Closed type calcium carbide furnace charging nozzle and process for producing same

A calcium carbide furnace, a closed technology, applied in the direction of manufacturing tools, metal processing equipment, furnaces, etc., can solve the problems of negative impact on production cost and output quality, influence on the quality of calcium carbide in furnace conditions, and easy burnout of feed nozzles, etc., to achieve improvement Material layer quality structure, process operation control, high yield, high quality, low energy consumption, and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

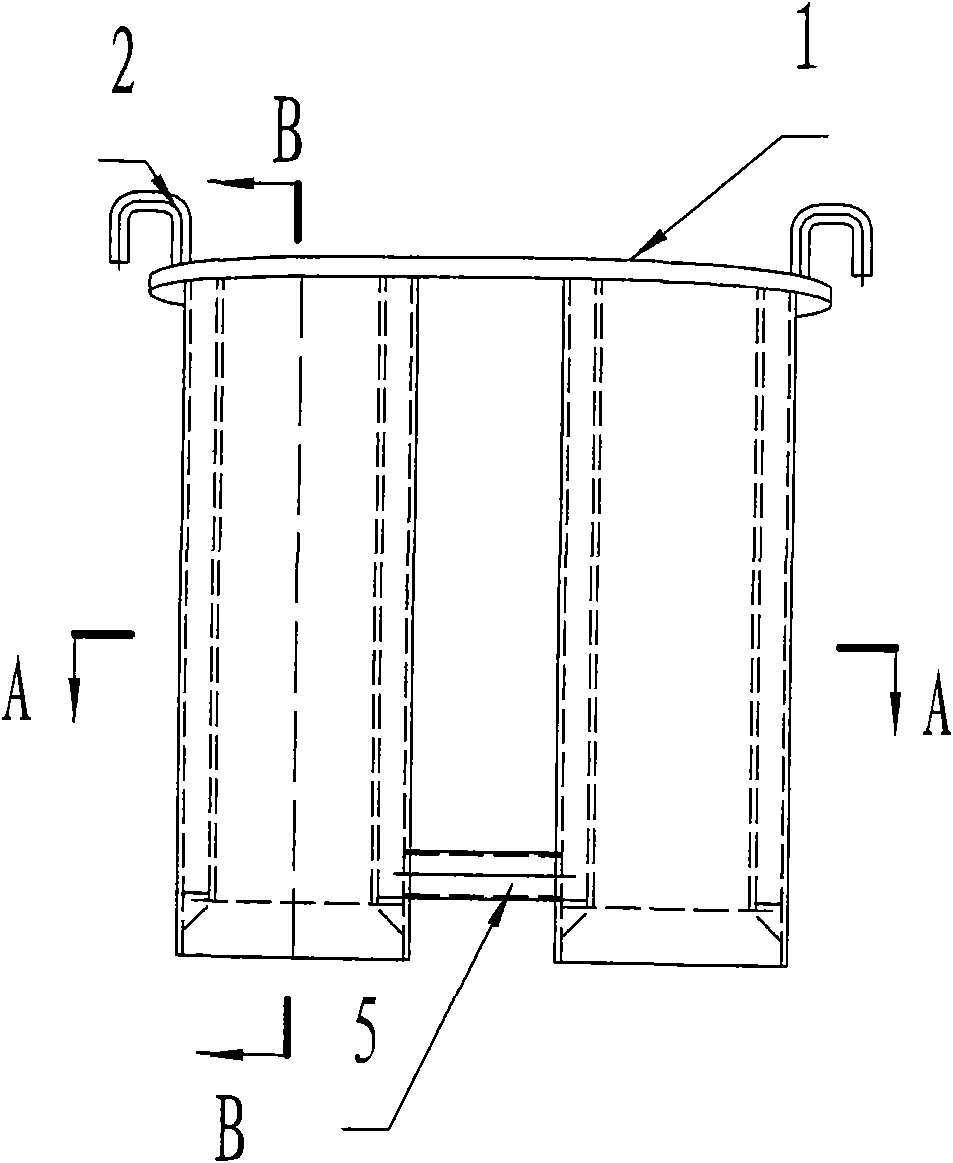

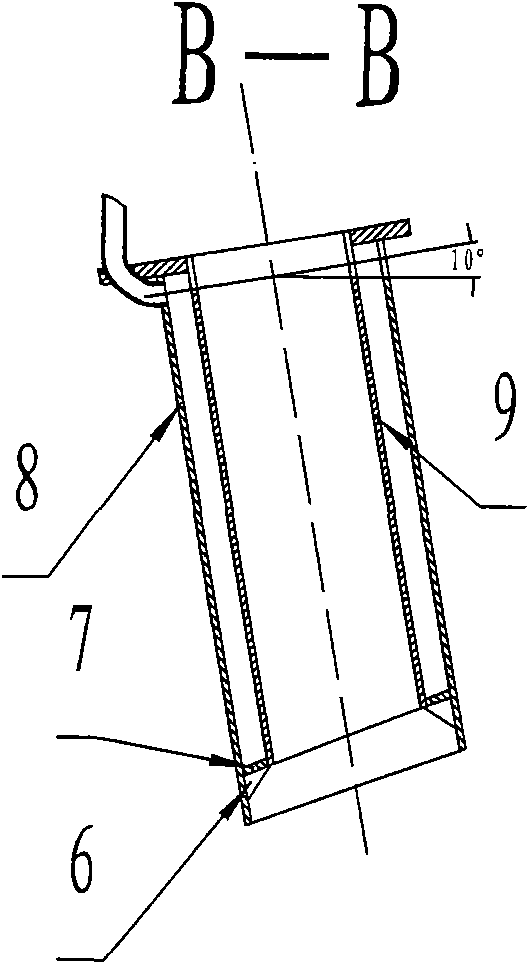

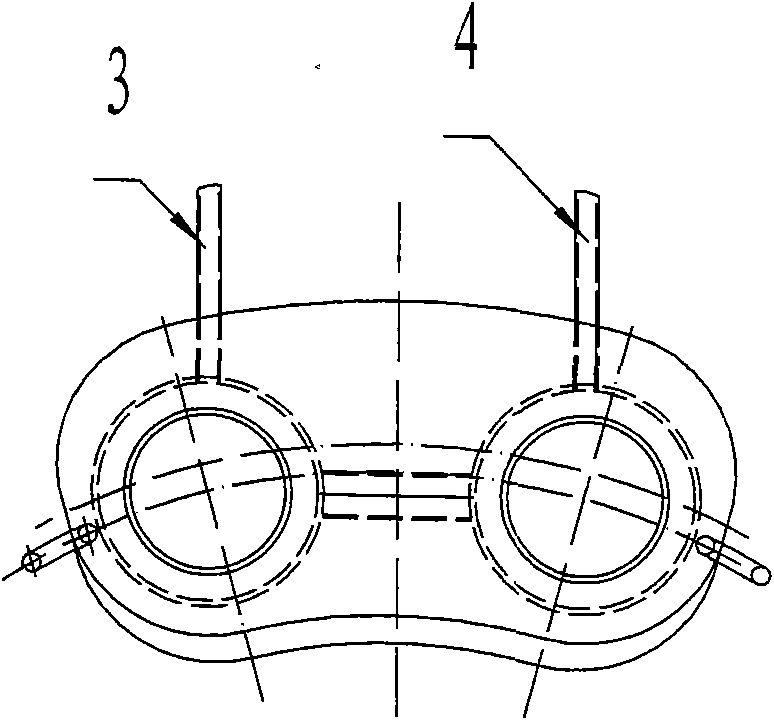

[0015] As shown in the figure, the charging nozzle of the closed calcium carbide furnace of the present invention consists of two sets of seamless outer casings 8, seamless inner casings 9, water inlet pipes 3, water outlet pipes 4, connecting pipes 5, and flanges 7 inlaid on the bottom. The seamless inner casing 9 is placed in the seamless outer casing 8, the bottom edge is inlaid with the flange 7, the water inlet pipe 3 and the water outlet pipe 4 are installed on two sets of seamless outer casings respectively, and the connecting pipe 5 connects the two Set of seamless casings. Install the hanging plate 1 and the lifting lug 2 on the two sets of seamless outer casings, and the bottom opening has a reinforcing triangle plate 6.

[0016] Production Method:

[0017] After inserting the outer sleeve 8 and the inner sleeve 9 first, the outer sleeve 8 and the inner sleeve 9 are separated by the bottom edge inlaid flange 7, spot welded in sections, and then the same method is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com