Patents

Literature

49results about How to "Improve furnace condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

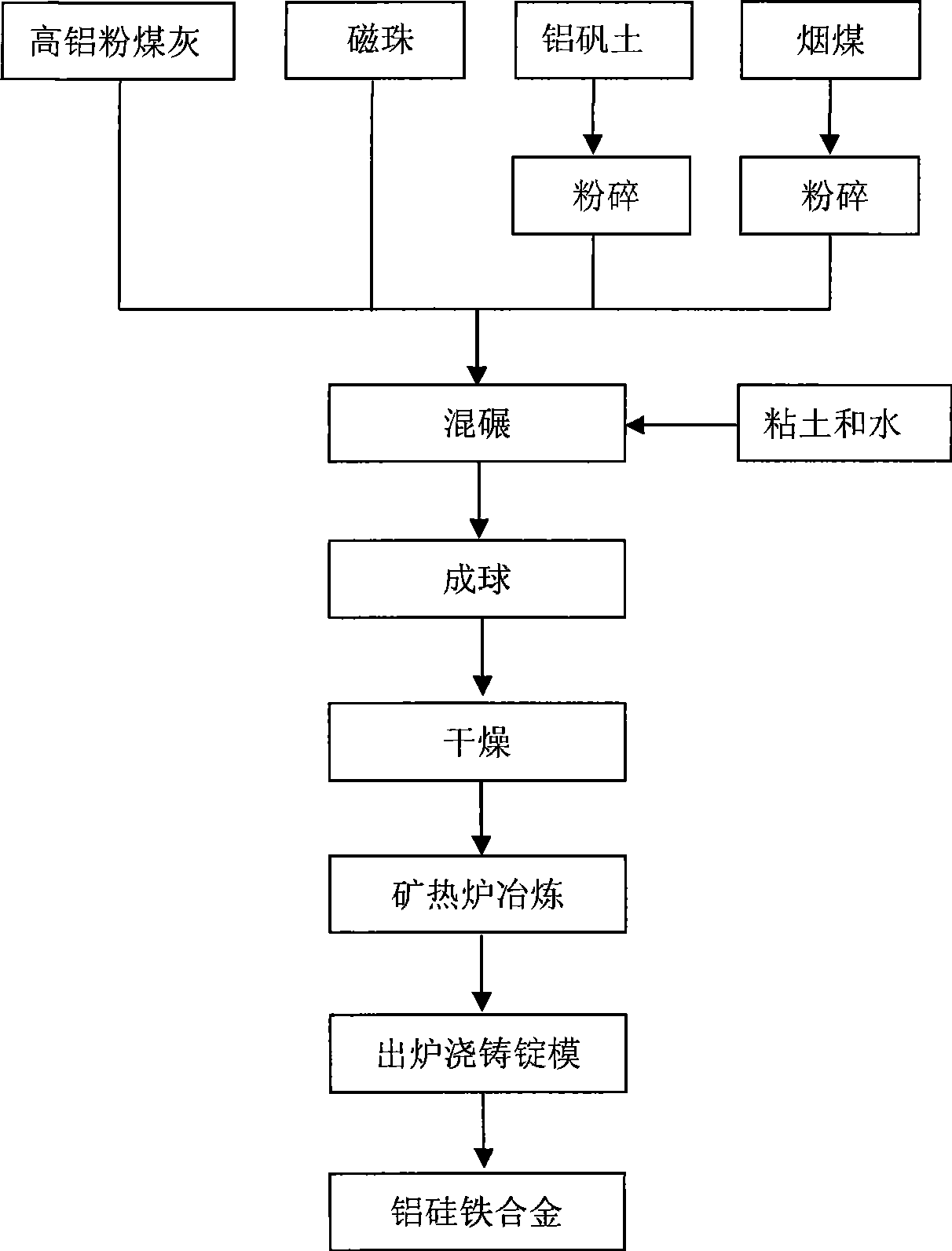

Method for preparing alsifer from high-alumina fly ash and magnetic beads

ActiveCN101469378AEvenly distributedHigh activityMagnetic separationResource utilizationMagnetic bead

The invention discloses a method for preparing AL-Si-Fe alloy by utilizing high-aluminum fly ash and magnetic beads, which relates to the technical field of nonferrous metallurgy. The method comprises the following steps: 1) a bauxite raw material and a reducing agent-bituminous coal are crushed, and the crushed materials and raw materials (the high-aluminum fly ash and the magnetic beads) are sent into a mixing pan; 2) an adhesive-clay and a certain amount of water are added into the mixing pan to mixedly roll the materials; 3) the materials which are mixedly rolled evenly enter a twinroller machine for granulation; 4) pellets which come from the twinroller machine enter a drying kiln for drying; 5) the dried pellets are added into a submerged arc furnace for high-temperature smelting; and 6) molten iron is taken out of the furnace, and an ingot mold is cast to obtain the AL-Si-Fe alloy. The method has the advantages of broad raw material source, low production cost, good performance of the pellets containing fly ash, even furnace-entering smelting constituents, and complete reaction, makes the submerged arc furnace keep good furnace condition, ensures that the produced AL-Si-Fe alloy has steady performance, and realizes the resource utilization of waste.

Owner:TONGFANG ENVIRONMENT

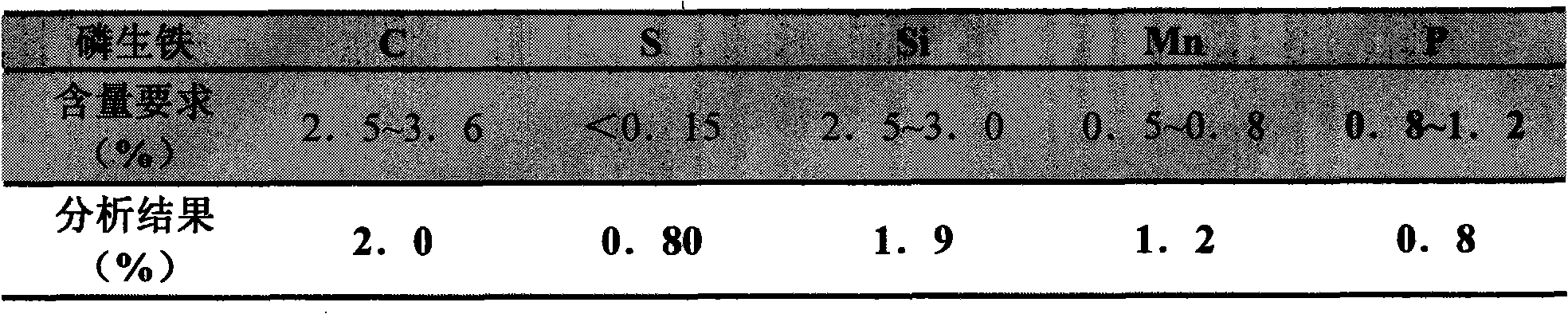

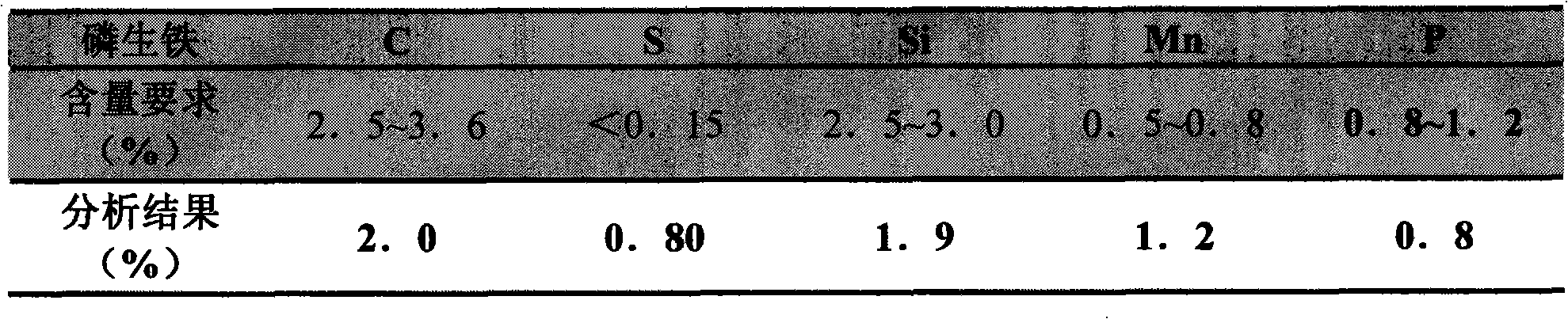

Phosphorous pig iron desulfurizer used for casting pre-roasting anode

InactiveCN101570803AIncrease smelting speedShorten smelting timeGas emission reductionWorking environmentGraphite

The invention discloses a phosphorous pig iron desulfurizer used for casting a pre-roasting anode. The desulfurizer is prepared from the following raw materials by mass percentage: 2 to 4 percent of graphite, 35 to 45 percent of CaO, 3 to 5 percent of CaF2, 1 to 3 percent of Na2CO3, 40 to 50 percent of Na2SiO3, and 1 to 3 percent of FeO. By adopting the phosphorous pig iron desulfurizer used for casting the pre-roasting anode, the adding amount of the desulfurizer is 2.5 percent in each ton of phosphorous pig iron; when the desulfurizer is used in a 1.6-ton induction furnace, the produced phosphorous pig iron can meet use requirements on composition as well as performance, so that the speed of smelting the phosphorous pig iron in the induction furnace is quickened, the smelting time of the phosphorous pig iron is shortened, the electric energy is saved, and the smelting cost is saved by about 15 percent; moreover, good furnace conditions and operational conditions are kept for smelting, the working environment for workers is improved, and the labor intensity of the workers is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

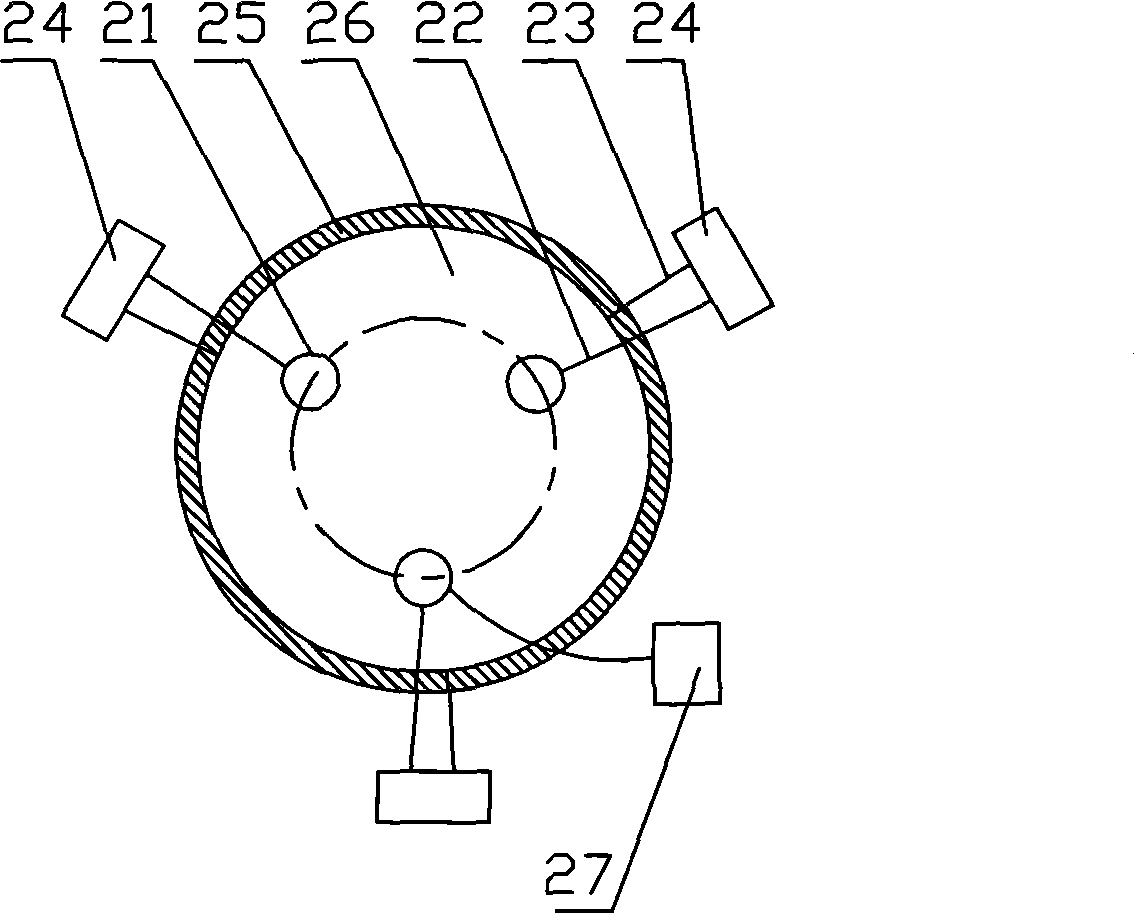

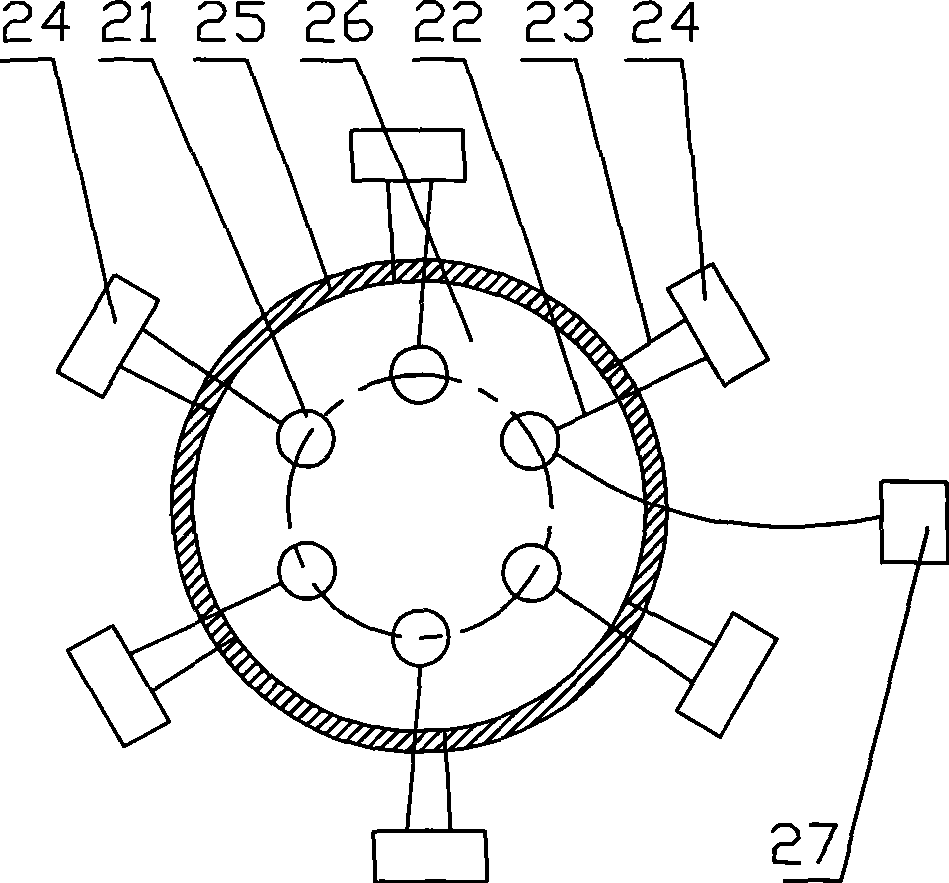

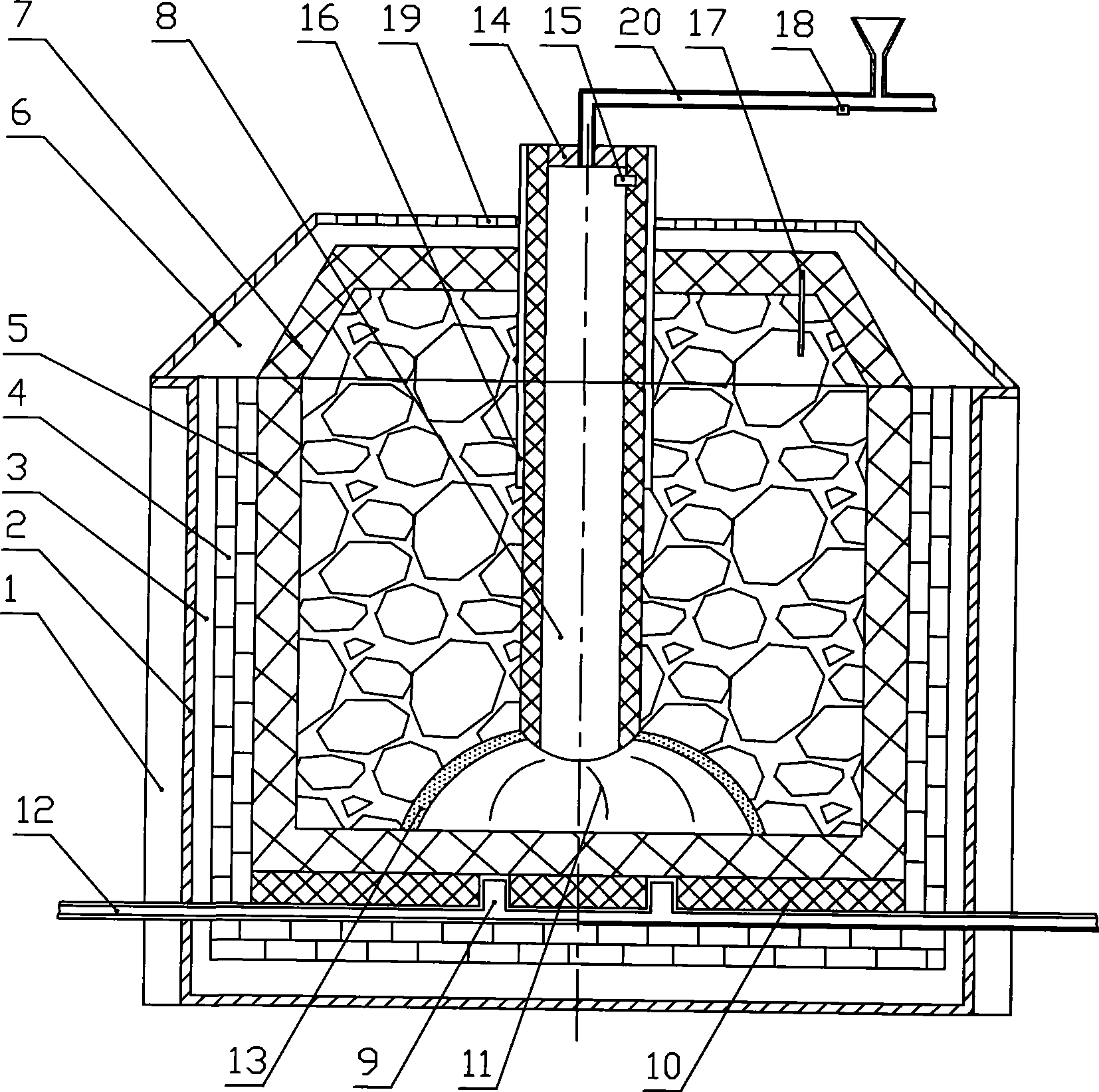

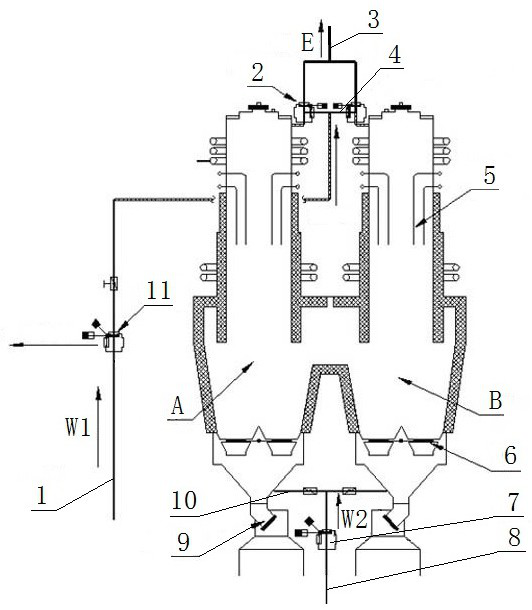

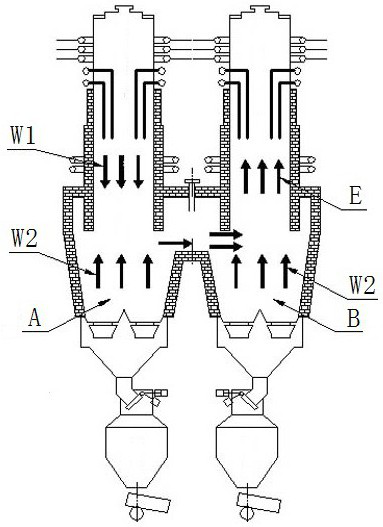

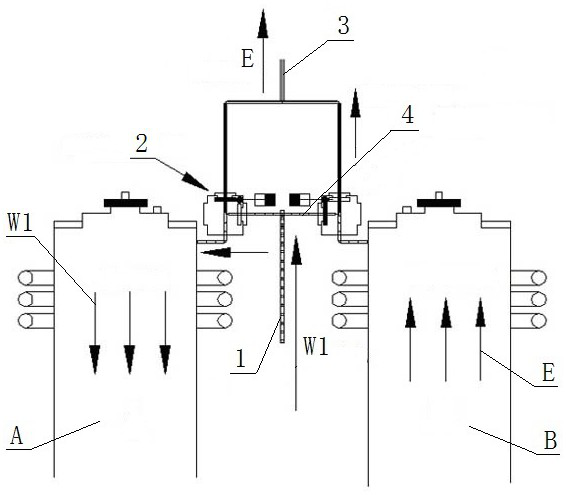

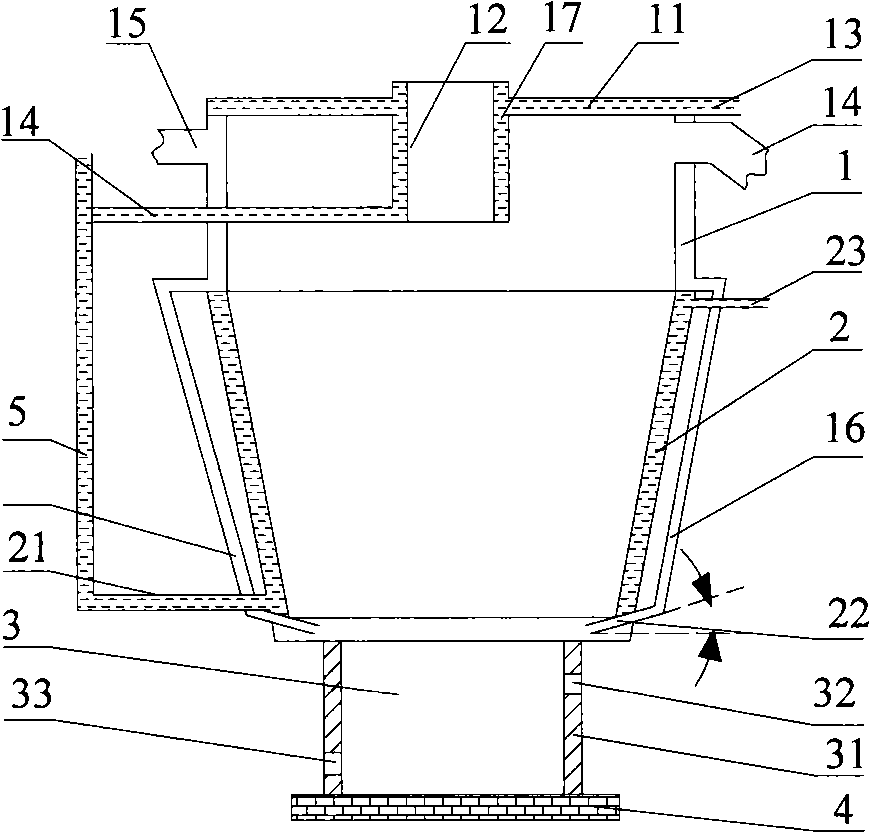

Sealed submerged arc furnace system

ActiveCN101532781AImprove securityEliminate potential safety hazardsEnergy industryCharge manipulationWaste heat recovery unitElectricity

The invention relates to a sealed submerged arc furnace system, and solves the problems that the existing direct current electrical arc furnace can not be applied to the submerged arc furnace and an alternating current sealed submerged arc furnace, and has high power consumption, large electrode consumption and low safety. The solution is as follows: the sealed submerged arc furnace system comprises a sealed submerged arc furnace, a waste heat recovery device and a waste gas treatment and utilization device; the waste heat recovery device comprises a turbonator and a heat pump; the waste gas treatment and utilization device comprises a waste heat boiler connected with a waste gas outlet of the sealed submerged arc furnace, a waste gas dust removing device connected with a gas outlet of the waste heat boiler and a waste gas reaction device connected with a gas outlet of the waste gas dust removing device; a water inlet of the heat pump is connected with a water outlet of a hollow electrode cooling system and a water outlet of the turbonator; a hot water outlet of the heat pump is connected with the inlet of a heat exchanger of the waste heat boiler; a cold water outlet of the heat pump is connected with a water inlet of the hollow electrode cooling system; and the outlet of the heat exchanger of the waste heat boiler is connected with a steam inlet of the turbonator. The sealed submerged arc furnace system has the advantages of high safety, improvement of product quality and yield and low consumption.

Owner:北京平希节能环保科技有限公司

Ultra high power direct-current arc furnace deoxidation furnace-protective agent, making method and use thereof

InactiveCN101302569AImprove the yield of all ironIncrease viscosity and alkalinityProcess efficiency improvementElectric furnaceScrapSmelting process

The invention relates to a deoxidation furnace protective agent for an ultrahigh power direct current electric arc furnace, a method for manufacturing the same and an application of the deoxidation furnace protective agent. The deoxidation furnace protective agent comprises the following compositions in percentage by weight: 15 to 25 percent of total carbon, 38 to 55 percent of MgO, 15 to 25 percent of SiC, more than or equal to 3 percent of metallic aluminum, 4 to 10 percent of CaO, more than or equal to 6 percent of metallic iron and 0.05 to 0.2 percent of H2O; the manufacturing process is simple and comprises the following steps that: firstly, materials are weighed according to the mixture ratio, added with 7 to 9.5 weight percent of wedding agent and molded by a ball forming mill to manufacture a rugby-shaped product with a density of more than or equal to 1.8 g / cm<3>. In proportioning, aluminium scraps, carborundum, sponge iron and graphite adopt a parallel mode and have a weight mixture ratio of 1:4 - 6:1 - 2: 4- 6; in the whole smelting process, the deoxidation furnace protective agent is added for three times according to a proportion of 4 to 3 to 3 in order that the total iron content in the slag is reduced from average 40 percent to 10 to 15 percent around, thereby prolonging the service life of a furnace brick lining and a furnace cover and reducing elecrictiy consumption.

Owner:上海柯瑞冶金炉料有限公司

Carborundum

The invention relates to carborundum. The content of the impurity of a fifth element of the carborundum is within a specific range, and a carbothermic reduction method, a production method by a purification method and a purpose of being industrially used as a reducer of the carborundum are provided.

Owner:于旭宏

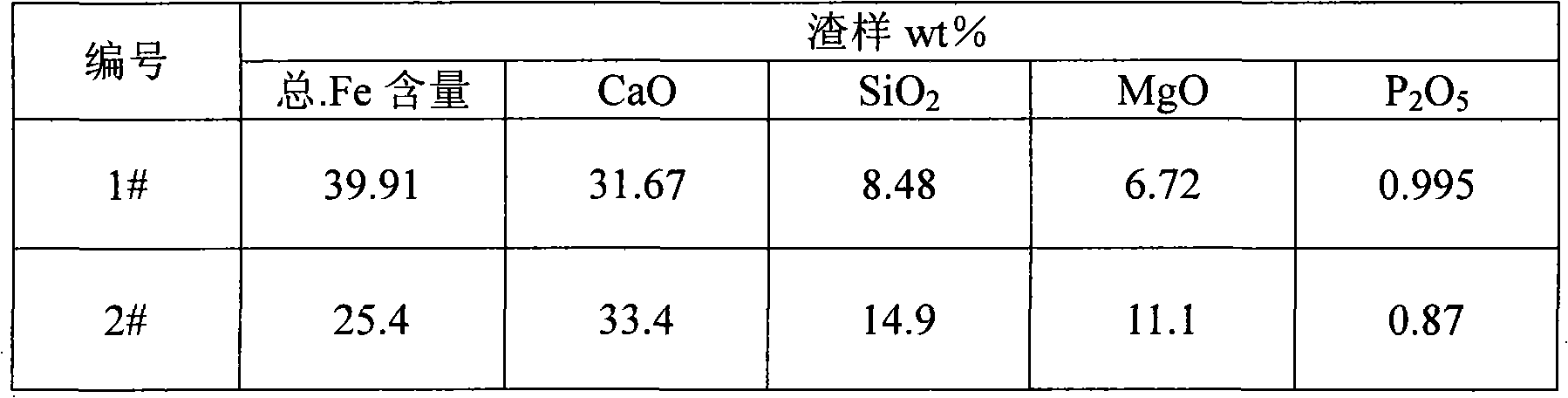

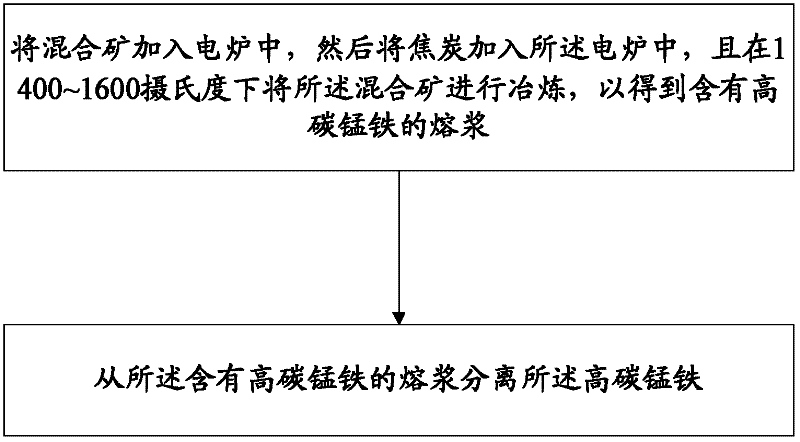

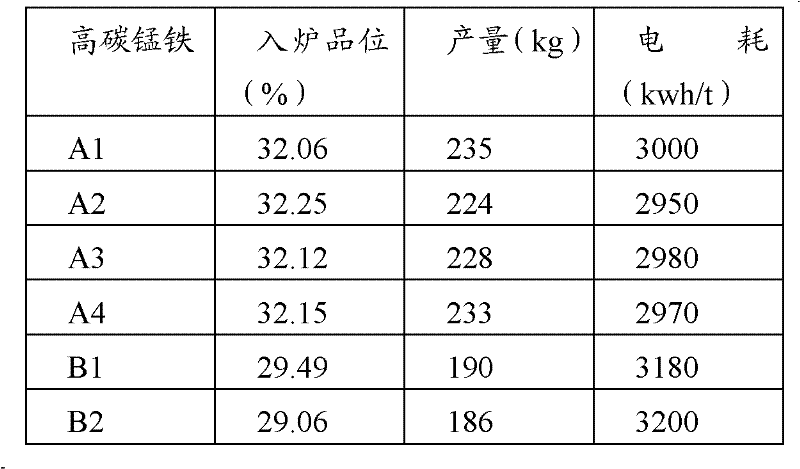

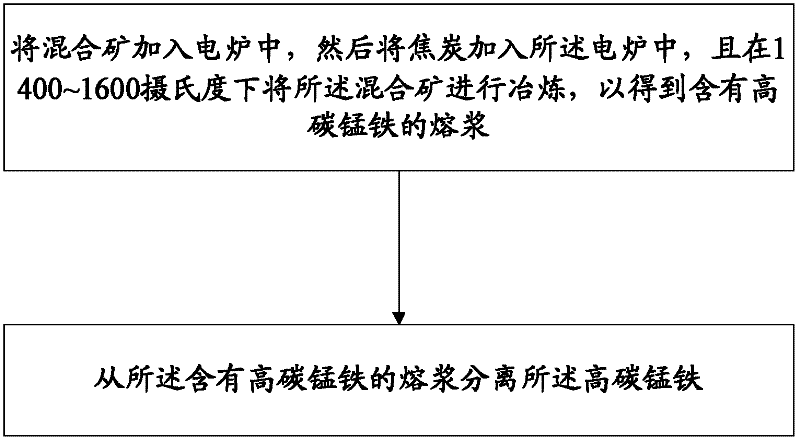

Method for preparing high carbon ferromanganese

The invention discloses a method for preparing high carbon ferromanganese. The method comprises the following steps: a) adding mixed ore in an electric furnace, adding coke in the electric furnace to smelt the mixed ore at 1400-1600 DEG C and obtain fused slurry with high carbon ferromanganese; and b) separating high carbon ferromanganese from the fused slurry. The high carbon ferromanganese comprises the following components by weight percent: 75.5% of manganese, 14.71% of iron, 2% of silicon, 0.25% of phosphorus, 7% of carbon and 0.03% of sulfur. According to the embodiment of the invention, by controlling the particle size of the raw material, the air permeability of the furnace charge can be improved, the furnace condition can be improved, the utilization rate of heat energy can be effectively increased and the power consumption can be reduced.

Owner:云南文山斗南锰业股份有限公司

Method for preventing air release valves of double-hearth kiln from spraying ash

ActiveCN112146447AReduce operating pressureImprove furnace conditionHuman health protectionMaintainance of heating chambersCombustionDust control

The invention discloses a method for preventing air release valves of a double-hearth kiln from spraying ash. The method comprises the following steps as follows: A, when a system cuts off conveying coal gas to the kiln, an electric control valve is opened to convey the gas in the kiln to a dust remover, and the pressure in the kiln is reduced to 10kpa or lower before entering a reversing period;B, blowing is conducted on a dust removal cloth bag once per hour; C, during reversing, a combustion-supporting air release valve is opened for 3 seconds, and then a cooling air release valve is opened; D, raw material granularity control is conducted; and E, the opening and closing action time of each valve is adjusted to be 4-5 seconds by adopting a mode of feeding during combustion. Compared with the prior art, during reversing of the kiln, the gas in the kiln is released to the dust remover in advance, dust sprayed out of the combustion-supporting air release valve is recycled, the pressure in the kiln is reduced through technological operation improvement and other means, and the ash spraying phenomenon generated by the combustion-supporting air release valve and the cooling air release valve is prevented.

Owner:LIUZHOU IRON & STEEL CO LTD

Method for preparing rare earth ferrosilicon alloy

The invention provides a method for preparing a rare earth ferrosilicon alloy, which relates to the field of alloy smelting, and comprises the following steps: (1) roasting bastnaesite concentrate at a temperature of 400-500°C, adding coke powder and charcoal powder, mixing and grinding into Mix the powder, then add water and mix the mixed powder with 1% of the total weight of the mixed powder, press into agglomerates and dry to obtain rare earth concentrate pellets; (2) mix the rare earth concentrate pellets, silica, coke After mixing uniformly with steel at a weight ratio of 0.1-0.5:2-3:1.5-1.8:0.15-0.35, it is continuously added into a submerged arc furnace, heated and melted, and poured out of the furnace to obtain the rare earth ferrosilicon alloy, the rare earth silicon The ferroalloy is composed of the following chemical components in mass fractions: RE 18-40%, Si 30-50%, Ca 3-8%, and the rest is Fe. The invention has the advantages of less energy consumption, low operation difficulty, and can suppress the generation of furnace warts. The advantages of safety and environmental protection.

Owner:安吉绿金金属材料有限公司

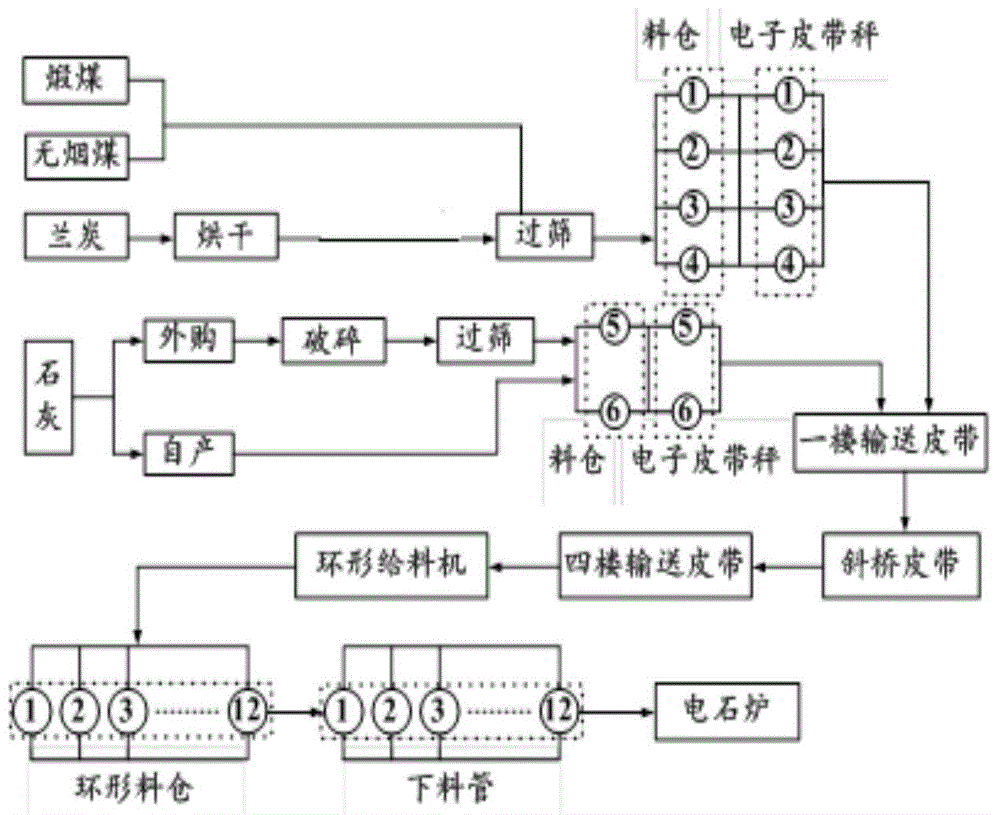

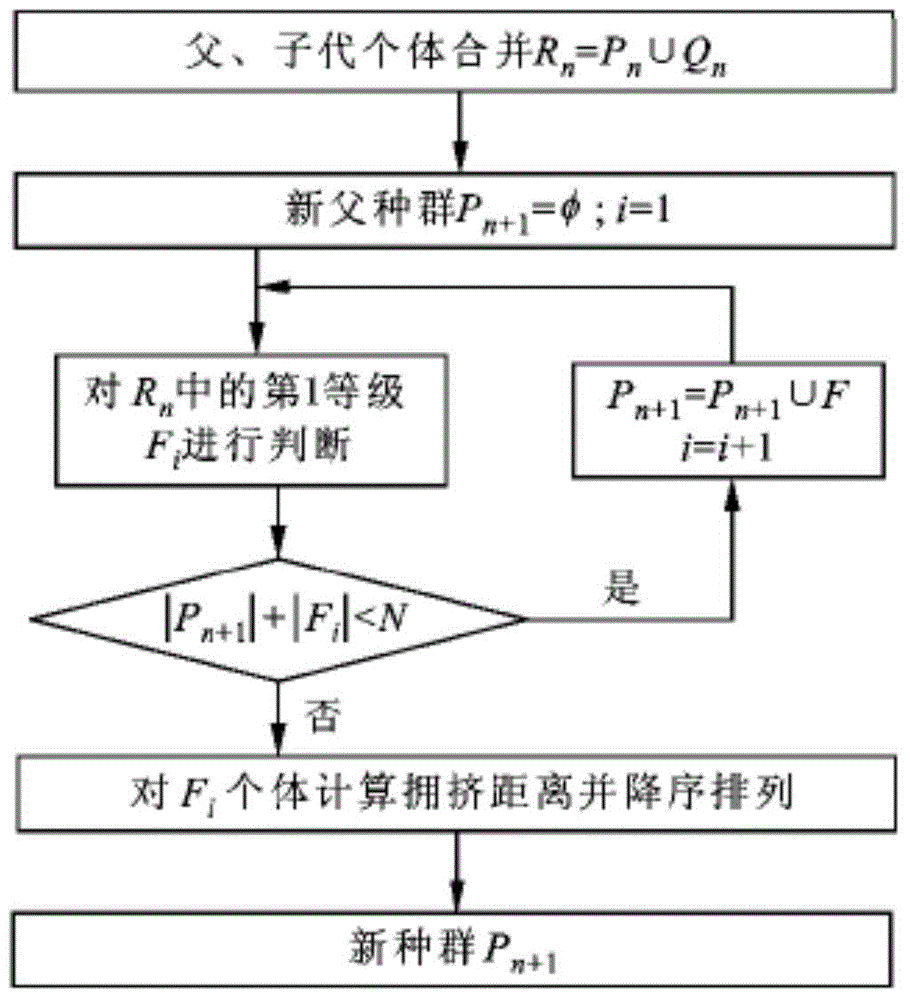

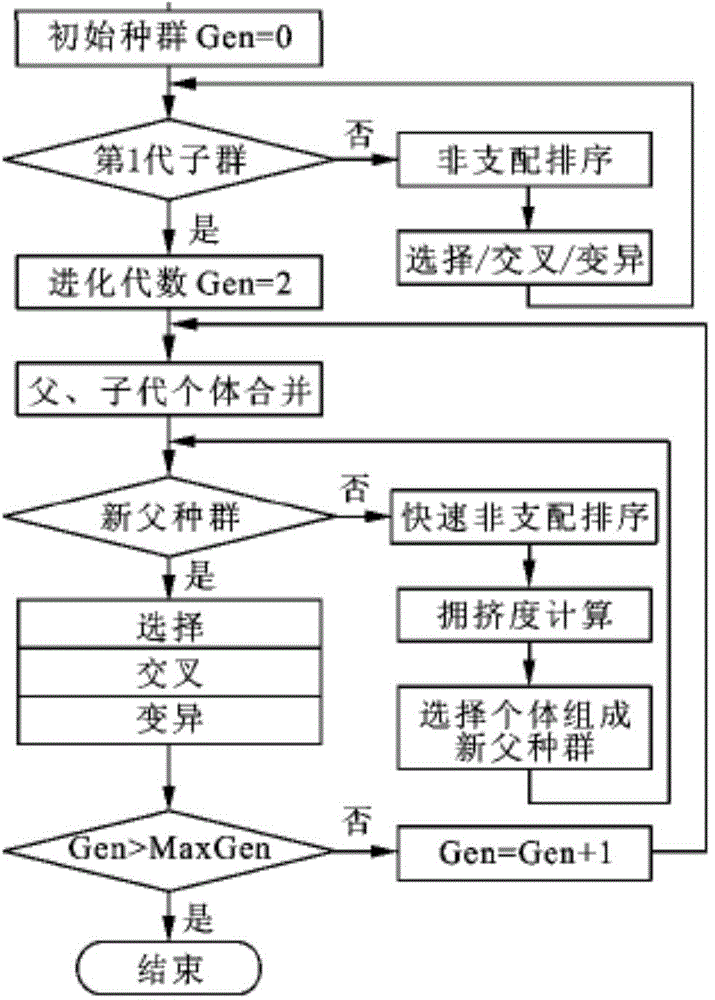

Controlling method for burdening of calcium carbide production

InactiveCN103950930AGuaranteed tasteImprove furnace conditionCalcium carbideChemical compositionMathematical model

The invention relates to a controlling method for burdening of calcium carbide production, and belongs to the technical field of calcium carbide production. According to the influences of resistivity and permeability of material on smelting and with the maximum permeability and resistivity as optimization objectives, a mathematical model for optimization burdening is established; and through the calculation of optimization burdening, the optimum charging burden is obtained; chemical composition of the charging burden is controlled, so that the chemical composition of the charging burden can meet the quality requirements for calcium carbide production, and stability of chemical composition of the charging burden is maintained; and on the promise of ensuring quality of calcium carbide, optimization calculation of resistivity and permeability of the charging burden are conducted, and influence of other constraints are fully considered, so as to improve the furnace condition for calcium carbide production.

Owner:STATE GRID CORP OF CHINA +2

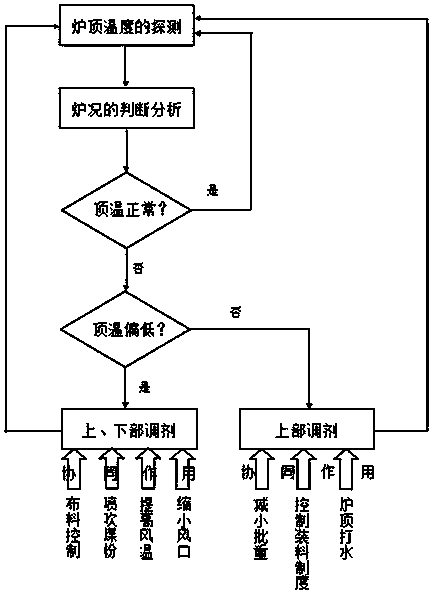

Method for regulating and controlling temperature of furnace top through upper part and lower part of blast furnace under oxygen-enriched condition

ActiveCN108611456AImproves responsivenessImprove furnace conditionBlast furnace detailsTime informationFurnace temperature

The invention relates to a method for regulating and controlling a temperature of a furnace top through the upper part and the lower part of a blast furnace under the oxygen-enriched condition. The method is characterized by comprising the following steps of step 1, real-time detection of the temperature of the furnace top: dividing the furnace top of the blast furnace into a plurality of regionswith an equal interval in a radial direction, and acquiring real-time data of the temperature of the furnace top in each region through a temperature detection device installed in each region; step 2,judgement analysis of the furnace condition; step 3, regulation with the upper part and the lower part of the blast furnace: according to judgement analysis on the real-time furnace condition, when the furnace temperature is abnormal, starting regulation; and step 4, real-time information feedback: judging a change of the temperature of the furnace top in each region in real time, entering the step 2, and forming a system of regulating the temperature of the furnace top in real time.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

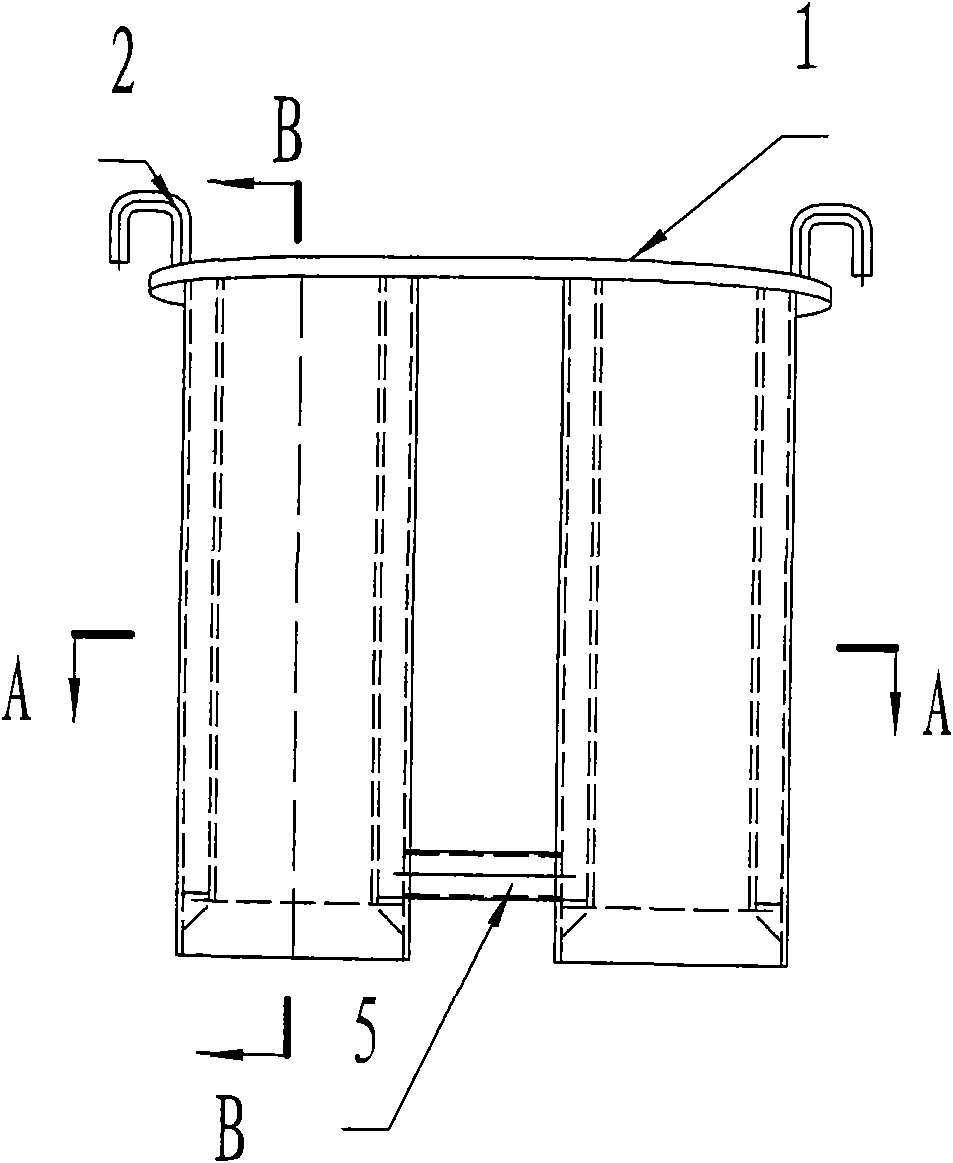

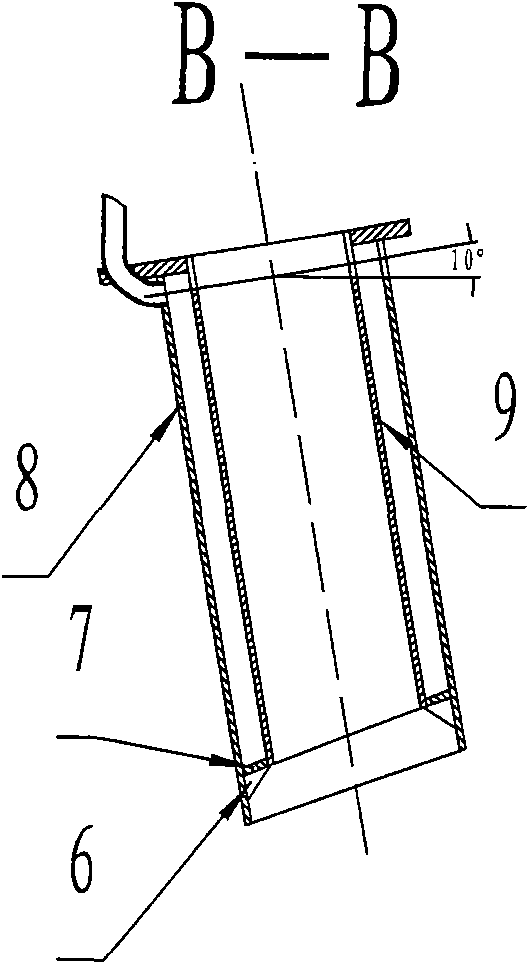

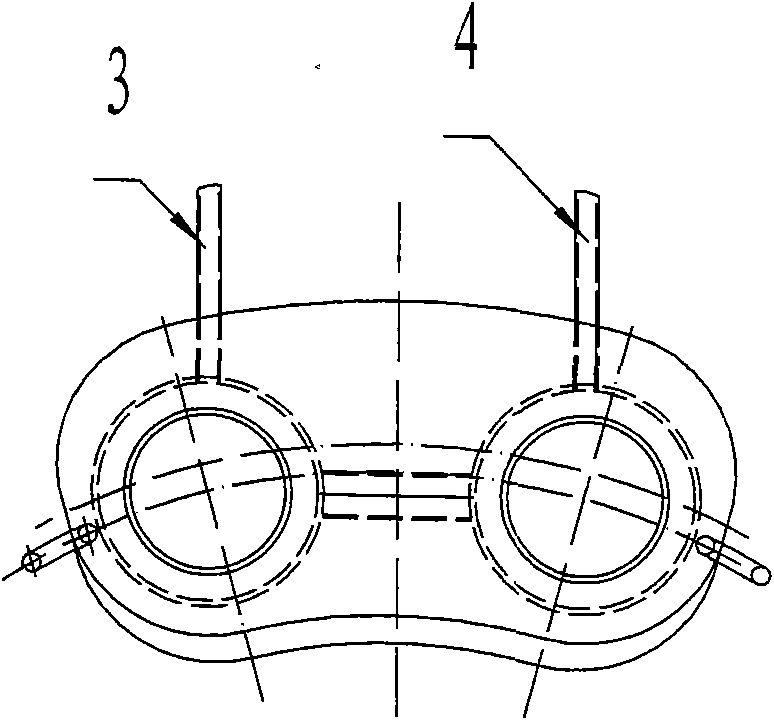

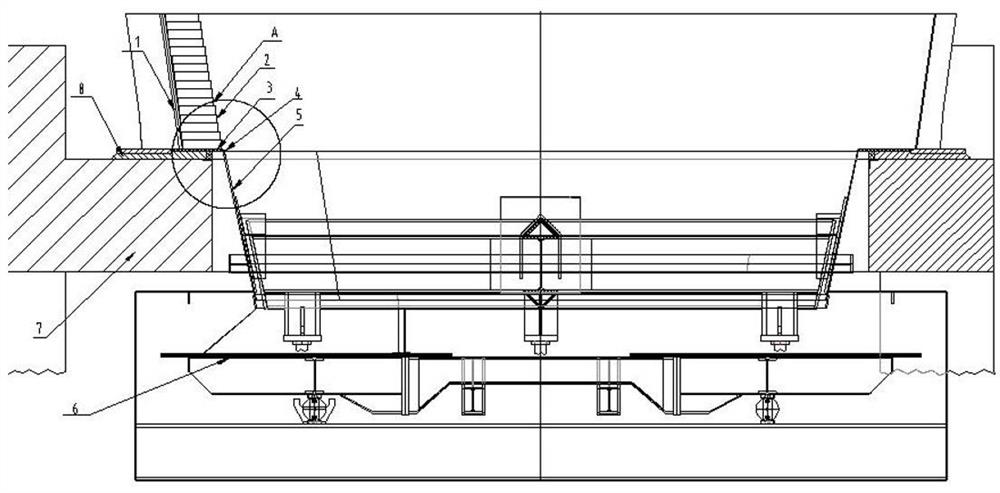

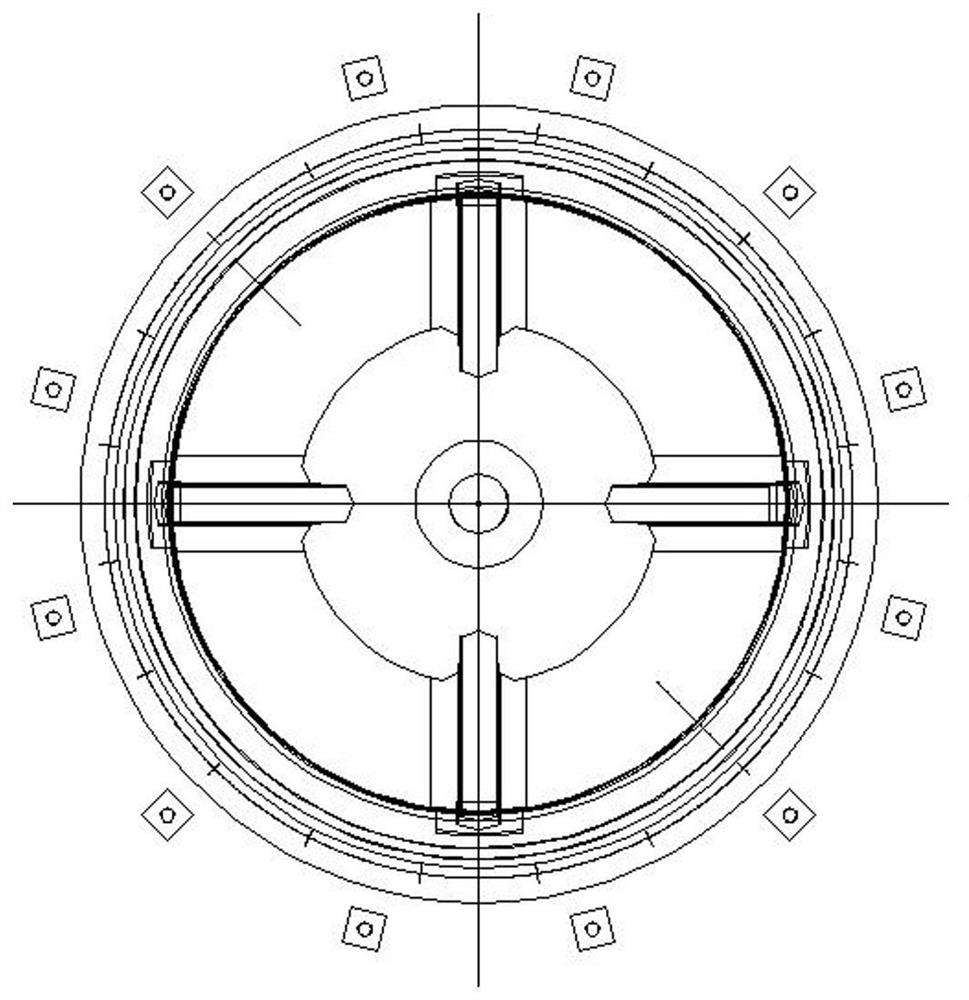

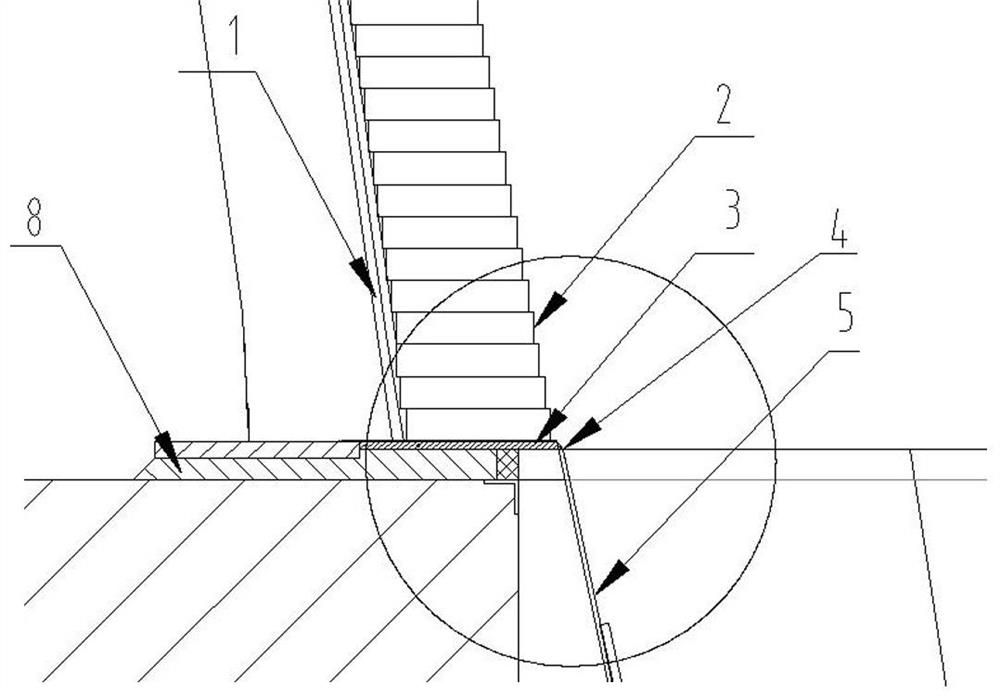

Closed type calcium carbide furnace charging nozzle and process for producing same

InactiveCN101526309AImprove the quality structure of the material layerImprove furnace conditionArc welding apparatusCharge manipulationEnergy consumptionCrucible

The invention provides a closed type calcium carbide furnace charging nozzle and a process for producing the same. The charging nozzle mainly comprises two groups of seamless external casings, seamless internal casings, water inlet pipes, water outlet pipes, communication pipes and bottom edge embedded flanges; the seamless internal casings are arranged in the seamless external casings; the bottom edge embedded flanges, the water inlet pipes and the water outlet pipes are arranged on the two groups of the seamless external casings respectively; and the two groups of seamless external casings are communicated with the communication pipes. The charging nozzle has the advantages of solving the problems of water leakage due to frequent breakage and frequent shut-down of the furnace for exchange, meeting the requirements on the charging production of a closed type calcium carbide furnace, effectively improving quality structure of material layers around electrodes, greatly improving furnace conditions (avoiding piling of materials on the outer side of the charging nozzle), making the materials keep a steamed bread-shaped charge surface around the electrodes, further effectively reducing thermal loss, alleviating the insufficiency of the materials in the central region of the furnace, reducing the temperature of the charge surface, reducing exposing areas of the electrodes, reducing the thermal loss of electrode resistances, improving the quality structure of the material layers, contributing to improving the pre-heating of the furnace materials and forming a big crucible region, ensuring good furnace conditions, avoiding frequent occurrence of material stamping and material throwing, and further facilitating the technical operation and control of the furnace and high yield, high quality and low energy consumption of the furnace.

Owner:YUNNAN YUNWEI CO LTD

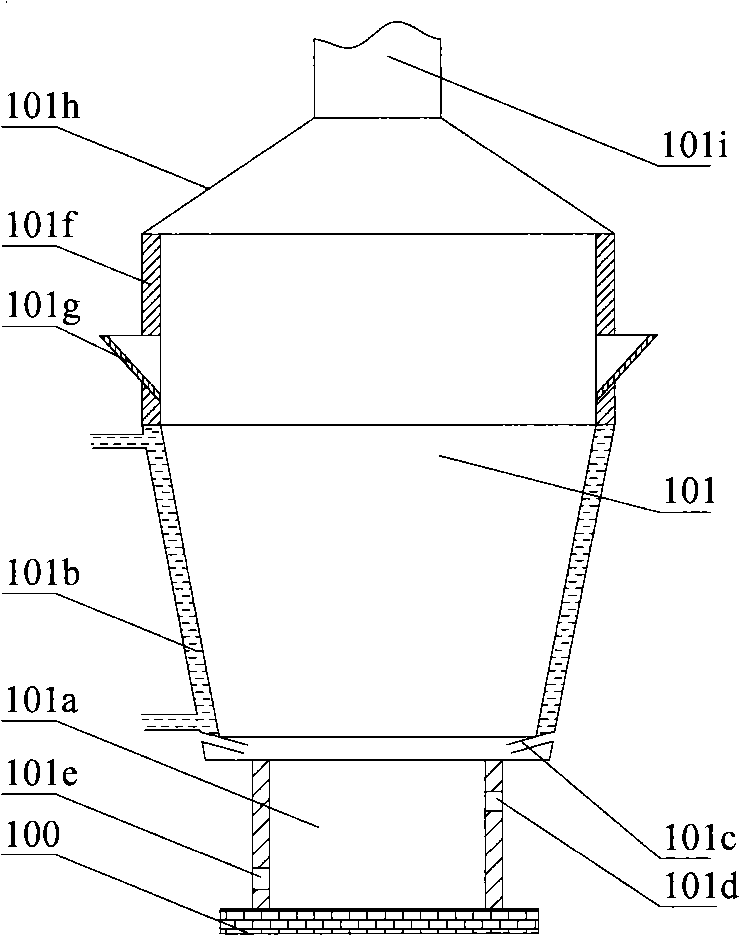

Blast furnace

The present invention discloses a blast furnace, and comprises a furnace hearth, wherein, the furnace hearth comprises a hearth side wall, a slag-discharging port that is arranged on the upper part of the hearth side wall, and a discharging port that is arranged at the lower part of the hearth side wall; the furnace hearth is also provided with a stack water jacket that is connected with the furnace hearth; the stack water jacket comprises a plurality of blast orifices; the stack water jacket is connected with a wind jacket; the wind jacket is provided with a smoke-exhausting pipe that is arranged on the side wall of the wind jacket; the wind jacket is connected with the blast orifices; the wind jacket is connected with a furnace top wall; the furnace top wall comprises a vertical feeding pipe; the feeding pipe comprises a feeding pipe water bushing. The wind jacket is connected with the stack water jacket, and the wind jacket is connected with the blast orifices through a wind pipe; since the wind jacket can use the surplus heat of the smoke to pre-heat the air, so as to provide the hot air for the smelting reaction, the temperature at the wind port can be increased, thereby saving the fuel, and optimizing the condition of the furnace, and improving the capacity of the furnace.

Owner:CHAOYANG HAOTIAN NONFERROUS METAL

Stibium blast furnace treatment method using oxygenized air

The invention relates to a melting method of the antimony blast furnace adopting oxygen-rich air. The melting method is characterized in that the oxygen produced by an air separation oxygen manufacture equipment or a liquid oxygen vaporizing device is transmitted into an air pipe at the front end or the back end of a blast fan through a pipeline, and mixed with air into oxygen-bearing oxygen-richair with volume concentration more than or equal to 22 percent according to a set proportion, and the oxygen-rich air is led into blast furnace through a blast hole. The melting method is suitable for processing various antimony bearing materials such as oxidized antimony ore, antimony sulfide ore, mixed sulfide-oxide antimony ore, jamesonite, recycled material during the antimony smelting, etc. which bear more than 15 percent of antimony; and the melting method is also suitable for processing the block or powder antimony material provided with various different appearances which is processedby balling. The bed processing ability of the melting method is enhanced by more than or equal to 50 percent, the coking rate is reduced by more than or equal to 40 percent, the iron ore rate is reduced by more than or equal to 40 percent, the comprehensive recycling rate for the antimony is up to 97 percent or more than 97 percent, the SO2 concentration in the waste gas is enhanced by 50 percentto 100 percent, and the better condition for the next waste gas desulphurization (or acid making ) processing and the standard discharging is provided.

Owner:锡矿山闪星锑业有限责任公司

Combustion-supporting fire coal additive and use method thereof

PendingCN105199806AImprove combustion effectImprove combustion thermal efficiencySolid fuelsCombustionSlag

The invention relates to a combustion-supporting fire coal additive. The combustion-supporting fire coal additive is prepared by taking steel-making furnace slags as the main raw material through blending and grinding. The combustion-supporting fire coal additive is prepared from, by weight, 13%-20% of FeO, 6%-15% of SiO2, 0.8%-2.5% of Al2O3, 40%-60.0% of CaO, 3.0%-8.0% of MgO, 0-0.8% of S, 0-0.1% of K2O, 0-0.1% of Na2O, 0.1%-1.0% MnO, 0.2%-0.75% of TiO2 and the balance H2O. After the combustion-supporting additive which takes the steel slags as the main raw material and contains all the components is added in combusted pulverized coal, the combustion efficiency of fire coal and the combustion furnace conditions of a blast furnace are both improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

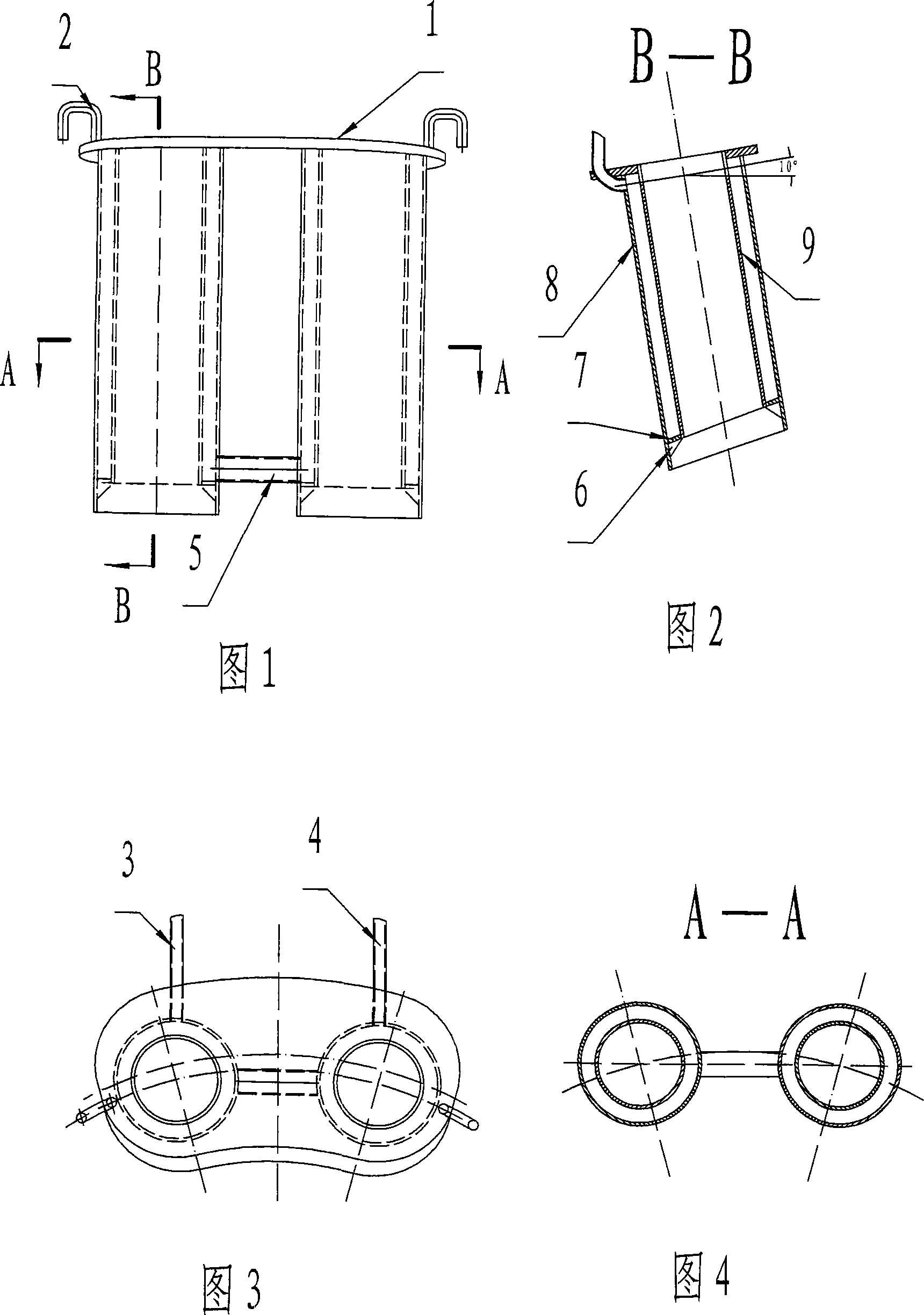

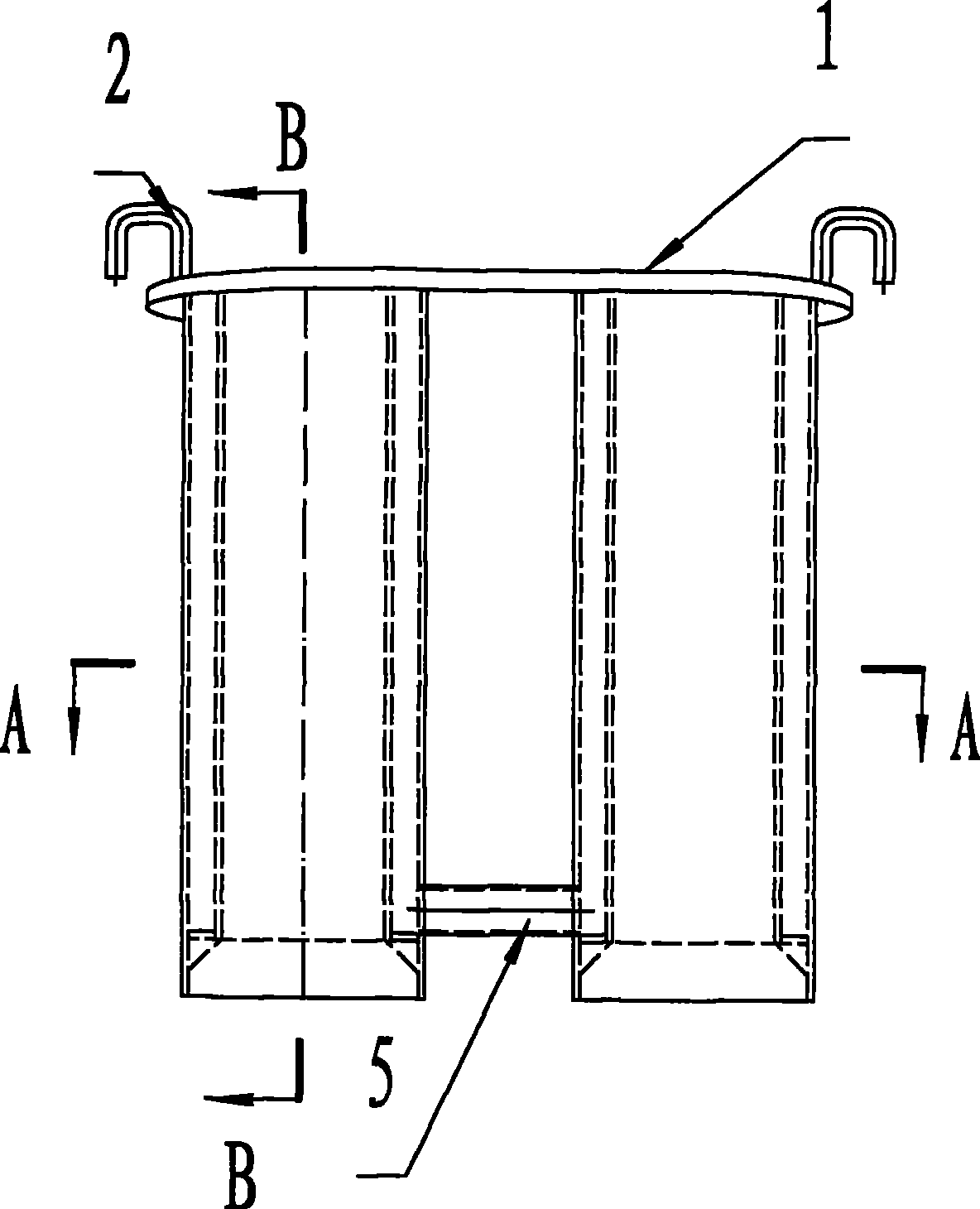

Supporting construction for upper layer tanks of double row tank magnesium reducing furnace

InactiveCN101363686AResistance to lateral thrustExtended service lifeFurnace componentsMuffle furnacesBrickEngineering

The invention relates to a double-row tank magnesium reduction furnace in the field of non-ferrous metal metallurgy, in particular to a bearing structure of an upper tank of the double-row tank magnesium reduction furnace, which consists of upper tank supporting bricks and lower pedestal lattice bricks, wherein, the upper tank supporting bricks take a shape of saddle, while the lower pedestal lattice bricks are twin type connected by a base. The invention solves the problems of poor strength of bearing bricking-up structure of the upper tank, easy damage, largely shielding heating to the lower part of a reduction tank, uneven heating of materials in the tanks, small flowing section of smoke in the furnace, uneven temperature in the furnace, and the like.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Automatic feeding method for metallurgical production system

ActiveCN104044928AReduce the impactReduce instabilityLoading/unloadingLaser transmitterPosition sensor

The invention discloses an automatic feeding method for a metallurgical production system, which is applied to a feeding system of a large-sized production mode. A stock bin is provided. The method is characterized in that a vibrating sieve for weighing materials is arranged below the stock bin; a material basket is arranged below the vibrating sieve, and is arranged on a transport trolley; the transport trolley runs on a transport channel; an elevator is arranged beside a blast furnace; a material level meter is arranged on the top of the blast furnace; a laser reflecting plate is arranged at the front end of the transport trolley; a laser emitter, a laser receiver and a position sensor are arranged at the head end of the transport channel; limit switches are arranged at the head end and the tail end of the transport channel. By adopting the automatic feeding method, high automatic degree is realized, the influence of human factors on feeding is reduced, and the instability of the furnace condition caused by improper manual operation is lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Maintenance method for converter lining in later stage of furnace age

InactiveCN113930577AEfficient maintenance methodEffective maintenanceManufacturing convertersProcess efficiency improvementIndustrial engineeringTrunnion

The invention discloses a maintenance method for a converter lining in the later stage of furnace age. The maintainance method comprises the following steps that 2-4 tons of furnace repairing material is poured into a converter, and a deslagging surface or a tapping surface is covered with the furnace repairing material by observing and rocking the converter; sintering of the furnace repairing material is finished after 10-15 min, the converter is rocked to a spraying repairing angle, the two sides of a trunnion of the converter are uniformly subjected to spraying repairing for the first time by using a spraying repairing vehicle, and 1 ton of spraying repairing material is subjected to spraying repairing in 5-8 minutes; after the first-time uniform spraying repairing is finished, manual feeding material is adopted for throwing repairing, special point maintenance is conducted on other weak parts in the converter lining, and 0.3-0.5 ton of manual feeding material is subjected to throwing repairing in 3-5 minutes; at 10 minutes after the first time uniform spraying repairing is completed, uniform spraying repairing is carried out for the second time, and 1 ton of spraying repairing material is subjected to spraying repairing in 5-8 minutes; after the second time uniform spraying repairing is finished, if the final purpose of spraying repairing is not achieved according to the spraying repairing result, manual feeding material is subjected to throwing repairing for the second time after furnace repairing is finished, the converter is rocked for adding steel scrap and adding iron; maintenance is carried out in a mode of using the furnace repairing materials, spraying repairing of the spraying repairing vehicle and the manual feeding material, point and face maintenance is carried out on the converter lining, the furnace condition is improved, and the service life of the converter is prolonged.

Owner:SD STEEL RIZHAO CO LTD

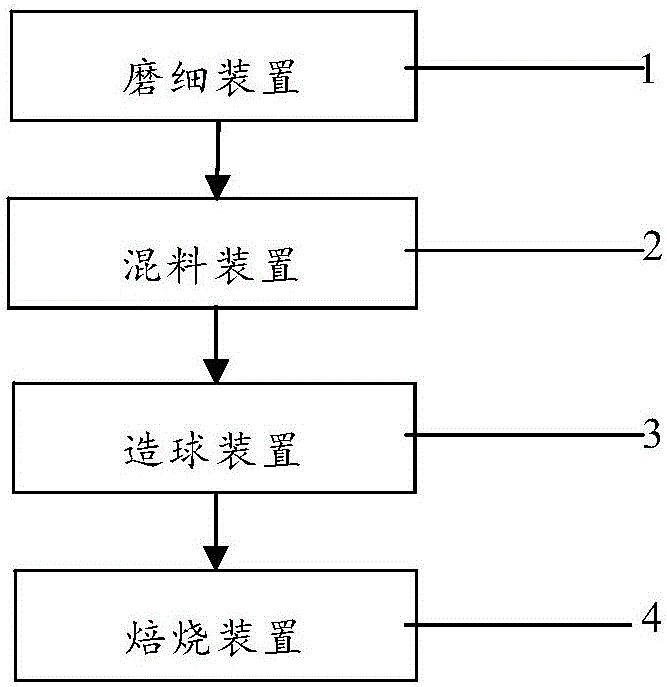

Method and system for restraining reduction degradation of kakoxene pellet

PendingCN106591569AIncrease calcium ferrite contentReduce the formation temperatureBoric acidAqueous solution

The invention discloses a method and system for restraining reduction degradation of kakoxene pellet. The method for restraining reduction degradation of the kakoxene pellet is firstly disclosed and comprises the following steps that firstly, kakoxene is levigated, and kakoxene powder is obtained; secondly, the kakoxene powder and bentonite are mixed, and a mixture is obtained; thirdly, the mixture is subjected to pelletizing, and a green ball is obtained, wherein in the pelletizing process, a boric acid water solution is added and serves as pelletizing water; and fourthly, the green ball is roasted, and the kakoxene pellet is obtained. The system for implementing the method is also disclosed and comprises a levigating device, a material mixing device, a pelletizing device and a roasting device. By means of the water adding link in the procedure of pellet production pelletizing, the boric acid water solution is sprayed to the green ball in the pelletizing process, pellet pelletizing is completed, the reduction degradation rate of the prepared kakoxene pellet is remarkably reduced, and the metallurgical performance of the pellet in the smelting reduction process is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Phosphorous pig iron desulfurizer used for casting pre-roasting anode

InactiveCN101570803BIncrease smelting speedShorten smelting timeGas emission reductionWorking environmentGraphite

The invention discloses a phosphorous pig iron desulfurizer used for casting a pre-roasting anode. The desulfurizer is prepared from the following raw materials by mass percentage: 2 to 4 percent of graphite, 35 to 45 percent of CaO, 3 to 5 percent of CaF2, 1 to 3 percent of Na2CO3, 40 to 50 percent of Na2SiO3, and 1 to 3 percent of FeO. By adopting the phosphorous pig iron desulfurizer used for casting the pre-roasting anode, the adding amount of the desulfurizer is 2.5 percent in each ton of phosphorous pig iron; when the desulfurizer is used in a 1.6-ton induction furnace, the produced phosphorous pig iron can meet use requirements on composition as well as performance, so that the speed of smelting the phosphorous pig iron in the induction furnace is quickened, the smelting time of thephosphorous pig iron is shortened, the electric energy is saved, and the smelting cost is saved by about 15 percent; moreover, good furnace conditions and operational conditions are kept for smelting, the working environment for workers is improved, and the labor intensity of the workers is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Mixed sintering ore

ActiveCN104988258AIncrease usage ratioImprove blast furnace conditionBlast furnace detailsAlkalinityBlast furnace

The invention discloses mixed sintering ore. The mixed sintering ore is prepared by mixing the following materials: acid sintering ore with the alkalinity being 0.6 to 0.8 and alkaline sintering ore with the alkalinity being 1.8 to 2.3 according to the weight ratio of being 1:3 to 5. The mixed sintering ore is prepared by mixing the following materials: acid sintering ore with the alkalinity being 0.6 to 0.8 and alkaline sintering ore with the alkalinity being 1.8 to 2.3 according to the weight ratio of being 1:3 to 5, wherein the acid sintering ore accounts for 1 part, and the alkaline sintering ore accounts for 3 to 5 parts, due to the mixed matching, the condition that the acid sintering ore with the alkalinity being 0.6 to 0.8 can not be independently used for blast-furnace production is overcome; the average alkalinity of the mixed sintering ore is about 1.62 by measurement, and the use ratio of the sintering ore in a blast furnace can reach 88 percent to 90 percent of the use amount of iron-making materials in the blast furnace, so that the productivity of a sintering machine can be fully exerted; after the use ratio of the sintering ore is greatly increased, more benefit is brought for smooth conduction of the furnace condition, reduction of fuel consumption, improvement of technical indexes of the blast furnace and reduction of molten iron.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

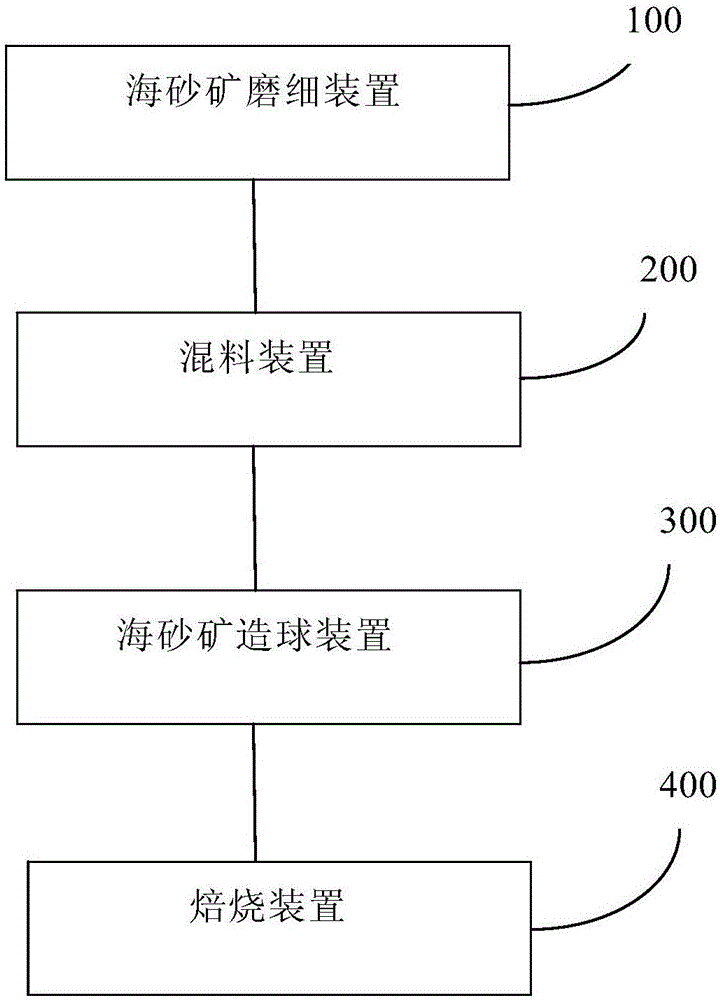

Method for restraining and reducing reduction degradation of iron sand pellets and system special for method for restraining and reducing reduction degradation of iron sand pellets

InactiveCN106591567AIncrease calcium ferrite contentImproved metallurgical propertiesHigh heatCalcium ferrite

The invention discloses a method for restraining and reducing reduction degradation of iron sand pellets and a system special for the method for restraining and reducing the reduction degradation of the iron sand pellets. The method for restraining and reducing the reduction degradation of the iron sand pellets comprises the steps that iron sand is ground to be fine, so that iron sand powder is obtained; the iron sand powder is evenly mixed with bentonite, so that a mixture is obtained; the mixture is made into green pellets in a pelletizer, wherein when the mixture in made into the green pellets in the pelletizer, a boric acid water solution is added in the growing process of the green pellets to be used as a pelletizing solution; and the green pellets are roasted, so that the pellets are obtained. The invention further discloses the system special for the method for restraining and reducing the reduction degradation of the iron sand pellets. According to the method for restraining and reducing the reduction degradation of the iron sand pellets and the system special for the method for restraining and reducing the reduction degradation of the iron sand pellets, by the adoption of the feature that boric acid is low in melting point, the liquid phase forming temperature is lowered, the content of calcium ferrite in the pellets is increased, and the reduction temperature of phosphosiderite pellets is greatly lowered; and in this way, the metallurgical performance of the phosphosiderite pellets in the reduction process is greatly improved, serious degradation at the high temperature is restrained, the problem that reduction degradation is serious during blast furnace smelting of the iron sand is effectively solved, the energy consumption is greatly lowered, the furnace condition is lowered, and economic benefits are increased.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for producing high-quality sintered ore through ore blending of various manganese ore powders

The invention relates to a method for producing high-quality sintered ore through ore blending of various manganese ore powders. The method comprises the steps of material blending, uniform mixing, sintering, cooling, crushing, screening and the like, and all the steps are specifically limited, so that the prepared sintered ore is high in strength, and the porosity is higher in a reasonable range, so that good reducibility can be shown in the subsequent smelting process in a submerged arc furnace, the furnace condition of the submerged arc furnace is improved, and coke consumption and power consumption in the smelting process can be greatly reduced.

Owner:UNIV OF SCI & TECH BEIJING +1

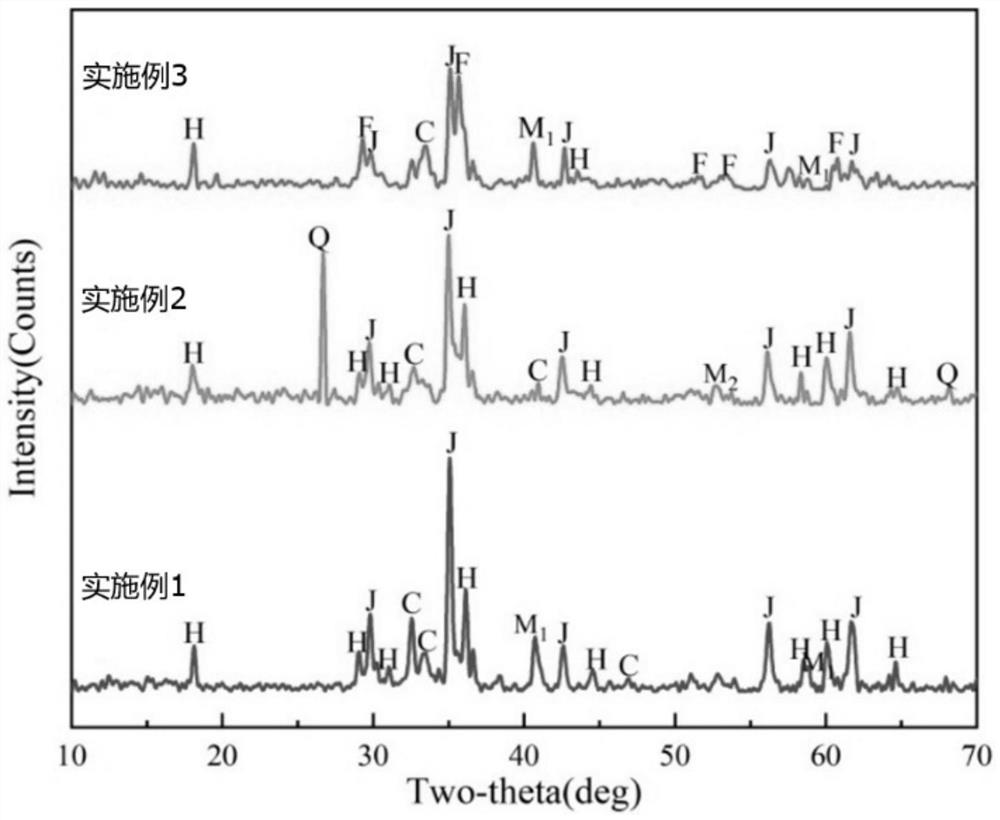

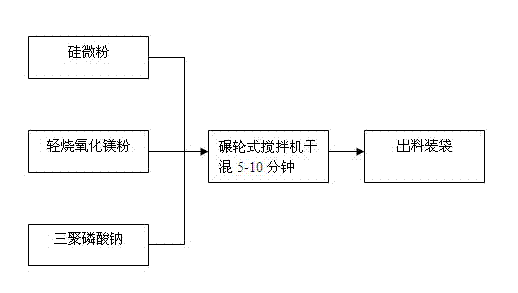

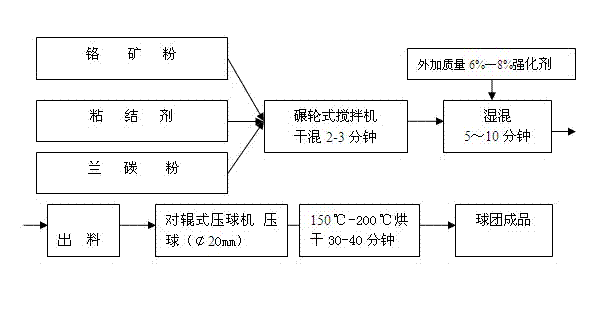

Cr-Fe powder ore cold-hardened pellet binder and process for pelleting by using same

The invention discloses a Cr-Fe powder ore cold-hardened pellet binder comprising the following components in percentage by weight: 70-80 percent of silicon micro powder, 19.81-29.78 percent of light calcined magnesia and 0.19-0.22 percent of trimeric sodium phosphate. The invention also discloses a process for pelleting by using the binder, which comprises the following steps of: adding 6-8 percent by weight of binder in 76-84 percent by weight of Cr-Fe powder ore; then adding 4-8 percent by weight of blue carbon powder; after dryly mixing for 2-3min by an edge milling type stirring mill, adding 6-8 percent by weight of reinforcer, and wetly mixing for 5-10min; then discharging and putting into a roller type ball press for pressing to form pellets; and then drying at the temperature of 150-200 DEG C and the wind speed of 1.0-1.8m / s for 30-40min to obtain finished Cr-Fe pellets. The carbon ferrochrome produced by the invention has the advantages of increasing the yield by 15-20 percent, reducing the electricity consumption by 12-16 percent and lowering the comprehensive cost by 10-12 percent.

Owner:兰州三普电力有限公司

Sealing device for ash discharge conical hopper of Maerz kiln

ActiveCN112414108AEliminate cracking factorsAvoid cracking and powder leakageFurnace componentsVertical furnacesFire brickProcess engineering

The invention discloses a sealing device for an ash discharge conical hopper of a Maerz kiln, and relates to the technical field of furnaces and kilns. The sealing device comprises the ash discharge conical hopper arranged above an ash discharge flat plate, and a steel foundation base plate for supporting refractory bricks in a kiln shell, the top of the ash discharge conical hopper is at least 5cm higher than the steel foundation base plate in the vertical height; the joint of the ash discharge conical hopper and the steel foundation base plate is subjected to full-length welding; a pluralityof triangular rib plates are welded to the connecting arc surface of the ash discharge conical hopper and the steel foundation base plate at intervals; a gap formed by the ash discharging conical hopper, the steel foundation base plate and the kiln shell is filled with castable; the castable completely covers the back welding point of the welding part of the ash discharge conical hopper and the steel foundation base plate and the triangular rib plates; and the refractory bricks are built on the hardened castable. According to the sealing device, the problems that an existing sealing structureof the ash discharging conical hopper of the Maerz kiln is prone to cracking, air leakage is generated, maintenance is difficult, and normal production of the kiln is greatly affected are solved.

Owner:广西柳钢新材料科技有限公司 +1

Method for supplementing carbon at furnace bottom in metal silicon smelting process

ActiveCN102502645AImprove furnace conditionPlay a role in restoringSilicon compoundsElectric furnacesSmelting process

The invention relates to a method for supplementing carbon at the furnace bottom in a metal silicon smelting process. Waste carbon electrodes of electric furnace smelting and / or waste carbon bricks of electric furnace smelting are / is used as carbon supplementing raw materials, and after crushing and during the electric furnace smelting production, the addition time and the addition quality are determined according to the electrode current intensity and the furnace condition change. When one phase or two phases of the electrode current are lower than the normal control range being 70 to 80KA, the electrode current is firstly improved through the electrode voltage drop, and when the electrode current still cannot be improved after 8 hours, the addition of the waste carbon electrodes and / or the waste carbon bricks is needed for carbon supplementation. The problems that the carbon is lacked in a reaction for a long time, excessive silicon dioxide is generated, furnace slag is sticky and cannot be easily discharged, the furnace bottom temperature is low, a silicon outlet is not easy to open, a furnace hole is not smooth, and the furnace bottom is raised are solved.

Owner:云南永昌硅业股份有限公司

A correction method for blast furnace spiral cloth

ActiveCN104894318BActive airflowReasonable air distributionBell-and-hopper arrangementBlast furnace smeltingMaterial distribution

The present invention provides a blast furnace screw material distribution correcting method. According to the method, an inverse carrying material distribution performing mark button is arranged in a screw material distribution list image; a material distribution correcting process is additionally set in a blast furnace top material distribution process; a screw material distribution performing ring position Xj corresponding to the final material distribution ring position X1 is set in advance; during an ore material distribution process, the material distribution sluice tilting angle of the X1 is performed according to the Xj tilting angle; during the material distribution process, when the weight displayed by a weighing cabinet produces the large change, the material distribution collecting process is manually started, and the material distribution sluice automatically tilts upward according to the retrieved tilting angle of the screw material distribution performing ring position Xj; and after the batch material distribution is completed, the tilting angle of the screw material distribution recovers to perform the originally-set furnace top material distribution process. With the method of the present invention, the condition that the material at the final ring position is centralized and distributed at the center position in the furnace can be avoided, such that the center gas flow in the blast furnace is active, the distribution of the gas flow in the furnace is rational, the furnace condition is improved, and the smooth blast furnace smelting production can be ensured.

Owner:ANGANG STEEL CO LTD

Deslagging agent for improving slagging and slagging efficiency in industrial silicon smelting and preparation method thereof

PendingCN114046670AImprove liquidityReduce the amount addedSilicon compoundsIncrustation removal devicesSlagFirming agent

The invention provides a slagging agent for improving slagging and slagging efficiency in industrial silicon smelting and a preparation method thereof. The slagging agent comprises the following main materials: calcium oxide and carbonaceous powder in a weight ratio of (1-3): (1-3). The preparation method of the slagging agent is characterized by comprising the following steps: firstly, crushing calcium oxide until the particle size is less than or equal to 3mm for later use, respectively preparing NaOH and a curing agent into a 25-50% NaOH solution and a 1.1-2.1% curing agent solution, uniformly mixing the NaOH solution and the curing agent solution, then adding the crushed calcium oxide and a mixture of charcoal powder, petroleum coke powder and dry powder binder, uniformly mixing, fully stirring in a material bin, enabling the materials to enter a ball pressing system under the action of self gravity to be cold-pressed into pellets, and drying the pellets. The carbon and calcium pellets replace large-particle limestone in a traditional process, the deslagging effect is obviously improved compared with that of a traditional method, the slag production rate is increased to 12.94% from 10.04% and is increased by 2.9%, due to the fact that the deslagging effect in a furnace is good, the furnace condition is improved, the yield is obviously increased, and the average daily yield is increased to 51.822 tons per day from 49.399 tons per day and is increased by 2.423 tons.

Owner:云南永昌硅业股份有限公司

Closed type calcium carbide furnace charging nozzle and process for producing same

InactiveCN101526309BAvoid accumulationTo meet the needs of production and feedingArc welding apparatusCharge manipulationElectrical resistance and conductanceWater leakage

The invention provides a closed type calcium carbide furnace charging nozzle and a process for producing the same. The charging nozzle mainly comprises two groups of seamless external casings, seamless internal casings, water inlet pipes, water outlet pipes, communication pipes and bottom edge embedded flanges; the seamless internal casings are arranged in the seamless external casings; the bottom edge embedded flanges, the water inlet pipes and the water outlet pipes are arranged on the two groups of the seamless external casings respectively; and the two groups of seamless external casings are communicated with the communication pipes. The charging nozzle has the advantages of solving the problems of water leakage due to frequent breakage and frequent shut-down of the furnace for exchange, meeting the requirements on the charging production of a closed type calcium carbide furnace, effectively improving quality structure of material layers around electrodes, greatly improving furnace conditions (avoiding piling of materials on the outer side of the charging nozzle), making the materials keep a steamed bread-shaped charge surface around the electrodes, further effectively reducing thermal loss, alleviating the insufficiency of the materials in the central region of the furnace, reducing the temperature of the charge surface, reducing exposing areas of the electrodes, reducingthe thermal loss of electrode resistances, improving the quality structure of the material layers, contributing to improving the pre-heating of the furnace materials and forming a big crucible region, ensuring good furnace conditions, avoiding frequent occurrence of material stamping and material throwing, and further facilitating the technical operation and control of the furnace and high yield,high quality and low energy consumption of the furnace.

Owner:YUNNAN YUNWEI CO LTD

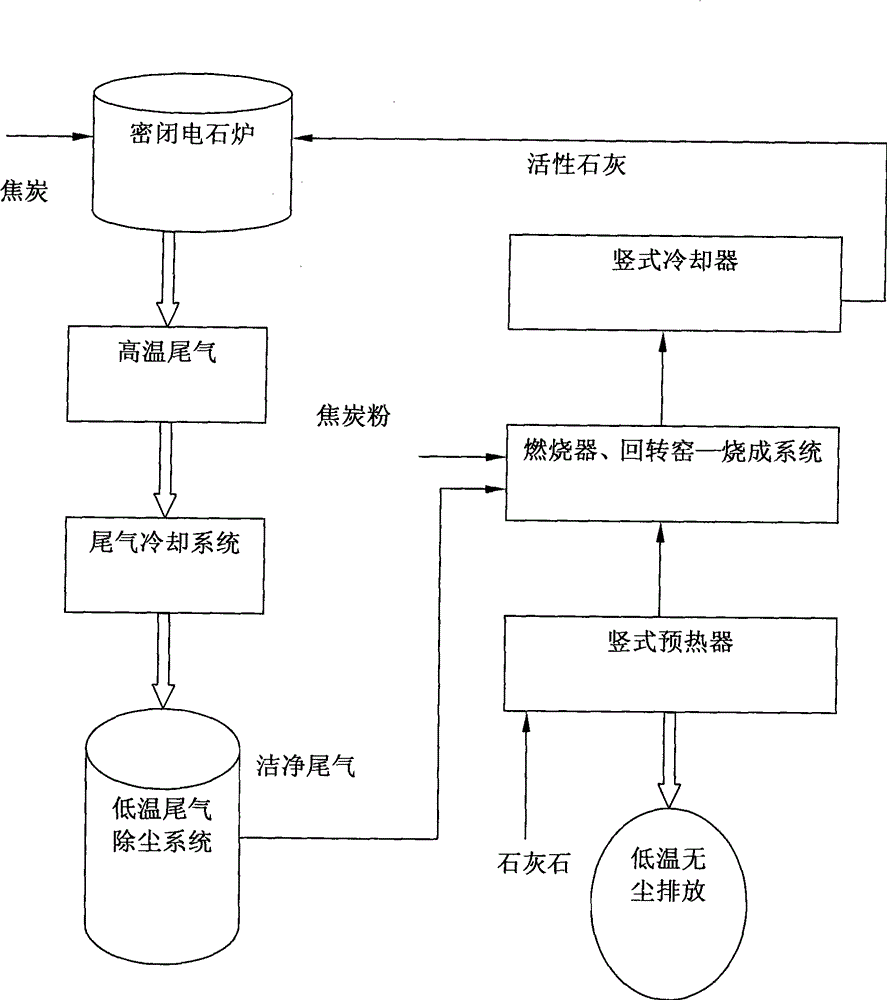

Method for calcining active lime by taking tail gas from sealing type calcium carbide furnace as fuel for rotary kiln

A method for calcining active lime by taking tail gas from a sealing type calcium carbide furnace as fuel for a rotary kiln comprises the following steps: dust-containing high-temperature tail gas from the sealing type calcium carbide furnace which also produces CO enters a tail gas cooling system to be cooled and reduced therein after passing through a closed pipeline, and then is purified in a dust remover through a low temperature tail gas dust removing system; the purified tail gas and coke powder or coal dust are sent to a combustor of a rotary kiln calcination system to be taken as fuelfor lime calcination equipment; limestone enters the rotary kiln calcination system after being preheated by kiln tail hot gas in a vertical preheater and realizing predecomposition; after being calcined by tail gas and coke powder, the preheated limestone appears in the rotary kiln calcination system as active lime which after being cooled by a vertical cooler is sent by transportation equipmentto a finished products storage; air involved in the cooling enters the rotary kiln as primary air which is burnt therein, and the involvement of preheated air in the combustion compensates for the problem that tail gas from the sealing type calcium carbide furnace has a low thermal value; flue gas for preheating the limestone can be emitted at a low temperature and without dust after being subjected to dust removal by a bag type dust remover; and active lime produced by using the method is taken as the raw material for manufacturing calcium carbide.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Furnace maintenance vanadium-titanium pellet for normal blast furnace and production method thereof

InactiveCN103266223BImprove furnace conditionGuaranteed travelBlast furnace detailsAdhesiveSmelting process

The invention provides a furnace maintenance vanadium-titanium pellet for normal blast furnace and a production method thereof. The vanadium-titanium pellet comprises the following constituents: 50%-55% of TFe, 5%-8% of SiO2, 2%-4% of MgO, 2%-3% of Al2O3, less than 1% of MnO, less than 1% of V2O5 and 5%-15% of TiO2. The method comprises the following steps of: dosing with vanadium-titanium mineral powder, vanadium extraction tailings and iron ore concentrate powder; further adding 1%-5% of adhesive, and then, mixing materials while stirring; and after mixing the materials, further adding water for pelletizing, wherein the dosage of the vanadium-titanium mineral powder, the vanadium extraction tailings and the iron ore concentrate powder is determined according the requirements on the constituents of the furnace maintenance vanadium-titanium pellet for normal blast furnace. The furnace maintenance vanadium-titanium pellet can be used for improving the slag melting point and viscosity of the blast furnace in normal iron ore smelting process on the premise of meeting the normal production of the blast furnace, and after the furnace maintenance vanadium-titanium pellet is used, the furnace condition of the blast furnace can be improved, the smooth operation of the blast furnace is guaranteed, and the furnace age of the blast furnace is prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com