Method for calcining active lime by taking tail gas from sealing type calcium carbide furnace as fuel for rotary kiln

A technology of calcium carbide furnace tail gas and active lime, which is applied in the direction of lime production, etc., can solve the problems that the closed calcium carbide furnace tail gas cannot be comprehensively and effectively utilized, does not have chemical product sales channels, and cannot meet large-scale production, and achieves the reduction of unit electricity consumption. consumption, realize the comprehensive utilization of resources, and achieve the effect of saving energy and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

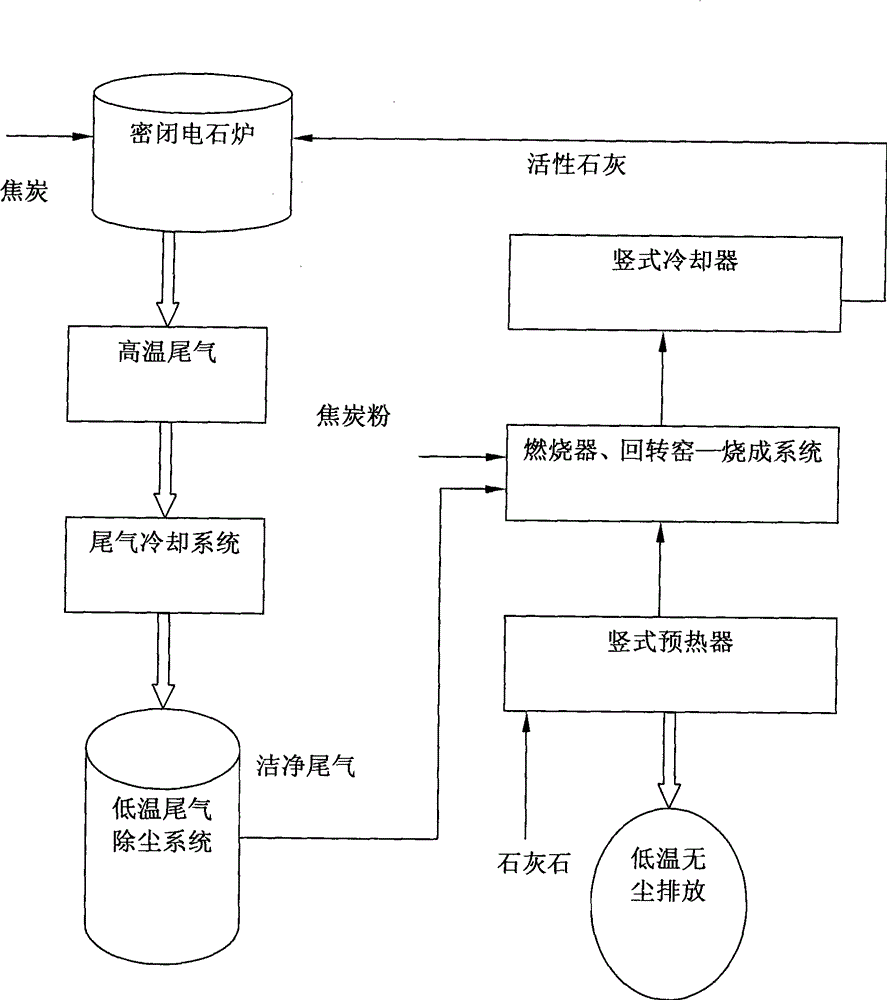

[0012] The specific implementation is that the closed calcium carbide furnace produces 74-85% CO and dust-containing high-temperature tail gas (550-800°C); the tail gas enters the tail gas cooling system through a closed pipeline and reduces to below 260°C after being cooled, and then passes through the low-temperature tail gas for dust removal The system is purified in the dust collector; the purified clean tail gas and coke powder (or coal powder) are sent to the burner of the rotary kiln firing system as fuel for the lime calcination equipment; the limestone passes through the kiln tail in the vertical preheater The hot gas is preheated to above 900°C and achieves pre-decomposition of more than 25%, and enters the firing system of the rotary kiln; the preheated limestone becomes active lime in the firing system of the rotary kiln after being calcined by tail gas and coke powder. After the lime is cooled by the vertical cooler, it is sent to the finished product warehouse thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com