Method for preventing air release valves of double-hearth kiln from spraying ash

A technology of air release and double-chamber kiln, which is applied in the field of metallurgical production, can solve problems such as environmental pollution, and achieve the effects of avoiding environmental pollution, realizing valve opening, and reducing the amount of gas conveyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

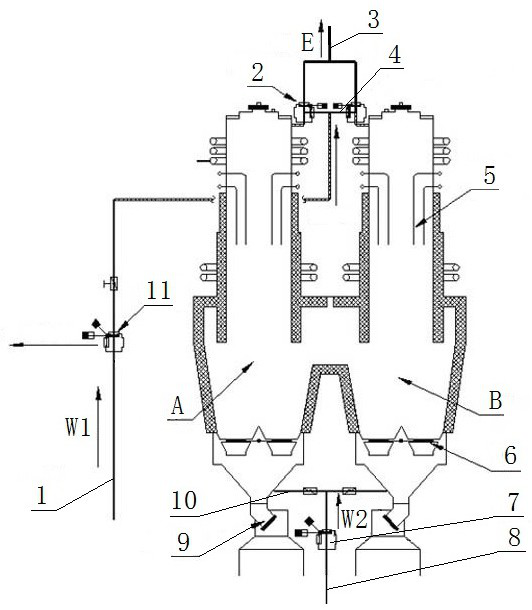

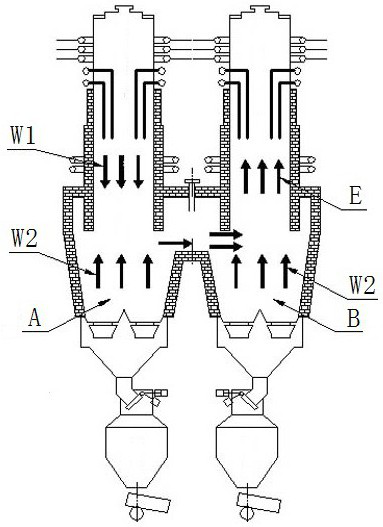

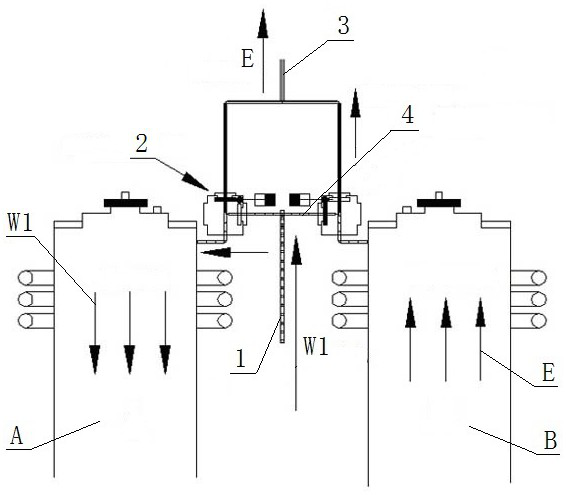

[0033] A method of preventing soot spraying on an air release valve of a double chamber kiln comprising the use of a Figure 6 , Figure 7 , Figure 8 The specific method for preventing the soot spraying device of the air release valve of the double-chamber kiln shown is as follows:

[0034] A. When the system cuts off the gas transported to the kiln, that is, before entering the burnout time, the system controls to open the electric control valve 14, and the gas in the kiln is transported to the dust collector through the exhaust pipe 13 and the waste gas pipe 3, and the pressure in the kiln enters Reduce to below 10kpa before the reversing period; when the burnout time is short and the pressure in the kiln drops below the set value, further set to prolong the burnout time to achieve a sufficient reduction in the gas pressure in the kiln; then open the combustion air release valve 11, Adjust the opening speed of the combustion air release valve 11 to 8 seconds to realize th...

Embodiment 2

[0040] A method of preventing soot spraying on an air release valve of a double chamber kiln comprising the use of a Figure 6 , Figure 7 , Figure 8 The specific method for preventing the soot spraying device of the air release valve of the double-chamber kiln shown is as follows:

[0041] A. When the system cuts off the gas transported to the kiln, that is, before entering the burnout time, the system controls to open the electric control valve 14, and the gas in the kiln is transported to the dust collector through the exhaust pipe 13 and the waste gas pipe 3, and the pressure in the kiln enters Reduce to below 10kpa before the reversing period; when the burnout time is short and the pressure in the kiln drops below the set value, further set to prolong the burnout time to achieve a sufficient reduction in the gas pressure in the kiln; then open the combustion air release valve 11, Adjust the opening speed of the combustion-supporting air release valve 11 to 10 seconds t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com