Method for optimizing industrial circulating water system

An industrial circulating water and circulating water system technology, applied in the field of circulating water systems, can solve problems such as unsatisfactory effects, disconnected optimization schemes, and lack of full-process optimization of circulating water systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

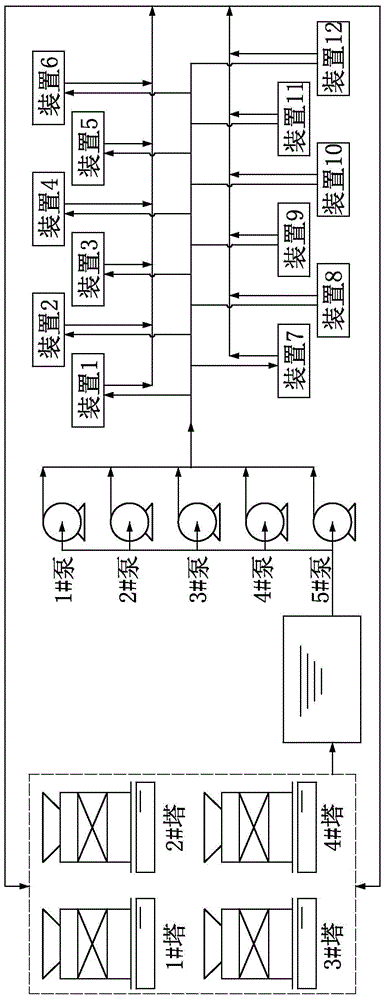

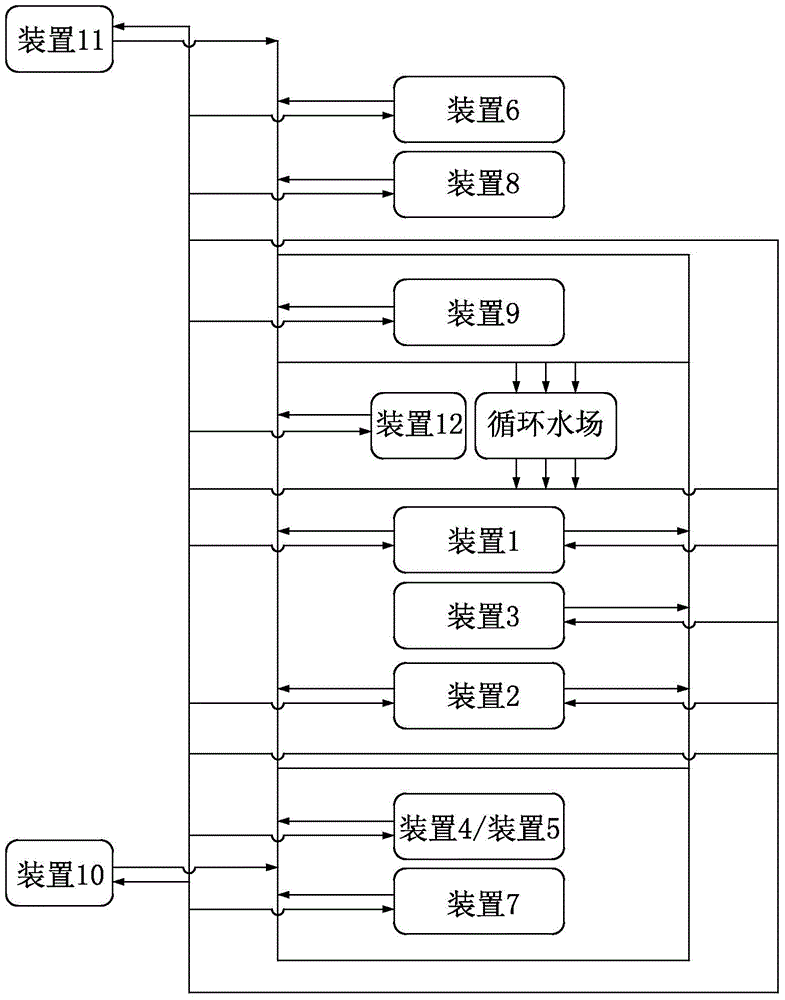

[0055] figure 1 It is a process flow diagram of the circulating water system of an oil refinery. The circulating water system provides circulating cooling water for the heat exchange equipment of 12 sets of devices. The circulating water system is equipped with 5 circulating water pumps and 4 fan cooling towers. figure 2 Schematic diagram of the main network before optimization of the circulating water system of the refinery.

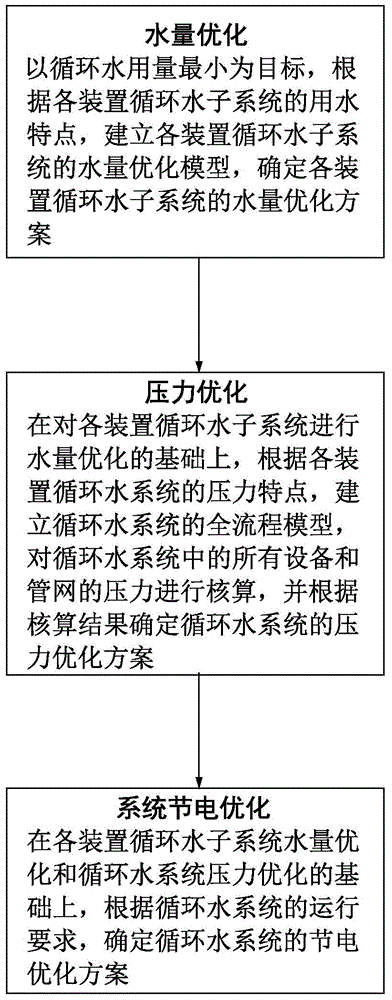

[0056] The process flow of a kind of industrial circulating water system optimization method of the present invention is as follows image 3 As shown, the specific implementation method includes the following steps:

[0057] The first step is to optimize the water consumption of the circulating water system, and determine the water optimization scheme for the circulating water subsystem of each device.

[0058] In this step, on the premise of meeting the production needs, aiming at the minimum amount of circulating water in the circulating water subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com