular for use in a medical-electronic implant, is provided having a terminal pin which has a section which can be soft soldered at least in the interior of the electrolyte capacitor, an aluminum flange enclosing the terminal pin, and a glass solder plug which hermetically seals the terminal pin in relation to the aluminum flange.

Owner:BIOTRONIK SE & CO KG

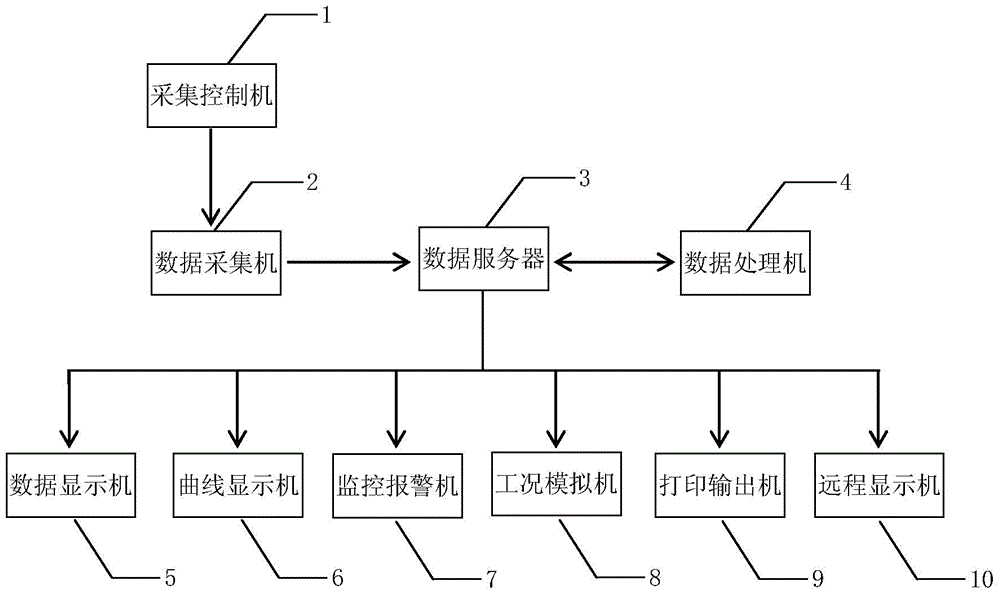

Logging information monitoring system

InactiveCN104863567ARealize acquisitionImplement storageSurveyConstructionsData displayControl software

The invention relates to a logging information monitoring system. The logging information monitoring system comprises an acquisition controller, a data acquisition machine, a data server, a data processor, a data display machine, a curve display machine, a monitoring alarm, a working condition simulation machine, a printout machine and a remote display machine, wherein the acquisition controller is connected with the data acquisition machine, calibration control software is installed in the acquisition controller and used for performing scale calibration and process control on data acquisition of the data acquisition machine, data acquisition software is installed in the data acquisition machine and used for acquiring physical quantities from sensors and all measuring units in real time, the acquired physical quantities are calculated, stored, displayed and controlled according to settings of the acquisition controller, the data acquisition machine stores two copies of the acquired data, one copy of the acquired data is stored in the data acquisition machine, and the other copy of the acquired data is stored in the data server through a network. The logging information monitoring system classifies logging information scientifically, provides convenience for field operation, data monitoring, process control and scientific decision-making and has the significant effect on safety production in an oil field.

Owner:CHINA PETROCHEMICAL CORP +1

Low-carbon hot-rolled ultrahigh-strength high-toughness steel and preparation method thereof

A low-carbon hot-rolled ultrahigh-strength high-toughness steel and a preparation method thereof belong to the technical field of metallurgy. The low-carbon hot-rolled ultrahigh-strength high-toughness steel comprises the following ingredients by weight percent: 0.10-0.11 percent of C, 1.35-1.5 percent of Si, 1.85-2.0 percent of Mn, 0.7-0.8 percent of Cr, 0.28-0.3 percent of Mo, less than or equal to 0.004 percent of P, less than or equal to 0.003 percent of S and the balance of Fe, the yield strength is 900-980 MPa, and the impact absorbing energy at the low temperature of 20 DEG C below zero is 86.8-117.8 J. The preparation method comprises the following steps: (1) smelting, refining and casting to obtain casting blanks according to the set ingredients, re-heating the casting blanks to the austenitizing temperature, keeping the temperature for more than 2.5 hours, and forging at the temperature of 950-1050 DEG C to obtain billets; (2) heating up to 1190-1210 DEG C, keeping the temperature for at least 2 hours, and then performing air-cooling to the room temperature. The characteristics that the ingredients are reasonably designed and the process is simple, convenient and feasible in control are achieved; as on-line direct quenching is adopted, and no tempering procedure exists, the production efficiency is high, the energy consumption is low, and the obtained steel material has superhigh strength and favorable low-temperature ductility.

Owner:NORTHEASTERN UNIV

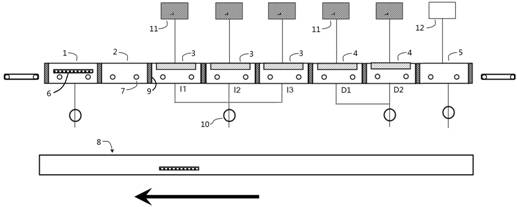

Film coating equipment, method and system, solar cell, assembly and power generation system

ActiveCN111739971AReduce processing waiting timeImprove processing efficiencyFinal product manufactureChemical vapor deposition coatingHeterojunctionEngineering

The invention discloses heterojunction solar cell coating equipment, method and system, a solar cell, an assembly and a power generation system, and belongs to the field of solar cell processing. Theheterojunction solar cell coating equipment is used for depositing a heterojunction solar cell amorphous silicon-based thin film, and comprises a process cavity, wherein the process cavity comprises at least two intrinsic process cavities used for deposition of an intrinsic layer silicon thin film process, and at least one doping process cavity used for deposition of an N-type silicon film or P-type silicon film process, and the cavities in the intrinsic process cavities and the doping process cavity are isolated by isolation valves. By combining the control of gas proportion and pressure, theequipment can process a plurality of solar cells at the same time, so that the overall processing efficiency is greatly improved, and the equipment is suitable for commercial use.

Owner:SUZHOU MAIZHENG TECH CO LTD

Wheat-based protein polypeptide and modified starch compounded wheat grain simulant and preparation method thereof

InactiveCN108902676APromote absorptionReasonable and comprehensive nutritional compositionFood shapingProtein food ingredientsWhey protein powderGrain structure

The invention provides an artificial compound wheat grain simulator which has a wheat-like grain structure having an embryoid encapsulated with an endosperm-like material. The embryoid component includes a wheat germ peptide extract, germ globulin, soybean isolate protein and an octacosanol compound extracted from wheat germ oil, as well as malt syrup, edible glue and other molding components; theendosperm-like component includes gelatinized modified wheat starch, wheat gluten flour, whey protein powder, 50-60 wt% wheat malt syrup, wheat protein oligopolypeptide, and lecithin. An artificial wheat-like grain has high-stability compound wheat germ components with improved content, and reduced starch content and poor-taste wheat protein content, has more reasonable nutritional composition, processing convenience and high utilization rate, can be directly eaten through brewing at high temperature, and can also be used as additives for cooked wheaten food processing.

Owner:SHANDONG QUFENG FOOD TECH

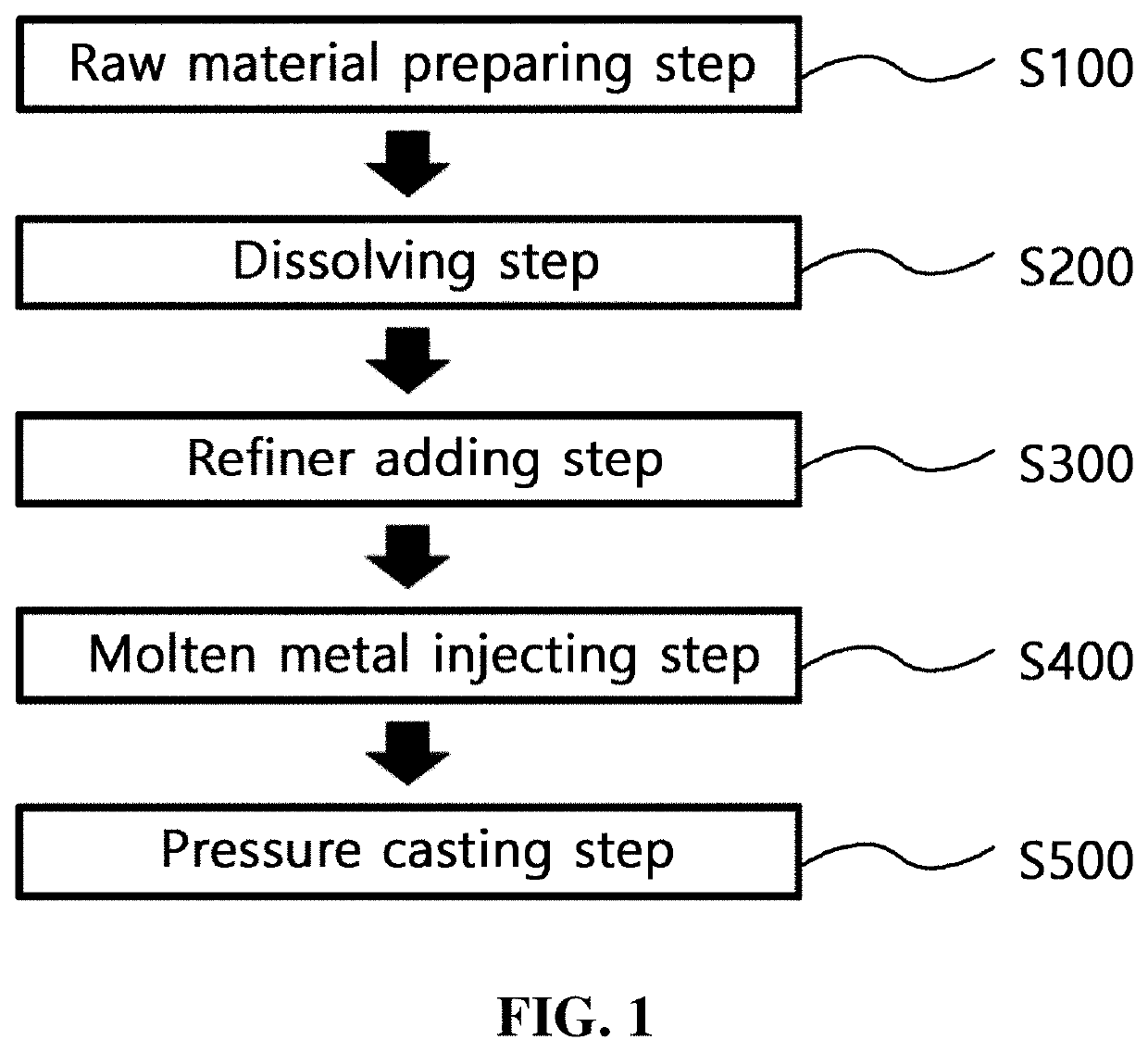

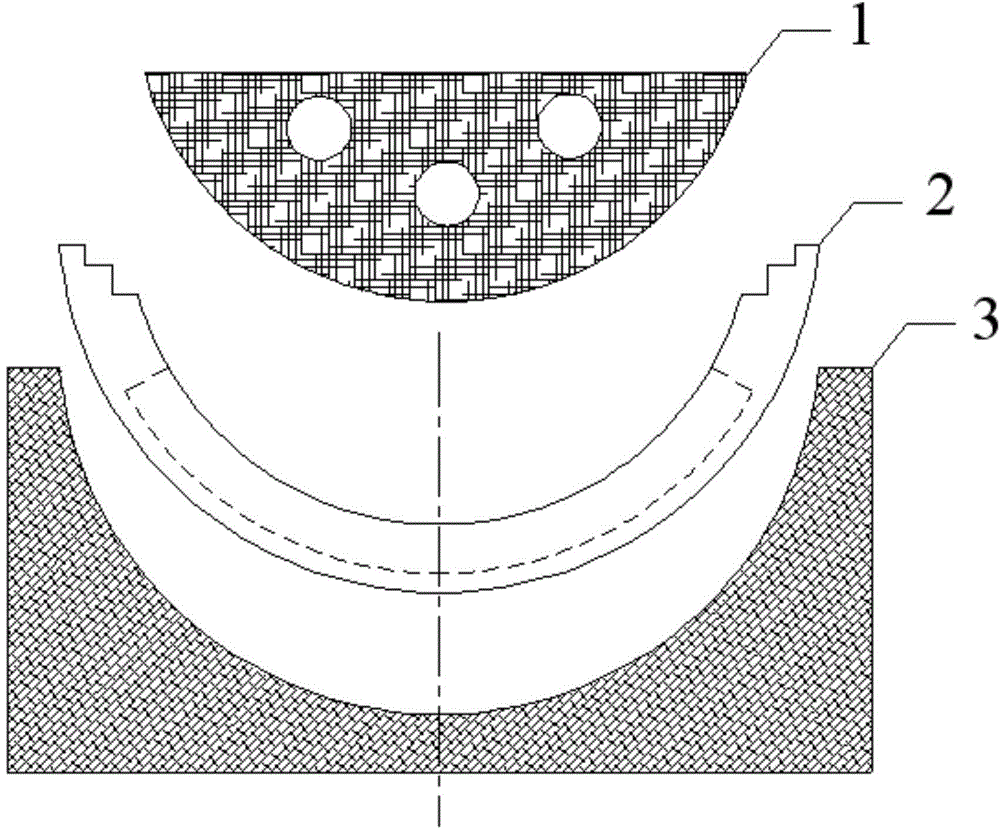

Method for manufacturing aluminum casting, and aluminum casting manufactured thereby

A method for manufacturing a high-quality aluminum casting includes preparing an aluminum alloy raw material including Si in an amount of 9-12 wt %, melting the raw material to prepare a molten metal, adding a refiner containing Ti, B, and Sr to the molten metal, injecting the molten metal into a casting apparatus to maintain the temperature of the molten metal added with the refiner at 585-610° C., and operating the casting apparatus to cast the injected molten metal into a product having a predetermined shape.

Owner:SAMKI

Liquefied natural gas (LNG) cold energy comprehensive utilization system and method

ActiveCN106285808AUnaffected power generationFunctionality is not affectedLighting and heating apparatusIce productionElectronic systemsSuperheater

The invention relates to an LNG cold energy comprehensive utilization system which comprises a combined Rankine cycle electricity generation subsystem, an ice-making subsystem and a direct expansion electricity generation subsystem, wherein the combined Rankine cycle electricity generation subsystem comprises an LNG evaporator, a mixed working medium booster pump, a heat exchanger, a mixed working medium heater, a mixed working medium evaporator, a mixed working medium expansion machine, a single medium booster pump, a single medium evaporator and a single working medium expansion machine; the ice-making subsystem comprises a first natural gas superheater, an ice maker unit and a natural gas heater; the direct expansion electricity generation subsystem comprises a natural gas expansion machine and a second natural gas superheater. According to the LNG cold energy comprehensive utilization system and method, the cooling capacity of LNG from minus 162 DEG C to minus 10 DEG C is used, only little cooling capacity is taken away by seawater, and most comprehensive utilization of LNG cooling capacity is realized under the condition that the complexity degree of the technological process is not increased.

Owner:AEROSUN CORP +2

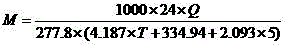

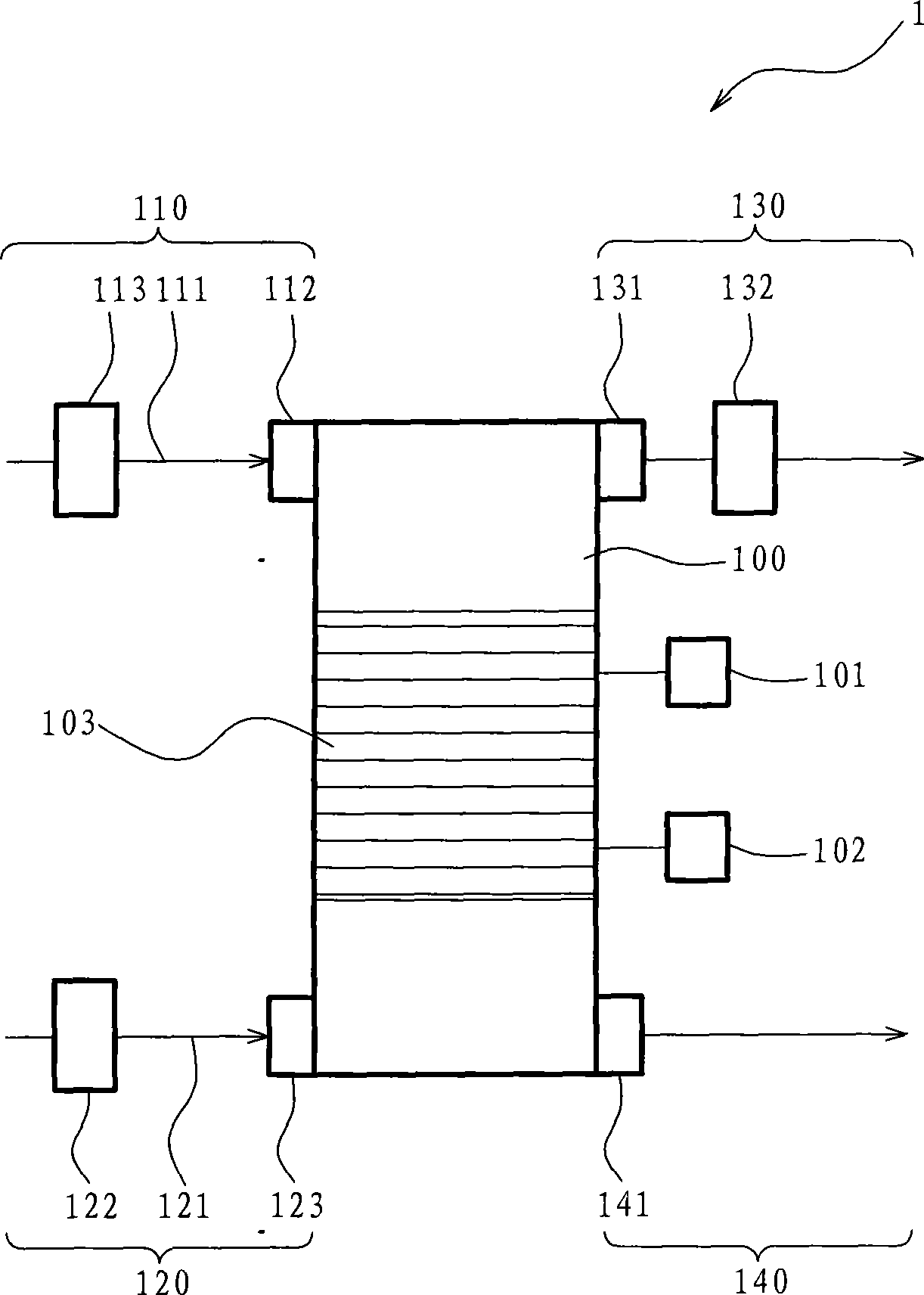

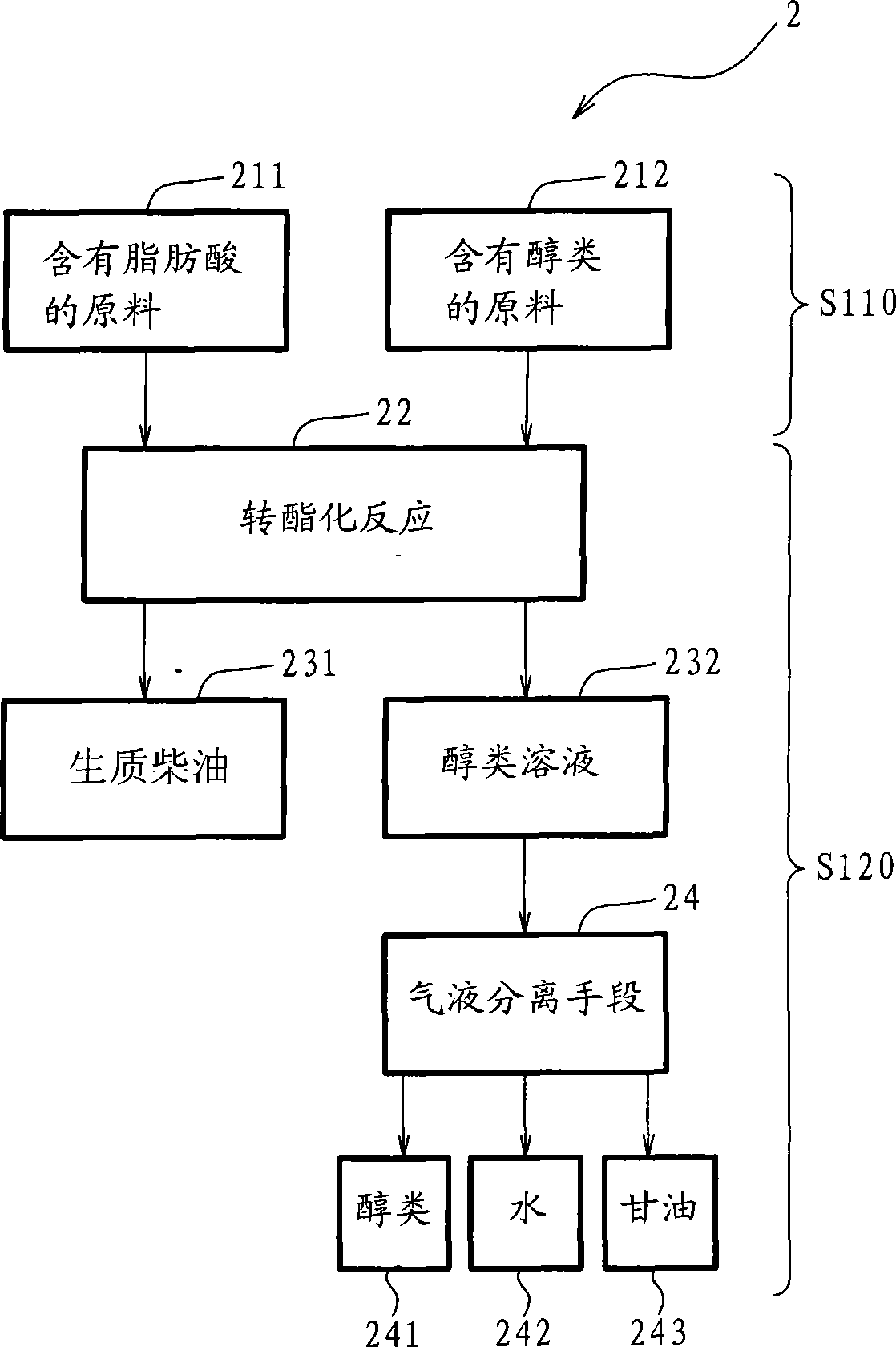

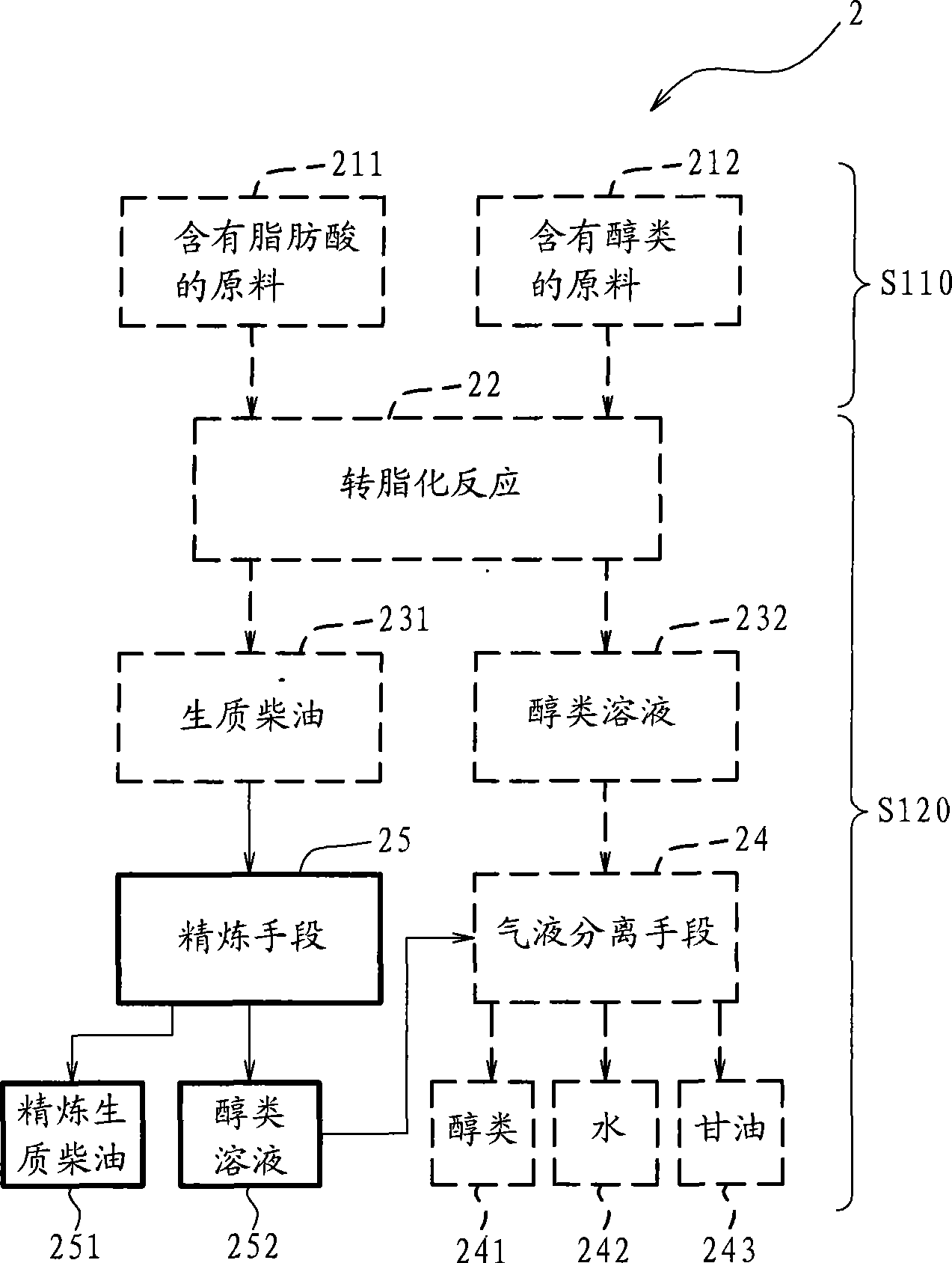

Countercurrent flow esterification reactor for preparing biodiesel and method thereof

The invention relates to a reverse flow esterifier for producing biodiesel and a method thereof. The reverse flow esterifier comprises an esterification reaction tower, a first feeding device, a second feeding device, a first discharging device and a second discharging device. The raw material containing fatty acid and the raw material containing ethanol are put into the reverse flow esterifier to produce the biodiesel through the esterification reaction in the esterification reaction tower.

Owner:ASIA GIANT ENG

Equipment indicator light and installation method thereof

InactiveCN102494270AExtend your lifeReduce in quantityLighting applicationsMechanical apparatusElectricityEngineering

The invention discloses an equipment indicator light and an installation method thereof. The equipment indicator light comprises a light source which is fixed on and electrically connected with a circuit board, and a display component arranged on a casing of equipment. Light from the light source ejects out of the equipment through the display component. The equipment indicator light is few in components, thereby reducing material cost and processing procedures, being easy in processing control, prolonging service life of the light source and enabling assembly of the whole structure to be brief and attractive in appearance.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD +2

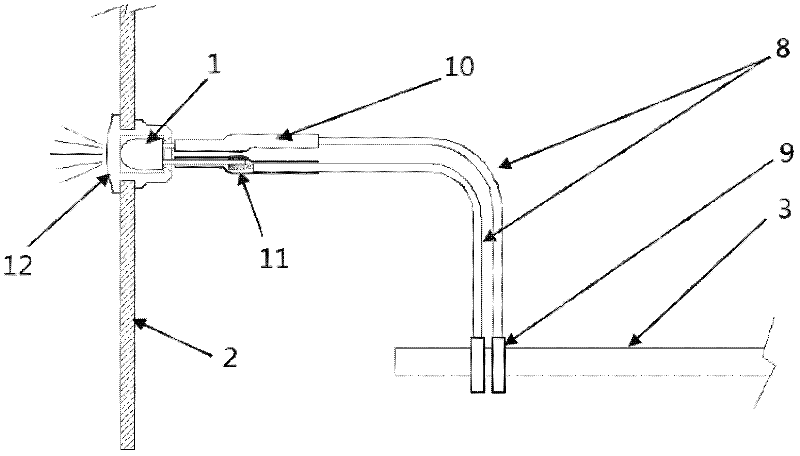

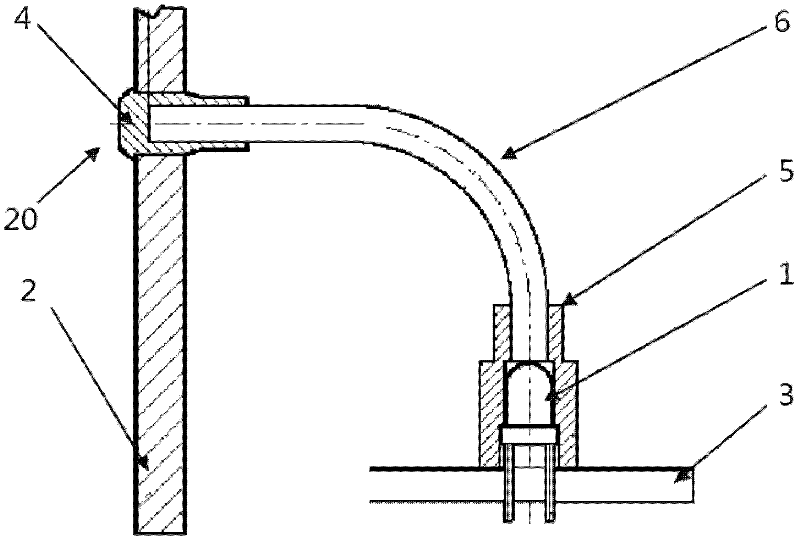

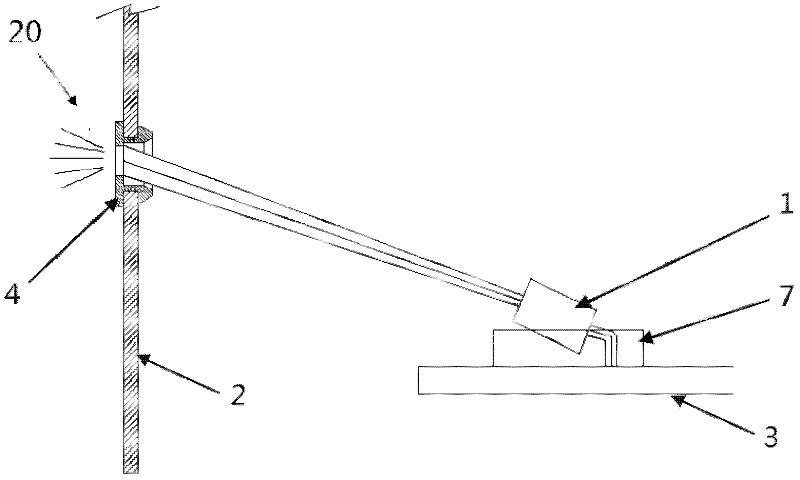

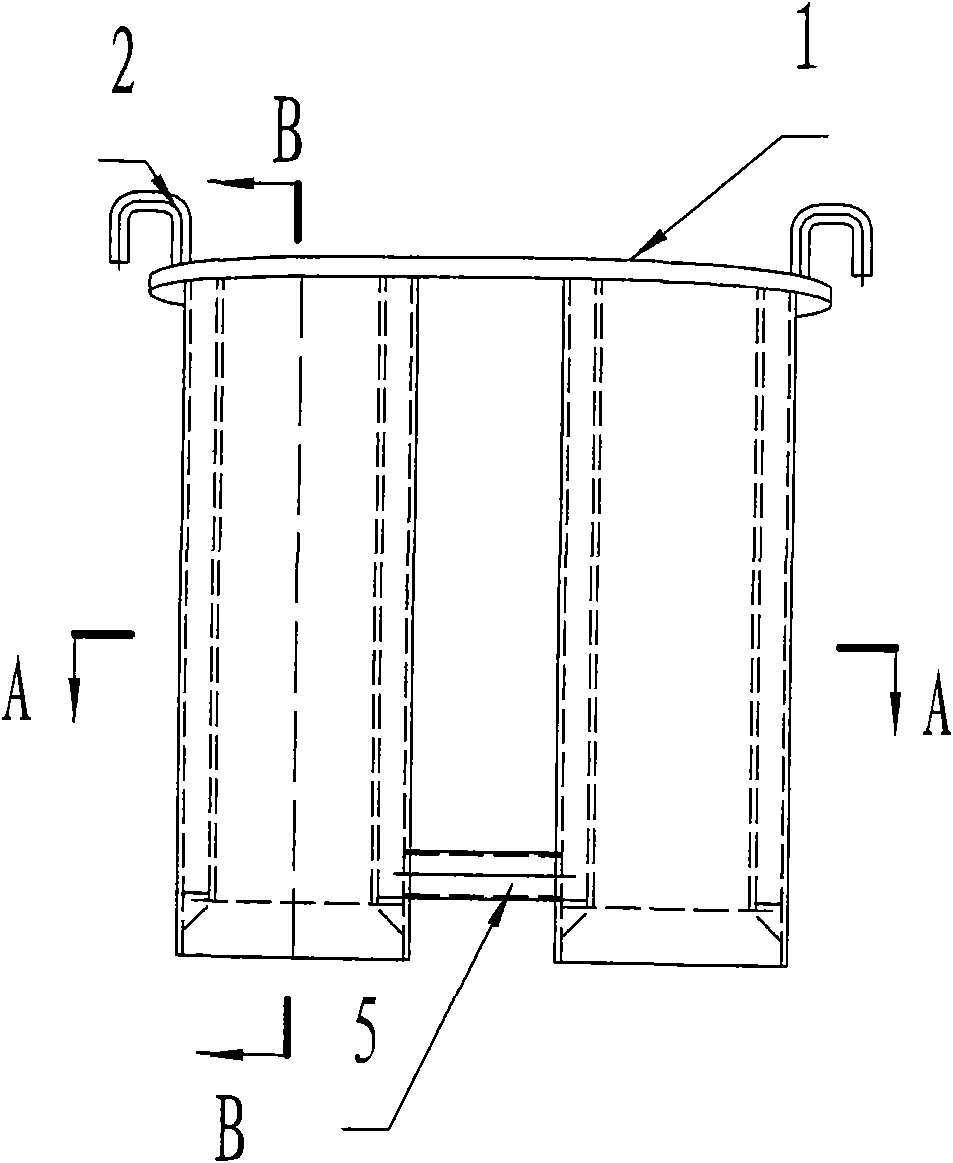

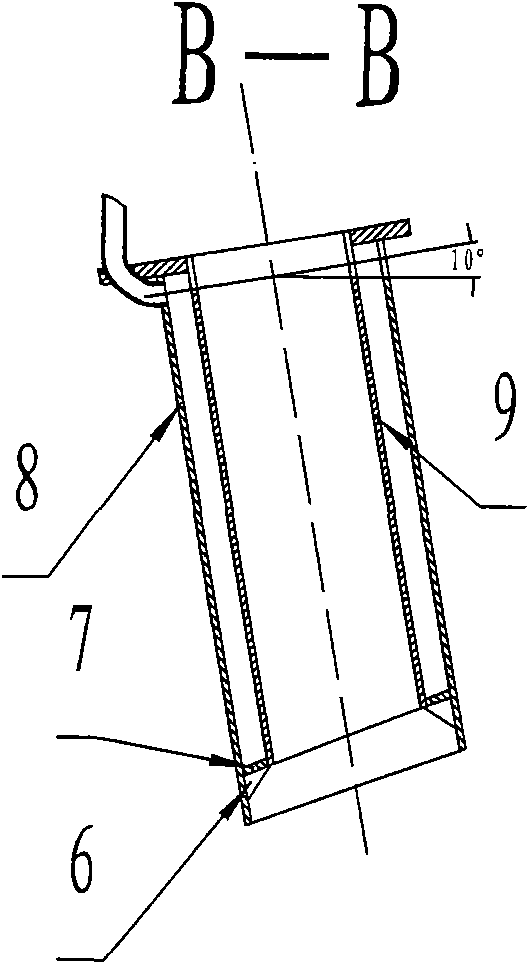

Closed type calcium carbide furnace charging nozzle and process for producing same

InactiveCN101526309AImprove the quality structure of the material layerImprove furnace conditionArc welding apparatusCharge manipulationEnergy consumptionCrucible

The invention provides a closed type calcium carbide furnace charging nozzle and a process for producing the same. The charging nozzle mainly comprises two groups of seamless external casings, seamless internal casings, water inlet pipes, water outlet pipes, communication pipes and bottom edge embedded flanges; the seamless internal casings are arranged in the seamless external casings; the bottom edge embedded flanges, the water inlet pipes and the water outlet pipes are arranged on the two groups of the seamless external casings respectively; and the two groups of seamless external casings are communicated with the communication pipes. The charging nozzle has the advantages of solving the problems of water leakage due to frequent breakage and frequent shut-down of the furnace for exchange, meeting the requirements on the charging production of a closed type calcium carbide furnace, effectively improving quality structure of material layers around electrodes, greatly improving furnace conditions (avoiding piling of materials on the outer side of the charging nozzle), making the materials keep a steamed bread-shaped charge surface around the electrodes, further effectively reducing thermal loss, alleviating the insufficiency of the materials in the central region of the furnace, reducing the temperature of the charge surface, reducing exposing areas of the electrodes, reducing the thermal loss of electrode resistances, improving the quality structure of the material layers, contributing to improving the pre-heating of the furnace materials and forming a big crucible region, ensuring good furnace conditions, avoiding frequent occurrence of material stamping and material throwing, and further facilitating the technical operation and control of the furnace and high yield, high quality and low energy consumption of the furnace.

Owner:YUNNAN YUNWEI CO LTD

Method for controlling deformation of snap-ring parts through heat treatment

ActiveCN104404232AEffective controlEasy process controlFurnace typesHeat treatment process controlEngineeringMachining process

The invention discloses a method for controlling deformation of snap-ring parts through heat treatment. The method comprises the following steps: (1) confirming the treatment process parameters of a blank T6; (2) carrying out first stabilizing treatment; (3) carrying out second stabilizing treatment; (4) carrying out tooling and sizing; (5) carrying out third stabilizing treatment; (6) carrying out tooling and sizing again; (7) carrying out fourth stabilizing treatment. Through adoption of the method, the defects that the deformation of snap rings during the cold-working process is high and the final sizes of parts deviate from the original design are overcome, the needs for subsequent assembly can be effectively met, and the performance indicators meet the design requirements.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

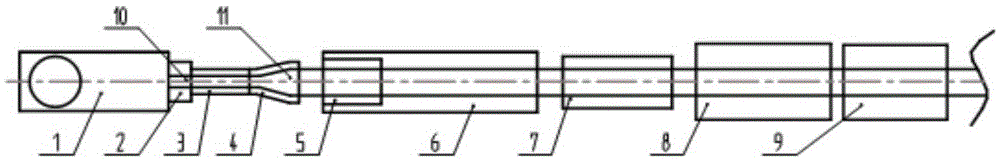

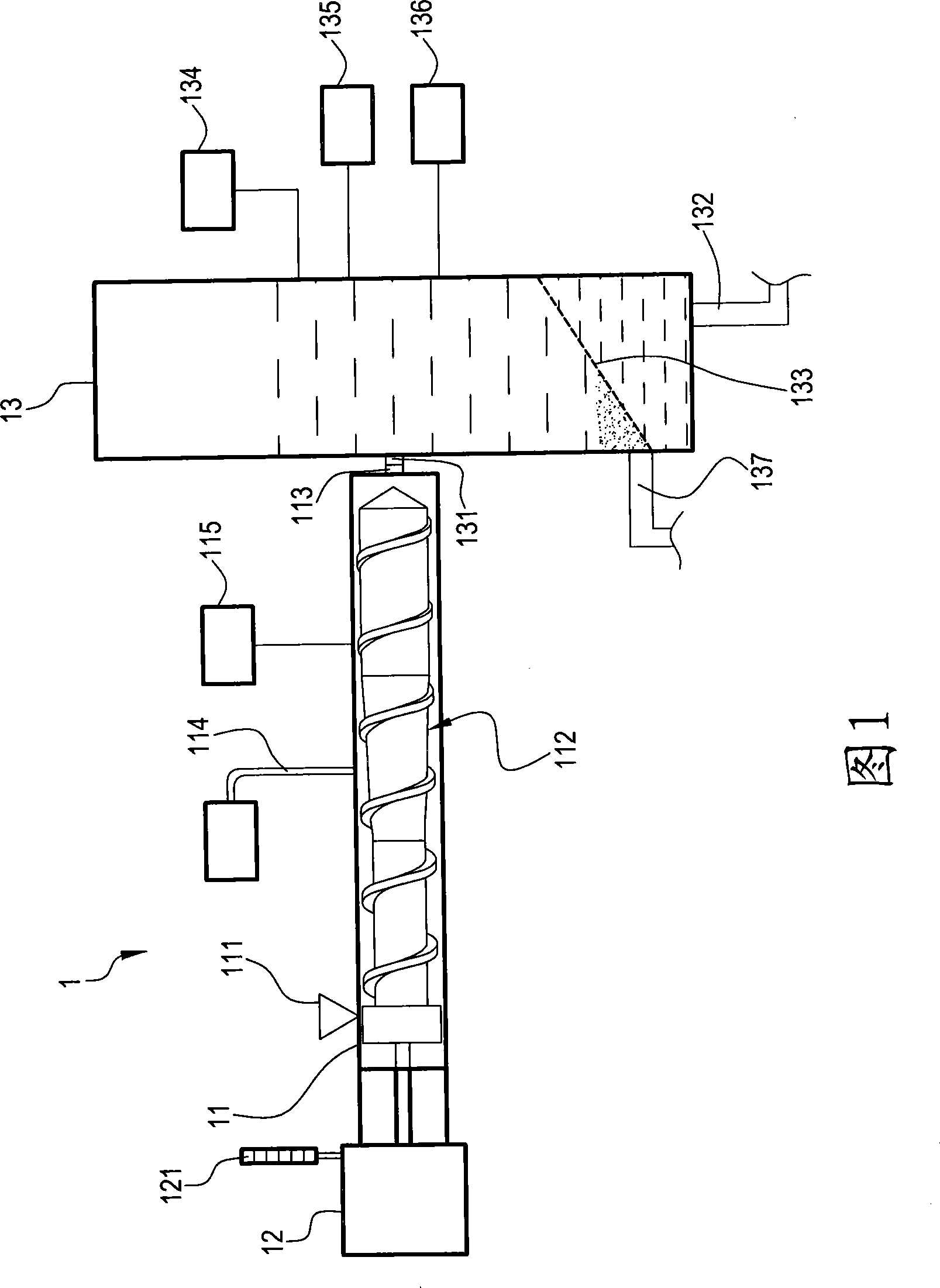

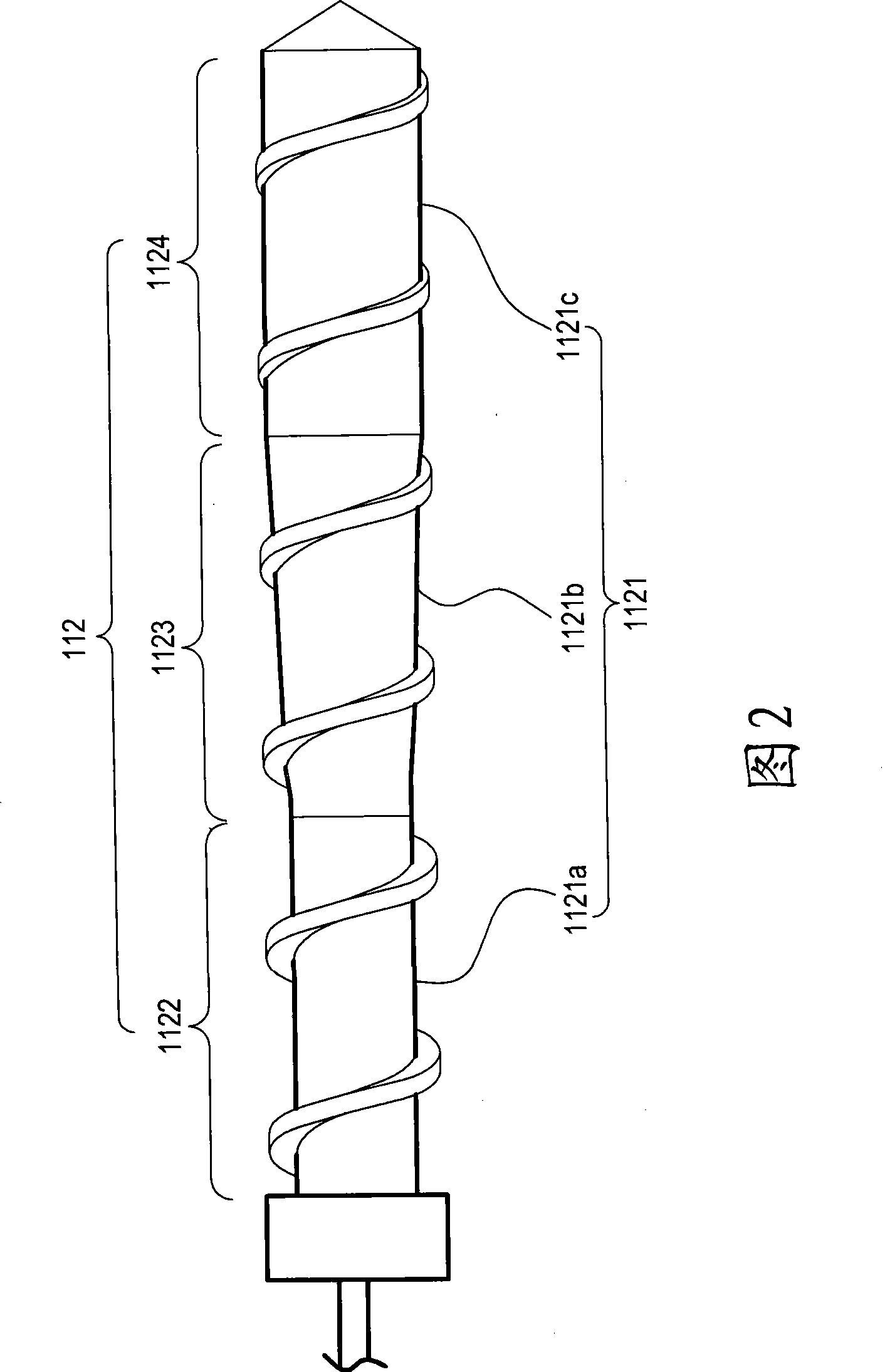

Technological method and device for preparing biaxial orientation plastic pipe through one-step method

InactiveCN105235228AAchieve Radial OrientationAchieve Axial OrientationProduction lineUltimate tensile strength

The invention relates to a technological method and device for preparing a biaxial orientation plastic pipe through a one-step method. The device comprises a plastic extruder, an extruding pipe die head, a pipe blank cooling heat-preserving section, a two-way drawing die, a vacuum cooling sizing device, a cooling box, a traction machine, a cutting machine and an automatic pipe discharge machine which are sequentially and linearly positioned to form a production line. The outer wall of a pipe blank is closely attached to the inner wall of the two-way drawing die to move, so that the two-way drawing die draws the pipe blank both in the radial direction and the axial direction. Radial drawing and axial drawing are completed through the two-way drawing die and the traction machine together. According to the method and device, the pipe is drawn through adsorption force of a vacuum machine and traction force of the traction machine, and radial orientation and axial orientation of the pipe are achieved. Besides, orientation is uniform, two-way performance of the oriented pipe can be greatly improved. Compared with common pipes, the tensile strength and the elasticity modulus of pipes in the same specification after biaxial orientation are improved by over 20%, the circular performance of the pipes is better than axial performance, and the actual use requirements of the oriented pipes are met.

Owner:RIFENG ENTERPRISE GRP CO LTD +1

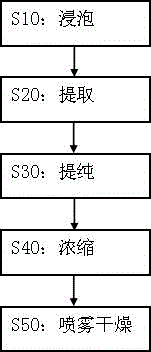

Method for extracting chlorogenic acid

InactiveCN106831419ASimplified extraction stepsEasy process controlOrganic compound preparationCarboxylic acid esters separation/purificationChemistrySimulated moving bed

The invention relates to a method for extracting chlorogenic acid. The method is characterized by comprising the following steps: soaking the crushed green coffee bean in an extracting tank filled with an extracting agent for a preset period of time; extracting a mixture of the crushed green coffee bean and the extracting agent in the extracting tank, thereby acquiring a primary extracting solution; separating and purifying the primary extracting solution through a simulated moving bed chromatography, thereby acquiring a chlorogenic acid extracting solution; performing vacuum concentration on the chlorogenic acid extracting solution, thereby acquiring a concentrated chlorogenic acid solution and recovering the extracting agent; and spray-drying the concentrated chlorogenic acid solution, thereby acquiring the end product of chlorogenic acid. In the extracting manner of the scheme provided by the invention, the purity of the extracted chlorogenic acid is increased and the production energy consumption and the production cost are lowered.

Owner:内蒙古昶辉生物科技股份有限公司

Thermal-insulation luminescent ceramic brick and preparation method thereof

InactiveCN109836042AExtended service lifeEasy process controlClaywaresThermal insulationMaterials science

The invention discloses a thermal-insulation luminescent ceramic brick and a preparation method thereof. A photoluminescent material is made into a photoluminescent glassy layer on a ceramic biscuit through a printing or distribution process, and the photoluminescent glassy layer shows various colors in the dark and the afterglow time is long. A silk-screen printing or distribution process can beadopted, patterns can be replaced momentarily, and with the cooperation of pigment toning and concave and convex molds, various decorative artistic effects with strong three-dimensional sense and richpattern layers can be presented. By the method of the invention, problems of existing photoluminescent materials such as poor wear resistance, weatherability and chemical corrosion resistance are solved.

Owner:韩璐

Large-scale entomopathogenic nematode production method and entomopathogenic nematode

The invention belongs to the production field of entomopathogenic nematodes and relates to a large-scale entomopathogenic nematode production method and entomopathogenic nematodes. The production method comprises the steps that the entomopathogenic nematodes in an infection period are inoculated onto greater wax moths for infection, and the entomopathogenic nematodes are collected to prepare an entomopathogenic nematode suspension after the greater wax moths die; separated entomopathogenic nematodes are utilized to infect greater wax moths, then the entomopathogenic nematodes are separated from died greater wax moth bodies for single bacterium culture, and the entomopathogenic nematodes cultured based single bacteria are separated for production and propagation; the entomopathogenic nematodes in the infection period are utilized to infect living greater wax moth bodies, then died greater wax moth hemolymphs are collected, and a symbiotic bacterium solution for production is obtained through culture, authentication, adaption, fermentation and symbiotic bacterium propagation; the obtained symbiotic bacterium solution is firstly inoculated to breeding bags of a shared culture medium,and then the obtained entomopathogenic nematodes are inoculated into the breeding bags of the shared culture medium for culture. The large-scale entomopathogenic nematode production method is convenient to operate, capable of making product quality good and higher in yield and efficiency and makes factory-like large-scale breeding easy to achieve.

Owner:吉林省怡科农业生物科技有限公司 +1

Quick cooling mould for plastic molding cover and processing process for threaded core

The invention relates to the technical field of moulds and particularly discloses a quick cooling mould for a plastic molding cover. The quick cooling mould comprises a threaded core, wherein the threaded core is provided with a first accommodating cavity; a molding insert is arranged in the first accommodating cavity; a water transporting regulating assembly is further arranged between the molding insert and the threaded core; a cooling gap is formed between the water transporting regulating assembly and the inner wall of the first accommodating cavity; the forming insert is connected with a cooling water tube; the water transporting regulating assembly is provided with a water inlet and a water outlet; cooling water of the cooling water tube sequentially passes through the molding insert, the water inlet, the cooling gap and the water outlet; and a water outlet channel communicating with the water outlet is arranged between the outer side of the cooling water tube and the threaded core. The cooling mould disclosed by the invention is good in cooling effect, the molding period is shortened, and the production efficiency is improved. The invention further discloses a processing process or the threaded core. The processing process has the advantages of being simple in process, easy to manufacture and high in strength of the threaded core.

Owner:DONG GUAN JIN FU IND CO LTD

Continuous three phase mixing reactor

InactiveCN106582475ASimple working principleEasy process controlChemical/physical/physico-chemical stationary reactorsFeed devicesChemical reactionPositive pressure

A continuous three phase mixing reactor comprises conveying equipment, raw material storage equipment, and a vertical cylindrical mixing reaction tank. The conveying equipment is connected to the raw material storage equipment and the mixing reaction tank through pressure pipelines. The discharge pipeline of the raw material storage equipment is connected to the mixing reaction tank feed inlet arranged in the lower end of the mixing reaction tank. The mixing reaction tank overflow opening is arranged in the upper end of the mixing reaction tank. Through the conveying equipment, three phase (gas, liquid, and solid) materials are uniformly introduced into the vertical cylindrical mixing reaction tank according to a ratio; the three phase materials are evenly stirred and mixed in the mixing reaction tank to generate a uniform mixture or participate into chemical reactions; due to the input pressure, the mixing reaction tank has a positive pressure, the uniformly mixed reactants are discharged from the upper part through a low-in high-out mode, and continuous production is realized. The reactor is suitable for liquid-liquid mixing reactions, solid-liquid mixing reactions, gas-liquid mixing reactions, and gas-liquid-solid mixing reactions, has the advantages of wide application range, convenient process control, and high production efficiency, and can meet the requirements of production under various conditions.

Owner:XIANGYANG CANGHAI TECH CO LTD

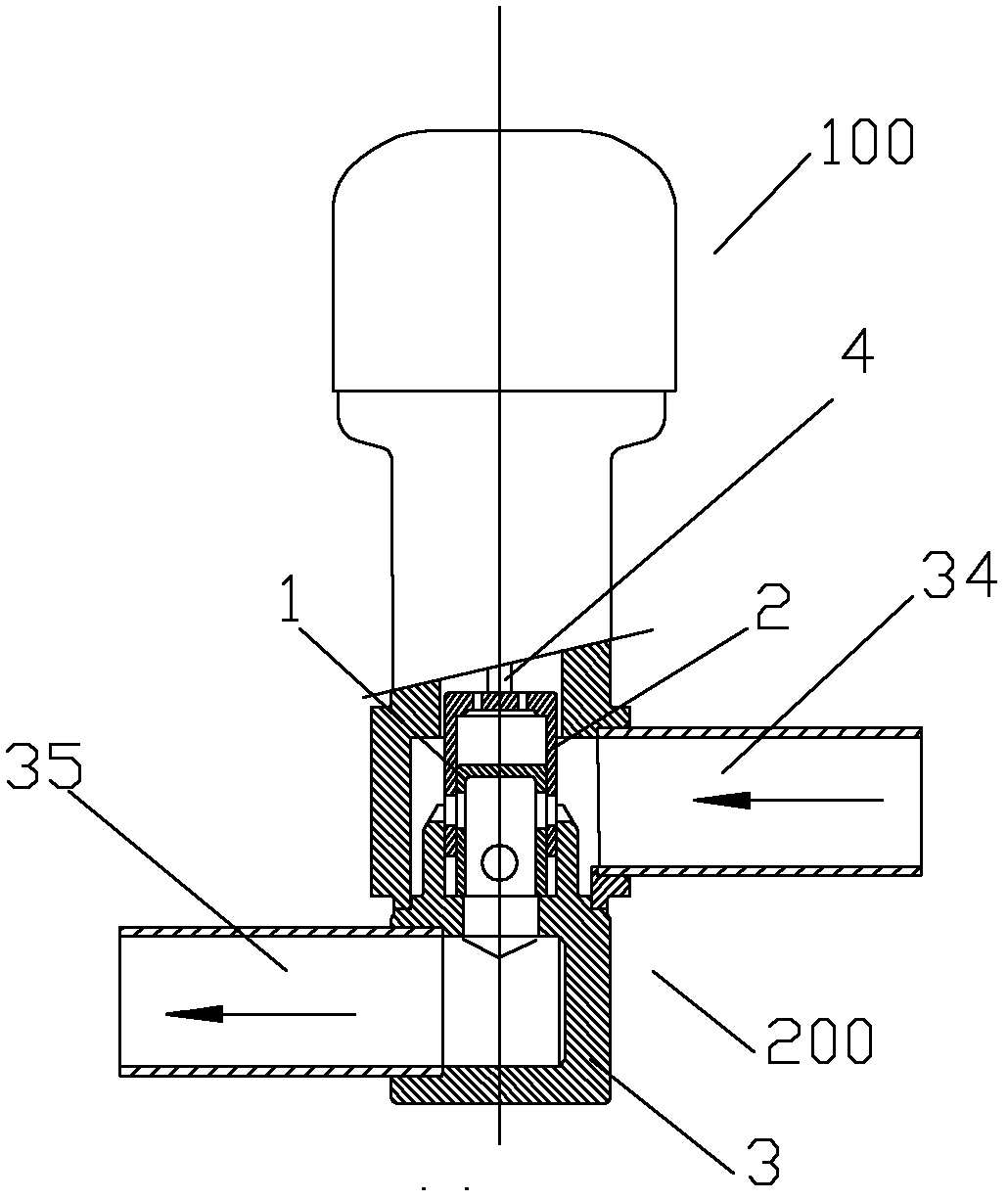

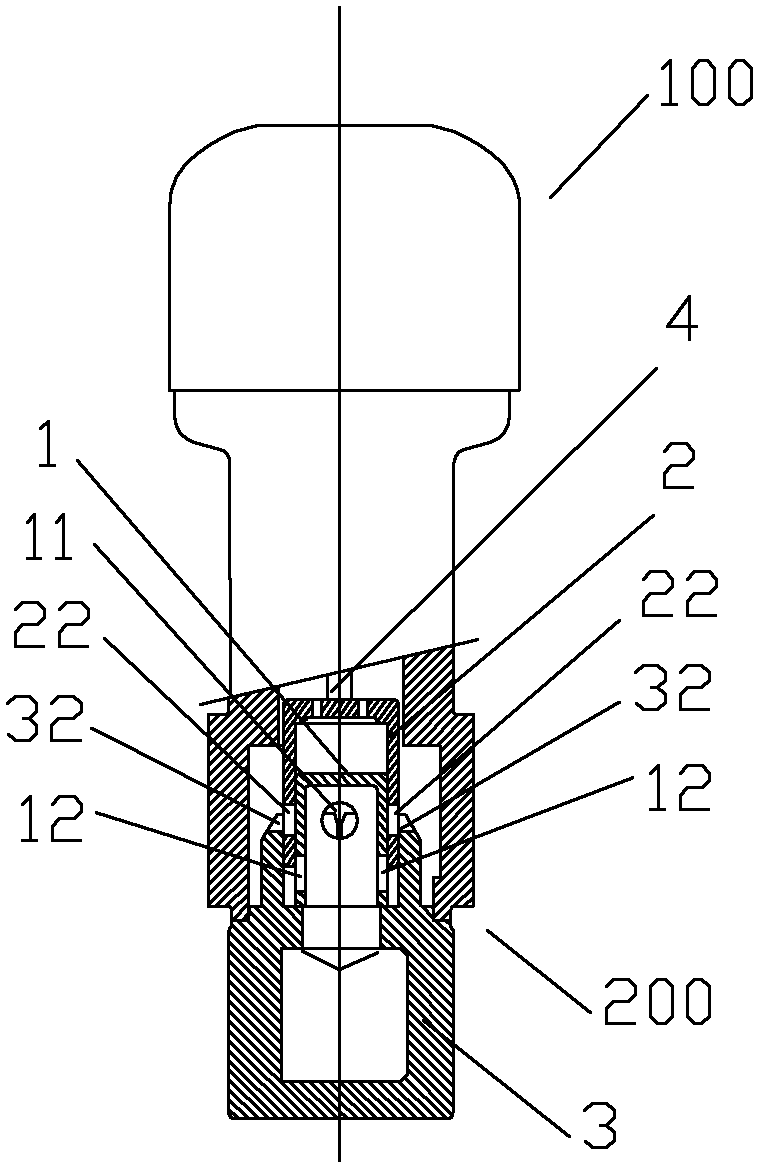

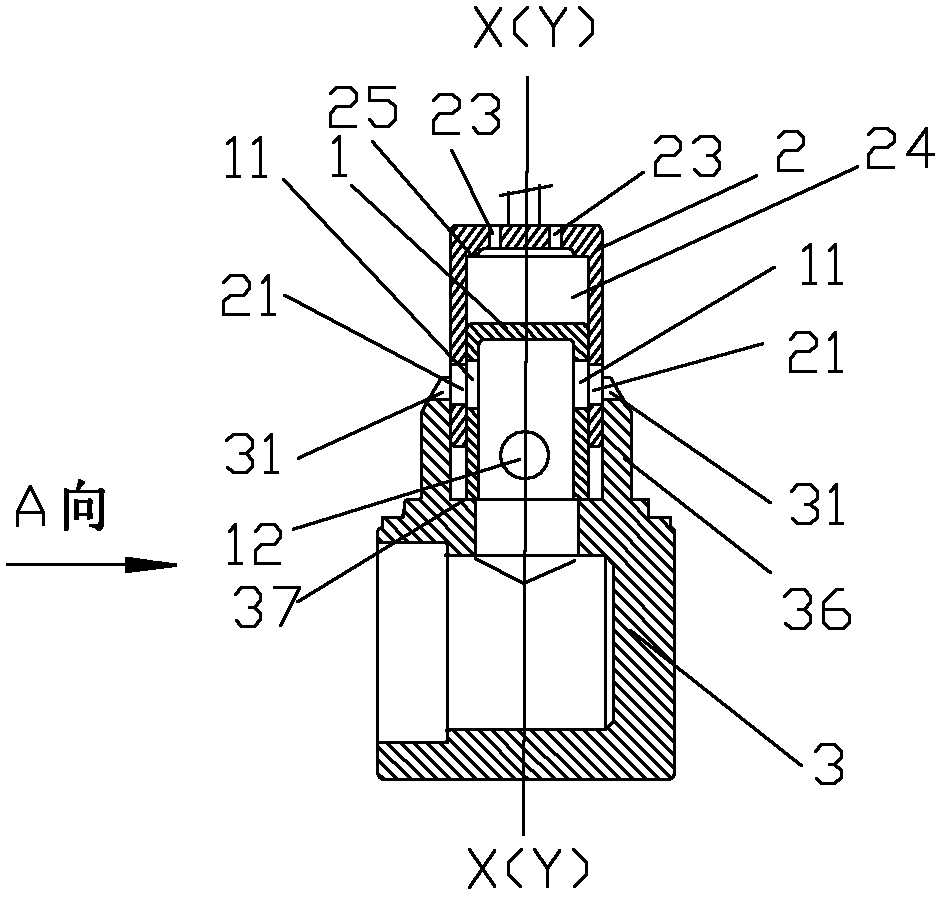

Bidirectional throttling electronic expansion valve

ActiveCN102538319AAvoid disturbanceAvoid shockEfficient regulation technologiesFluid circulation arrangementEngineeringRefrigeration

The invention relates to a bidirectional throttling electronic expansion valve, and belongs to the technical field of refrigeration control. The bidirectional throttling electronic expansion valve comprises a driving mechanism (100) and an execution mechanism (200) which are controlled by virtue of signals, wherein the execution mechanism (200) comprises a valve body (3) with a first channel (34) and a second channel (35), and a valve core part arranged in a valve cavity (33) of the valve body (3), and is characterized in that the valve core part comprises a valve core (2) and a switching part (1); an inner cavity (24), as well as a positive throttling channel (21) and a negative throttling channel (22) which are communicated with the inner cavity (24) are formed in the valve core (2); and the switching part (1) is arranged in the inner cavity (24) of the valve core (2). According to the bidirectional throttling electronic expansion valve, structures of throttling parts of the positive throttling channel and the negative throttling channel can be designed independently according to optimized data required by a refrigeration system; and the bidirectional throttling electronic expansion valve has a simple and reliable structure, and the heat utilization efficiency for refrigeration or heating can be improved.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

Natural faric hydrolysis reactor

InactiveCN101418353ACause vaporizationNo burdenSugar derivativesSugar derivatives preparationManufacturing cost reductionTemperature control

The invention relates to a natural fiber hydrolytic reactor, which at least comprises an extruder charging barrel device, a power-driven device and a gas-liquid separation tank device, wherein the inside of the extruder charging barrel device is provided with a feeding compression screw, and the extruder charging barrel device is provided with a temperature control device and provided with a first feed opening and a first discharge opening; the power-driven device is connected with the feeding compression screw and drives the feeding compression screw to rotate; and the gas-liquid separation tank device is provided with a second feed opening and a second discharge opening, and the second feed opening is connected with the first discharge opening of the extruder charging barrel device. Starch or raw materials which are mixed with plant cellulose and hemicellulose are placed into the natural fiber hydrolytic reactor, and subjected to plasticizing, supercharging and heating of the natural fiber hydrolytic reactor to initiate hydrolysis, so as to prepare a sugar solution. The natural fiber hydrolytic reactor can prepare the resultant - the sugar solution by utilization of the natural starch or the raw materials which are mixed with the plant cellulose and the hemicellulose and without any additive, has an environment-friendly processing procedure, can not cause environmental burden, and has the efficacies of simple and easily controlled processing procedure, reduction of the manufacturing cost and so on.

Owner:TOP INT BIOMASS ENERGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com