Film coating equipment, method and system, solar cell, assembly and power generation system

A technology for solar cells and solar cells, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as low processing efficiency, and achieve the effect of improving processing efficiency and reducing processing waiting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

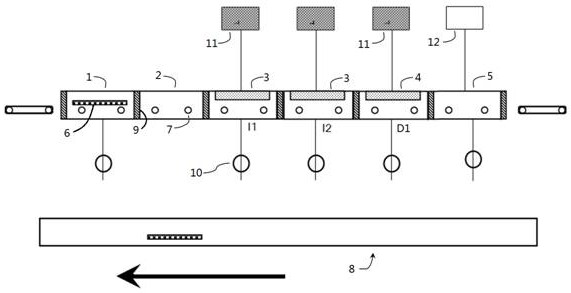

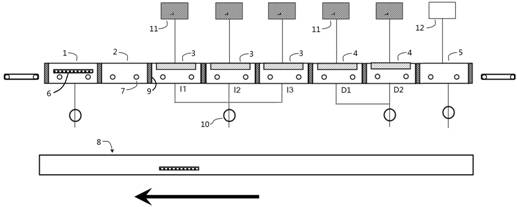

[0107] A coating device for heterojunction solar cells in this embodiment is used for depositing amorphous silicon-based thin films on heterojunction solar cells, which may include linearly arranged loading chamber 1, preheating chamber 2, process chamber, and unloading chamber The basic cavity structure required for processing such as cavity 5, among which:

[0108] Loading chamber 1: responsible for the entry of loading and loading carrier plates.

[0109] Preheating chamber 2: responsible for preheating the carrier board. Non-contact heating can be used to preheat the carrier plate to reach the temperature required by the process.

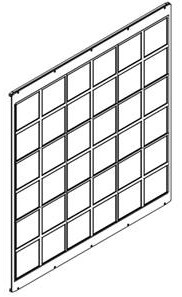

[0110] Process chamber: used for deposition and coating processing. According to the requirements of the process, feed the corresponding gas, use the vacuum pump 10 to form a vacuum environment or maintain the air pressure, use the plasma power supply and process gas 11 to form a processing environment, and perform intrinsic layer silicon thin...

Embodiment 2

[0119] This embodiment further limits the solution in Embodiment 1. The intrinsic process chamber and the doping process chamber are provided with a capacitively coupled flat plate structure for forming a thin film by chemical vapor deposition. The scheme preferably adopts plasma chemical vapor deposition to form a thin film. In this structure, a capacitively coupled flat plate structure is connected with an RF / VHF radio frequency power supply, and the frequency of the radio frequency power supply is 10MHz-100MHz.

[0120] When performing the silicon thin film coating of the intrinsic layer, the frequency of the radio frequency power supply between different intrinsic process chambers can be set as required.

[0121] The thickness and defect density of the intrinsic silicon thin film have an important impact on the conversion efficiency of the cell. By decomposing the intrinsic silicon thin film processing technology, it is easier to realize the control of process parameters fo...

Embodiment 3

[0124] In the heterojunction solar cell coating equipment of this embodiment, a roller mechanism is provided at the bottom of each cavity, and the carrier is transported by the roller mechanism.

[0125] combine figure 1 , the carrier does not move during the static coating process. When transmission is required, the speed of the carrier board can be moved at a speed of 90 ~ 800mm / s. When moving, the carrying pallet passes through the linearly arranged loading chamber 1, preheating chamber 2, I1 intrinsic process chamber, I2 intrinsic process chamber, D1 doping process chamber, and unloading chamber 5, and uses the roller mechanism to realize Transport of the carrier board.

[0126] More preferably, the speed of the carrier board can be controlled at 200-700 mm / s, and preferably, the conveying speed of the rollers is 300-600 mm / s. For example, a speed of 320 mm / s is used for motion.

[0127] If the speed is too high, the carrier plate is easy to vibrate, and the friction b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com