Low-carbon hot-rolled ultrahigh-strength high-toughness steel and preparation method thereof

A technology for ultra-high-strength and high-toughness steel, which is applied in the field of low-carbon hot-rolled ultra-high-strength and high-toughness steel and its preparation, can solve the problems of high cost, complicated process, and no significant improvement in production efficiency, and achieve high production efficiency and energy efficiency. The effect of low consumption and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

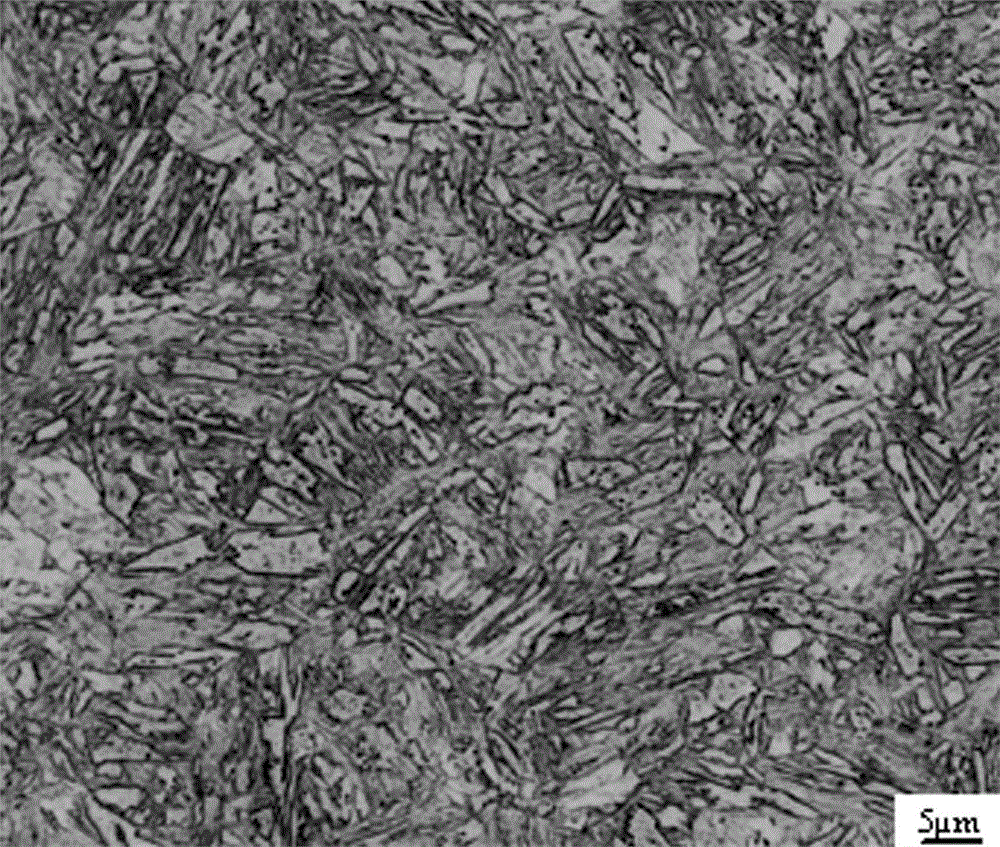

Embodiment 1

[0025] Smelting, refining and pouring according to the set composition to make a slab, the composition of the slab contains C 0.10%, Si 1.43%, Mn 1.85%, Cr 0.7%, Mo 0.28%, P 0.003%, S 0.003%, balance The amount is Fe;

[0026] Reheat the billet to the austenitizing temperature, control the heating temperature at 1050°C, keep it warm for 2.5 hours, and then forge it into a billet within the temperature range of 950~1050°C (forging at a forging ratio of 1.7);

[0027] Heat the billet to 1200±10°C for 2 hours, and carry out the first-stage rolling and the second-stage rolling in the austenite recrystallization zone and the austenite non-recrystallization zone respectively, and the first-stage rolling temperature is 1130 ℃, the final rolling temperature is controlled at 1100 ℃; the starting rolling temperature of the second stage is 930 ℃, and the final rolling temperature is controlled at 900 ℃; The rate is 75%, and the hot-rolled steel plate is obtained;

[0028] Cool the hot-...

Embodiment 2

[0030] Smelting, refining and pouring according to the set composition to make slabs, the composition of slabs contains C 0.11%, Si 1.35%, Mn 1.89%, Cr 0.8%, Mo 0.29%, P 0.004%, S 0.002%, balance The amount is Fe;

[0031] Reheat the billet to the austenitizing temperature, control the heating temperature at 1080°C, keep it warm for 3 hours, and then forge it into a billet within the temperature range of 950~1050°C (forging at a forging ratio of 1.5);

[0032] Heat the billet to 1200±10°C for 3 hours, and carry out the first-stage rolling and the second-stage rolling in the austenite recrystallization zone and the austenite non-recrystallization zone respectively, and the first-stage rolling temperature is 1140 ℃, the final rolling temperature is controlled at 1110 ℃; the second-stage rolling start temperature is 940 ℃, and the final rolling temperature is controlled at 920 ℃; the total rolling reduction rate of the first stage rolling is 35%, and the second stage The rate is...

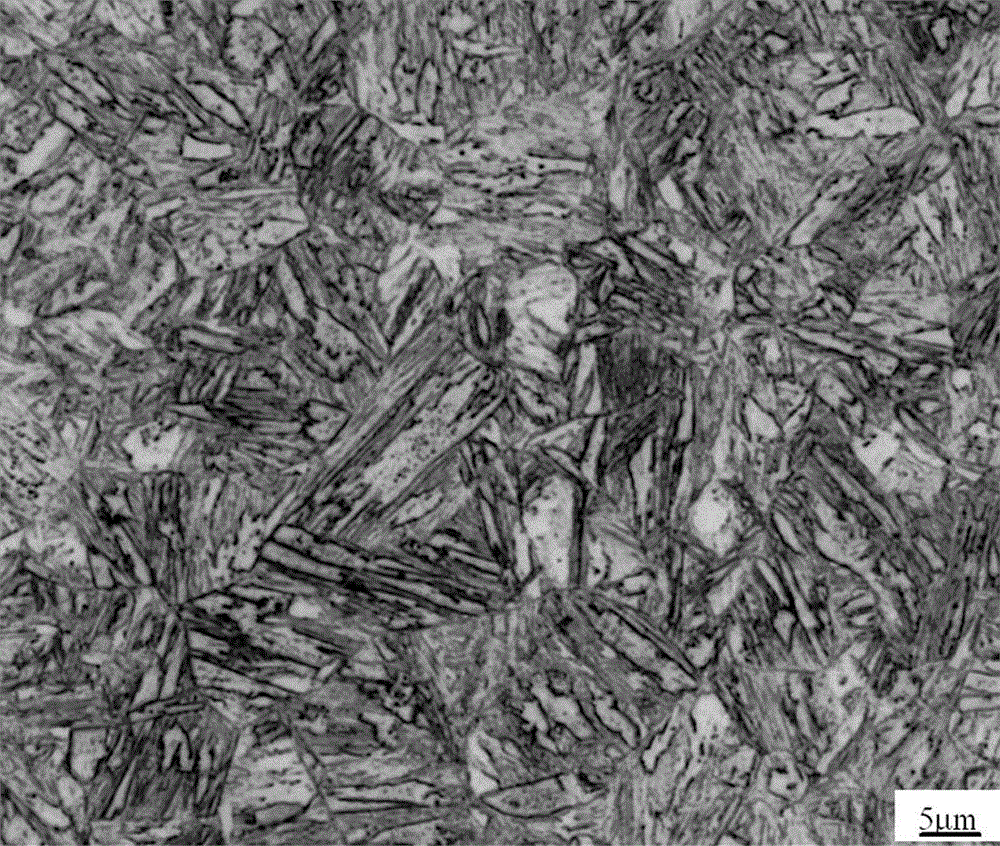

Embodiment 3

[0035] Smelting, refining and pouring according to the set composition to make slab, the composition of slab contains 0.10% C, 1.4% Si, 1.92% Mn, 0.7% Cr, 0.3% Mo, 0.001% P, 0.002% S, etc. The amount is Fe;

[0036] Reheat the billet to the austenitizing temperature, control the heating temperature at 1100°C, keep it warm for 2.5 hours, and then forge it into a billet in the temperature range of 950~1050°C (forging at a forging ratio of 1.7);

[0037] Heat the billet to 1200±10°C for 2.5 hours, and carry out the first-stage rolling and the second-stage rolling in the austenite recrystallization zone and the austenite non-recrystallization zone respectively, and the first-stage rolling temperature is 1150 ℃, the final rolling temperature is controlled at 1120 ℃; the second-stage rolling start temperature is 950 ℃, and the final rolling temperature is controlled at 930 ℃; The rate is 80%, and the hot-rolled steel plate is obtained;

[0038] Cool the hot-rolled steel plate at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com